Custom made bends - Bilfinger

Custom made bends - Bilfinger

Custom made bends - Bilfinger

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Piping Systems<br />

<strong>Bilfinger</strong> Piping Technologies GmbH<br />

Bend geometry<br />

<strong>Custom</strong> <strong>made</strong> <strong>bends</strong> from steel pipes have<br />

a high accuracy of shape. Bending with<br />

induction heat input is an advanced<br />

procedure using a highly automated and<br />

continuous forming process. During the<br />

process the pipe will be pushed into a<br />

narrow zone which is heated by a ring<br />

shaped inductor. The bending force will be<br />

applied axially to the pipe, the front end of<br />

which is fixed in a swivel-arm. During the<br />

bending process the bending arm will move<br />

around its axis on a circular arc with the<br />

specified radius. Through the applied axial<br />

force the pipe follows the set circular path.<br />

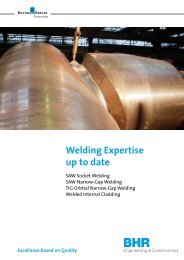

WALL THICKNESS<br />

During the bending process the pipe<br />

wall thickness at the bend extrados will<br />

decrease, the same at the bend intrados<br />

will increase. The percentage amount of<br />

difference between the wall thickness of the<br />

finished bend and that of the actual wall<br />

thickness of the prepipe depends mainly on<br />

the ratio of bending radius to pipe outside<br />

diameter (R/D). The following chart gives<br />

guidelines of the changes in the wall<br />

thickness when using our bending<br />

machines.<br />

CHANGE OF WALL THICKNESS AT BENDING<br />

% Increase % Reduction<br />

20<br />

10<br />

0<br />

10<br />

20<br />

30<br />

40<br />

50<br />

max. reduction<br />

min. increase<br />

Air<br />

Water<br />

60<br />

0<br />

1 2<br />

3 4 5 6 7 8 9 10 11<br />

R/D ratio<br />

12<br />

<strong>Custom</strong> <strong>made</strong> <strong>bends</strong>