You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

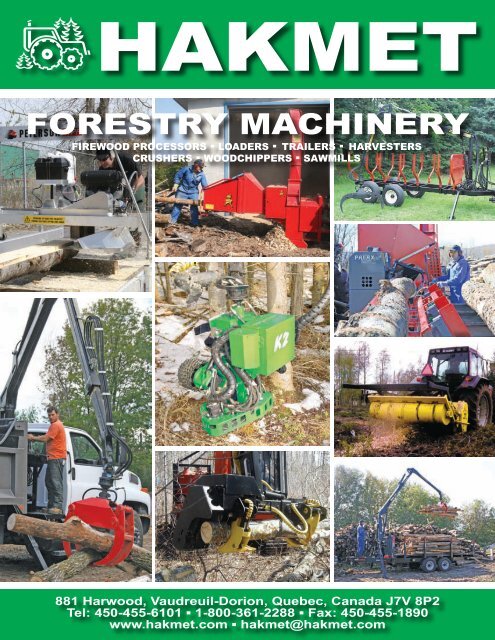

HAKMET<br />

<strong>FORESTRY</strong> <strong>MACHINERY</strong><br />

FIREWOOD PROCESSORS ▪ LOADERS ▪ TRAILERS ▪ HARVESTERS<br />

CRUSHERS ▪ WOODCHIPPERS ▪ SAWMILLS<br />

881 Harwood, Vaudreuil-Dorion, Quebec, Canada J7V 8P2<br />

Tel: 450-455-6101 ▪ 1-800-361-2288 ▪ Fax: 450-455-1890<br />

www.hakmet.com ▪ hakmet@hakmet.com

HAKMET INFORMATION<br />

TABLE OF CONTENTS<br />

ARBRO STROKE HARVESTERS .................03<br />

K HARVESTERS ........................................04<br />

NORRHYDRO FELLING GRAB ..................04<br />

NORRHYDRO LOADER ..............................05<br />

JC-PETE TRAILERS ...................................05<br />

PETE SKIDDING WINCHES .......................06<br />

HUD-SON SAWMILLS ...............................07<br />

PETERSON SAWMILLS ............................08<br />

NOKKA LOADERS ......................................10<br />

SILVAHILL TRAILERS ...............................10<br />

PETE WOODCHIPPERS .............................12<br />

MERI CRUSHERS .......................................14<br />

PALAX FIREWOOD PROCESSORS ............16<br />

NOKKA TRAILERS ....................................19<br />

NOKKA TIMBER GRABS ............................19<br />

PETE LOADERS & TRAILERS ...................20<br />

Please call for a DVD.<br />

For more information on our products and updates<br />

please check our website or call us!<br />

We also have some used inventory for sale on our website.<br />

<strong>Hakmet</strong> offers financing through our financial partners.<br />

All our products have a warranty!<br />

If you are interested in dealerships, please give a call.<br />

We have been in business for almost 30 years!<br />

<strong>Hakmet</strong> Ltd., a Canadian corporation, has been in the<br />

forest machinery business since 1977. Our head<br />

office is located just west of Montreal in Vaudreuil-Dorion,<br />

Quebec. To assure a high level of customer service and<br />

support, we have technical and sales representatives or<br />

dealers across Canada and the U.S.A.<br />

<strong>Hakmet</strong> both manufactures and distributes a wide range<br />

of agricultural and forestry machinery.<br />

We specialize in timber harvesting machinery from<br />

felling, delimbing and cutting to transporting the material<br />

and utilising the material. We cover the whole spectrum.<br />

Depending on your preferences we can help you get the<br />

most out of the work. At the moment we offer two different<br />

types of harvesters; the ARBRO stroke harvesters and the<br />

K-series harvesters. To move your logs around we can<br />

offer our PETE skidding winches or NOKKA timber grabs.<br />

The NOKKA brand also has excellent loaders and trailers<br />

for loading and hauling your logs. If you are in need of a<br />

highway trailer check out our SilvaHill trailers.<br />

Once you have your logs piled we can offer our Palax<br />

firewood processors. Due to high energy prices many<br />

woodlots have realized that our processors can ease<br />

the job and bring in more money faster than traditional<br />

manpower. For the saw millers, we carry two sawmill<br />

brands the affordable HUD-SON band sawmills and the<br />

revolutionary PETERSON swing blade sawmills. With our<br />

PETE woodchippers you can chip your logs for mulching<br />

or heating.<br />

For landscaping, we have the world famous MERI<br />

crusher, which grinds up to 10 inches below soil,<br />

depending on the model. And that makes a difference<br />

if you want to utilise your land now not years later. An<br />

excellent way to get rid of the old stumps and bushes.<br />

With years of experience in the forest machinery field,<br />

<strong>Hakmet</strong> has gained a solid reputation in excellent knowhow,<br />

superior products, innovative product development<br />

and committed customer service.<br />

We hope you will enjoy our new catalogue. For further<br />

information on our products, availability and pricing please<br />

contact our head office at 1-800-361-2288. One of our<br />

friendly staff will be happy to help you.<br />

THE HAKMET TEAM<br />

We reserve the right to change the specifications or to modify the designs without prior notice.<br />

We are not obliged to implement any improvements to previously purchased equipment.<br />

Approximate values for all specifications.<br />

02<br />

1-800-361-2288 ■ WWW.HAKMET.COM

ARBRO STROKE HARVESTERS<br />

Arbro-Stroke is a stroke harvester,<br />

which fells, delimbs and cuts trees<br />

to length. Arbro-Stroke harvester is<br />

available in two models that can be<br />

easily installed on a standard loader.<br />

Arbro-Stroke 400 is especially meant<br />

for thinning operations and Arbro-<br />

Stroke 1000 can also handle bigger<br />

tasks. Compared to other same size<br />

harvester heads the Arbro-Stroke has<br />

a lot of delimbing power.<br />

Arbro-Stroke can easily be<br />

connected and disconnected on<br />

the rotator of the loader. And most<br />

common farm tractors have enough<br />

hydraulic power to operate model 400.<br />

Model 1000 requires a heavier carrier.<br />

A good choice would be an excavator.<br />

The harvester has a superior<br />

quality measuring device that makes<br />

the production highly efficient. The<br />

exceptional measuring device comes<br />

as standard equipment.<br />

The harvester head is equipped with a reliable Volvo saw motor. The cutter bar is available in either 14’’ or 16’’ for model 400<br />

and 20’’ for model 1000. The operating handles have been designed for professional use. The design of them makes the use of<br />

the loader and the Arbro-Stroke harvester head a pleasure.<br />

The harvester has an automatic stroke and the tree can be delimbed with a one-button function. Arbro-Stroke is equipped<br />

with a measuring device and the stroke will stop at the pre-selected length for the log to be cut. The measuring device can be<br />

programmed for various pre-selected lengths. In<br />

addition any length can be chosen at any time. As<br />

optional equipment the thickness of the log can also<br />

be measured. The delimbing knives and grip arms<br />

can be opened separately.<br />

ARBRO STROKE HARVESTERS<br />

Technical specifications ARBRO 400 ARBRO 1000<br />

Oil flow<br />

Operating Pressure<br />

Weight (without oil)<br />

45-80 l/min 80-120 l/min<br />

12-21 GPM 21-31 GPM<br />

175 bar 180 bar<br />

2,500 PSI 2,600 PSI<br />

280 kg 450 kg<br />

616 lbs 990 kg<br />

Saw Motor Volvo F11-5 F11-10<br />

Saw Bar 14’’ or 16’’ 20’’<br />

Stroke<br />

Delimbing force<br />

Maximum opening of delimbing knives<br />

Maximum opening of grip arms<br />

Approximate values for all specifications<br />

660 mm 660 mm<br />

26’’ 26’’<br />

2,200 kp 3,500 kp<br />

4,850 lbs 7,800 lbs<br />

360 mm 450 mm<br />

14.2’’ 17.7’’<br />

430 mm 550 mm<br />

16.9’’ 21.7’’<br />

1-800-361-2288 ■ WWW.HAKMET.COM<br />

03

K HARVESTERS<br />

The K harvester series is a new concept in tree<br />

harvesting. Now available in three different models<br />

from the light weight K2 to the larger K3 and K4<br />

models. Fell, delimb and cut to length. The K2 can be<br />

mounted on a loader attached to a farm tractor.<br />

K HARVESTERS K2 K3 K4<br />

Weight 220 kg / 485 lbs 370 kg / 815 lbs 750 kg / 1,655 lbs<br />

Maximum delimbing diameter 240 mm / 9.45” 320 mm / 12.6” 500 mm / 19.7’’<br />

Maximum cutting diameter 280 mm / 11” 360 mm / 14.2” 550 mm / 21.7’’<br />

Number of knives 4 (3 moving ones) 4 (3 moving ones) 4 (3 moving ones)<br />

Feed force 8 kN 12 kN 20 kN<br />

Saw bar type 404’’ 14” 16” 18’’/20’’<br />

Oil flow (20Mpa/200bar)<br />

120 l/min / 32 G/min 150 l/min / 40 G/min 160 l/min / 42 G/min<br />

Delimbing speed 3.0 m/s / 9.8 ft/s 4.0 m/s / 13.1 ft/s 4.0 m/s / 13.1 ft/s<br />

Crane requirement 30 kNm 50 kNm 90 kNm<br />

Carrier size 55 hp 80 hp 110 hp<br />

Measuring options Length Length & diameter Volume<br />

Approximate values for all specifications.<br />

The K2 harvester<br />

is ideal for first<br />

thinnings. The machine<br />

is capable of doing 9.5’’<br />

trees. The K3 can cut<br />

12.6’’ trees. The largest<br />

available harvester in<br />

the K-series is the K4<br />

harvester which is able<br />

to cut up to 19.7’’ trees.<br />

All the harvesters are<br />

easy to use and service.<br />

The harvester head<br />

has a computer system<br />

that can be programmed<br />

for different measuring<br />

options.<br />

NORRHYDRO FELLING GRAB<br />

The NH016 felling grab is a<br />

high quality product aimed<br />

for the agricultural and forestry<br />

industry. The NH016 has a<br />

wide range of use from tree<br />

top cutting on power lines<br />

to basic felling. The<br />

felling grab is easy<br />

to operate and<br />

maintain.<br />

NORRHYDRO FELLING GRAB<br />

Grab size 0.16 m 2 1.72 ft 2<br />

Maximum height open 900 mm 35.2’’<br />

Maximum overall width 400 mm 15.7’’<br />

Jaws maximum width 270 mm 10.6’’<br />

Jaws maximum opening 960 mm 37.8’’<br />

Minimum tree diameter 60 mm 2.3’’<br />

Maximum cutting diameter 300 mm 12’’<br />

Oil flow minimum 55 l/min 14.5 GPM<br />

Maximum working pressure 230 bar 3,360 PSI<br />

Cutter chain speed 10000 rpm 34 m/sec 111 ft/sec<br />

Cutter bar rotation 90°<br />

Cutter bar speed adjustable<br />

0.5-5 sec<br />

Weight 106 kg 234 lbs<br />

Approximate values for all specifications<br />

04<br />

1-800-361-2288 ■ WWW.HAKMET.COM

The NH log loader is an excellent choice for removing logs, brush,<br />

rocks and scrap. The NH loader is lightweight, but sturdy. It is plate<br />

mounted for use on trailers, trucks and stationary mounted applications.<br />

The NH loader has a continuous turn rotator with a 39’’ grapple, which<br />

is very handy. The loader requires very little maintenance and it is easy<br />

to use. The picture below features a Norrhydro loader mounted on a<br />

JC-Pete trailer.<br />

NORRHYDRO GRAPPLE LOADER<br />

Working pressure 17.5 Mpa 2,400 PSI<br />

Lifting momentum 17.3 kNm 12,760 lbf-ft<br />

Maximum reach 4.2 m 13.8 ft<br />

Lifting capacity at max reach 405 kg 890 lbs<br />

Slewing angle of the boom 360°<br />

Slewing torque of the boom 3.3 kNm 2,430 lbf-ft<br />

Slewing torque of the grapple 0.75 kNm 555 lbf-ft<br />

Size of the grapple 0.15-0.16 m 2 1.61-1.72 sq ft<br />

Maximum opening of the grapple 930 mm 36.6’’<br />

Weight of the grapple 400 kg 880 lbs<br />

Maximum transport height 1.65 m 5.4 ft<br />

Maximum transport width 1.3 m 4.3 ft<br />

Approximate values for all specifications<br />

JC-PETE LOG TRAILERS<br />

Technical specifications TR-14 TR-12<br />

Capacity<br />

Overall length<br />

Load length<br />

Width<br />

Clearance<br />

Tires<br />

Hubs<br />

Weight<br />

Approximate values for all specifications.<br />

9,070 kg 3,175 kg<br />

20,000 lbs 7,000 lbs<br />

6.1 m 5.2 m<br />

20’ 17’<br />

4.25 m 3.5 m<br />

14’ 11.5’<br />

2,030 mm 1,680 mm<br />

80’’ 66’’<br />

430 mm 380 mm<br />

17’’ 15’’<br />

295/75 R22.5<br />

12LTx15<br />

NORRHYDRO LOADER<br />

JC-PETE LOG TRAILERS<br />

3,630 kg/each<br />

8,000 lbs/each<br />

11LTx15<br />

1,450 kg 820 kg<br />

3,200 lbs 1,800 lbs<br />

The heavy-duty JC-Pete log trailers with high capacity tandem<br />

wheel hubs. Trailers come in different lengths ranging from the 12<br />

feet model, recommended for the Norrhydro loader, to 14 and 16 feet<br />

models, which can be equipped with<br />

the heavier Nokka<br />

loaders (see picture below). Ask<br />

for package pricing!<br />

1-800-361-2288 ■ WWW.HAKMET.COM<br />

05

PETE SKIDDING WINCHES<br />

SM-PETE 4.1 Winch<br />

■ Pulling capacity of 4,000 kg (8,800 lbs)<br />

■ Winch is sold with a 40 m (135 ft)<br />

of 9 mm (3/8 in) cable<br />

■ ROSS hydraulic motor<br />

■ Weight 200 kg (440 lbs)<br />

■ Maximum operating<br />

pressure 175 bar (2 600 psi)<br />

■ Oil flow 60 - 80 l/min (15-21 GPM)<br />

■ Northman electro-valve (option)<br />

■ Electric system 12 Volts (option)<br />

PETE PV-5 Winch<br />

■ Pulling capacity of 5,000 kg (11,000 lbs)<br />

■ Winch is sold with 50 m (164 ft)<br />

of 10 mm (0.39 in) cable<br />

■ Winching speed 0.8 m/s (2.6 ft/s)<br />

■ Supplied with an automatic brake system<br />

■ Weight 340 kg (750 lbs)<br />

■ Mounts either to category<br />

I or II 3-point hitch<br />

■ Recommended tractor size is<br />

45 to 75 kW (60 to 100 HP)<br />

PETE PV-2 Winch<br />

■ Pulling capacity of 2,800 kg (6,170 lbs)<br />

■ Winch is sold with a 50 m (164 ft) of 8 mm (0.31 in) cable<br />

■ Winching speed 0.5 to 1.3 m/s (1.6 to 4.3 ft/s)<br />

■ Weight 275 kg (606 lbs)<br />

■ Mounts to category I 3-point hitch<br />

■ Recommended tractor size is 30 to 75 kW (40 to 100 HP)<br />

06<br />

1-800-361-2288 ■ WWW.HAKMET.COM

HUD-SON PORTABLE SAWMILLS<br />

Hud-Son portable sawmills are available in many models;<br />

from the smallest Oscar18’’ to the largest Oscar 52’’. The<br />

sawmill model number refers to the log diameter cutting capacity.<br />

Oscar 18”<br />

By far, the most portable sawmill that can perform as well<br />

as larger sawmills. Oscar 18” comes standard with a 6.5 HP<br />

engine, cuts 18” (457 mm) diameter logs and has two 6’ (1.83<br />

m) ground tracks. Also, an optional trailer package is available<br />

for off road or deep woods towing.<br />

Oscar 36”<br />

This sawmill is Hud-Son’s best selling unit with many features<br />

offered by larger mills at a great price. The Oscar 36” makes<br />

quick work of any log-to-lumber needs using a 12 volt winch to<br />

control the height of the sawmill head. Oscar 36” also features<br />

a 16 HP V-Twin Overhead Valve Briggs & Stratton Motor<br />

allowing you to slice through any wood up to 36” (914 mm) in<br />

diameter. Also available with a 16, 21 or 23 HP engine.This<br />

model is available as a ground track unit or complete unit with a<br />

tow trailer.<br />

Farm Boss 36”<br />

The Farm Boss 36” is true accessibility and affordability. This<br />

unit features a 24’ (7.3 m) cutting bed supported by a 3x6 steel<br />

trailer frame. The sturdy construction of frame and head allows<br />

the mill to go anywhere with ease. Set up is a breeze with 6<br />

drop down legs that allow you to obtain level in any terrain. This<br />

unit features a 16 HP motor. Equipped with an electric powered<br />

Superwinch for touch of a button height adjustment makes this<br />

sawmill user friendly and ready to cut on the spot. Also available<br />

with a 20 or 23 HP engine.<br />

Oscar 228 - formerly the Oscar 28”<br />

The Oscar 228” sawmill is a new addition to the Hud-Son line<br />

of sawmills. It will accept 28” (710 mm) diameter logs with<br />

12’ (3.66 m) of 2” (51 mm) angle iron tracks. It will even fit in<br />

the back of a short box pick-up truck! This model has an 8 HP<br />

Briggs & Stratton motor. Also, a towable trailer is available for off<br />

road or deep woods towing.<br />

Oscar 30”<br />

The Oscar 30” is stealing the portable sawmill market with its<br />

affordability and efficiency. The standard model features a 10<br />

HP Briggs & Stratton Motor and two 7’ (2.13 m) ground tracks.<br />

Also available with a 10, 13 or 16 HP engine. This portable<br />

sawmill can accommodate a 30” (762 mm) diameter log and<br />

provide you with all of your lumber needs.Optional trailer<br />

packages also available.<br />

Oscar 52”<br />

The Oscar 52” is only available with ground track due to the<br />

width exceeding D.O.T. regulations. Hud-Son’s sawmills are<br />

currently being used in many unique applications including<br />

paper mills, log home building, and furniture making. Hud-Son<br />

is singular in our ability to handle oversized wood or crooked<br />

wood, making 52” mills to meet your needs. The 23 HP V-twin<br />

engine is standard on both of these models.<br />

H2HG - Hud-Son 2nd Generation Hydraulic Mill<br />

The new H2HG has fully hydraulic features that can<br />

accommodate a 36” (914 mm) diameter log. With heavy duty<br />

head construction it comes standard with a 23 HP Briggs and<br />

Stratton engine and many user friendly features. Get consistent<br />

and smooth lumber with this high production mill!<br />

1-800-361-2288 ■ WWW.HAKMET.COM<br />

07

PETERSON SAWMILLS<br />

The All Terrain Sawmill easily handles the tough milling conditions of any remote terrain. The mill is lightweight, easy to<br />

use and easy to maintain. These mills are also a popular choice for our part time millers.<br />

ATS – ALL TERRAIN SAWMILLS<br />

■ 6” (160mm), 8” (210mm), or 10” (260mm) blade<br />

options.<br />

■ Range of power head options.<br />

■ Set up in 5-15 minutes (even on a hill).<br />

■ Saw logs from 6m (20’) long - longer with extension<br />

■ Saw logs up to 1.5m (5’) diameter with chocking.<br />

■ Cuts 2-6m3 + (800-2400 bft +) per day<br />

■<br />

■<br />

■<br />

■<br />

■<br />

Double your cut size easily on any model; with up to<br />

260mm x 520mm (10” x 20”) on 10” model.<br />

Easy 2 point Vertical sizing at the operators end.<br />

One side track raising fro easy log loading.<br />

Ability to follow the log taper or terrain lie for maximum<br />

recovery.<br />

Quick disassemble for hand carrying.<br />

The Winch Production Frame mills are designed for fast production of high quality, extremely accurate timber, in portable<br />

or fixed site milling. Hi/Lo track option allows easy loading of logs and is ideally suited for the commercial / contract<br />

portable miller. Plus you have the versatility to take on any job – no matter how long the log!<br />

WPF – WINCH PRODUCTION FRAME (SAWMILL)<br />

■ 6” (160mm), 8” (210mm), or 10” (260mm) blade options.<br />

■ Cuts 3-8m3 + (1200-3000bft+) per day<br />

■ Range or power head options.<br />

■ Sets up in 10 – 30 minutes.<br />

■ Saw logs up to and from 6m (20’) length as standard<br />

– longer with extensions.<br />

■<br />

■<br />

■<br />

■<br />

Saw logs up to 1.2m (4’) diameter on the small frame,<br />

1.5 (5’) on the large frame, or 2m (7’) on GIANT.<br />

Easily double the width of your cut on any blade e.g.<br />

260mm x 520mm (10” x 20”) on 10” model.<br />

Single winch sizing system for spot-on accuracy.<br />

Hi/Lo track option for the fixed site log loading.<br />

08<br />

1-800-361-2288 ■ WWW.HAKMET.COM

The Automated Swingblade Mill delivers commercial production with much less effort. Make horizontal & vertical cuts,<br />

change the size or depth of the cut, and remove the previous board, all from the control panel.<br />

ASM – AUTOMATED SWINGBLADE MILL<br />

■ 8” (210mm) or 10” (260mm) blade options.<br />

■ Range of power head options.<br />

■ Set up in 40-60 minutes.<br />

■ Saw logs up to 1.5m or 2m (5’ or 7’) diameter.<br />

■ Saw logs to 6m (20’) long with std tracks – longer with<br />

extensions.<br />

■ Cuts 1-2m3 (424-848bft+) per machine hour.<br />

■<br />

■<br />

■<br />

■<br />

■<br />

Hi Track as standard for fixed site milling.<br />

Double your cut size easily on any model; with up to<br />

260mm x 520mm (10” x 20”) on 10” model.<br />

Automated board removal plate for easy tailing out either end.<br />

Electric rise & fall, horizontal sizing, and blade pivot, for<br />

commercial production.<br />

Totally portable mill is moved with jockey wheels by<br />

hand plus fits in the back of a standard trailer.<br />

The Dedicated Wide Slabber produces accurate wide slabs with a high quality finish. These units can be used on our<br />

WPF, ASM or ATS mills, so the operator can quickly change between sawing and slabbing, for optimum usage<br />

DWS – DEDICATED WIDE SLABBER<br />

■ 404 ripping or double skip tooth chain; less fuel<br />

consumption and longer chain life.<br />

■ Range of power head options.<br />

■ Saw logs up to 6m (20’) long with standard tracks<br />

– longer with extensions.<br />

■ Saw logs up to 1.5m (5’) in diameter.<br />

■<br />

■<br />

■<br />

■<br />

Cut slabs of up to 8” thick.<br />

Cuts 6-30 slabs an hour depending on specs (2-10<br />

mins per slab dependent on size).<br />

Single winch sizing system for spot-on accuracy.<br />

Can be used on same tracks as the other mills to get<br />

optimum grade recovery out of your logs.<br />

1-800-361-2288 ■ WWW.HAKMET.COM<br />

09

NOKKA LOADERS & SILVAHILL<br />

Nokka Grapple Loaders are efficient and strongly built equipment for use all year round. Due to many<br />

available mounting alternatives, wide ranges of accessories and versatile operating features, the Nokka<br />

loaders are well suited for various loading and lifting tasks on different kinds of base machines.<br />

SILVAHILL 12 SILVAHILL 15 SILVAHILL 18<br />

Nokka offers loaders from the<br />

compact 2551 model through<br />

the 34-series, 36-series, 41-series,<br />

46-series to the biggest 60-series<br />

models. Nokka has optimised<br />

the dimensioning of the boom<br />

sections so the best capacity is<br />

available at the most important<br />

lifting height between 2 m (6.5 ft)<br />

and 3 m (9.8 ft). Check the specs<br />

on the following page. Ask for our<br />

special package deal when buying<br />

a loader and a trailer together!<br />

6 000 lb Dexter axles with electric<br />

brakes at all wheels on 12,000 lb.<br />

235 x 85R 16 E range radials on<br />

12,000 lb trailer<br />

Use on a 3/4 ton pick-up truck<br />

For all models<br />

7 000 lb Dexter axles with electric brakes at all wheels on 14,000 lb.<br />

235 x 85R 16 G range radials on<br />

15,000 lb trailer<br />

Use on a 1 ton pick-up truck<br />

2 X 5 tube bunks 3 X 5 tube bunks<br />

7’2’’ wide 7’6’’ wide<br />

235 x 85R 17.5 G range radials on<br />

18,000 lb trailer<br />

3,500 lb slipper springs with greasable equalizers Primed and painted gloss black or Nu Cat yellow<br />

12 000 lb drop leg jack with side crank Reflecting taping<br />

Rated grate 70 safety chains with safety hooks<br />

New spare tire, wheel and holder<br />

3 X 3 tube with open headboard for airflow 3 ratchet binders and 4’’ X 27’ straps<br />

Deck height 30’’<br />

Pintle hook or 2 5/16 ball<br />

3 X 3 removable uprights Loader mount and operators station<br />

Lights all sealed LED with wiring in conduit<br />

Fenders and mudguards over tires<br />

Options for all models<br />

Standard bed length 16’<br />

D.O.T. approved / Highway approved<br />

Standard equipped with Vin.#<br />

Made in the U.S.A.<br />

Oil bath axles Gooseneck hitch Alcoa wheels Ramp and floor kit<br />

Custom paint Longer frames Dump bed Hydraulic power pack<br />

Approximate values for all specifications<br />

10<br />

1-800-361-2288 ■ WWW.HAKMET.COM

TRAILERS<br />

NOKKA GRAPPLE LOADERS<br />

Mounting 3-point 2-cyl Slew 2551 3467 3655 3668H 4155 4166HL4 4170H<br />

Mounting Flange 4-cyl Slew 2551L 3467HL4 3655L 3668HL 4155L4 4166L4 4170HL4 4670HL4 4676HCL4 6068 6084<br />

Lifting momentum gross<br />

Maximum reach<br />

Extension length<br />

Slewing torque<br />

Slewing torque<br />

with 4-cyl slew<br />

kNm 25 34 34 34 41 41 41 46 46 60 60<br />

lbf-ft 18,440 25,080 25,080 25,080 30,240 30,240 30,240 33,930 33,930 44,255 44,255<br />

m 5.1 6.7 5.3 6.8 5.55 6.6 7 7 7.5 6.8 8.4<br />

ft 16.7 22 17.4 22.3 18.2 21.7 23 23 24.6 22.3 27.6<br />

m - 1.375 - 1.4 - 1.25 1.6 1.6 2x1.26 1x1.65 2x1.65<br />

ft - 4.5 - 4.6 - 4.1 5.25 5.25 2x4.1 1x5.4 2x5.4<br />

kNm 6.5 7.5 7.5 7.5 7.5 7.5 7.5 - - - -<br />

lbf-ft 4,790 5,530 5,530 5,530 5,530 5,530 5,530 - - - -<br />

kNm 9.6 9.6 9.6 9.6 9.6 9.6 9.6 12.5 12.5 16 16<br />

lbf-ft 7,080 7,080 7,080 7,080 7,080 7,080 7,080 9,220 9,220 11,800 11,800<br />

Slewing angle degrees 400 380<br />

Wide angle joint<br />

Weight depends on equipment<br />

kg 700 835 800 890 850 905 945 1,070 1,130 1,320 1,400<br />

lbs 1,550 1,840 1,760 1,960 1,875 1,995 2,085 2,360 2,490 2,910 3,090<br />

with standard equipment 3-point 4-cyl slew<br />

Working pressure<br />

Minimum hydraulic output<br />

Approximate values for all specifications.<br />

Mpa 17.5 17 17.5 17.5<br />

PSI 2,540 2,465 2,540 2,540<br />

l/min 30 40 45 - 50 55 - 60<br />

GPM 7.9 10.6 11.9 - 13.2 14.5 - 15.9<br />

yes<br />

1-800-361-2288 ■ WWW.HAKMET.COM<br />

11

PETE WOODCHIPPERS<br />

Pete woodchippers are suitable for producing wood chips for heating or mulching.<br />

The Pete woodchipper product range includes several models for both private<br />

and professional use. All Pete woodchippers feature a massive cutting disc with fan<br />

blades to ensure a steady flow of chips. Chip size is adjustable due to the sets of<br />

adjustable bottom and side counter blades and adjustable rotary cutting blades.<br />

PETE HJ4<br />

A 3-point hitch mounted lightweight chipper for chipping brush and stems<br />

up to 4 inches. The standard M model is equipped with a manual infeed<br />

chute. An alternative model HJ4 G with a hydraulic feeding system is also<br />

available.<br />

PETE HJ5<br />

A 3-point hitch mounted chipper for chipping stems and small tree trunks<br />

up to 6.5 inches. The standard M model is equipped with a manual infeed<br />

chute. An alternative model HJ6.5 G with a hydraulic feeding system is also<br />

available. A regular farm tractor provides power for this model.<br />

PETE HJ10<br />

A 3-point hitch mounted woodchipper for chipping stems and small trees<br />

up to 10 inches. The standard M model is equipped with a manual infeed<br />

chute. There are also available two alternative models HJ10 G with a<br />

hydraulic feeding system and HJ10 GT with its own hydraulics including a<br />

pump, an oil tank and a feeding unit. A regular farm tractor provides power<br />

for this model.<br />

12<br />

1-800-361-2288 ■ WWW.HAKMET.COM

The HJ200 and HJ260<br />

series offer a choice<br />

of two operating speeds<br />

according to the application.<br />

The higher speed is usually<br />

used for producing chips for<br />

compost. Due to the speed<br />

the blowing capacity is also<br />

increased which is useful for<br />

chipping brush. The lower<br />

speed is used for chipping<br />

thicker wood.<br />

The hydraulic feeder<br />

offers a firm grip for chipping<br />

different kinds of material.<br />

The feed roller takes the<br />

wood towards the cutting<br />

disc where the blades cut<br />

the wood into chips. Then<br />

the chips move to the blower<br />

blades through the blade<br />

opening and are blown out<br />

through the output chute.<br />

The feeding speed can be<br />

adjusted by changing the<br />

speed of the hydraulic motor.<br />

The feed roller is equipped<br />

with sharp teeth for a firm<br />

grip and stable movement. If<br />

necessary the feed rollers can<br />

be stopped.<br />

The G model uses the<br />

tractors hydraulic system in<br />

feeding the wood. The GT<br />

model has its own hydraulic<br />

system and it is powered by<br />

the tractors PTO.<br />

The HJ200 Mobile chipper<br />

is mounted on a trailer for<br />

easy transportation. The<br />

chipper has a self-contained<br />

diesel engine for power.<br />

The HJ500 is a heavyduty<br />

chipper designed<br />

for demanding contractor<br />

applications. It can produce<br />

well over 100 cubic meters<br />

per hour. With high power<br />

capacity and a robust loader<br />

chute the chips can be<br />

directed straight onto a lorry<br />

platform or into a trailer.The<br />

feed channel is set to a 45<br />

degree angle against the<br />

cutting disc and the infeed<br />

chute takes wood with a<br />

maximum diameter of almost<br />

18 inches.<br />

PETE WOODCHIPPERS HJ 4, HJ 5, HJ 10, HJ200, HJ260 & HJ500<br />

Technical specifications HJ 4 M HJ 5 M HJ 10 M HJ 200 G HJ 260 G HJ 500 C<br />

Feed funnel size<br />

7 7/8 x 6 7/10’’ 7 7/8 x 7 7/8’’ 10 1/4 x 10 1/4’’ 7 1/2 x 7 1/2’’ 10 1/4 x 10 1/4’’ 17 3/4 x 17 3/4’’<br />

20 x 17 cm 20 x 20 cm 26 x 26 cm 19 x 19 cm 26 x 26 cm 45 x 45<br />

Cutting disc diameter<br />

17’’ 24 1/4’’ 31 1/2’’ 25 1/4’’ 34 1/2’’ 54 3/8’’<br />

430 mm 630 mm 800 mm 640 mm 870 mm 1380 mm<br />

Cutting disc weight<br />

99 lbs 214 lbs 374 lbs 222 lbs 378 lbs 1 430 lbs<br />

45 kg 97 kg 170 kg 100 kg 170 kg 650 kg<br />

Flange 540 - 1000 RPM 540 - 1000 RPM 540 - 1000 RPM 540 - 1000 RPM 540 - 1000 RPM 540 - 1000 RPM<br />

Number of blades 3 4 4 4 4 2<br />

Chip size<br />

5/32 - 1/2’’ 3/16 - 1/2’’ 1/8 - 2/3’’ 1/8 - 2/3’’ 1/8 - 3/4’’ 3/16 - 13/16’’<br />

4 - 12 mm 5 - 12 mm 3 - 15 mm 3 - 15 mm 3 - 18 mm 5 - 20 mm<br />

Maximum wood diameter<br />

4’’ 6 3/5’’ 9 7/8’’ 7 1/2’’ 9 7/8’’ 17 3/4’’<br />

10 cm 17 cm 25 cm 19 cm 25 cm 45 cm<br />

Output<br />

2 - 6 m 3 /h 4 - 8 m 3 /h 7 - 20 m 3 /h 4 - 10 m 3 /h 7 - 20 m 3 /h 30 - 100 m 3 /h<br />

70 - 210 cu.ft/h 140 - 280 cu.ft/h 250 - 710 cu.ft/h 140 - 350 cu.ft/h 250 - 710 cu.ft/h 1 060 - 3 530 cu.ft/h<br />

Power requirement 14 - 50 hp 27 - 70 hp 27 - 75 hp 27 - 70 hp 40 - 100 hp 110 - 200 hp<br />

Weight (basic model)<br />

382 lbs 655 lbs 1 178 lbs 1 245 lbs 1 710 lbs 5 500 lbs<br />

172 kg 295 kg 530 kg 560 kg 740 kg 2 500 kg<br />

Length in working position<br />

49’’ 57’’ 67’’ 95 1/3’’ 96’’ 169 1/4 - 190’’<br />

125 cm 145 cm 170 cm 242 cm 244 cm 430 - 483 cm<br />

Length in transport position<br />

47 1/4’’ 47 1/4’’ 55’’ 68 1/2’’ 69 1/3’’ 169 1/4 - 190’’<br />

120 cm 120 cm 140 cm 174 cm 176 cm 430 - 483 cm<br />

Width in transport position<br />

57’’ 47 1/4’’ 41 1/4’’ 41’’ 41’’ 90 1/2’’<br />

145 cm 120 cm 105 cm 104 cm 104 cm 230 cm<br />

Height in transport position<br />

74 4/5’’ 94 1/2’’ 108 1/4’’ 92 9/10’’ 116 1/7’’ 124’’<br />

190 cm 240 cm 275 cm 236 cm 295 cm 315 cm<br />

Approximate values for all specifications<br />

1-800-361-2288 ■ WWW.HAKMET.COM<br />

13

MERI CRUSHERS<br />

THE HEAVY-DUTY MERI CRUSHERS FOR ROUGH WORK!<br />

Superior crushing power for stumps, roots,<br />

branches, ice, soil and gravel roads!<br />

Forestry<br />

■ Crushing slash<br />

■ Clearing tracks<br />

■ Preparing to forest<br />

■ Preparing fire safety lanes<br />

■ Maintaining forest roads<br />

■ Clearing and maintaining<br />

power lines<br />

Municipalities<br />

■ Gardening and landscaping<br />

■ Crushing stumps<br />

■ Maintaining park paths<br />

■ Preparing and maintaining<br />

jogging and ski tracks<br />

Agriculture<br />

■ Crushing old fruit and<br />

berry trees<br />

■ Preparing soil<br />

■ Maintaining farm roads<br />

■ Keeping fallow land<br />

in presentable condition<br />

■ Reclaiming old farm land<br />

MERI CRUSHERS<br />

Technical specifications MJ-1.0 MJ-1.4 MJ-1.8 MJ-2.3 MJS-1.0 MJS-2.0 DT MJS-2.5 DT<br />

Working width<br />

mm 1,000 1,400 1,800 2,300 1,000 2,000 2,500<br />

in 39 59 71 91 39 79 98<br />

Total width<br />

mm 1,400 1,800 2,200 2,700 1,420 2,420 2,920<br />

in 55 71 87 106 56 95 115<br />

Weight ST<br />

kg 535 590 765 870 655 - -<br />

lbs 1,180 1,300 1,686 1,918 1,444 - -<br />

Weight DT<br />

kg 645 720 960 1,115 930 1,245 1,360<br />

lbs 1,422 1,588 2,117 2,459 2,050 2,745 2,999<br />

Rear drum<br />

kg 150 170 190 240 160 235 280<br />

lbs 331 375 419 530 353 518 617<br />

Felling frame<br />

kg 55 85 115 155 55 130 185<br />

lbs 121 187 254 342 121 287 408<br />

Mounting category II II II + III II + III II II + III II + III<br />

Primary shaft in - z 1’’3/4 - 6 1’’3/4 - 6 1’’3/4 - 6 1’’3/4 - 6 1’’3/4 - 6 1’’3/4 - 6 1’’3/4 - 6<br />

Power range ST hp 30-100 40-100 65-100 80-100 60-100 - -<br />

Power range DT hp 30-180 40-180 65-180 80-180 60-180 110-180 120-180<br />

Number of cutters # 36 51 64 85 36 74 93<br />

Cutting drum<br />

mm 360 360 360 360 460 460 460<br />

in 14 14 14 14 18 18 18<br />

Cutting depth maximum<br />

mm 200 200 200 200 250 250 250<br />

in 8 8 8 8 10 10 10<br />

ST = Single transmission, DT = Double transmission. All models have 1000 rpm pto as standard.<br />

Main gears are oil lubricated chain gears with heat-treated chain and sprockets. Approximate values for all specifications.<br />

14<br />

1-800-361-2288 ■ WWW.HAKMET.COM

Amazing how MERI crusher grinds almost anything from small<br />

trees, stumps and branches with its extra hard carbide teeth.<br />

The crusher has low power demand compared to its crushing<br />

capacity. The crusher is able to crush up to 30 cm (12 inches)<br />

below ground level depending on the model. The design of the<br />

crusher is module-based so you can choose the right equipment for<br />

your specific needs.<br />

The MERI crusher is equipped with a built-in safety clutch that<br />

protects the transmission components from too high torque peaks.<br />

All models can be equipped with double transmission (DT) so you<br />

can use it on tractors up to 280 hp. The crusher can be used both<br />

for down-cutting or counter milling. The crusher can be mounted on<br />

different base machines either in the rear or front. Light, but strong<br />

construction enables the use of both small and big tractors.<br />

Optional equipment<br />

1. Counter blade for crushing<br />

wood.<br />

2. Rear drum.<br />

3.<br />

4.<br />

5.<br />

Felling frame.<br />

Support wheels.<br />

Hydraulic controlled rear<br />

drum and felling frame.<br />

MERI CRUSHERS<br />

Technical specifications MJH-1.2 DTG MJH-2.0 DTG MJH-2.5 DTG MJH-2.8 DTG<br />

Working width<br />

mm 1,200 2,000 2,500 2,800<br />

in 47 79 98 98<br />

Total width<br />

mm 1,550 2,350 2,850 3,150<br />

in 61 93 112 124<br />

Weight<br />

kg 1,800 2,200 2,500 2,700<br />

lbs 4,000 4,850 5,500 5,950<br />

Power range hp 130-300 150-300 170-300 190-300<br />

Number of cutters # 42 84 104 116<br />

Cutting drum<br />

mm 600 600 600 600<br />

in 24 24 24 24<br />

Cutting depth<br />

mm 50-300 50-300 50-300 50-300<br />

in 2-12 2-12 2-12 2-12<br />

Operating speed<br />

km/h 0.5-3.5 0.5-3.5 0.5-3.5 0.5-3.5<br />

mph 0.3-2.2 0.3-2.2 0.3-2.2 0.3-2.2<br />

Approximate values for all specifications.<br />

MERI pressure operated safety clutches<br />

The efficiency of the MERI safety clutch as a “peak<br />

killer” is based on its superior ability<br />

to withstand high temperatures and<br />

resist wearing. All the key components<br />

used in the safety clutch have been<br />

widely tested and are used in the<br />

car industry. They are designed to<br />

withstand thousands of sliding motions in difficult working<br />

conditions. By using the POC safety clutch there is no<br />

loss in torque resulting from the sliding motions of the<br />

clutch. You can be sure that the torque level you select<br />

is transmitted without diminution to the application in<br />

question.<br />

■<br />

■<br />

■<br />

Using the pressure operated safety clutch:<br />

Saves time and repair costs on machinery<br />

No need for oversized power transfer components<br />

Quick, accurate and easy adjustment with a grease gun<br />

MERI Crusher MJS-2.5 STG<br />

Working width 2,500 mm 98 in<br />

Total width 2,750 mm 108 in<br />

Weight 1,900 kg 4 200 lbs<br />

Power range<br />

120 - 200 hp<br />

Number of cutters 97<br />

Cutting drum 500 mm 19.7 in<br />

Cutting depth maximum 250 mm 10 in<br />

Working speed 0.5 - 3.0 km/h 0.3 - 1.9 mph<br />

Also available in working widths of 2000 mm (79 in) and 2300 mm (90.5 in)<br />

Approximate values for all specifications.<br />

1-800-361-2288 ■ WWW.HAKMET.COM<br />

15

PALAX FIREWOOD PROCESSORS<br />

Palax KS35 is a robust firewood processor with<br />

a 15” chainsaw. The standard configuration<br />

comprises a 2.2 m (7.2 ft) long and 0.2 m (7.9 in)<br />

wide in-feed conveyor, a 4.3 m (14.1 ft) long,<br />

swinging and folding discharge conveyor as well<br />

as an automatic lubricator of the saw-chain. The<br />

machine is an optimal choice, if the diameter of the<br />

processed trees varies a lot. The maximum cutting<br />

diameter is 35 cm (13.8 in) and the length of the<br />

log can be between 25 and 60 cm (10 in and 2 ft).<br />

Transporting and storing the machine is really easy<br />

Thanks to its foldable conveyor, the machine fits<br />

into a small space. The machine is 2.85 m (9.3 ft)<br />

wide, 2.4 m (7.8 ft) high and 0.95 m (3.1 ft) deep.<br />

Putting the machine into operation is easy and fast.<br />

The machine is always delivered ready assembled<br />

The in-feed conveyor and the discharge conveyor<br />

are equipped with easy-to-use quick-releases. In<br />

addition the discharge conveyor has a lift. This<br />

means operations may be started quickly without<br />

having to use any tools.<br />

Automatic tightening of the V-belts<br />

The transmission of the tractor-powered models<br />

features automatic tightening of the V-belts<br />

between the angular gear and the blade shaft. The<br />

automatic tightening requires less servicing and<br />

consequently reduces strain on the transmission,<br />

thus increasing its service life.<br />

Unobstructed and spacious splitting chute<br />

The ram pushes the tree in one piece from the<br />

higher in-feed chute to the lower splitting chute.<br />

This enables lowering the splitting ax even during<br />

operations.<br />

Clean firewood<br />

The debris drops down through the grate with<br />

large holes in the bottom of the splitting chute<br />

and as a result the processed firewood is of even<br />

measure, clean and dries quickly.<br />

Automatic high-speed valve<br />

The automatic high-speed valve considerably<br />

speeds up the operation of the machine. Small<br />

trees are split up at high speed. While splitting<br />

thick logs, the approach stroke occurs at high<br />

speed but decelerates at the start phase of the<br />

splitting. Then, as the force requirement again<br />

decreases, the high-speed motion resumes<br />

immediately.<br />

Precise length adjustment<br />

The machine comes with a log-stop that always<br />

swings to the rear for the crosscut movement. This<br />

ensures the log falls unobstructed into the splitting<br />

chute. The log-stop guides are equipped with ball<br />

bearings. The length of the log can be adjusted<br />

from 25 to 60 cm (10 in to 2 ft).<br />

Safe and easy-to-use patented tree clamp<br />

As the operating levers of the clamp and the saw<br />

are located at a convenient distance from each<br />

other, they are easy and effortless to operate<br />

simultaneously. The crosscut lever is actuated by<br />

pulling and the clamp lever is actuated by pushing.<br />

This increases the operating comfort even more.<br />

Self-cleaning in-feed conveyor<br />

The drive and return rollers of the in-feed<br />

conveyor are equipped with efficient scrapers,<br />

which keep the rollers clean under all conditions.<br />

This feature is even more significant in winter as<br />

snow is not able to gather and pack between the<br />

roller and the belt.<br />

Reliable and easy-to-operate height<br />

adjustment of the splitting ax<br />

Height position of the splitting wedge is adjusted<br />

by the control lever which is equipped with a<br />

friction lock. A robust two-way / four-way ax comes<br />

as standard. The splitting ax comes with a quickrelease.<br />

The conveyor can be locked in 5 different<br />

positions. The quick lock is released by foot. A<br />

hydraulic height adjustment of the ax is available<br />

as an option.<br />

A 4.3 m (14.1 ft) long, open and<br />

unobstructed discharge conveyor<br />

The discharge conveyor with polyethylene scrapers,<br />

two chains and gear drive is driven by a hydraulic<br />

motor. Even high trailers can be loaded with a<br />

conveyor of standard length. As both the top and<br />

the underside of the conveyor are completely<br />

open, operations are reliable under all conditions.<br />

16<br />

1-800-361-2288 ■ WWW.HAKMET.COM

The robust Palax Power100S is equipped with a<br />

1000 mm (39.3 in) overhead hard-metal blade,<br />

a thrust force of 16 tons kg (35 300 lbs) and fully<br />

hydraulic control. The machine is at its best when<br />

processing hardwood. The maximum tree diameter<br />

allowed is 40 cm (15.7 in).<br />

Automatic high-speed valve<br />

The Palax Power100S is a firewood processor for<br />

professional use. It has several unique features that<br />

make it the most efficient, productive and reliable<br />

machine of its size for processing big trees. The<br />

machine comes with an automatic high-speed valve for<br />

the splitting cylinder. As a rule, the work stroke is always<br />

performed at high speed. If the smaller splitting force<br />

induced by the high-speed function is great enough,<br />

the wood will split up. If the splitting force at high speed<br />

is not great enough, it will immediately be boosted by<br />

16 tons kg. As soon as the splitting of the wood starts<br />

and the force requirement is reduced, the high-speed<br />

operation will automatically resume. The high-speed<br />

motion brings added speed for small trees and added<br />

force for big trees.<br />

Optimizing the stroke length<br />

increases the splitting speed<br />

The Palax Optimi is the method for optimizing the<br />

length of the splitting stroke by limiting the cylinder<br />

stroke in accordance with the length of the processed<br />

wood. A full stroke is used for processing 55 cm (21.6<br />

in) long firewood. If the length of the processed wood<br />

is 30 cm (9.8 in), then the cylinder stroke is reduced<br />

to almost a half and thus the splitting speed is virtually<br />

doubled! As the length of the firewood in general is<br />

between 25 and 33 cm (9.8 and 21.6 in) the processing<br />

is really efficient. Even though the cutting of short<br />

firewood using the hard-metal blade takes place quickly,<br />

the Palax Optimi method and the automatic high-speed<br />

valve enable a sufficiently fast splitting procedure to<br />

ensure that no bottleneck is created during the splitting<br />

phase.<br />

Automatic tightening of the V-belts<br />

The transmission drive belts of the Palax Power100S<br />

are equipped with automatic tightening. Automatic<br />

tightening of the belts completely eliminates the need<br />

for repeated retightening of the belts or malfunctions<br />

due to slack or too-tight drive belts. Keeping the belts at<br />

the correct tightness greatly extends the service life of<br />

the belts and the entire transmission.<br />

Long service intervals - increased productivity<br />

Lubed-for-life ball bearings in all the control levers make<br />

operation of the machine precise, reliable and long lived<br />

and extend the service intervals.<br />

Full control of the tree during all phases of cutting and splitting<br />

The machine is equipped with a hydraulic clamp and a moving log-stop<br />

with hydraulic locking. During the in-feed operation, the clamp follows the<br />

shape of the log and the log-stop adapts exactly to the shape of the log.<br />

This enables that rough and crooked trees also remain in position during<br />

the sawing operation.<br />

Fully hydraulic control and operation<br />

All the control levers are concentrated in logical groups conveniently<br />

placed within reach of the operator. Quick-couplings for an external loglifting<br />

deck and a log transfer conveyor are standard. The pump group<br />

comprises 4 hydraulic pumps, which means there is a separate pump for each<br />

pressure and flow range. Also the external log deck has a pump of its own.<br />

Splitting axes of 2/4, 2/6, 2/8 and 12 ways are available<br />

The bottom of the splitting chute is equipped with a grate for easy debris removal.<br />

State-of-the-art discharge conveyor technology<br />

A scraper-type discharge conveyor comprising a completely open underside,<br />

two chains, and polyethylene scrapers. The conveyor is driven by a hydraulic<br />

motor and it works reliably in all kinds of operational and weather conditions.<br />

The chains have automatic tightening. The height of the conveyor can be<br />

adjusted using an easy-to-operate winch with an automatic brake.<br />

1-800-361-2288 ■ WWW.HAKMET.COM<br />

17

PALAX FIREWOOD PROCESSORS<br />

PALAX KS 35 (P.T.O. DRIVEN)<br />

HYDRAULICS<br />

Hydraulic oil VGA 32 40 l / 10.5 G<br />

Splitting cylinder, 8 tons (kg) / 17,600 lbs<br />

Automatic high-speed valve<br />

TRANSMISSION<br />

Articulated shaft, suitable size e.g. Bondioli 143<br />

OUTPUT<br />

Max. diameter of the tree : 35 cm / 13.8 in<br />

Speed standard/high-speed with 8 t (kg) : 5/3.3 sec<br />

CHAINSAW<br />

Flow of hydraulic pump : 36 l / min or 9.5 G / min<br />

Articulated shaft at 400 r.p.m.<br />

Additional circuit for external log-deck<br />

Cutting length : 25…60 cm / 10 in…2ft<br />

15” sawbar/chain driven by hydraulic motor Automatic lubricator, separate tank, vol 2 l / 0.5 G<br />

SPLITTING OF LOG<br />

Splitting ax 2/4 as standard<br />

Stepless height adjustment of the splitting ax<br />

Log-stop, gives way automatically<br />

Control/operating levers with ball bearings<br />

DISCHARGE CONVEYOR<br />

Palax 43 scraper conveyor, length 4.3 m / 14.1 ft, with 2 chains<br />

Lifting winch for conveyor<br />

Conveyor swings 2.2 m / 7.2 ft to the side, quick-release<br />

IN-FEED CONVEYOR<br />

In-Feed conveyor 200 x 2,200 mm / 7.9 x 86.6 in<br />

DIMENSIONS AND WEIGHT<br />

Length, incl. conveyor 3.5 m / 11.5 ft : 2,850 mm / 9.3 ft<br />

Width, incl. conveyor 3.5 m / 11.5 ft : 950 mm / 3.1 ft<br />

Height, incl. 3.5 m / 11.5 ft conveyor : 2,390 mm / 7.8 ft<br />

Weight : 720 kg /1,590 lbs<br />

Approximate values for all specifications.<br />

Splitting ax 2/6 or 2/3 as an option<br />

Quick-release of splitting ax<br />

Debris removal grate in the splitting chute<br />

Automatic tightening of the chains<br />

Debris removal scrapers on rollers<br />

ACCESSORIES FOR THE PALAX FIREWOOD PROCESSORS<br />

Robust Palax Mega log-deck for big trees<br />

Equipped with a step feeder and a hydraulic in-feed deck with a chaindrive.<br />

The deck is equipped with four 4-meter (14.1 ft) long chain beams.<br />

The chains may be driven both forward and reverse. Capacity about<br />

10-12 cubic meters.<br />

Palax Cleaner<br />

High-output cleaner Palax Cleaner with efficient rotary debris removal<br />

cylinder. The cylinder can also be equipped with an extension conveyor<br />

to fill the bags easy. Powered by a hydraulic motor.<br />

Light Palax log-deck<br />

Light Palax log-decks for KS35. The stand can also be equipped with a<br />

hydraulic feed roller which helps handling long logs. Capacity about 4-6<br />

cubic meters.<br />

Palax Motti bag-packing stands are very handy<br />

In the bags the firewood dries quickly. Storing of the bags is also easy<br />

as 2 bags can be stacked one on top of the other on a level surface.<br />

The bags make also good retail packages. The bags are made of UVprotected<br />

polyprophelene. The bags may be reused several times and<br />

they can be disposed by burning.<br />

Filling firewood bags is easy with Palax Packer and Motti bag-packing<br />

equipment. Put the firewood in the box, pull over the bag, turn around<br />

and bind. Place the bags onto a pallet.<br />

PALAX POWER100S (P.T.O. DRIVEN)<br />

HYDRAULICS<br />

Splitting cylinder 16 tons (kg) / 35,300 lbs<br />

Hydraulic oil ISO VGA 32, (VGA 46 for hot conditions) : 160 l / 42.3 G<br />

Separate hydraulics<br />

Work + return motion<br />

Full force 16 tons (kg) / 35,300 lbs at 4.8 seconds<br />

High speed 4.8 tons (kg) / 10,500 lbs at 3.2 seconds<br />

Flow of hydraulic pump at 500 r.p.m.<br />

TRANSMISSION AND CONTROL<br />

Control levers with ball bearings<br />

Transmission disengagement clutch tractor powered<br />

CUTTING AND SPLITTING<br />

Hard-metal blade 1000 mm / 39.3 in<br />

Splitting ax 2/6 as standard<br />

Hydraulic log clamp<br />

Hydraulic height adjustment of splitting ax<br />

IN-FEED CONVEYOR<br />

Conveyor belt 0.33 m x 2.5 m / 13 in x 98.4 in<br />

Quick couplings for external feed conveyor<br />

Fully hydraulic control of the machine<br />

Extra hydraulic circuit for log-lifting deck<br />

Automatic high-speed valve<br />

Angular gear of cast iron<br />

Automatic tightening of the V-belts<br />

Automatic adjustable log-stop<br />

Splitting axes 2/4, 2/8 and 12 ways as optional<br />

Quick-release of splitting ax<br />

Multi-phase debris removal<br />

Hydraulic log-stop<br />

Automatic cleaning of drive and return wheels<br />

DISCHARGE CONVEYOR 0.35 m x 4.3 m / 13.8 in x 169.3 in, SCRAPER 2 in HD POLYETHYLENE<br />

Hydraulically-driven scraper conveyor with two chains<br />

Lifting winch for conveyor<br />

MAXIMUM SIZE OF TREE<br />

Max. diameter of the tree : 40 cm / 15.7 in<br />

DIMENSIONS AND WEIGHT IN TRANSPORT POSITION<br />

Length : 3,200 / 500 mm or 10.5 / 16.4 ft<br />

Width : 1,750 / 2500 mm or 5.7 / 8.2 ft<br />

OTHER OPTIONAL EXTRAS<br />

Folding and swinging conveyor<br />

Cutting length : 25...55 cm / 9.8… 21.6 in<br />

Height : 2,530 / 2,730 mm or 8.3 / 9 ft<br />

Weight : 1,780 / 2,110 kg or 3,920 / 4,650 lbs<br />

Sawdust aspirator Articulated shaft, e.g. Bondoli 105<br />

Transport platform, towed by tractor, tyre size 10.5/75 - 15.3<br />

Log-lifting deck<br />

CE AND GS APPROVED<br />

Approximate values for all specifications.<br />

18<br />

1-800-361-2288 ■ WWW.HAKMET.COM

NOKKA TRAILERS<br />

Nokka forest trailers are suitable for<br />

forwarding all kinds of timber. The light<br />

travelling one-beam trailer models 81 and<br />

91 are easy to move around. Best for small<br />

and medium size tractors and loaders.<br />

The robust two-beam trailer models<br />

102 and 132 with hydraulic drive offer<br />

excellent forwarding capacity for heavy-duty<br />

contracting. Several mounting positions for<br />

front grill and support poles and adjustable<br />

mechanical frame extension. Available with<br />

automatic (HD) 4-wheel drive. Hydraulic<br />

drawbar steering and a rotating hitch eye<br />

come as standard. The two-beam models<br />

can be equipped with a 3-point or flanged<br />

mounting table. Choose the best alternative<br />

depending on the tractor, operating<br />

requirements and conditions. With a wide<br />

range of accessories the trailers can be<br />

custom made according to the operators<br />

needs. Nokka forest trailers feature a wellbalanced<br />

combination of reliable quality,<br />

efficiency and easy operation.<br />

GRABS<br />

NOKKA TIMBER GRABS<br />

Technical specifications Nokka 1200 Nokka Super<br />

Grapple cylinder<br />

50/35 mm 70/40 mm<br />

2/1.4’’ 2.8/1.6’’<br />

Grab force (160 bar / 2320 PSI)<br />

31 kN 61 kN<br />

6 970 lbf 13 715 lbf<br />

Grapple opening<br />

2,000 mm 2,200 mm<br />

78.7’’ 86.6’’<br />

Clearance between grapple and slew joints<br />

1,200 mm 1,280 mm<br />

47.2’’ 50.4’’<br />

Weight<br />

205 kg 310 kg<br />

452 lbs 683 lbs<br />

Double acting slew cylinder<br />

optional standard 63/30 mm<br />

optional standard 2.5/1.2’’<br />

Approximate values for all specifications.<br />

Nokka timber grabs are an economical<br />

and efficient forwarding tool for thinning<br />

or harvesting firewood. Large bundles can<br />

be forwarded due to the wide opening of the<br />

grapple and a fair clearance between the<br />

grapple and the slew joint. Great grapple force,<br />

supports between the grapple and the mounting<br />

frame and the optional tooth bar in model Super<br />

holds longer stems and bundles tight in the<br />

grapple. Wide 90° slewing angle helps skidding<br />

long logs and bundles. Model Super is equipped<br />

with double acting ram as standard.<br />

1-800-361-2288 ■ WWW.HAKMET.COM<br />

19

HAKMET<br />

PETE LOADERS & TRAILERS<br />

PETE GRAPPLE LOADERS 40 41<br />

Lifting momentum gross<br />

kNm 33 40<br />

lbf-ft 24,340 29,500<br />

Maximum reach<br />

m 8.5 8.3<br />

ft 27.9 27.2<br />

Slewing torque<br />

kNm 17.4<br />

lbf-ft 12,800<br />

Slewing angle degrees 390<br />

Weight<br />

kg 1,200<br />

lbs 2,645<br />

Working pressure<br />

bar 180 - 195<br />

PSI 2,610 - 2,830<br />

Minimum hydraulic output<br />

l/min 40 - 60<br />

GPM 10.6 - 15.9<br />

Approximate values for all specifications.<br />

PETE TRAILER 10<br />

Load capacity<br />

10,000 kg - 22,000 lbs<br />

Weight<br />

2,000 kg - 4,400 lbs<br />

Load area 2.5 m 2 - 26.9 ft 2<br />

Frame tube dimensions 100x200x8 mm - 3.9x7.9x0.3 in<br />

Wheels with drive device 500/55 - 15.5<br />

Brakes<br />

Hydraulic brakes in front hubs<br />

Equipment & accessories<br />

Trailer hitch lock for road traffic<br />

Extension for the frame Hydraulic steering with two cylinders<br />

Stand support<br />

Rear light<br />

Approximate values for all specifications.<br />

Lifting capacities (kg/lbs) for Pete loaders<br />

Reach Pete 40 Pete 41<br />

3 m - 9.8 ft 1,150 kg - 2,535 lbs -<br />

3.1 m - 10.2 ft - 1,150 kg - 2,535 lbs<br />

5 m - 16.4 ft 700 kg - 1,540 lbs -<br />

5.3 m - 17.4 ft - 700 kg - 1,545 lbs<br />

6.6 m - 21.7 ft 540 kg - 1,190 lbs -<br />

6.7 m - 22 ft - 500 kg - 1,100 lbs<br />

8.5 m - 27.9 ft 420 kg - 925 lbs -<br />

8.3 m - 27.2 ft - 300 kg - 660 lbs<br />

Approximate values for all specifications.<br />

881 Harwood, Vaudreuil-Dorion, Quebec, Canada J7V 8P2<br />

Tel: 450-455-6101 ▪ 1-800-361-2288 ▪ Fax: 450-455-1890<br />

www.hakmet.com ▪ hakmet@hakmet.com