UH Series - Mason Technology

UH Series - Mason Technology

UH Series - Mason Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

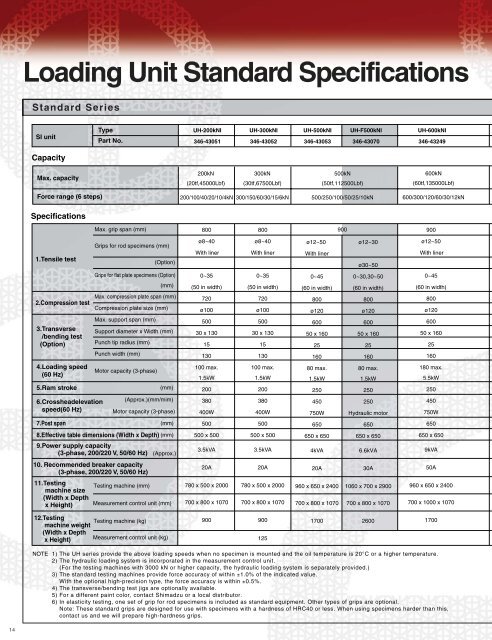

Loading Unit Standard Specifications<br />

Standard <strong>Series</strong><br />

SI unit<br />

Type<br />

Part No.<br />

<strong>UH</strong>-200kNI<br />

346-43051<br />

<strong>UH</strong>-300kNI<br />

346-43052<br />

<strong>UH</strong>-500kNI<br />

346-43053<br />

<strong>UH</strong>-F500kNI<br />

346-43070<br />

<strong>UH</strong>-600kNI<br />

346-43249<br />

Capacity<br />

Max. capacity<br />

200kN<br />

(20tf,45000Lbf)<br />

300kN<br />

(30tf,67500Lbf)<br />

500kN<br />

(50tf,112500Lbf)<br />

600kN<br />

(60tf,135000Lbf)<br />

Force range (6 steps)<br />

200/100/40/20/10/4kN 300/150/60/30/15/6kN<br />

500/250/100/50/25/10kN<br />

600/300/120/60/30/12kN<br />

Specifications<br />

Max. grip span (mm)<br />

800<br />

800<br />

900<br />

900<br />

1.Tensile test<br />

Grips for rod specimens (mm)<br />

(Option)<br />

ø8~40<br />

With liner<br />

ø8~40<br />

With liner<br />

ø12~50<br />

With liner<br />

ø12~30<br />

ø30~50<br />

ø12~50<br />

With liner<br />

Grips for flat plate specimens (Option)<br />

(mm)<br />

Max. compression plate span (mm)<br />

2.Compression test<br />

Compression plate size (mm)<br />

Max. support span (mm)<br />

3.Transverse<br />

/bending test<br />

(Option)<br />

4.Loading speed<br />

(60 Hz)<br />

5.Ram stroke<br />

6.Crossheadelevation<br />

speed(60 Hz)<br />

7.Post span<br />

Support diameter x Width (mm)<br />

Punch tip radius (mm)<br />

Punch width (mm)<br />

Motor capacity (3-phase)<br />

(mm)<br />

(Approx.)(mm/mim)<br />

Motor capacity (3-phase)<br />

(mm)<br />

0~35<br />

(50 in width)<br />

720<br />

ø100<br />

500<br />

30 x 130<br />

15<br />

130<br />

100 max.<br />

1.5kW<br />

200<br />

380<br />

400W<br />

500<br />

0~35<br />

(50 in width)<br />

720<br />

ø100<br />

500<br />

30 x 130<br />

15<br />

130<br />

100 max.<br />

1.5kW<br />

200<br />

380<br />

400W<br />

500<br />

0~45<br />

(60 in width)<br />

800<br />

ø120<br />

600<br />

50 x 160<br />

25<br />

160<br />

80 max.<br />

1.5kW<br />

250<br />

450<br />

750W<br />

650<br />

0~30,30~50<br />

(60 in width)<br />

800<br />

ø120<br />

600<br />

50 x 160<br />

25<br />

160<br />

80 max.<br />

1.5kW<br />

250<br />

250<br />

Hydraulic motor<br />

650<br />

0~45<br />

(60 in width)<br />

800<br />

ø120<br />

600<br />

50 x 160<br />

25<br />

160<br />

180 max.<br />

5.5kW<br />

250<br />

450<br />

750W<br />

650<br />

8.Effective table dimensions (Width x Depth) (mm)<br />

9.Power supply capacity<br />

(3-phase, 200/220 V, 50/60 Hz)<br />

(Approx.)<br />

500 x 500<br />

3.5kVA<br />

500 x 500<br />

3.5kVA<br />

650 x 650<br />

4kVA<br />

650 x 650<br />

6.6kVA<br />

650 x 650<br />

9kVA<br />

10. Recommended breaker capacity<br />

(3-phase, 200/220 V, 50/60 Hz)<br />

20A<br />

20A<br />

20A<br />

30A<br />

50A<br />

11.Testing<br />

machine size<br />

(Width x Depth<br />

x Height)<br />

Testing machine (mm)<br />

Measurement control unit (mm)<br />

780 x 500 x 2000<br />

700 x 800 x 1070<br />

780 x 500 x 2000<br />

700 x 800 x 1070<br />

960 x 650 x 2400<br />

700 x 800 x 1070<br />

1060 x 700 x 2900<br />

700 x 800 x 1070<br />

960 x 650 x 2400<br />

700 x 1000 x 1070<br />

12.Testing<br />

machine weight<br />

(Width x Depth<br />

x Height)<br />

Testing machine (kg)<br />

Measurement control unit (kg)<br />

900<br />

900<br />

125<br />

1700<br />

2600<br />

1700<br />

NOTE<br />

1) The <strong>UH</strong> series provide the above loading speeds when no specimen is mounted and the oil temperature is 20°C or a higher temperature.<br />

2) The hydraulic loading system is incorporated in the measurement control unit.<br />

(For the testing machines with 3000 kN or higher capacity, the hydraulic loading system is separately provided.)<br />

3) The standard testing machines provide force accuracy of within ±1.0% of the indicated value.<br />

With the optional high-precision type, the force accuracy is within ±0.5%.<br />

4) The transverse/bending test jigs are optionally available.<br />

5) For a different paint color, contact Shimadzu or a local distributor.<br />

6) In elasticity testing, one set of grip for rod specimens is included as standard equipment. Other types of grips are optional.<br />

Note: These standard grips are designed for use with specimens with a hardness of HRC40 or less. When using specimens harder than this,<br />

contact us and we will prepare high-hardness grips.<br />

14