Laser-Distance-Sensor - Iberica de Automatismos

Laser-Distance-Sensor - Iberica de Automatismos

Laser-Distance-Sensor - Iberica de Automatismos

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

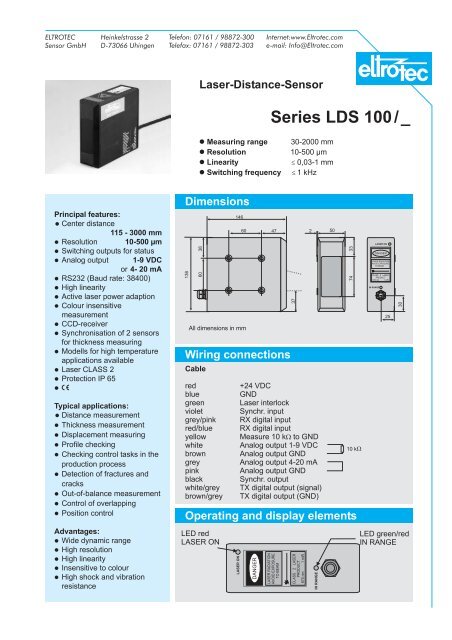

ELTROTEC<br />

<strong>Sensor</strong> GmbH<br />

Heinkelstrasse 2<br />

D-73066 Uhingen<br />

Telefon: 07161 / 98872-300<br />

Telefax: 07161 / 98872-303<br />

Internet:www.Eltrotec.com<br />

e-mail: Info@Eltrotec.com<br />

<strong>Laser</strong>-<strong>Distance</strong>-<strong>Sensor</strong><br />

Measuring range 30-2000 mm<br />

Resolution<br />

10-500 µm<br />

Linearity<br />

£ 0,03-1 mm<br />

Switching frequency £ 1 kHz<br />

Series LDS 100 / _<br />

Principal features:<br />

Center distance<br />

115 - 3000 mm<br />

Resolution 10-500 µm<br />

Switching outputs for status<br />

Analog output 1-9 VDC<br />

or 4- 20 mA<br />

RS232 (Baud rate: 38400)<br />

High linearity<br />

Active laser power adaption<br />

Colour insensitive<br />

measurement<br />

CCD-receiver<br />

Synchronisation of 2 sensors<br />

for thickness measuring<br />

Mo<strong>de</strong>lls for high temperature<br />

applications available<br />

<strong>Laser</strong> CLASS 2<br />

Protection IP 65<br />

¢<br />

Typical applications:<br />

<strong>Distance</strong> measurement<br />

Thickness measurement<br />

Displacement measuring<br />

Profile checking<br />

Checking control tasks in the<br />

production process<br />

Detection of fractures and<br />

cracks<br />

Out-of-balance measurement<br />

Control of overlapping<br />

Position control<br />

Advantages:<br />

Wi<strong>de</strong> dynamic range<br />

High resolution<br />

High linearity<br />

Insensitive to colour<br />

High shock and vibration<br />

resistance<br />

Dimensions<br />

136<br />

38<br />

60<br />

146<br />

All dimensions in mm<br />

60 47<br />

Wiring connections<br />

Cable<br />

red<br />

+24 VDC<br />

blue<br />

GND<br />

green <strong>Laser</strong> interlock<br />

violet Synchr. input<br />

grey/pink RX digital input<br />

red/blue RX digital input<br />

yellow Measure 10 kW<br />

to GND<br />

white Analog output 1-9 VDC<br />

brown Analog output GND<br />

grey<br />

Analog output 4-20 mA<br />

pink<br />

Analog output GND<br />

black Synchr. output<br />

white/grey TX digital output (signal)<br />

brown/grey TX digital output (GND)<br />

Operating and display elements<br />

LED red<br />

LASER ON<br />

LASER ON<br />

DANGER<br />

LASER RADIATION<br />

AVOID EXPOSURE<br />

TO BEAM<br />

37<br />

CLASS 2 LASER<br />

PRODUCT<br />

670 nm 1mW<br />

2<br />

IN RANGE<br />

50<br />

33<br />

74<br />

10 kW<br />

IN RANGE<br />

LASER ON<br />

DANGER<br />

LASER RADIATION<br />

AVOID EXPOSURE<br />

TO BEAM<br />

CLASS 2 LASER<br />

PRODUCT<br />

670 nm 1 mW<br />

25<br />

30<br />

LED green/red<br />

IN RANGE

Technical data<br />

Electrical data<br />

Lightsource<br />

Data on ambiente<br />

conditions<br />

Supply voltage 24 VDC +/-10%<br />

Power consumption<br />

~ 4.5 W typ.<br />

Measuring / testing frequency<br />

0.5 /1kHz<br />

Analog output<br />

1-9 VDC<br />

4-20 mA<br />

Serial output RS232 (Baudrate: 38400)<br />

Cable<br />

7x2x0.14 mm², shiel<strong>de</strong>d, 2.5 m length<br />

<strong>Laser</strong>, Wave length<br />

typ. 670 nm<br />

<strong>Laser</strong> power<br />

< 1 mW<br />

<strong>Laser</strong> CLASS 2 (EN 60825-1:1994)<br />

Max. operating temperature 0 to +45 °C<br />

Max. storage temperature -20 to + 70 °C<br />

Max. rel.humidity<br />

90% (not con<strong>de</strong>nsing)<br />

Protection IP 65<br />

Specifical data <strong>Sensor</strong> LDS 100/...<br />

30 100 200 300 500 700 900 900/M 1400 2000<br />

Sensing range from 100 100 100 100 200 400 700 1500 700 2000<br />

(mm) up to 130 200 300 400 700 1100 1600 2400 2100 4000<br />

Center distance 115 150 200 250 450 750 1150 1950 1400 3000<br />

Spot Ø mm 1 1 1-2 1-2 1-2 1-2 4 5 5 5<br />

Resolution* mm 0.002 0.01** 0.05 0.25 0.1 0.5 0.1 0.3 0.2 0.5<br />

Linearity* +/- mm 0.03 0.1 0.3 0.45 0.5 1.05 0.9 1.0 1.4 1.0<br />

Reproduceability* mm 0.01 0.01** 0.05 0.25 0.1 0.5 0.1 0.3 0.2 0.5<br />

Temp.drift +/- µm/°C 9 30 60 90 150 210 270 270 420 600<br />

Dimensions<br />

Weight<br />

136x146x50mm<br />

approx. 1.6 kg<br />

230x70x200mm<br />

approx. 3.6 kg<br />

* Static measurement on white paper ** Specification for digital output; analog output: 0.05 mm<br />

Or<strong>de</strong>ring information<br />

Part No.<br />

10652067<br />

10652068<br />

10652069<br />

10652070<br />

10652071<br />

10652072<br />

10652073<br />

10652075<br />

10652074<br />

10652076<br />

ELT/LDS/LDS100E5<br />

Application<br />

Contour control<br />

Application<br />

Diameter check<br />

Presented by:<br />

LASER CLASS 2<br />

EN 60825-1:1994<br />

Do not stare<br />

into beam!<br />

© Eltrotec 07/06 (we reserve the right to make changes in the interest of technical progress)

ELTROTEC<br />

<strong>Sensor</strong> GmbH<br />

Heinkelstrasse 2<br />

D-73066 Uhingen<br />

Telefon: 07161 / 98872-300<br />

Telefax: 07161 / 98872-303<br />

Internet:www.Eltrotec.com<br />

e-mail: Info@Eltrotec.com<br />

<strong>Laser</strong>-<strong>Distance</strong>-<strong>Sensor</strong><br />

Series LDS 400<br />

Time of flight measurement<br />

Measuring range<br />

300-4000 mm<br />

Digital resolution<br />

³ 0.9 mm<br />

Switching frequency 100 Hz / 500 Hz<br />

2x PNP or NPN, 4-20mA, RS485<br />

Specification:<br />

The LDS 400 series offers an innovative<br />

laser distance sensor with time of<br />

flight measurement. This technology<br />

is based on the measurement of the<br />

time between the emmision and the<br />

receipt of the laser light pulses.<br />

In the 300-4000 mm distance range,<br />

it provi<strong>de</strong>s a very accurate measurement<br />

in<strong>de</strong>pen<strong>de</strong>nt of the target's<br />

colour with 12 bit resolution and high<br />

linearity. A 4-digit display on the<br />

sensors top visualises the value of<br />

the measured distance in mm, as well<br />

as all the parameters that can be set<br />

with three pushbuttons.<br />

The LDS 400 sensors have two<br />

switching outputs, available as PNP<br />

or NPN mo<strong>de</strong>ls, that can be set at<br />

different distances, while the<br />

measurement value ist supplied at<br />

the 4-20 mA analogue output and<br />

RS485 interface. This interface can<br />

also be used to set all the parameters.<br />

A response time selection with 5 ms<br />

normal and 1 ms fast response is<br />

available.<br />

¢<br />

U L<br />

Typical applications:<br />

<strong>Distance</strong> measurement<br />

Thickness measurement<br />

Presence control<br />

Automatic control for<br />

coiling/uncoiling machines<br />

<strong>Distance</strong> measurement for<br />

overhead conveyors<br />

<strong>Distance</strong> measurement up<br />

to 1200 °C hot steel<br />

Advantages:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Wi<strong>de</strong> measuring range<br />

High linearity<br />

2 switching points<br />

Highly shock- and<br />

vibration-resistant<br />

4-digit display<br />

Connector turnable<br />

Visible laserbeam<br />

Dimensions<br />

18<br />

15.5 40<br />

34<br />

15<br />

All dimensions in mm<br />

Alarm LED red<br />

Wiring connections<br />

6<br />

7 8<br />

5<br />

Output LED yellow<br />

1 2<br />

Operating and display elements<br />

90<br />

2 holes M5<br />

8 mm <strong>de</strong>ep<br />

Plug connector M12<br />

Switching output<br />

indicator LEDs<br />

green<br />

Switching output<br />

LED yellow<br />

4<br />

3<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

14.5<br />

73<br />

8<br />

7 22<br />

73<br />

50<br />

M12<br />

64<br />

wh Rx/Tx -<br />

bn +10-30VDC<br />

gn Analogue output<br />

ye Output 1<br />

gr Output 2<br />

pi Rx/Tx +<br />

bl<br />

rd<br />

SET<br />

+ -<br />

GND<br />

SYNC<br />

Fast LED<br />

green<br />

LDS 400<br />

+ pushbutton – pushbutton<br />

SET-pushbutton<br />

LASERSTRAHLUNG<br />

NICHT IN DEN STRAHL BLICKEN<br />

LASERKLASSE 2<br />

P 1 mW; = 670 nm<br />

nach DIN EN 60825-1 03.97<br />

4 digit display<br />

15,5<br />

Ø 5.2<br />

90° turnable

Technical data<br />

Electrical data<br />

Specific data<br />

Outputs<br />

Light source<br />

Ambient<br />

conditions<br />

Housing<br />

Or<strong>de</strong>ring information<br />

<strong>Laser</strong> <strong>Distance</strong> <strong>Sensor</strong><br />

LDS 400/RS485/PNP<br />

LDS 400/RS485/NPN<br />

Supply voltage<br />

15 - 30 VDC<br />

Ripple<br />

max. 2Vpp<br />

Current consumption typ. max. 170 mA (110 mA at 24V)<br />

Data memory<br />

EEPROM<br />

Measuring range<br />

300 - 4000 mm (18% grey to 90% white)<br />

(at specified surf. reflection)<br />

400-2500 (at 6% black)<br />

Digital resolution (RS485)<br />

³ 0.9 mm<br />

Analogue resolution<br />

³ 3 mm<br />

Response time<br />

5 ms (normal), 1 ms (fast)<br />

Switching frequency<br />

100 Hz (normal), 500 Hz (fast)<br />

Linearity typ. 0.3 %<br />

(at 24VDC, at 90% white surface, 25 °C)<br />

Switching outputs<br />

2x PNP or NPN<br />

max. 30 VDC, 100 mA, short circuit protected<br />

Analogue output<br />

4-20 mA<br />

Input<br />

SYNC-input, PNP<br />

Serial connection<br />

RS485, 9600 Bd<br />

Wave length<br />

665 nm<br />

<strong>Laser</strong> class 2 (EN 60825-1:1994)<br />

Measuring spot size typ.<br />

~ Ø 12 mm at 2000 mm distance<br />

~ Ø 20 mm at 4000 mm distance<br />

Operating temperature -10 to +50 °C<br />

Storage temperature -20 to + 70 °C<br />

Protection IP 67<br />

Ambient light protection according to EN 60947-5-2<br />

Vibration<br />

0,5 mm amplitu<strong>de</strong>, 10-55 Hz<br />

according to EN 60068-2-6<br />

Shock resistance<br />

11 ms (30 G) , acc.to EN60068-2-27<br />

Material<br />

Aluminium housing, optical elements: Glas<br />

Weight<br />

approx. 330 g<br />

Connections<br />

8-pol plug connector, M12, turnable<br />

Part No.<br />

10652680<br />

10652683<br />

Accessories<br />

Cable 3 m, 8-pin, M12 plug 11232681<br />

Cable 5 m, 8-pin, M12 plug 11232682<br />

Application<br />

<strong>Distance</strong> measurement on paper, coils or films<br />

LDS 400<br />

Presented by:<br />

LASER CLASS 2<br />

EN 60825-1:1994<br />

Do not stare<br />

into beam!<br />

© Eltrotec 07/06 (we reserve the right to make changes in the interest of technical progress) ELT/LDS/LDS400e4

Operating and display elements LDS400<br />

LED indicators on LDS400 frontsi<strong>de</strong><br />

OUTPUT LED<br />

ALARM LED<br />

Yellow LED indicates an active Output<br />

(Output 1 OR Output 2)<br />

The red ALARM LED indicates a missing receiver signal<br />

Pushbuttons and Display on top<br />

Alarm LED red<br />

Output LED yellow<br />

OUTPUT LED Yellow LED indicates an active Output<br />

(Output 1 OR Output 2)<br />

Display (green, 4-digit)<br />

LED OUT1, OUT2<br />

LED FAST<br />

SET-pushbutton<br />

+/- pushbuttons<br />

In normal working mo<strong>de</strong>, the distance in mm is shown on the display<br />

Green LED1 indicates the activated switching output 1<br />

Green LED2 indicates the activated switching output 2<br />

Green LED3 indicates the activated FAST mo<strong>de</strong> (500 Hz)<br />

A short press on this key activates the self-setting procedure.<br />

A long pressure on the key allows the user to access into the mo<strong>de</strong><br />

(FAST/NORM) and the setting of output <strong>de</strong>lay.<br />

Short pressure on this key allows the user to run through<br />

parameters and the settings menu of the sensor.<br />

Long pressure allows to change the switching threshold value. LED yellow<br />

(see also “Switching threshold adjustment ”)<br />

Switching diagram<br />

Switching output<br />

Switching output<br />

indicator LEDs<br />

green<br />

123<br />

SET<br />

+ -<br />

+ Pushbutton<br />

Fast LED<br />

green<br />

Display<br />

4-digit<br />

– Pushbutton<br />

SET-Pushbutton<br />

Analogue output<br />

mA<br />

20<br />

12<br />

4<br />

0<br />

Measuring range<br />

300 4000 mm <strong>Distance</strong><br />

Digital output<br />

V<br />

24<br />

0<br />

Switching<br />

distance<br />

Hysteresis<br />

<strong>Distance</strong><br />

RS485 serial connection<br />

The RS485 serial interface allows the complete remote control of the<br />

sensor. All functions as channel status, normal/fast mo<strong>de</strong> selection or<br />

output <strong>de</strong>lay can be configured by serial connection. The serial<br />

communication parameters are:<br />

9600 baud, non-parity, 8 data bits,1 stop bit.<br />

The SYNC-input is used to <strong>de</strong>termine the communication direction.<br />

SYNC active (LOW)<br />

LDS400 -> user<br />

SYNC passive (HIGH)<br />

user -> LDS400<br />

With SYNC active, the sensor continuously transmits the <strong>de</strong>tected<br />

distance value (with a precision of 12 bit) by means of a binary data<br />

format. 2 byte are used; one with bit 0 at logic level 1 i<strong>de</strong>ntifies the high<br />

byte.<br />

7 0 7 0<br />

0 0 D11 D10 D9 D8 D7 1 D6 D5 D4 D3 D2 D1 D0 0<br />

All the commands have to be sent via terminal in ASCII-format according<br />

to the following:<br />

- Remote configuration:<br />

To access the remote configuration mo<strong>de</strong>, SYNC-input<br />

must be passive. (SYNC passive = HIGH)<br />

The available commands are:<br />

@ beginning of remote setting mo<strong>de</strong><br />

cx channel selection, with x. {1,2}<br />

vxxx distance selection,<br />

with xxxx {0-4095}<br />

bx <br />

MSB<br />

dark/light mo<strong>de</strong> selection, with x {1,2}<br />

b1 = dark-switching<br />

b2 = light-switching<br />

memorisation to the configuration sequence<br />

e <br />

q exit from remote setting mo<strong>de</strong> without saving<br />

At the receipt of the ‘ q’ or ‘e’ -commands, the<br />

sensor visualises ok <br />

LSB<br />

- Delay configuration:<br />

To access the remote configuration mo<strong>de</strong>, SYNC-input must<br />

be passive.<br />

(SYNC passive = HIGH). The available commands are:<br />

@ beginning of <strong>de</strong>lay configuration<br />

dx <strong>de</strong>lay selection with x {0,1,2,3,4,5}<br />

d0=0ms d3=20ms<br />

d1=5ms d4=30ms<br />

d2=10ms d5=40ms<br />

e memorisation of the new <strong>de</strong>lay value<br />

q exit from <strong>de</strong>lay setting mo<strong>de</strong> without saving<br />

At the receipt of the ‘ q’ or ‘e’ -commands, the<br />

sensor visualises ok <br />

- Normal/ fast mo<strong>de</strong> configuration:<br />

To acces the remote configuration mo<strong>de</strong>, SYNC-input must be passive.<br />

(SYNC passive = HIGH). The available commands are:<br />

@ beginning of remote setting mo<strong>de</strong><br />

mx operating mo<strong>de</strong> selection with x {1,2}<br />

m1 = normal<br />

m2 = fast<br />

e execution of configuration sequence<br />

q exit from remote setting mo<strong>de</strong> without saving<br />

At the receipt of the ‘ q’ or ‘e’ -commands, the<br />

sensor visualises ok <br />

- Receipt of the channel status:<br />

At any moment, the receipt of the ‘r’ remote command<br />

(and SYNC passive), the sensor configuration is restored.<br />

NOTE:<br />

The single digits have to be distanced amongst themselves<br />

at least 1 ms, during the command transmission.

Settings LDS400<br />

Setting of the 2 channels<br />

Display<br />

1945<br />

CH-1<br />

1945<br />

1960<br />

saved value<br />

new value<br />

Quick status display<br />

At each pressure of the SET-button, the user can run through the options<br />

of the selected channel. By pressing the SET -button repeatedly, all options<br />

will be visualized sequencially.<br />

Detection<br />

Place the object to <strong>de</strong>tect in front of the sensor.<br />

The actual distance value in mm is shown on display.<br />

1945 <strong>Distance</strong> value<br />

By pressing the SET-button (for at least 2 sec.) you will reach the channel selection.<br />

Channel selection<br />

CH-1<br />

To select the channels, press the +/- - buttons.<br />

You confirm the selection by a short press (0,5 s) of the SET- button and will reach CH-2<br />

the dark/light-selection.<br />

Dark/light-mo<strong>de</strong><br />

LOn Light switching<br />

To select the dark/light mo<strong>de</strong> of the channels, use the +/- -buttons.<br />

dOn<br />

Press the SET - pushbutton again for at least 0,5 sec.<br />

Dark switching<br />

On display, the "updt" message starts to blink ( 4Hz, for 2 s)<br />

updt Settings saved<br />

The <strong>de</strong>tection distance value appears on display, LED for the memorised channel<br />

is active. The +/- -pushbuttons can be used to change the <strong>de</strong>tected distance value. 1945 <strong>Distance</strong> value<br />

(Units change if the pushbuttons pressed repeatedly, the tens if the buttons keep pressed)<br />

Press the SET- button again for at least 0.5 s to end the setting of the channels phase.<br />

Switching threshold adjustment<br />

Channel selection<br />

Press the +/- - button for at least 2 sec. the “CH 1”- message appears.<br />

To select the channels, press the +/- - buttons.<br />

You confirm the selection by a short press (0,5 s) of the SET- button<br />

<strong>Distance</strong> of threshold phase<br />

The previously <strong>de</strong>tected distance value appears. With a press of the +/-<br />

pushbuttons the <strong>de</strong>tected distance value can be changed, (Units change if the<br />

pushbuttons pressed repeatedly, the tens if the buttons keep pressed).<br />

Press the SET- button again for at least 0.5 s to end the threshold adjustment phase.<br />

Setting of the parameter<br />

Press the SET-button for at least 6stoenter into the parameter setting menu.<br />

By pressing the +/- pushbuttons, the user can run up and down within this<br />

menu.<br />

Switching frequency<br />

Use the SET-pushbutton to select the <strong>de</strong>ci<strong>de</strong>d option. Setting of normal or<br />

fast mo<strong>de</strong> is equal to both outputs.<br />

Delay setting<br />

The <strong>de</strong>lay value setting is equal to both channels. When a <strong>de</strong>lay value, different<br />

from zero, is set, outputs are active for at least the time (in ms) as shown in<br />

the display.<br />

Setting: with the SET pushbutton you can run through the available <strong>de</strong>lay steps.<br />

You confirm the selection by pressing the SET- button again.<br />

Memorisation of the parameter set<br />

Pressing the SET-button (the "SAVE"-message blinks for 2 s, 4 Hz) all the changed<br />

values are saved and the user exits from the menu and returns to normal mo<strong>de</strong>.<br />

To return to the setting menu, one of the +/- -buttons has to be pressed.<br />

After a 10 s inactivity of the pushbuttons, the sensor returns to normal mo<strong>de</strong><br />

visualising the disance.<br />

Keylock (SET pushbutton block)<br />

The keylock function is activated after powering on, if the SYNC terminal is connected to the positive<br />

power supply (+VDC) for at least 1 s.<br />

(After the first second, the SYNC signal is available for normal operations)<br />

To <strong>de</strong>activate the keylock function, the sensor has to be turned off and re-powered while maintaining<br />

the SYNC wire not connected or ground connected (GND).<br />

SYNC-Input<br />

The SYNC signal allows to calculate the beginning and the ending instants<br />

of the measurement. Reading cycle beginns after the transition of the SYNC<br />

signal from passive to active and the sensor outputs are updated after<br />

max. 400 µs. All the outputs are <strong>de</strong>activated after max. 400 µs from<br />

the active-passive transition. (SYNC passive=Vcc, SYNC active=GND)<br />

The SYNC wire is also used to <strong>de</strong>termine the transmission direction<br />

when the RS485 serial connection is used.<br />

Passive<br />

SYNC<br />

Aktive<br />

ON<br />

Output<br />

OFF<br />

MEnu<br />

nOrM<br />

FASt<br />

d-00<br />

d-05<br />

d-10<br />

...<br />

d-40<br />

CH-1<br />

1945<br />

LOn<br />

CH-2<br />

...<br />

SAVE<br />

max.<br />

400 µs<br />

normal, 100 Hz<br />

fast, 500 Hz<br />

no <strong>de</strong>lay<br />

5ms<br />

10 ms<br />

20 ms<br />

30 ms<br />

40 ms<br />

max.<br />

400 µs<br />

© Eltrotec 07/06 (we reserve the right to make changes in the interest of technical progress) ELT/LDS/LDS400e4

ELTROTEC<br />

<strong>Sensor</strong> GmbH<br />

Heinkelstrasse 2<br />

D-73066 Uhingen<br />

Telefon: 07161 / 98872-300<br />

Telefax: 07161 / 98872-303<br />

Internet:www.Eltrotec.com<br />

e-mail: Info@Eltrotec.com<br />

<strong>Laser</strong>-<strong>Distance</strong>-<strong>Sensor</strong><br />

<strong>Laser</strong>-Triangulation with<br />

CMOS-Technology<br />

Basic features:<br />

Center distance<br />

40-160 mm<br />

Resolution typ. 4-100 µm<br />

Analogue output 4-20 mA<br />

optional: 1-5 VDC<br />

High linearity<br />

Colour insensitive<br />

measurement<br />

<strong>Laser</strong> Class 2<br />

Protection IP 67<br />

¢<br />

Dimensions<br />

Series LDS 60<br />

Measuring range 20, 50, 100, 200 mm<br />

Resolution<br />

4, 10, 50, 100 µm<br />

Outputs<br />

4-20 mA / 1-5 VDC<br />

Measuring rate 500 Hz<br />

Small dimensions (65 x 50 x 20) mm<br />

Mounting<br />

holes<br />

2x Ø 4,3 / 5,8<br />

<strong>Laser</strong>beam<br />

65<br />

16<br />

57<br />

4<br />

5<br />

50<br />

40<br />

LDS 60<br />

LASERSTRAHLUNG<br />

NICHT IN DEN STRAHL BLICKEN<br />

LASERKLASSE 2<br />

P 1 mW; = 670 nm<br />

nach DIN EN 60825-1 03.97<br />

20<br />

Glass optic<br />

All dimensions in mm<br />

Wiring connections<br />

Typical applications:<br />

<strong>Distance</strong> measurement<br />

Thickness measurement<br />

Positioning of robotic arm<br />

Profile checking<br />

Out-of-balance measurement<br />

Control of overlapping<br />

Position on conveyor<br />

<strong>de</strong>formation<br />

Stroke, oscillation<br />

Advantages:<br />

Metal housing<br />

Small dimensions<br />

High resolution<br />

High linearity<br />

Vibration resistance 15 g/<br />

(10 Hz - 1 kHz)<br />

2<br />

3<br />

1<br />

4<br />

7<br />

5<br />

7 pin plug<br />

rear sight<br />

Description<br />

6<br />

Pin Colour Reference<br />

1 gn Error output, open collector<br />

NPN; switching to GND,<br />

Uce max. 30 VDC,<br />

100 mA, short circuit protected<br />

2 ye <strong>Laser</strong> ON/OFF<br />

connect pin 2+6 => <strong>Laser</strong> ON<br />

3 bl N.C.<br />

4 pink N.C.<br />

5 gr Output 4-20 mA,<br />

short circuit protected<br />

6 bn GND<br />

7 wt Supply 12-30 VDC<br />

inverse polarity protected<br />

(---) Shield (PE)<br />

The <strong>Laser</strong> Triangulation <strong>Sensor</strong> LDS 60 is based on latest CMOS<br />

technology. It is working with a visible red laser.<br />

The measuring values are linearised by an internal signal<br />

processor. Due to this the sensor measures the distance very<br />

accurate and in<strong>de</strong>pen<strong>de</strong>nt from colour of surface. The LDS 60<br />

provi<strong>de</strong>s an analogue output with 4-20 mA. Optional there is a<br />

connection cable with shunt for 1-5 VDC output available.

Technical data<br />

Electrical data<br />

Supply voltage<br />

Measuring rate<br />

12-30 VDC, typ. 24 VDC, 150 mA<br />

500 Hz<br />

Analogue output<br />

4-20 mA<br />

(option: 1-5 VDC)<br />

Light source<br />

Wavelength<br />

Power<br />

typ. 670 nm, visible/red<br />

< 1 mW<br />

<strong>Laser</strong> Class 2 DIN (EN 60825-1:11.01)<br />

Data on ambience<br />

conditions<br />

max. operating temp.<br />

max. storage temp.<br />

0 to +55 °C (+32 to +130 °F)<br />

-20 to + 70 °C (-4 to +158 °F)<br />

Protection class/ weight<br />

IP 67/ approx. 100 g<br />

EMC EN 50081-1 , EN 50082-2<br />

Specifical data <strong>Sensor</strong> LDS 60/...<br />

20 50 100 200**<br />

Measuring range<br />

+/- 10 mm +/- 25 mm +/- 50 mm +/- 100 mm<br />

Center distance<br />

40 mm 70 mm 100 mm 160 mm<br />

Linearity typ.<br />

+/- 20 µm +/- 50 µm +/- 100 µm +/- 200 µm<br />

Resolution*stat.(typ.)<br />

4µm 10µm 50µm 100µm<br />

dyn. at 1 kHz<br />

10 µm 25 µm 100 µm 200 µm<br />

Spot diameter Ø typ.<br />

~0.3 mm ~0.1 mm ~0.13 mm ~2 mm<br />

at center distance<br />

Temp. stability<br />

0.03 % of measuring range / °C<br />

0.08 % o.m.r. / °C<br />

* All values at white, diffuse reflecting surfaces (AL 2 O 3<br />

- ceramic) as reference<br />

Or<strong>de</strong>ring information<br />

LDS 60 20 50 100 200<br />

Part No. 10653338 10653339 10653340 10653341<br />

plug connector inclu<strong>de</strong>d<br />

** Other ranges see LDS 70, LDS 85, LDS 100 on request or www.eltrotec.com<br />

Cable length:3 m, plug M12, 7-pin, output 4-20 mA 11242835<br />

Cable length:3 m, plug M12, 7-pin, output 1-5 VDC 11242836<br />

ELT/LDS/LDS60e1<br />

Contour, thickness and<br />

profile measurement<br />

Displacement measuring<br />

Positioning of robotic arm.<br />

Edge <strong>de</strong>tection<br />

LDS 70<br />

Oscillation,<br />

Out-of balance measurement<br />

Presented by:<br />

LASER CLASS 2<br />

DIN EN 60825-1: 11.01<br />

<strong>Laser</strong> radiation<br />

Avoid exposure to beam<br />

<strong>Sensor</strong>s of CLASS 2 don’t need<br />

environment with special protection<br />

© Eltrotec 11/06 (we reserve the right to make changes in the interest of technical progress)<br />

certified DIN EN ISO 9001: 2000

ELTROTEC<br />

<strong>Sensor</strong> GmbH<br />

Heinkelstrasse 2<br />

D-73066 Uhingen<br />

Telefon: 07161 / 98872-300<br />

Telefax: 07161 / 98872-303<br />

Internet:www.Eltrotec.com<br />

e-mail: Info@Eltrotec.com<br />

<strong>Laser</strong>-<strong>Distance</strong>-<strong>Sensor</strong><br />

<strong>Laser</strong>-Triangulation with<br />

CMOS-Technology<br />

Basic features:<br />

Center distance<br />

25 - 160 mm<br />

Resolution typ. 0.6-40 µm *<br />

Analogue output 4- 20 mA<br />

optional: 1-5 VDC with integrated<br />

shunt in connection cable<br />

RS232 interface<br />

High linearity<br />

Colour insensitive<br />

measurement<br />

<strong>Laser</strong> Class 2<br />

Protection IP 67<br />

¢<br />

(* <strong>de</strong>pends on version)<br />

Typical applications:<br />

<strong>Distance</strong> measurement<br />

Thickness measurement<br />

Displacement measuring<br />

Profile checking<br />

Out-of-balance measurement<br />

Control of overlapping<br />

Position control<br />

Cone belt measurement<br />

Stroke, oscillation<br />

Advantages:<br />

Small dimensions<br />

High resolution<br />

High linearity<br />

Wi<strong>de</strong> dynamic range<br />

High insensitive to colour<br />

due to CMOS-Technology and<br />

intern. digital signal processor<br />

with intelligent logic<br />

Vibration resistance 15 g/<br />

(10 Hz - 1 kHz)<br />

Measuring range<br />

Resolution<br />

Outputs<br />

Sampling rate<br />

Small dimensions<br />

Dimensions<br />

Mounting<br />

holes<br />

2x Ø 4,3 / 5,8<br />

<strong>Laser</strong>beam<br />

65<br />

16<br />

Wiring connections<br />

2<br />

3<br />

1<br />

4<br />

7<br />

5<br />

7 pin plug<br />

rear sight<br />

Description<br />

6<br />

57<br />

4<br />

Series LDS 70/232<br />

5<br />

5-200 mm (7 versions)<br />

0.6-40 µm*<br />

4-20 mA / 1-5 VDC / RS232<br />

1000 Hz<br />

(65 x 50 x 20) mm<br />

50<br />

40<br />

LDS 70<br />

LASERSTRAHLUNG<br />

NICHT IN DEN STRAHL BLICKEN<br />

LASERKLASSE 2<br />

P 1 mW; = 670 nm<br />

nach DIN EN 60825-1 03.97<br />

20<br />

All dimensions in mm<br />

Pin Colour Reference<br />

1 gn Error output, open collector<br />

NPN; switching to GND,<br />

Uce max. 30 VDC,<br />

100 mA, short circuit protected<br />

2 ye <strong>Laser</strong> ON/OFF<br />

connect pin 2+6 => <strong>Laser</strong> ON<br />

3 bl Rx 232<br />

4 pink Tx 232<br />

5 gr Output 4-20 mA,<br />

short circuit protected<br />

6 bn GND<br />

7 wt Supply 12-30 VDC<br />

inverse polarity protected<br />

--- Shield (PE)<br />

The <strong>Laser</strong> Triangulation <strong>Sensor</strong> LDS 70 is based on latest CMOS<br />

technology. It is working with a visible red laser.<br />

The measuring values are linearised by an internal signal<br />

processor. Due to this the sensor measures the distance very<br />

accurate and in<strong>de</strong>pen<strong>de</strong>nt from colour of surface. The LDS 70<br />

provi<strong>de</strong>s an analogue output with 4-20 mA. Optional there is a<br />

connection cable with shunt for 1-5 VDC output available.The<br />

RS232 interface is inclu<strong>de</strong>d.

Technical data<br />

Electrical data<br />

Light source<br />

Data on ambience<br />

conditions<br />

Or<strong>de</strong>ring information<br />

Supply voltage<br />

12-30 VDC, typ. 24 VDC, 150 mA<br />

Frequency<br />

1 kHz<br />

Analogue output<br />

4-20 mA<br />

(option: 1-5 VDC)<br />

Wavelength<br />

typ. 670 nm, visible/red<br />

Power<br />

< 1 mW<br />

<strong>Laser</strong> Class 2 DIN (EN 60825-1:11.01)<br />

max. operating temp.<br />

0 to +55 °C (+32 to +130 °F)<br />

max. storage temp.<br />

-20 to + 70 °C (-4 to +158 °F)<br />

Protection class IP 67<br />

EMC EN 50081-1 , EN 61000-6-2<br />

Specifical data <strong>Sensor</strong> LDS 70/...<br />

5 10 20 50 100 200**<br />

Measuring range 5 mm 10 mm 20 mm 50 mm 100 mm 200 mm<br />

Center distance 22.5 mm 25 mm 40 mm 70 mm 100 mm 160 mm<br />

Linearity typ.<br />

+/- 5 µm +/- 10 µm +/- 20 µm +/- 50 µm +/- 100 µm +/- 400 µm<br />

Resolution*stat.(typ.) 0.6µm 1µm 2µm 5µm 20µm 40µm<br />

dyn. at 1 kHz 3 µm 5 µm 10 µm 25 µm 100 µm 200 µm<br />

Meas. area Ø typ. ~0.5 mm ~0.8 mm ~0.3 mm ~0.1 mm ~0.1 mm ~2 mm<br />

at center distance<br />

Temp. stability<br />

0.03 % of measuring range / °C<br />

0.08 % o.m.r. / °C<br />

* All values at white, diffuse reflecting surfaces (AL2O3- ceramic) as reference<br />

LDS70/232 5 10 20 50 100 200<br />

Part No. 10652789 10652849 10652841 10652850 10652848 10652635<br />

plug connector inclu<strong>de</strong>d<br />

** 250 mm measuring range available, see datasheet LDS 70/250-F, RS232 see user manual<br />

Cable length:3 m, plug M12, 7-pin, output 4-20 mA and RS232 (6 m optional) 11242835<br />

Cable length:3 m, plug M12, 7-pin, output 1-5 VDCand RS232 (6 m optional) 11242836<br />

Cable length:3 m, plug M12, 7-pin, output 4-20 mA, 9pin Sub-D RS232 connector 11242790<br />

ELT/LDS/LDS70-232E7<br />

Displacement measuring<br />

Contour, thickness and<br />

profile measurement<br />

LDS 70<br />

Oscillation,<br />

Out-of balance measurement<br />

<strong>Distance</strong>/profile measurement<br />

Presented by:<br />

LASER CLASS 2<br />

DIN EN 60825-1: 11.01<br />

<strong>Laser</strong> radiation<br />

Avoid exposure to beam<br />

<strong>Sensor</strong>s of CLASS 2 don’t need<br />

environment with special protection<br />

© Eltrotec 07/06 (we reserve the right to make changes in the interest of technical progress)

ELTROTEC<br />

<strong>Sensor</strong> GmbH<br />

Heinkelstrasse 2<br />

D-73066 Uhingen<br />

Telefon: 07161 / 98872-300<br />

Telefax: 07161 / 98872-303<br />

Internet:www.Eltrotec.com<br />

e-mail: Info@Eltrotec.com<br />

<strong>Laser</strong>-<strong>Distance</strong>-<strong>Sensor</strong><br />

Series LDS 70/250-F<br />

Measuring range 250 mm<br />

Resolution<br />

³ 50 µm<br />

Measuring frequency 1000 Hz<br />

Small dimensions (65 x 50 x 20) mm<br />

High shock resistance ~ 20g<br />

Principal features:<br />

Measuring distance<br />

100 - 350 mm<br />

Resolution typ. ³ 50 µm<br />

Analogue output 4- 20 mA<br />

optional: 1-5 VDC with integrated<br />

shunt in connection cable<br />

RS232 optional<br />

High linearity<br />

<strong>Laser</strong> Class 2<br />

Protection IP 67<br />

¢<br />

Typical applications:<br />

Dimensions<br />

Mounting<br />

holes<br />

2x Ø 4,3 / 5,8<br />

<strong>Laser</strong>beam<br />

65<br />

16<br />

57<br />

4<br />

Wiring connections<br />

Pin<br />

5<br />

50<br />

40<br />

LDS 70/250-F<br />

LASERSTRAHLUNG<br />

NICHT IN DEN STRAHL BLICKEN<br />

LASERKLASSE 2<br />

P 1 mW; = 670 nm<br />

nach DIN EN 60825-1 03.97<br />

Colour Reference<br />

20<br />

All dimensions in mm<br />

<strong>Distance</strong> measurement to road or rail<br />

Advantages:<br />

Small dimensions<br />

High resolution<br />

High linearity<br />

Wi<strong>de</strong> dynamic range<br />

Insensitive to colour and<br />

surface due to special<br />

interference optic<br />

Vibration resistance 20g<br />

Extremely resistance sensor<br />

for online distance measurement<br />

“car to road” or<br />

“train to rail”<br />

2<br />

1<br />

3<br />

5 pin plug<br />

rear sight<br />

Description<br />

5<br />

4<br />

1 gn Error output, open collector<br />

NPN; switching to GND,<br />

Uce max. 30 VDC,<br />

100 mA, short circuit protected<br />

2 ge <strong>Laser</strong> ON/OFF<br />

connect pin 2+ 4 => <strong>Laser</strong> ON<br />

3 gr Output 4-20 mA,<br />

short circuit protected<br />

4 bn GND<br />

Potential for (2) and U b (5)<br />

5 ws Supply 11-30 VDC<br />

inverse polarity protected<br />

--- Shield (PE)<br />

The <strong>Laser</strong>triangulation <strong>Sensor</strong> LDS 70 is based on latest CCDtechnology.<br />

It is working with a visible red laser.<br />

The measuring values are linearised by a internal signal processor.<br />

Due to this the sensor measures the distance very accurate and<br />

in<strong>de</strong>pen<strong>de</strong>nt from colour of surface. The LDS 70/250-F provi<strong>de</strong>s an<br />

analogue output with 4-20 mA. Optional there is a connection cable<br />

with shunt for 1-5 VDC output available.<br />

Special application is, to measure distance car body to road or train<br />

body to rail.

Technical data<br />

Electrical data<br />

Light source<br />

Data on ambiente<br />

conditions<br />

Measuring<br />

Resolution<br />

Measuring area<br />

Temperature<br />

Or<strong>de</strong>ring information<br />

Supply voltage<br />

11-30 VDC, typ. 24 VDC, 150 mA<br />

Frequency<br />

1000 Hz<br />

Analogue output<br />

4-20 mA<br />

(option: 1-5 VDC/ 2-10 VDC with shunt)<br />

Wavelength<br />

typ. 670 nm, visible/red<br />

Power<br />

< 1 mW (IEC standard)<br />

<strong>Laser</strong> Class 2 DIN (EN 60825-1:03.97)<br />

max. operating temp. 0 to +55 °C<br />

max. storage temp. -20 to +70 °C<br />

Protection IP 67<br />

max. permis. daylight<br />

ELTROTEC<strong>Sensor</strong>GmbH<br />

Heinkelstr.2<br />

D-73066Uhingen<br />

www.eltrotec.com<br />

Series LDS 85/<br />

Measurement Range [mm]:<br />

2<br />

10<br />

20<br />

50<br />

100<br />

200<br />

250<br />

500<br />

750<br />

C<br />

Highestresolution in class<br />

Highestrepeatabilityin class<br />

Highestaccuracy in class<br />

Bestperformance/price ratioin class<br />

Intelligent laseroptical<br />

displacement measurement<br />

<strong>Laser</strong> <strong>Distance</strong> <strong>Sensor</strong><br />

LDS 85

Series LDS 85<br />

Compact laser displacement sensors<br />

SeriesLDS85isanlaseropticaldisplacementmeasurement<br />

system with extensive functional features. Through the<br />

integral controller the system can be completelyconfigured<br />

via the supplied PC software and also offers extensive<br />

functions such as limit switches, averaging, adjustable<br />

measurement ratesand the synchronizationoftwosensors,<br />

e.g. for thickness measurement. With the unique Real-Time<br />

Surface Compensation (RTSC) the system facilitates<br />

measurements against awi<strong>de</strong> range of material surfaces<br />

(e.g. bare metals, black rubber or shiny painted surfaces).<br />

Due to the large selection of different measurement ranges<br />

from 2 to 750 mm there is a perfect sensor for each<br />

application. The compact <strong>de</strong>sign makes the series LDS 85<br />

sensors particularly suitable for industrial applications in<br />

automatedmachineryandproductionequipment.<br />

The series LDS 85 operates according to the triangulation<br />

principle.Alaserdio<strong>de</strong>projectsavisiblespotoflightontothe<br />

target surface. The light reflected from this spot is directed<br />

throughanopticalreceivingsystemontoaposition-sensitive<br />

element(CCDarray).Ifthetargetchangesitsdistancetothe<br />

sensor,this leads to achange of the imaging spot on the<br />

CCDarray.Thepositionofthespotinci<strong>de</strong>ntontheCCDarray<br />

isevaluated.<br />

ADVANTAGES<br />

• RTSC fast adaptation to changing surfaces<br />

• Compact <strong>de</strong>sign with integral electronics<br />

•Configuration and control via software PC<br />

• Synchronization of two sensors mandatory<br />

for differential and thickness measurement<br />

• Analog and digital outputs<br />

•Programable limits<br />

Performanceproof<br />

Every sensor is calibrated according to ISO<br />

9000 quality standards and an individual<br />

calibration protocol is inclu<strong>de</strong>d with every<br />

sensor.<br />

Compact<strong>de</strong>signwithintegralcontroller<br />

Despite its compact dimensions, the LDS 85 series has a<br />

completely integrated controller. There is no separate<br />

controllerhousingwhichmeansthatinstallationandwiringis<br />

carriedouteasilyandquickly.Itssmallsizeallowsthesensor<br />

tobeintegratedintotightinstallationspaces.<br />

The measurements are processed digitally in the integral<br />

controller.The data are output either analog or digitally via<br />

RS422 (optionally with USB - cable EL-PC85-3/USB<br />

required).<br />

CCD-array<br />

with RTSC<br />

multi-lens<br />

optics<br />

filter<br />

optics<br />

laserdio<strong>de</strong><br />

LASER RADIATION<br />

Do not stare into the beam<br />

CLASS 2LASER PRODUCT<br />

IEC 60825-1: 2001-11<br />

P

Typical applications<br />

Contourmeasurementoncatalyticconverters<br />

During the production of ceramic billets for car catalytic<br />

converters, the billets are measured for roundness and<br />

diameteronanumberofradialtracksforclassification.Using<br />

the IF2004 interface card (page 6),<br />

the enco<strong>de</strong>r and sensor signalsare<br />

synchronized to obtain precise<br />

correspon<strong>de</strong>nce in angle and<br />

shape.<br />

Partsmeasurement<br />

On machined surfaces of metal products,<br />

the LDS 85 is employed for quality<br />

assurance.Quantitiessuchasroundness,<br />

concentricity, eccentricity and bending<br />

<strong>de</strong>flectionare<strong>de</strong>termined.<br />

Synchronousthicknessmeasurement<br />

Thethicknessofthevariouswebmaterials<br />

can be reliably acquired with LDS 85<br />

sensors. With their high measuring rate<br />

andthepossibilityofsynchronizingtwoor<br />

more sensors (simultaneous<br />

measurement), the sensors are i<strong>de</strong>al for<br />

movingandoscillatingtargets.<br />

FlatnessmeasurementofICpins<br />

Toachievethebestqualityduringboardassembly,allICpins<br />

mustlie inone plane. Inmo<strong>de</strong>rn<br />

automatic placement systems<br />

the ICs are therefore measured<br />

directly before placement. The<br />

tiny light spot diameters enable<br />

the measurement of the finest<br />

pingeometries.<br />

Shapeconformanceon<br />

aluminumwheels<br />

After casting, aluminum wheels<br />

are measured for a range of<br />

features, e.g. hub <strong>de</strong>pth, roundness,<br />

bulging, etc., before being<br />

processedfurther.<br />

Surfaceprofiling<br />

Due to the small measuring spot and<br />

RTSC(Real-TimeSurfaceCompensation),<br />

the LDS 85 is excellent for the high<br />

precision mapping of any target<br />

regardless of its reflectivity, angle, shape<br />

andcolor.<br />

Partpositioninginproductionlines<br />

Forautomatedprocessing stagesoncarbodiesorvehicles<br />

an exact <strong>de</strong>termination of the<br />

position relative to the<br />

processing tool is necessary<br />

(drilling, punching, fitting subassemblies).<br />

Due to the<br />

adjustable exposure time and<br />

the real-time surface<br />

compensation, the series LDS<br />

85 is particularly suitable for the<br />

highprecisionacquisitionofhighlyglossysur-faces.<br />

<strong>Distance</strong>ofvehicletoroadsurface<br />

In road tests pitching and rolling movements, spring<br />

compression during braking and other quantities are<br />

measured with LDS 85 sensors. The series LDS 85 is<br />

particularly suitable here due to<br />

the compact construction and<br />

the possibility of supplying the<br />

sensor from the vehicle power<br />

supply(11...30VDC).Forthese<br />

applications there are special<br />

mo<strong>de</strong>ls LDS 85-250 VT available<br />

with increased tolerance to<br />

extra-neouslightandvibration.<br />

03

Series LDS 85<br />

Compact laser displacement sensors<br />

RTSC:Real-TimeSurfaceCompensation<br />

WithRTSC,aworld-wi<strong>de</strong>uniqueinnovation,the<strong>de</strong>greeof<br />

reflection from the target is compensated during the ongoingexposureandinreal-time.Theexposuretimeorthe<br />

amountoflightproducedbythelaserisoptimallymatched<br />

to the currentlyrunning exposure cycle. It is only sensors<br />

from ELTROTEC which are equipped with this innovative<br />

real-time control and consequently they always achieve<br />

optimumresultsevenwithchangingsurfaces.<br />

Adjustableexposuretime/measurementrate<br />

Fortargetswithlittlediffusereflectivitytheexposuretimecan<br />

be adjusted. The programed measurement cycle remains<br />

always constant, therefore the real-time data rate is<br />

guaranteed.<br />

Adjustableexposuretime/measurementrate<br />

Measuring rate 2.5kHz 1.25kHz 625 Hz 312.5Hz<br />

Max.exposuretime 0.4ms 0.8 ms 1.6ms 3.2ms<br />

Standard commercially available laser triangulation<br />

sensorsoperatewithatime-shift controlwhichisadditive<br />

to the measurement cycles already conclu<strong>de</strong>d. In this<br />

casethe<strong>de</strong>greeofreflectionfromthelastmeasurementis<br />

used to <strong>de</strong>rive the <strong>de</strong>gree of reflection for the next<br />

measurement. With changing or structured surfaces the<br />

measurement results therefore <strong>de</strong>viate noticeably from<br />

the actual measurement quantity,whereas the LDS 85 is<br />

controlledinrealtimeattherespectiveoptimumoperating<br />

point.<br />

Configurationviasoftware<br />

Besi<strong>de</strong>susingthesensorkeys,theconfigurationcanalsobe<br />

carriedoutconvenientlyviathePC.Thesoftwarerequiredfor<br />

thisisinclu<strong>de</strong>dinthesupplieditems.<br />

Configurablevia software<br />

RS422 or USB(option)<br />

Principle<br />

RTSCReal-TimeSurface Compensation<br />

compared totime-shift control.<br />

Adjustablelimitswitches<br />

Foraprecisemeasurement,theLDS85 sensorscanalsobe<br />

programed for tolerance or limit monitoring. Two switching<br />

pointsareavailablewhichcanbeadjustedviathesoftware.A<br />

hysteresisforeachlimitcanbeprogramed.<br />

y(mm)<br />

correct measurement<br />

y(mm)<br />

measurement error<br />

LDS85<br />

withRTSCreal-time<br />

surface compensation<br />

t<br />

Standardlasersensorswith<br />

time-shift control give<br />

distinctlyincorrectsignals<br />

withachange of surface<br />

t<br />

04

Features<br />

SynchronousdatarecordingwiththeIF2004<br />

With the IF2004 PCI interface card, which is available as an<br />

accessory, the data from up to four sensors can be<br />

synchronously read via aFIFO memory.Readings from an<br />

enco<strong>de</strong>rorlinearmeasurementsystemasthefourthchannel<br />

canbeusedtomapuptothreeLDS85sensors.<br />

Synchronous data recording withtheIF2004<br />

interfacecard<br />

IF2004<br />

enco<strong>de</strong>r<br />

upto 4sensors<br />

Synchronizationoftwosensors<br />

Simultaneousmeasurementusingtwosensorsisnecessary<br />

inor<strong>de</strong>rtoobtainpreciseresults,withthicknessordifferential<br />

measurements,whenthetargetismovingoroscillating.The<br />

LDS85seriessupportsthisfunction,whereonesensoracts<br />

as the master and provi<strong>de</strong>s the clock for the slave.<br />

Consequently, the measurements are always synchronous<br />

andthereforesupplyexactmeasurementresults.<br />

Synchronization oftwo sensors<br />

sensor 1 sensor 1<br />

t d<br />

Highflexcablesratedformovingcabletracks<br />

The type EL-PC 85-xx cables are rated for operation in<br />

movingcabletrackswithaminimumcablebendingradiusof<br />

80mm.<br />

Analoganddigitaloutputs<br />

Withtwoanalogueoutputsignals0...10Vand4...20mAas<br />

well as the serial RS422 interface, the LDS 85 range of<br />

sensorsfulfilsallinterfacerequirements.Thebaudrateofthe<br />

RS422 can be set in standard steps from 9,600 to 115,200<br />

baud. This allows adirect communication to aPLC or any<br />

other host. In addition the dataformat of the serial interface<br />

canbechangedfrombinarytoASCIIcharacteroutput.<br />

Wi<strong>de</strong>inputrange(11...30VDC)<br />

The 11 ... 30 VDC supply also enables operation in 12 V<br />

networks or direct supply from a car's on-board power<br />

supply.<br />

real<br />

thickness<br />

LDS85 with<br />

simultaneoussynchronization<br />

sensor 2 sensor 2<br />

t<br />

error<br />

Commonsensorwith<br />

typicalmeasurement<strong>de</strong>lay<br />

t<br />

Adjustablefilterfunctions<br />

Toachieve the best results for each application,<br />

three different filter functions can be applied to the<br />

measurementresults.<br />

The recursive mean works similar to an analog<br />

low-passfilter.<br />

The moving average enables ahigh dynamic<br />

responseevenwithfiltering.<br />

The median filter is especially suitable for<br />

surfaceswithrandomfalsereadings.<br />

Allfiltersettingsdonotreducetheoutput frequency<br />

(datarate)oftheanaloganddigitaloutputs.<br />

3.5<br />

3<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

3.5<br />

3<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.,5<br />

oszillation(original)<br />

200<br />

400 600<br />

positionsignal<br />

800<br />

oszillation<br />

moving average (N =128)<br />

1000<br />

8.5<br />

0 200 400 600 800 1000 0 200 400 600 800 1000<br />

positionsignal<br />

positionsignal<br />

11<br />

10.5<br />

10<br />

9.5<br />

9<br />

8.5<br />

0<br />

11<br />

10.5<br />

10<br />

9.5<br />

9<br />

200<br />

profile (original)<br />

400 600<br />

positionsignal<br />

profile<br />

median(N =9)<br />

800<br />

1000<br />

05

Series LDS 85<br />

Software and interface card<br />

sensorCONFIGconfiguration/DAQsoftware<br />

sensorCONFIGisthesoftwareinclu<strong>de</strong>dinthesupplieditems<br />

for easy sensor configuration. All the settings can be<br />

implemented conveniently via aWindows user interface on<br />

thePC.Thesensorparametersaresenttothesensorviathe<br />

serialportandcanalsobesavedifrequired.<br />

IF 2004 PCI card<br />

The IF2004 interface card enables the synchronous<br />

acquisition of manysensor signalsand an enco<strong>de</strong>r.The<br />

dataare saved inaFIFOmemoryto facilitate resourcesaving<br />

block-by-block processing inthe PC.<br />

sensorCONFIG also inclu<strong>de</strong>s aeasy to use DAQ module<br />

whichcandisplayandsavemeasurementresults.Thelinkto<br />

the PC is ma<strong>de</strong> via the EL-PC 85-3/USB sensor cable<br />

(optional). All the connections are then realized using timesavingplugconnectors.<br />

Driversupportforcustomersoftware<br />

FortheLDS85sensorsadocumenteddriverDLLisavailable<br />

freeofchargewhichenableseasyintegrationofthesensors<br />

intoexistingsoftware.<br />

Features<br />

-4-channel version (foursensor inputs)<br />

-Enco<strong>de</strong>r input<br />

-Gate input<br />

-FIFO memory of 2kByte for each channel, which<br />

increases when all channels are occupied<br />

-Incremental enco<strong>de</strong>rinput, optically<strong>de</strong>coupled,<br />

nominally5V(min. 3V)<br />

Technical data IF2004<br />

Programingofthesensor<br />

select<br />

zero<br />

output<br />

speed<br />

avg<br />

zero<br />

state<br />

<strong>de</strong>fault<br />

>5s<br />

function<br />

enter<br />

All important functions can be set directly on the<br />

sensorusingthetouchkeys.<br />

Bus<br />

Interface<br />

FIFO<br />

Input<br />

Input<br />

Software<br />

sensors<br />

32 bit PCI /33 MHz /5VDC

Technical data<br />

Mo<strong>de</strong>l<br />

LDS 85/2 LDS 85/10 LDS 85/20 LDS 85/50<br />

LDS<br />

85/100<br />

LDS<br />

85/200<br />

LDS<br />

85/500<br />

LDS<br />

85/750<br />

Measuringrange 2mm 10 mm 20 mm 50 mm 100 mm 200 mm 500 mm 750 mm<br />

Start measuringrange 24 mm 30 mm 40 mm 45 mm 70 mm 70 mm 200 mm 200 mm<br />

Midrange 25 mm 35 mm 50 mm 70 mm 120 mm 170 mm 450 mm 575 mm<br />

Endmeasuringrange 26 mm 40 mm 60 mm 95 mm 170 mm 270 mm 700 mm 950 mm<br />

Linearity<br />

Resolution (at 2.5 kHz<br />

without averaging)<br />

Measuringrate<br />

Light source<br />

Permissable ambient light<br />

<strong>Laser</strong>safety class<br />

Spot diameter<br />

Operatingtemperature<br />

Storage temperature<br />

Output<br />

Switch Input<br />

Operation<br />

Powersupply<br />

<strong>Sensor</strong> cable length<br />

Synchronization<br />

measurements<br />

switchingoutputs<br />

Electromagnetic compatibility<br />

Protection class<br />

Vibration<br />

Shock<br />

Weight (with 0.25 cm cable)<br />

Dimensions /Course of beam dimensions in mm, not to scale<br />

Dimensions LDS85/2-LDS85/<br />

200<br />

Course ofbeamLDS85/2-LDS85/200<br />

3xmounting<br />

holes ø4.5<br />

A<br />

B<br />

<strong>Laser</strong> beam<br />

80<br />

89<br />

97<br />

13.4<br />

ø4<br />

13.4<br />

startof measuring<br />

range (SMR)<br />

15<br />

ø8<br />

24.2 36.1<br />

Dimensions LDS85/ 500 / LDS85/ 750mm<br />

75<br />

end of measuring<br />

range (EMR)<br />

Course ofbeamLDS85/500/LDS85/750mm<br />

mounting<br />

holes<br />

3xø4.5<br />

101<br />

85<br />

130<br />

140<br />

150<br />

laser beam<br />

15<br />

ø5<br />

15<br />

(SMR)<br />

17.5<br />

12<br />

Cable connector<br />

sensor<br />

31<br />

75<br />

~50<br />

(EMR)<br />

MR SMR a j e A B<br />

2 24 35° 40° 44.8° 25.8 16.8<br />

10 30 34.3° 35.2° 35.6° 28.7 20.5<br />

20 40 28,8° 27.5° 26.7° 30.1 22<br />

50 45 26.5° 23.0° 18.3° 31.5 22.5<br />

100 70 19.0° 15.4° 10.9° 32.6 24.1<br />

200 70 19.0° 9.78° 6.97° 33.1 24.1<br />

500 200 19.3° 9.8° 7.0° - -<br />

750 200 19.3° 7.7° 5.0° - -<br />

ELTROTEC <strong>Sensor</strong> GmbH<br />

Heinkelstr.2<br />

73066 Uhingen<br />

Tel.: +49 7161 /98872-300<br />

Fax: +49 7161 /98872-303<br />

info@<br />

eltrotec.com<br />

www.eltrotec.com<br />

certified DIN EN ISO 9001 :2000<br />

modifications reserved /Eltrotec 02/07