Desalination Plants - DEMONT srl

Desalination Plants - DEMONT srl

Desalination Plants - DEMONT srl

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>DEMONT</strong><br />

EPC<br />

Products<br />

Services<br />

Località Braia Zona Industriale, Millesimo (SV) Italy<br />

Tel: + 39 019 56601 | Fax: + 39 019 5600317<br />

info@demont.it | www.demont.it

...more than 40 years of experience<br />

Demont was founded in 1972 with the goal to perform erection and maintenance works on small and medium-sized chemical<br />

and petrochemical plants as well as power generation plants.<br />

The company presented itself as a production unit able to acquire important contracts for the supply and erection of plants<br />

and components for power generation (both conventional as well as nuclear plants) and paper production already in the early<br />

80’s.<br />

Towards the end of the 80’s, Demont got involved in the marine division for the installation of heating, ventilation and air-conditioning<br />

systems in cruise ships, and in the upcoming years, also for the supply of prefabricated bathroom units, outfitting of<br />

public areas (theaters, atriums, restaurants etc.) and “Turnkey” supply of the heating, ventilation and air-conditioning system.<br />

In the same period, the company strengthened its presence in the power generation industry as a partner for the construction<br />

of important national and international projects regarding new plants, repowering, and adjustments of existing plant in order<br />

to comply with new environmental standards, both in Italy as well as in other European countries.<br />

Today, Demont is able to present itself on the international market as a reliable partner for the design, supply, installation,<br />

start-up and maintenance of civil and industrial buildings, production plants, plants for power generation, transformation and<br />

distribution, chemical and petrochemical plants and technological plants. Furthermore, Demont supplies design, fabrication,<br />

installation, start-up and maintenance of HRSGs, Heaters (for chemical, petrochemical and metallurgic plants) and Pressure<br />

Parts.

Mission & Core Values<br />

“Assist our clients in reaching their objectives by supplying high<br />

quality products and services at a competitive price in a time-saving<br />

way, always with a prime focus on safety”<br />

Safety<br />

Flexibility,<br />

Creativity,<br />

Innovation<br />

Integrity &<br />

Transparency<br />

Added Value<br />

Quality<br />

Time & Cost<br />

Efficiency

Organization<br />

Rev.: 8<br />

Updated: 01/01/2014<br />

Organisation Chart: DEM_ORG_GEN<br />

C.E.O<br />

Procurement<br />

Cost Control<br />

Human Resources<br />

Administration<br />

IT Systems<br />

Sales Support<br />

Engineering<br />

HSE<br />

Quality<br />

Estimation<br />

Field Personnel<br />

Foreign Market Sales<br />

Sales Sales Sales Sales Sales<br />

Millesimo<br />

Workshops<br />

Ex-ITEM<br />

Worksites<br />

Industrial*<br />

Civil* & Marine**<br />

<strong>Plants</strong><br />

Oil & Gas<br />

Site Vehicles,<br />

Lifting and Rental<br />

Boilers &<br />

Heaters<br />

<strong>Desalination</strong><br />

High Voltage &<br />

Mechanical<br />

Machining<br />

Short and Fast Decision Making<br />

Lean Organization and Flat Hierarchy

Demont’s Operative Units<br />

Polska Sp.zo.o<br />

Millesimo<br />

Headquarters &Workshop<br />

Area: 26.550 m 2 /<br />

13.350 m 2 covered<br />

Milan<br />

Offices<br />

Area: 1.000 m 2<br />

Battaglia Terme<br />

Offices & Workshop<br />

Area: 75.000 m 2 /<br />

40.000 m 2 covered<br />

Reggio<br />

Emilia<br />

Offices<br />

Area: 240 m 2<br />

Demont is a company established to<br />

offer comprehensive solutions tailored<br />

to the needs of the customer.<br />

More than 1100 employees in 9<br />

different countries, 12 offices and<br />

production units and about 30 operating<br />

construction sites constitute<br />

a “machinery” efficient and prompt<br />

in responding, effective in problem<br />

solving, open to the opportunities of<br />

the market.<br />

Lipno<br />

Poland<br />

East-Europe s.r.l.<br />

Romania<br />

Bucarest<br />

SOWIT<br />

Tripoli<br />

Libya<br />

Latina<br />

Office & Workshop<br />

Area: 43.115 m 2 / 27.400<br />

m 2 covered<br />

bh d.o.o.<br />

Bihac<br />

Bosnia<br />

Herzegovina<br />

ASTER<br />

INTERNATIONAL<br />

South Africa Pty Limited - Subsidiary of <strong>DEMONT</strong> S.r.l. (Italy)<br />

South Africa<br />

Augusta<br />

Offices & Warehouse<br />

Surface: 7.000 m 2 /<br />

1.400 m 2 covered<br />

Johannesburg<br />

Chile<br />

Santiago<br />

Slovakia<br />

Bratislava<br />

(Permanent Establishment)<br />

Germany<br />

Munchen<br />

(Permanent Establishment)

Worksites in Italy 2013<br />

Client<br />

BURGO GROUP SPA<br />

ENI SPA<br />

ENI SPA<br />

ENI POWER SPA<br />

ESSO ITALIANA SRL<br />

ENI POWER S.p.A.<br />

ENI POWER S.p.A.<br />

ISAB SRL<br />

ERG POWER<br />

FENICE SPA<br />

TIRRENO POWER SPA<br />

Cordioli & C. spa<br />

METSO PAPER<br />

LINDE GAS ITALIA SRL<br />

ESSO ITALIANA SRL<br />

ESSO ITALIANA SRL<br />

FERRERO S.p.A.<br />

INFINEUM ITALIA S.r.l.<br />

IPLOM SPA<br />

ITALIANA COKE SRL<br />

PETROLIG S.r.l.<br />

SANOFI -AVENTIS S.p.A.<br />

SYNDIAL SPA<br />

Terminal Rinfuse Italia SPA<br />

POLIMERI EUROPA SPA<br />

SYNDIAL SPA<br />

FINCANTIERI SPA<br />

Site<br />

Duino Aurisina (TS)<br />

c/o Refinery of Ferrera Erbognone (PV)<br />

c/o Refinery of Sannazzaro de' Burgondi (PV)<br />

c/o Refinery of Sannazzaro de' Burgondi (PV)<br />

c/o Refinery of SARPOM - Trecate (NO)<br />

San Donato Milanese - Bolgiano (MI)<br />

Municipality of San Donato Milanese (MI)<br />

Priolo Gargallo (SR) North Plant and South<br />

Plant<br />

Priolo Gargallo (SR) North Plant<br />

c/o Fiat Mirafiori - Turin<br />

Valleggia di Quiliano (SV)<br />

Municipality of Cassano d'Adda (MI)<br />

c/o CMPC of Talagante (Chile)<br />

c/o Sarpom - Trecate (NO)<br />

c/o Sarpom - Alessandria and Valleggia di<br />

Quiliano (SV)<br />

c/o ESSO - Vado Ligure (SV)<br />

Alba(CN)<br />

Vado Ligure (SV)<br />

Busalla (GE)<br />

San Giuseppe di Cairo (SV)<br />

Genoa<br />

Garessio (CN)<br />

Cengio (SV) and Pieve Vergonte (VB)<br />

Genoa and Vado Ligure (SV)<br />

Priolo Gargallo (SR)<br />

Priolo Gargallo (SR)<br />

Monfalcone (GO) and Marghera (VE)

Personnel<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

Turnover<br />

300.000.000<br />

€ Euro<br />

250.000.000<br />

200.000.000<br />

150.000.000<br />

100.000.000<br />

50.000.000<br />

-<br />

2002<br />

2003<br />

2004<br />

2005<br />

2006<br />

2007<br />

2008<br />

2009<br />

2010<br />

2011<br />

2012<br />

forecast 2013<br />

2002<br />

2003<br />

2004<br />

2005<br />

2006<br />

2007<br />

2008<br />

2009<br />

2010<br />

2011<br />

2012<br />

2013

Bank of Italy | Central Credit Register<br />

On the Italian bank system Demont has credit lines availability for € 155 mln, including € 95,6 mln for contractual guaranties<br />

(Advance payment bond, Performance bond, Guarantee bond).<br />

By virtue of its capability to generate cash flow, availment of credit lines for cash needs is limited to 17,5%.<br />

The existing credit lines for contractual guaranties and its own rating allow Demont to play a lead role in EPC contracting.<br />

Bank Rating Remarks<br />

3 (wide solvency) Scale from 1 to 11<br />

(ascending system to indicate major risk)<br />

1 Large Corporate Scale from 1 to 7<br />

(ascending system to indicate major risk)<br />

3 Large Corporate Scale from 1 to 10<br />

(ascending system to indicate major risk)<br />

5+ Scale with 30 positions<br />

(ascending system to indicate major risk)<br />

Prime Grade Investment Undisclosed Scale

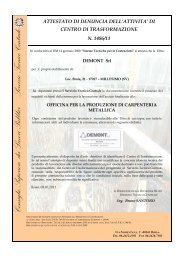

GESTIONE DI CONTRATTI E.P.C. (ACQUISIZIONE, GESTIONE, PROGETTAZIONE, FORNITURA, COSTRUZIONE, INSTALLAZIONE, MESSA IN SERVIZIO E<br />

MANUTENZIONE) RELATIVI A EDIFICI CIVILI ED INDUSTRIALI E RELATIVE FINITURE, OPERE IN C.A., IMPIANTI TECNOLOGICI (TERMO-FLUIDI ED<br />

ELETTRICO-ELETTRONICI), RETI DI DISTRIBUZIONE FLUIDI, IMPIANTI CHIMICI, PETROLCHIMICI, PETROLIFERI, DI PRODUZIONE, TRASFORMAZIONE E<br />

DISTRIBUZIONE ENERGIA. SVILUPPO TECNOLOGICO, PROGETTAZIONE, FABBRICAZIONE, INSTALLAZIONE, MESSA IN SERVIZIO E MANUTENZIONE DI<br />

GENERATORI DI VAPORE E FORNI PER IMPIANTI CHIMICI, PETROLCHIMICI E METALLURGICI. PROGETTAZIONE, COSTRUZIONE E MONTAGGIO DI<br />

APPARECCHIATURE IN PRESSIONE E CARPENTERIE. PROGETTAZIONE, COSTRUZIONE ED ASSEMBLAGGIO DI LOCALI IGIENE, PORTE,<br />

ARREDAMENTO E PARTICOLARI PER IL SETTORE NAVALE E CIVILE. PRODUZIONE DI PANNELLI COIBENTATI DESTINATI ALL'ARREDAMENTO NAVALE<br />

E CIVILE. REALIZZAZIONE ED ASSISTENZA DI INTERRUTTORI E STAZIONI BLINDATE PER LA TRASMISSIONE E LA DISTRIBUZIONE DI ENERGIA<br />

ELETTRICA IN ALTA TENSIONE. DEMOLIZIONE DI OPERE. LAVORAZIONE DI COMPONENTI MECCANICI CONTO TERZI MEDIANTE TORNITURA ED<br />

ALESATURA SU MACCHINE CNC. PROVE DI PRESSIONE E RICERCA FUGHE CON METODO LT.<br />

MANAGEMENT OF EPC CONTRACTS (ACQUISITION, MANAGEMENT, DESIGN, SUPPLY, CONSTRUCTION, INSTALLATION, COMMISSIONING AND<br />

MAINTENANCE) RELATED TO CIVIL AND INDUSTRIAL BUILDINGS AND PERTINENT FINISHING WORKS, REINFORCED CONCRETE WORKS,<br />

TECHNOLOGICAL PLANTS (THERMAL-FLUID AND ELECTRICAL-ELECTRONIC), FLUID DISTRIBUTION NETWORKS, CHEMICAL, PETROCHEMICAL AND<br />

PETROLEUM PLANTS, ENERGY PRODUCTION, TRANSFORMATION AND DISTRIBUTION PLANTS. TECHNOLOGICAL DEVELOPMENT, DESIGN,<br />

MANUFACTURE, INSTALLATION, COMMISSIONING AND MAINTENANCE OF STEAM GENERATORS AND FURNACES FOR CHEMICAL, PETROCHEMICAL<br />

AND METALLURGICAL PLANTS. DESIGN, CONSTRUCTION AND ASSEMBLY OF PRESSURE EQUIPMENT AND STRUCTURAL WORKS. DESIGN,<br />

CONSTRUCTION AND ASSEMBLY OF TOILETS, DOORS, FURNISHINGS AND COMPONENTS FOR THE NAVAL AND CIVIL SECTORS. PRODUCTION OF<br />

INSULATED PANELS FOR NAVAL AND CIVIL FURNISHINGS. PRODUCTION AND SERVICING OF CIRCUIT BREAKERS AND GAS INSULATED<br />

SUBSTATIONS FOR THE DISTRIBUTION OF HIGH VOLTAGE ELECTRIC ENERGY. DEMOLITION WORKS. MACHINING OF MECHANICAL COMPONENTS<br />

FOR THIRD PARTIES THROUGH TURNING AND BORING WITH CNC MACHINES. PRESSURE TESTS AND LEAK TESTS USING THE LT METHOD.<br />

L'uso e la validità del presente certificato sono soggetti al rispetto del documento RINA: Regolamento per la Certificazione di Sistemi di Gestione Ambientale<br />

The use and the validity of this certificate are subject to compliance with the RINA document: Rules for the Certification of Environmental Management Systems<br />

La validità del presente certificato è subordinata a sorveglianza periodica annuale / semestrale ed al riesame completo del sistema di gestione con periodicità triennale<br />

The validity of this certificate is dependent on an annual / six monthly audit and on a complete review, every three years, of the management system<br />

SGQ N° 002 A SSI N° 001 G<br />

SGA N° 002 D DAP N° 001 H<br />

PRD N° 002 B PRS N° 066 C<br />

SCR N° 003 F LAB N° 0832<br />

Membro degli Accordi di Mutuo<br />

Riconoscimento EA, IAF e ILAC<br />

Signatory of EA, IAF and ILAC Mutual<br />

Recognition Agreements<br />

Via Corsica 12 - 16128 Genova Italy<br />

Per informazioni sulla validità<br />

del certificato, visitare il sito<br />

www.rina.org<br />

For information concerning<br />

validity of the certificate, you<br />

can visit the site<br />

www.rina.org<br />

CISQ è la Federazione Italiana di<br />

Organismi di Certificazione dei<br />

sistemi di gestione aziendale<br />

CISQ is the Italian<br />

Federation of management<br />

system Certification Bodies<br />

GESTIONE DI CONTRATTI E.P.C. (ACQUISIZIONE, GESTIONE, PROGETTAZIONE, FORNITURA, COSTRUZIONE, INSTALLAZIONE, MESSA IN SERVIZIO E<br />

MANUTENZIONE) RELATIVI A EDIFICI CIVILI ED INDUSTRIALI E RELATIVE FINITURE, OPERE IN C.A., IMPIANTI TECNOLOGICI (TERMO-FLUIDI ED<br />

ELETTRICO-ELETTRONICI), RETI DI DISTRIBUZIONE FLUIDI, IMPIANTI CHIMICI, PETROLCHIMICI, PETROLIFERI, DI PRODUZIONE, TRASFORMAZIONE E<br />

DISTRIBUZIONE ENERGIA. SVILUPPO TECNOLOGICO, PROGETTAZIONE, FABBRICAZIONE, INSTALLAZIONE, MESSA IN SERVIZIO E MANUTENZIONE DI<br />

GENERATORI DI VAPORE E FORNI PER IMPIANTI CHIMICI, PETROLCHIMICI E METALLURGICI. PROGETTAZIONE, COSTRUZIONE E MONTAGGIO DI<br />

APPARECCHIATURE IN PRESSIONE E CARPENTERIE. PROGETTAZIONE, COSTRUZIONE ED ASSEMBLAGGIO DI LOCALI IGIENE, PORTE,<br />

ARREDAMENTO E PARTICOLARI PER IL SETTORE NAVALE E CIVILE. PRODUZIONE DI PANNELLI COIBENTATI DESTINATI ALL'ARREDAMENTO NAVALE<br />

Per informazioni sulla validità<br />

E CIVILE. REALIZZAZIONE ED ASSISTENZA DI INTERRUTTORI E STAZIONI BLINDATE PER LA TRASMISSIONE E LA DISTRIBUZIONE DI ENERGIA<br />

del certificato, visitare il sito<br />

ELETTRICA IN ALTA TENSIONE. DEMOLIZIONE DI OPERE. LAVORAZIONE DI COMPONENTI MECCANICI CONTO TERZI MEDIANTE TORNITURA ED<br />

www.rina.org<br />

ALESATURA SU MACCHINE CNC. PROVE DI PRESSIONE E RICERCA FUGHE CON METODO LT.<br />

For information concerning<br />

validity of the certificate, you<br />

MANAGEMENT OF EPC CONTRACTS (ACQUISITION, MANAGEMENT, DESIGN, SUPPLY, CONSTRUCTION, INSTALLATION, COMMISSIONING AND<br />

can visit the site<br />

MAINTENANCE) RELATED TO CIVIL AND INDUSTRIAL BUILDINGS AND PERTINENT FINISHING WORKS, REINFORCED CONCRETE WORKS,<br />

www.rina.org<br />

TECHNOLOGICAL PLANTS (THERMAL-FLUID AND ELECTRICAL-ELECTRONIC), FLUID DISTRIBUTION NETWORKS, CHEMICAL, PETROCHEMICAL AND<br />

PETROLEUM PLANTS, ENERGY PRODUCTION, TRANSFORMATION AND DISTRIBUTION PLANTS. TECHNOLOGICAL DEVELOPMENT, DESIGN,<br />

MANUFACTURE, INSTALLATION, COMMISSIONING AND MAINTENANCE OF STEAM GENERATORS AND FURNACES FOR CHEMICAL, PETROCHEMICAL<br />

AND METALLURGICAL PLANTS. DESIGN, CONSTRUCTION AND ASSEMBLY OF PRESSURE EQUIPMENT AND STRUCTURAL WORKS. DESIGN,<br />

CONSTRUCTION AND ASSEMBLY OF TOILETS, DOORS, FURNISHINGS AND COMPONENTS FOR THE NAVAL AND CIVIL SECTORS. PRODUCTION OF<br />

INSULATED PANELS FOR NAVAL AND CIVIL FURNISHINGS. PRODUCTION AND SERVICING OF CIRCUIT BREAKERS AND GAS INSULATED<br />

SUBSTATIONS FOR THE DISTRIBUTION OF HIGH VOLTAGE ELECTRIC ENERGY. DEMOLITION WORKS. MACHINING OF MECHANICAL COMPONENTS<br />

FOR THIRD PARTIES THROUGH TURNING AND BORING WITH CNC MACHINES. PRESSURE TESTS AND LEAK TESTS USING THE LT METHOD.<br />

L’uso e la validità del presente certificato è soggetto al rispetto del documento RINA: Regolamento per la Certificazione dei Sistemi di Gestione della Sicurezza e Salute sul luogo di lavoro<br />

The use and validity of this certificate are subject to compliance with the RINA document: Rules for the Certification of Occupational Health and Safety Management Systems<br />

SGQ N° 002 A SSI N° 001 G<br />

SGA N° 002 D DAP N° 001 H<br />

PRD N° 002 B PRS N° 066 C<br />

SCR N° 003 F LAB N° 0832<br />

Membro degli Accordi di Mutuo<br />

Riconoscimento EA, IAF e ILAC<br />

Signatory of EA, IAF and ILAC Mutual<br />

Recognition Agreements<br />

Via Corsica 12 - 16128 Genova Italy<br />

La validità del presente certificato è subordinata a sorveglianza periodica annuale /<br />

semestrale ed al riesame completo del sistema di gestione con periodicità triennale<br />

The validity of this certificate is dependent on an annual / six monthly audit and on a<br />

complete review, every three years, of the management system<br />

CISQ è la Federazione Italiana di<br />

Organismi di Certificazione dei<br />

sistemi di gestione aziendale<br />

CISQ is the Italian<br />

Federation of management<br />

system Certification Bodies<br />

Management System Certifications<br />

CERTIFICATO N.<br />

CERTIFICATE No.<br />

EMS-2313/S<br />

SI CERTIFICA CHE IL SISTEMA DI GESTIONE AMBIENTALE DI<br />

IT IS HEREBY CERTIFIED THAT THE ENVIRONMENTAL MANAGEMENT SYSTEM OF<br />

<strong>DEMONT</strong> S.R.L.<br />

LOCALITA' BRAIA 21 17017 MILLESIMO (SV) ITALIA<br />

NELLE SEGUENTI UNITÀ OPERATIVE / IN THE FOLLOWING OPERATIONAL UNITS<br />

LOCALITA' BRAIA 21 17017 MILLESIMO (SV) ITALIA<br />

VIA III ARMATA 4-6 34074 MONFALCONE (GO) ITALIA<br />

VIA MAGGIORE 16 35041 BATTAGLIA TERME (PD) ITALIA<br />

VIA TIMAVO 6 34074 MONFALCONE (GO) ITALIA<br />

VIA DE MARINI, 1 16154 GENOVA (GE) ITALIA<br />

VIA PIER CARLO CADOPPI 4 42124 REGGIO EMILIA (RE) ITALIA<br />

VIA SAN BERNARDO STRADA 6 PALAZZO 2 20142 ROZZANO (MI) ITALIA<br />

CONTRADA SAN CUSUMANO 96011 AUGUSTA (SR) ITALIA<br />

E CANTIERI OPERATIVI<br />

È CONFORME ALLA NORMA / IS IN COMPLIANCE WITH THE STANDARD<br />

ISO 14001:2004<br />

E AL DOCUMENTO ACCREDIA RT-09<br />

PER I SEGUENTI CAMPI DI ATTIVITÀ / FOR THE FOLLOWING FIELD(S) OF ACTIVITIES<br />

Prima emissione<br />

First Issue<br />

01.07.2008<br />

Emissione corrente<br />

Current Issue<br />

17.01.2013<br />

Data scadenza<br />

Expiry Date 18.12.2015<br />

Dott. Roberto Cavanna<br />

(Managing Director)<br />

RINA Services S.p.A.<br />

EA:28<br />

EA:34<br />

EA:18<br />

CERTIFICATO N.<br />

OHS-389<br />

CERTIFICATE No.<br />

Si certifica che il Sistema di Gestione della Sicurezza e della Salute sul luogo di lavoro di<br />

It is hereby certified that the Occupational Health and Safety Management System of<br />

<strong>DEMONT</strong> S.R.L.<br />

LOCALITA' BRAIA 21 17017 MILLESIMO (SV) ITALIA<br />

nelle seguenti unità operative / in the following operational units<br />

LOCALITA' BRAIA 21 17017 MILLESIMO (SV) ITALIA<br />

VIA III ARMATA 4-6 34074 MONFALCONE (GO) ITALIA<br />

VIA MAGGIORE 16 35041 BATTAGLIA TERME (PD) ITALIA<br />

VIA TIMAVO 6 34074 MONFALCONE (GO) ITALIA<br />

VIA DE MARINI, 1 16154 GENOVA (GE) ITALIA<br />

VIA PIER CARLO CADOPPI 4 42124 REGGIO EMILIA (RE) ITALIA<br />

VIA SAN BERNARDO STRADA 6 PALAZZO 2 20142 ROZZANO (MI) ITALIA<br />

CONTRADA SAN CUSUMANO 96011 AUGUSTA (SR) ITALIA<br />

E CANTIERI OPERATIVI<br />

è conforme alla norma / is in compliance with the standard<br />

BS OHSAS 18001:2007<br />

E AL DOCUMENTO SINCERT RT-12<br />

per le seguenti attività / for the following activities<br />

Prima emissione<br />

Dott. Roberto Cavanna<br />

First Issue<br />

22.12.2009<br />

(Managing Director)<br />

Emissione corrente<br />

Current Issue<br />

17.01.2013<br />

Data scadenza<br />

Expiry Date 18.12.2015<br />

RINA Services S.p.A.<br />

EA:34<br />

EA:19<br />

EA:18<br />

EA:28<br />

EA:17<br />

ISO 9001:2008 ISO 14001:2004 OHSAS 18001:2007<br />

“Management of epc contracts (acquisition, management, design, supply, construction, installation, commissioning<br />

and maintenance) related to civil and industrial buildings and pertinent finishing works, reinforced<br />

concrete works, technological plants (thermal-fluid and electrical-electronic), fluid distribution networks,<br />

chemical, petrochemical and petroleum plants, energy production, transformation and distribution plants,<br />

desalination plants and related systems.<br />

Technological development, design, manufacture, installation, commissioning and maintenance of steam generators<br />

and furnaces for chemical, petrochemical and metallurgical plants.<br />

Design, construction and assembly of pressure equipment and structural works.<br />

Production and servicing of circuit breakers and gas insulated substations for the distribution of high voltage<br />

electric energy.<br />

Demolition works. Machining of mechanical components for third parties through turning and boring with<br />

CNC machines. Pressure tests and leak tests using the LT method.”<br />

Demont is OIMS certified according to<br />

ExxonMobil and Sarpom requirements

Authorizations<br />

R<br />

Power Boilers<br />

Pressure Vessels<br />

Alternative Rules for<br />

Pressure Vessels<br />

Repair

SOA Qualification for Italian Public Contracts<br />

Categories Classification Description<br />

OG1 VIII Constructions of Civil and Industrial buildings<br />

OG3 III Roads, Highways, Bridges, Railways, Subways, Funiculars, Airstrips<br />

OG6 VIII Waterducts, Gas Pipelines, Oil Pipelines, Watering Systems,<br />

Scavenging Systems<br />

OG9 VIII Power <strong>Plants</strong><br />

OG10 III <strong>Plants</strong> for transformation of High/Intermediate Tension for<br />

Energy Distribution<br />

OG11 VIII Technological <strong>Plants</strong><br />

OG12 V Environmental remediation and protection works and plants<br />

OS1 V Excavations, restoration and adjustments of land<br />

OS3 VIII Water supply and discharge system, kitchens, laundries<br />

OS4 VI Electromechanical systems, conveyors<br />

OS6 VIII Supply of general works in plastic, metal, glass or wood<br />

OS7 VIII Civil constructions<br />

OS14 VI <strong>Plants</strong> for waste disposal and recycling<br />

OS16 IV Technological plants like electrical plants for any type of Power<br />

Plant<br />

OS18-A VII Structural components in steel or metal<br />

OS22 I <strong>Plants</strong> for water treatment and purification<br />

OS23 VI Demolition works<br />

OS28 VIII Heating and Ventilation <strong>Plants</strong><br />

OS30 VIII Internal plants: electrical, telefonic, radio and television

SAP | Integrated Process Management System<br />

The company’s ERP system is SAP ECC6. This software makes it possible to manage all internal processes<br />

in a complete and integrated way.<br />

Our financial, patrimonial, logistic activities as well as those related to material, production and human<br />

resources management are managed and controlled by the following modules:<br />

• FI Financial Accounting<br />

• MM Materials Management<br />

• SD Sales & Distribution<br />

• AA Asset Accounting<br />

• CO Controlling and Profitability Analysis<br />

• PP Production and Planning<br />

• PS Project System<br />

• HR Human Resources<br />

SAP is an indispensable instrument for the optimization of relations with our clients and suppliers as it<br />

rationalizes all processes in the chain supply.<br />

The data privacy and safety is assured through a technological infrastructure in cluster configuration<br />

and supported by a disaster-recovery process.

Main Clients

Main Clients

Integrated Design System<br />

Demont uses tridimensional design techniques based on the Bentley AutoPLANT Suite which make it possible to optimize product<br />

control, particularly with respect to management of spaces and verification of interferences. The system makes a solid model of the<br />

plant, or parts of the plant, available to a wide range of software used for the development of structural and fluid dynamic calculations<br />

and stress analysis of piping from Front End up to detailed design.<br />

The very critical issue related to the procurement of bulk material for complex plants, is efficiently approached by the complete integration<br />

between both design and procurement environments through automatic procedures (MMS) for direct transfer of the material<br />

take off data to the company’s ERP system (SAP).<br />

AutoPLANT Structural<br />

Modeler<br />

Engineering<br />

Detailer<br />

AutoPLANT Plant Design<br />

Piping<br />

Equipment<br />

Isometrics<br />

AutoISOGEN<br />

Raceways<br />

Bentley Process & Instrumentation<br />

Instrumentation & Wiring<br />

Data Manager<br />

Hookups<br />

Project<br />

Database<br />

Bentley Navigator<br />

Interface Detection<br />

Rendering<br />

AutoPLANT P&ID<br />

Bentley AutoPIPE<br />

MMS*<br />

Bentley PlantFlow<br />

Bentley WinNozl<br />

* The Material Management System (MMS) fully integrates<br />

the procurement process through dedicated software

Selected References<br />

Services Products EPC<br />

• Power Generation<br />

• Oil & Gas<br />

• <strong>Desalination</strong> <strong>Plants</strong><br />

• Technological <strong>Plants</strong> (HVAC, Fire-Fighting, Civil)<br />

• Paper Mills<br />

• Liquid distribution networks<br />

• Civil & Industrial Constructions<br />

• Boilers<br />

• Heaters<br />

• Vessels<br />

• High Voltage<br />

• Prefabrication & Erection<br />

• Maintenance/Turnaround<br />

• Demolition<br />

• Crane Rental

EPC<br />

Iride Energia<br />

Torino<br />

Thermal Plant for Integration and backup to the “Politecnico”<br />

heat generation plant for district heating<br />

network of Torino<br />

Iride Energia<br />

Moncalieri<br />

1 Thermoelectric Combined Cycle unit<br />

Fusine Energia<br />

Fusine<br />

Biomass Plant for Power Generation<br />

Tirreno Power<br />

Vado Ligure<br />

Power Generation<br />

2 Thermoelectric Combined Cycle units<br />

TCVVV<br />

Santa Caterina Valfurva<br />

Heat Generation Biomass Plant for district heating<br />

network

EPC<br />

Eni<br />

Sannazzaro de’ Burgondi<br />

New Vacuum Unit and interconnecting inside refinery<br />

Enipower<br />

Mantova<br />

Cogeneration Plant<br />

Isab Energy<br />

Priolo Gargallo<br />

Complete reconstruction of HRSG 4000-B50-1-HRSG101<br />

Società Adriatica Idrocarburi<br />

Capparuccia<br />

Gas Treatment Plant for gas from Capparuccia 1 and 2 wells<br />

Oil & Gas<br />

Fincantieri<br />

Ancona<br />

Load/unload system (Ammonia, Butadiene, Butane, Propane,<br />

Propylene, Butane Mixtures etc.) and related system to<br />

maintain the gas in a liquid state for M/S Marola

EPC<br />

Daewoo E&C Co./GECOL<br />

Misurata (Libya)<br />

Nr. 2 Multi-effect distillation (MED) units.<br />

Total capacity 5040 m³/day.<br />

Alstom Power Centrales/<br />

Saudi Electricity Company<br />

Shoaiba (Saudi Arabia)<br />

Nr. 4 contracts for nr.5 Multi-stage flash (MSF) desalination<br />

plants<br />

Total capacity 3600 m 3 /day each.<br />

Edison S.p.a.<br />

Simeri-Crichi (Italy)<br />

Nr. 2 Impianti di dissalazione MED-TCV.<br />

Total capacity 6480 m³/day.<br />

Agip Gas BV<br />

Mellitah (Libya)<br />

<strong>Desalination</strong> <strong>Plants</strong><br />

Nr. 3 Multi-stage flash (MSF) desalination plants.<br />

Total capacity 15840 m 3 /day.<br />

Holst/Regione Siciliana<br />

Gela (Italy)<br />

N° 1 Multi-stage flash (MSF) Unit.<br />

Capacity 17280 m³/day.

EPC<br />

CERN<br />

Genève (Switzerland)<br />

Heating, Ventilation and Air-Conditioning System for the installations<br />

Atlas and CMS at the LHC (Large Hadron Collider)<br />

Project in the Genève laboratories (Points 1 & 5) with related<br />

chilled water plant<br />

ASL 2 Savona<br />

Albenga<br />

Hospital Complex in the district of Albenga<br />

Fincantieri<br />

Palermo<br />

Heating, Ventilation and Air-Conditioning System in<br />

Scarabeo 8 Platform<br />

Fincantieri<br />

Technological <strong>Plants</strong><br />

Monfalcone - Genova - Ancona - Marghera<br />

Heating, Ventilation and Air-Conditioning System in<br />

more than 30 cruise ships with capacities from 66.000<br />

to 130.000 Gross Tons<br />

Slovenske Elektrarne<br />

Mochovce (Slovakia)<br />

Heating, Ventilation and Air-Conditioning System for<br />

units 3 and 4 of NPP

EPC<br />

Al Sindian<br />

6th October City (Egypt)<br />

Tissue Machine Line MP3<br />

Al Snobar<br />

Amman (Jordan)<br />

Tissue Machine Line PM4<br />

Intertissue<br />

Port of Talbot (Great Britain)<br />

Tissue Machine Line PM1<br />

ICT France<br />

Montargis (France)<br />

Tissue Machine Line PM31<br />

Paper Mills<br />

Ibertissue<br />

Bunuel (Spain)<br />

Tissue Machine Line PM1

EPC<br />

Società Adriatica Idrocarburi (Eni)<br />

Capparuccia<br />

Installation of gas pipeline (80 bar)<br />

Genova Reti Gas<br />

Genova<br />

Extension, renewal and improvement of the gas distribution<br />

network in Genova<br />

AES Torino<br />

Torino<br />

Transportation and distribution network with related<br />

heat-exchange sub-stations in Torino (lots 2 and 3)<br />

Liquid Distribution Networks<br />

TCVVV<br />

Santa Caterina Valfurva<br />

Transportation and distribution network with related heatexchange<br />

sub-stations in Santa Caterina, included in the order<br />

for turnkey supply of a biomass district heating plant<br />

CERN<br />

Genève (Switzerland)<br />

Interconnecting for LHC Gas distribution network

AES<br />

Torino<br />

Construction of district heating transportation and distribution<br />

network in Torino:<br />

- Construction of valves pit<br />

- Stop and control valves pit<br />

- Dedicated pits for microtunnelling machine<br />

- Wells<br />

- Finish<br />

Iride Energia<br />

Torino<br />

Construction of Thermal Plant for integration and back-up to<br />

the “Politecnico” heat generation plant for the district heating<br />

network in Torino:<br />

- Thermal Plant Structure<br />

- Methan reduction and measuring structure<br />

- Underground wastewater basin<br />

- Underground fire-fighting basin<br />

- Internal and external supports for various equipment, chimney and tanks<br />

- Network for drainage and gathering of rainwater<br />

- Sewage and wastewater<br />

- Fences and entrances<br />

- Screens (Sails) and main building<br />

Civil & Industrial Constructions<br />

Demont<br />

Millesimo<br />

Construction of Office Building<br />

Fusine Energia<br />

Fusine<br />

Supply of 6 MWe biomass power plant.<br />

Complete reconstruction of:<br />

- Thermal Plant Structure<br />

- Offices<br />

Construction of:<br />

- Underground fire-fighting basin<br />

- Fire-fighting room and MV electrical boards<br />

- Network for rainwater gathering and drainage<br />

- Woodchip deposit<br />

- Sewage and wastewater system<br />

- Fences and entrances<br />

Demolitions<br />

- Buildings (selective)<br />

EPC

Products<br />

Iren Ambiente<br />

Reggio Emilia<br />

Direct fired boiler. Capacity 46,5 ton/h, Pressure 104 Bar,<br />

Temperature 505 °C<br />

Revamping of steam generator CA 101. Capacity 46,5 ton/h,<br />

Pressure 90 bar, Temperature 510 °C<br />

Enel<br />

Torrevaldaliga Nord<br />

Direct fired steam boiler. Capacity 60 ton/h, Pressure 20 Bar,<br />

Temperature 250 °C.<br />

Cabot<br />

Ravenna<br />

Direct fired Steam Generator. Capacity 110 ton/h, Pressure<br />

76 Bar, Temperature 510°C. Run on Tail Gas<br />

STC<br />

Sora<br />

HRSG with Post-Combustion and Fresh Air. Capacity 90 ton/h,<br />

Pressure 70 Bar, Temperature 450 °C<br />

Renco<br />

Boilers<br />

Azerbajan<br />

Nr. 3 Heat Recovery Water Heaters. Capacity 160 ton/h,<br />

Pressure 10 bar, Temperature 155 °C

Products<br />

Foster Wheeler USA<br />

Valero (USA)<br />

Nr 2 Coker Heaters for Valero Refinery<br />

UHDE GmbH<br />

Egypt<br />

Nr. 2 Start-Up Heaters, Thermal Capacity 6 MW, Pressure<br />

107-190 Bar, Capacity 40 ton/h<br />

UHDE GmbH<br />

Egypt<br />

Nr. 14 Convection Banks. Thermal Capacity 60 MW, Pressure<br />

35-122 Bar, Capacity 194 ton/h<br />

Nr. 2 Convection Banks. Thermal Capacity 19 MW, Pressure<br />

45 Bar, Capacity 69 ton/h<br />

Foster Wheeler<br />

Nigeria<br />

Nr. 1 Hydro Cracker Heater. Weight 290 ton<br />

Heaters<br />

Foster Wheeler UK/EXXON/AMOCO/<br />

CAPCO<br />

Singapore<br />

Nr. 2 Cylindrical Heaters

Products<br />

Saipem<br />

Algeria<br />

Nr 1 Column. Materials: SA 387 GR 11 CL2 Cladding.<br />

Thickness 60 mm<br />

Foster Wheeler<br />

Dubai<br />

Nr 4 Reactors and nr 1 Hydrotreating Reactor. Materials: SA<br />

387 GR 11 CL2/Cladding 347. Thicknesses from 50 to 31 mm<br />

Andritz Oy<br />

Portugal<br />

Nr 1 Deculator. Materials: AISI 316L<br />

Iride Energia<br />

Torino<br />

N° 9 Pressure vessels (25 bar Vol. 900 m3) for the district heating<br />

network of Torino. Materials: P460 NH EN10028<br />

Vessels<br />

Tirreno Power<br />

Vado Ligure<br />

Nr. 4 High Pressure Heat-Exchangers. Materials: ISPESL/EN 13445<br />

Standard. Plating in Carbon Steel, Piping in 16 M05

Products<br />

Siemens<br />

Enel Plant in Portotolle and Piombino 420 kV<br />

Regeneration of nr. 4 Dead Tank Circuit Breakers 420 kV with<br />

revision of chamber and pneumatic actuator with recertification<br />

and erection on site<br />

Siemens<br />

Enel Plant in Altomonte, Tavarnuzze and Ascoli Rosara 420<br />

kV<br />

Plant extension with supply of nr. 1 GIS system 420 kV complete<br />

with C.B. GIS, Disconnector-Line Switch, Disconnector-<br />

Earthing Switch (slow and fast) and head CT Cable<br />

Siemens<br />

Taiwan (PTC)<br />

Supply of nr. 3 Integrated Compact Modules (MCI) equipped<br />

with Circuit Breaker and a mechanical spring operation mechanism,<br />

motor operating mechanism, current transformer,<br />

Disconnector-Line and Earthing Switch<br />

Siemens<br />

Ascoli Rosara 420 kV Plant<br />

Plant extension with supply of nr. 7 GIS systems 170 kV. GIS<br />

complete with C.B. GIS, Disconnector-Line Switch, Disconnector-Earthing<br />

Switch (slow and fast) and head CT Cable<br />

High Voltage<br />

Siemens<br />

Enel 170 kV Plant in Villasor<br />

Plant extension with supply of nr. 1 170 kV GIS system complete<br />

with C.B. GIS, Disconnector-Line Switch, Disconnector-<br />

Earthing Switch (slow and fast), and head CT Cable

Services<br />

Eni<br />

Sannazzaro de’ Burgondi<br />

Mechanical erection of Lot M2 (including piping<br />

prefabrication and supports) for the “Impianto EST” project<br />

Eni<br />

Sannazzaro de’ Burgondi<br />

Mechanical erection of ROSE Deasphalting plant<br />

Snamprogetti Sud<br />

Taranto<br />

Extension of RHU hydrocracking section and related units in<br />

the refinery<br />

Prefabrication & Erection<br />

Enel Produzione<br />

Torrevaldaliga Nord<br />

Erection of Bulk Handling System for coal, limestone and gypsum<br />

Siirtec Nigi<br />

Mantova<br />

Mechanical erection, insulation and painting of sulphur recovery<br />

unit and related tail gas clean-up (TGCU) at IES refinery

Services<br />

Isab<br />

Priolo Gargallo<br />

Multiskilled turnaround:<br />

• Vacuum<br />

• Gofiner<br />

• Visbreaking<br />

• HDS<br />

Total<br />

Roma<br />

Multiskilled turnaround:<br />

• Visbreaking<br />

• HDS<br />

• Platform<br />

• Sulphur Plant<br />

• Gas Plant<br />

• Topping<br />

• Vacuum<br />

Tamoil<br />

Cremona<br />

Multiskilled turnaround:<br />

• Visbreaking<br />

• HDS<br />

• Platform<br />

• Sulphur Plant<br />

• Gas Plant<br />

• Topping<br />

Maintenance/Turnaround<br />

ExxonMobil - Sarpom<br />

Trecate, Quiliano, Vado Ligure, Arluno, Chivasso<br />

Maintenance Contract<br />

Infineum<br />

Vado Ligure<br />

Maintenance Contract

Services<br />

Tirreno Power<br />

Vado Ligure<br />

Disassembly of industrial plants and complete demolition of<br />

buildings. Included in the project for transformation of the<br />

existing units into combined cycles run on natural gas<br />

Isab Energy<br />

Priolo Gargallo<br />

Selective demolition of HRSG before complete reconstruction<br />

Isab<br />

Priolo Gargallo<br />

Demolition of Ethylene Plant, and the <strong>Plants</strong> CR1, 2, 6, 38<br />

Demolitions

Services<br />

Enel<br />

Torrevaldaliga Nord<br />

Lifting of main components related to the supply of nr. 3 Super-Hypercritical<br />

Coal Fired 660 MW boilers<br />

ERG Raffinerie Mediterranee<br />

Priolo Gargallo<br />

Lifting of Reactors 400R - 401 A/B<br />

ANAS<br />

Terni<br />

Lifting of bridge in Valnerina<br />

Snamprogetti<br />

Sannazzaro de’ Burgondi<br />

Lifting of flare for Isocracker interconnecting<br />

Crane Rental<br />

Vestas, Gamesa, etc.<br />

Italy - Altare (SV), Laterza (TA), Girifalco (CZ), Osiglia (SV)<br />

Lifting of wind turbines with tower heights of 76 m using the<br />

TC 2800 crane in configuration SH/ SL with 90 m boom;<br />

Maintenance activities of wind turbines with Demag AC 80/2<br />

cranes and platform Wumag 103 m.

Demont s.r.l.<br />

Loc. Braia 21, z.i.<br />

17017 Millesimo (SV)<br />

Italy<br />

Tel: +39 019 56601<br />

Fax: +39 019 5600317<br />

e-mail: info@demont.it