Untitled - Produkt

Untitled - Produkt

Untitled - Produkt

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

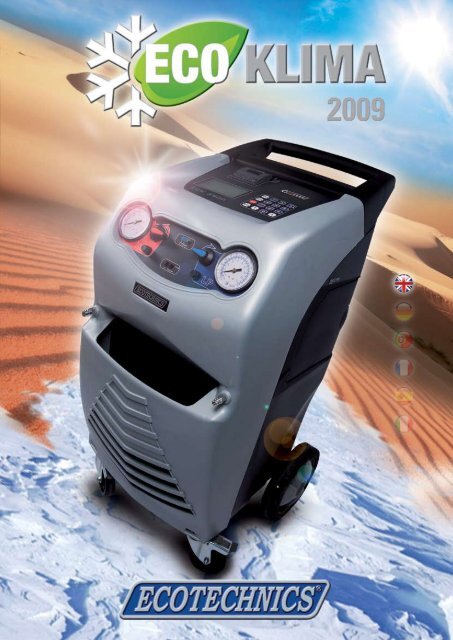

Ecotechnics was founded in 1995 with the aim of producing technologically<br />

advanced systems for today’s auto repair shop.<br />

The Ecotechnics product range is strictly aligned with new repair shop<br />

working philosophy: less direct intervention on the engine and better<br />

service exploiting new environment-friendly processes.<br />

In just a few years, Ecotechnics has become a world leader in the airconditioning<br />

sector, boasting a technical staff that develops new products,<br />

new design content, and new-model patents and prototypes<br />

in-house, and a spacious showroom and spaces for technical training<br />

courses and practical demonstrations on vehicles.<br />

All this is supported by close ties with the automobile manufacturers,<br />

whose precious collaboration has helped Ecotechnics to generate<br />

ideas and products tailored for the new-generation automobiles<br />

and coordinated with the new working parametres applied in modern<br />

repair shops.<br />

Continuing investment in Research and Development, an efficient<br />

production cycle, a never-ending search for perfection in assembly of<br />

its products, and use of only premier-quality components has made<br />

the Ecotechnics brand name a byword at the world level.<br />

Another Ecotechnics accent is on Quality Control. All our machines are<br />

rigorously checked by automatic testing programs and a staff of specialized<br />

test technicians, who with the aid of sophisticated computerized<br />

diagnostic systems check each single function to verify that each machine<br />

is in perfect operating condition when it leaves the factory.<br />

These are the simple but fundamental parametres on which company<br />

philosophy is based. And it is this philosophy that has made Ecotechnics<br />

a world leader in its sector in such a short time. Ecotechnics products are<br />

now distributed in over 50 countries throughout the world.

Function Table<br />

news<br />

ECK 3900<br />

ECK 2900<br />

ECK 1900<br />

ECK 1000<br />

ECK 750<br />

TRUCK EV.<br />

TRUCK CV<br />

Recovery<br />

A A A A A A A<br />

Oil discharge<br />

A A A A A A A<br />

Vacuum<br />

A A A A A A A<br />

Tracer<br />

Oil reintegration<br />

Gas charging<br />

High precision<br />

USB port<br />

A A* – A* – A* –<br />

A A M A M A M<br />

A A A A A A A<br />

X X – – – – –<br />

– X X X – – –<br />

A new<br />

Ecoklima line<br />

featuring new<br />

functions and<br />

a fully restyled<br />

new look.<br />

Injection-molded<br />

plastic housing.<br />

SANI<br />

SANIFLUX is the first<br />

purification system ever<br />

integrated into an A/C<br />

recharging station.<br />

<br />

Refrigerant<br />

management<br />

X X X – – – –<br />

Simplified refrigerant<br />

management<br />

Graphic display<br />

– – – X * – *<br />

X – – – – – –<br />

The A/C system<br />

diagnosis module<br />

is fully integrated<br />

with the recharging<br />

station.<br />

Data Base Basic<br />

– – – X * – –<br />

Data Base Advanced<br />

X X X * – – *<br />

Refrigerant identifier<br />

* – – – – – –<br />

A/C diagnosis<br />

Static A/C diagnosis<br />

Air purge<br />

Self-diagnosis<br />

Leak check<br />

Filling on-board bottle<br />

Bottle alarm<br />

Printer<br />

Update via serial port<br />

Service alarm<br />

Nitrogen bottle<br />

connector<br />

* * * * – – –<br />

– * * * – – *<br />

A A M M M A M<br />

X – – – – – –<br />

A A A/M A/M M A A/M<br />

A A A A M A A<br />

X X X X X X X<br />

X X * X * X *<br />

X X X X X X X<br />

A A A A A A A<br />

X * – – – – –<br />

Sealed tracer cartridge<br />

with special connector<br />

• Full protection against ambient humidity<br />

• Certainty of full product efficiency<br />

• Inalterability of properties; long shelf life.<br />

90 Kg<br />

Flushing software X X X X – – X<br />

Saniflux<br />

* * * * – – –<br />

A Automatic M Manual X Series – Not Available * Optional<br />

105 cm<br />

122 cm<br />

Information regarding dimensions, data, models, and colors is not binding. Ecotechnics reserves the right to make<br />

any modifications deemed necessary. The products are not covered by any other express or implicit warranties.<br />

<br />

55 cm<br />

60 cm<br />

69 cm<br />

70 cm

A/C SERVICE<br />

Ecotechnics<br />

and high-precision<br />

technology<br />

1<br />

THE ONLY COMPANY WORLDWIDE<br />

The first purification<br />

system integrated<br />

in an A/C recharging station<br />

SANI<br />

<br />

2<br />

Thanks to years of investment and research in the<br />

climate-control sector, Ecotechnics has developed<br />

a unique technology that has made it possible to<br />

create a whole new range of machines with special<br />

features; in fact, Ecotechnics is the only European<br />

manufacturer to have obtained certification under<br />

the strict American SAE J-2788 standards.<br />

Technology Specifications<br />

THE PROBLEM<br />

DAMP + COLD + DARK<br />

FORMATION OF:<br />

BACTERIA + MOLD + ODORS<br />

PERSISTENT, ANNOYING ODORS<br />

ALLERGENS AND IRRITANTS<br />

(under SAE J-2788):<br />

THE SOLUTION<br />

1 Stations must recover at least 95% of the<br />

gas contained in the A/C system in particularly<br />

challenging conditions (low temperature and<br />

flooded systems). The majority of the machines<br />

currently available on the market cannot comply<br />

with these specifications.<br />

Recovering 95% ca. of the gas means:<br />

A. Increasing profitability and productivity at every<br />

vehicle service interval.<br />

B. Faster return on investment.<br />

REFRIGERANT<br />

RECHARGING SYSTEM<br />

COMBINED SYSTEM<br />

HOW DOES IT WORK<br />

• Operation is fully controlled<br />

by the A/C charging station<br />

• Fully integrated, automatic operation<br />

• No operator intervention required<br />

PASSENGER COMPARTMENT<br />

AIR PURIFICATION SYSTEM<br />

SANI<br />

SANI<br />

• Ultrasound nebulization of the product<br />

• Complete service in 30 to 35 minutes<br />

• Certified purification liquid<br />

2 Stations must charge with a tolerance of 14 g<br />

(1/2 oz). Our test results show that the tolerance<br />

for certain machines now in use exceeds 50 g.<br />

Better tolerance means:<br />

A. The newer A/C systems are increasingly compact<br />

and use smaller quantities of refrigerant; for this<br />

reason, it is essential to respect manufacturer’s<br />

tolerances since system efficiency is strictly<br />

correlated with precision charging of the correct<br />

quantity of refrigerant gas.<br />

B. Avoiding customer complaints that may<br />

arise from charging erroneous quantities of<br />

refrigerant.

OFFERING 4 SERVICE OPTIONS IN A SINGLE A/C STATION<br />

Patented Ecotechnics<br />

Flushing Kit<br />

2<br />

1<br />

Patented<br />

3 4<br />

diagnosis system<br />

incorporated in<br />

the recycling<br />

stations<br />

Patent No.: EP 1177924 US 6,629,420<br />

Diagnosis is an increasingly critical tool for anyone -<br />

climate-control specialists and not -wanting to expand<br />

their business to include A/C system repair.<br />

2<br />

1<br />

PATENT PENDING<br />

ALL THE ADVANTAGES<br />

• Easy to use<br />

• Fast, accurate diagnosis of problems<br />

• Printout of diagnosis and possible remedial actions<br />

• Reliability<br />

• Cost savings, thanks to perfect station integration.<br />

1<br />

Why flush an A/C system<br />

• The compressor is a moving mechanical organ, and as such is subject to wear<br />

and - in time - to failure.<br />

• For correct repair in the case of compressor failure, it is essential to remove any<br />

metal shavings that may have accumulated inside the system - and which could<br />

jeopardize good operation - before the new compressor is installed.<br />

• Many compressor manufacturers void their warranties on the new component<br />

if the A/C system is not cleaned, using a suitable flushing system,<br />

before the component is installed.<br />

Novelties<br />

• The kit does not use solvents, only refrigerant for flushing.<br />

• Thanks to the vacuum bottle, the kit guarantees complete, safe removal of all<br />

metal shavings.<br />

• The vacuum in the bottle produces a “ramrod” effect, forcing the refrigerant<br />

through any obstructions in the system.<br />

All the Advantages<br />

• Speeds up the flushing procedure, for considerable time-saving.<br />

• The operator is free to do other work while the machine flushes the system.<br />

• Environmentally friendly.<br />

• Full automation if used with Ecotechnics stations equipped with dedicated<br />

software.<br />

• May be used with other charging stations (in the manual mode).<br />

• Since only refrigerant is used, flushing introduces no humidity into the A/C system.<br />

• Since no solvents are used, the kit complies with OEM manufacturers’ standards.<br />

• Safe and easy to use.<br />

Standard equipment<br />

Adapters carry-case<br />

5-liter bottle.<br />

Optional features<br />

Metal support: AEK102-N7-R2.<br />

VW adapter: AEK102-N7-R1.<br />

2<br />

Static Diagnosis<br />

This type of diagnosis utilizes the pressure and<br />

temperature values entered by the operator from<br />

the station pressure gauges and the thermometer,<br />

supplied as standard equipment.<br />

<br />

Dynamic Diagnosis<br />

With the pressure and temperature sensors<br />

connected to the system, analysis is fully automatic<br />

and conducted in real time for the entire duration of<br />

measurement.<br />

Sherlock 2000 CLIMA TESTER<br />

AEK102-N7<br />

AEK102-N7-R1<br />

AEK102-N7-R2

ECK 3900<br />

Fully automatic single-gas station for recovering,<br />

recycling, and recharging R134 refrigerant,<br />

compliant with SAE J-2788 standard.<br />

AUTOMATIC FUNCTIONS:<br />

RECOVERY<br />

OIL<br />

DISCHARGE<br />

VACUUM<br />

TRACER<br />

OIL REINTE-<br />

GRATION<br />

GAS<br />

CHARGING<br />

STANDARD FEATURES<br />

• SELF-DIAGNOSIS: automatic for each onboard solenoid valve.<br />

• LEAK TEST: automatic during the vacuum phase.<br />

• NITROGEN BOTTLE CONNECTOR (bottle not included): the station<br />

automatically charges the A/C system with nitrogen and checks for leaks,<br />

monitoring pressure drops and giving a leak alarm.<br />

• AUTOMATIC DISCHARGE of non-condensable gases from the bottle.<br />

• ONBOARD BOTTLE FILLING: automatic.<br />

• SERVICE ALARM: acoustic and visual, for maintenance and filter<br />

replacement request.<br />

• REFRIGERANT MANAGEMENT: for creating a customized archive of all<br />

refrigerant transactions.<br />

• OPERATOR CODE: for assigning an operator password to protect against<br />

unauthorized use of the station.<br />

• DISTRIBUTOR GROUP: built-in, patented unit optimized for top<br />

performance and dependability.<br />

• DATABASE ADVANCED: integrated database allowing the user to enter new<br />

vehicle models.<br />

• AUTOMATIC TRACER with collapsible cartridges.<br />

• FLUSHING SOFTWARE for automatic flushing of series A/C systems. For<br />

use with AEK102-N7.<br />

• SOFTWARE UPDATE: via Internet and RS-232 serial port.<br />

OPTIONS<br />

SANIFLUX (SANI+): the first sanitizing<br />

system integrated in an A/C charging<br />

station (green station body with this<br />

option).<br />

SANI<br />

<br />

XK702A000002 STANDARD VERSION<br />

Type of refrigerant R134a<br />

Service procedure Fully automatic or manual<br />

Voltage<br />

220-240 V - 50/60 Hz<br />

Scale resolution 10 g<br />

Oil scale resolution 5 g<br />

Working temperature range 11/49°C<br />

Filter system 2 filters for humidity<br />

Vacuum pump 115 liter/min capacity, 0.1 mbar vacuum level<br />

Sealed compressor 12 cc, high-pressure<br />

Recovery speed 300 g/min in liquid phase<br />

Refrigerant bottle 22 litres, refillable<br />

Hoses<br />

3 metres<br />

Overall size<br />

55 x 60 x 105 cm<br />

Weight<br />

90 kg<br />

Thermal printer Standard equipment<br />

Pressure sensors Class 1<br />

Pressure gauges Class 1<br />

Display<br />

Graphic<br />

Bottle temperature sensor Integrated<br />

Bottle heater Automatic<br />

<br />

FLUSHING KIT (AEK102-N7): for flushing<br />

the A/C system with refrigerant. External<br />

bottle and metal adapters included.<br />

A/C DIAGNOSIS MODULE (DIAKIT):<br />

integrated, for all types of A/C systems,<br />

featuring printout of diagnosis and<br />

problem solution.<br />

GAS IDENTIFIER MODULE<br />

(XS160.000000) featuring printout of<br />

analysis results.

Fully automatic single-gas station for recovering,<br />

recycling, and recharging R134 refrigerant,<br />

compliant with SAE J-2788 standard.<br />

ECK 2900<br />

AUTOMATIC FUNCTIONS:<br />

RECOVERY<br />

OIL<br />

DISCHARGE<br />

Vacuum<br />

TRACER<br />

optional<br />

OIL REINTE-<br />

GRATION<br />

GAS<br />

CHARGING<br />

STANDARD FEATURES<br />

• LEAK TEST: automatic during the vacuum phase.<br />

• ONBOARD BOTTLE FILLING: automatic.<br />

• AUTOMATIC DISCHARGE of non-condensable gases from the bottle.<br />

• SERVICE ALARM: acoustic and visual, for maintenance and filter<br />

replacement request.<br />

• USB PORT for software updates.<br />

• REFRIGERANT MANAGEMENT: for creating a customized archive of all<br />

refrigerant transactions.<br />

• OPERATOR CODE: for assigning an operator password to protect against<br />

unauthorized use of the station.<br />

• DISTRIBUTOR GROUP: built-in, patented unit optimized for top<br />

performance and dependability.<br />

• DATABASE ADVANCED: integrated database allowing the user to enter new<br />

vehicle models.<br />

• FLUSHING SOFTWARE for automatic flushing of series A/C systems. For<br />

use with AEK102-N7.<br />

OPTIONS<br />

SANIFLUX (SANI+): the first sanitizing<br />

system integrated in an A/C charging<br />

station (green station body with this<br />

option).<br />

SANI<br />

<br />

FLUSHING KIT (AEK102-N7): for flushing<br />

the A/C system with refrigerant. External<br />

bottle and metal adapters included.<br />

A/C DIAGNOSIS MODULE (DIAKIT):<br />

integrated, for all types of A/C systems,<br />

featuring printout of diagnosis and<br />

problem solution.<br />

AUTOMATIC TRACER KIT (UVKIT-7)<br />

featuring collapsible cartridges.<br />

NITROGEN BOTTLE CONNECTOR (N2)<br />

(bottle not included): the station<br />

automatically charges the A/C system with<br />

nitrogen and checks for leaks, monitoring<br />

pressure drops and giving a leak alarm.<br />

STATIC DIAGNOSIS KIT (KITSTA001.00)<br />

for diagnosing A/C systems.<br />

<br />

XK770A000000 STANDARD VERSION<br />

Type of refrigerant R134a<br />

Service procedure Fully automatic or manual<br />

Voltage<br />

220-240 V - 50/60 Hz<br />

Scale resolution 10 g<br />

Oil scale resolution 5 g<br />

Working temperature range 11/49°C<br />

Filter system 2 filters for humidity<br />

Vacuum pump 115 liter/min capacity, 0.1 mbar vacuum level<br />

Sealed compressor 12 cc, high-pressure<br />

Recovery speed 300 g/min in liquid phase<br />

Refrigerant bottle 22 litres, refillable<br />

Hoses<br />

3 metres<br />

Overall size<br />

55 x 60 x 105 cm<br />

Weight<br />

90 kg<br />

Thermal printer Standard equipment<br />

Pressure gauges Class 1<br />

Display<br />

LCD<br />

Bottle temperature sensor Integrated<br />

Bottle heater Automatic

ECK 1900<br />

Automatic single-gas station for<br />

recovering, recycling, and recharging<br />

R134 refrigerant.<br />

AUTOMATIC FUNCTIONS:<br />

RECOVERY<br />

OIL<br />

DISCHARGE<br />

Vacuum<br />

GAS<br />

CHARGING<br />

STANDARD FEATURES<br />

• SERVICE ALARM: acoustic and visual, for maintenance and filter<br />

replacement request.<br />

• ONBOARD BOTTLE FILLING: automatic.<br />

• REFRIGERANT MANAGEMENT: for creating a customized archive<br />

of all refrigerant transactions.<br />

• OPERATOR CODE: for assigning an operator password to protect against<br />

unauthorized use of the station.<br />

• FLUSHING SOFTWARE for automatic flushing of series A/C systems. For<br />

use with AEK102-N7.<br />

• GUIDED LEAK TEST: permits programming a delay time after the vacuum<br />

phase to conduct visual inspection for leaks by checking the pressure<br />

gauges.<br />

• DISTRIBUTOR GROUP: built-in, patented unit optimized for top<br />

performance and dependability.<br />

• DATABASE ADVANCED: for immediate availability of vehicle refrigerant<br />

capacity data.<br />

• USB PORT for software updates.<br />

OPTIONS<br />

SANIFLUX (SANI+): the first sanitizing<br />

system integrated in an A/C charging<br />

station (green station body with this<br />

option). For use with printer.<br />

SANI<br />

<br />

FLUSHING KIT (AEK102-N7): for flushing<br />

the A/C system with refrigerant. External<br />

bottle and metal adapters included.<br />

XK730A000000 STANDARD VERSION<br />

Type of refrigerant R134a<br />

Service procedure Automatic or manual<br />

Voltage<br />

220-240 V - 50/60 Hz<br />

Scale resolution 10 g<br />

Working temperature range 11/49°C<br />

Filter system 2 filters for humidity<br />

Vacuum pump 115 liter/min capacity, 0.1 mbar vacuum level<br />

Sealed compressor 12 cc, high-pressure<br />

Recovery speed 300 g/min in liquid phase<br />

Refrigerant bottle 22 litres, refillable<br />

Hoses<br />

3 metres<br />

Overall size<br />

55 x 60 x 105 cm<br />

Weight<br />

90 kg<br />

Thermal printer Optional<br />

Pressure gauges Class 1<br />

Bottle pressure gauge Class 2.5<br />

Display<br />

LCD<br />

Bottle temperature sensor Integrated<br />

Bottle heater Automatic<br />

<br />

A/C DIAGNOSIS MODULE:(DIAKIT)<br />

integrated, for all types of A/C systems,<br />

featuring printout of diagnosis and<br />

problem solution. For use with printer.<br />

STATIC DIAGNOSIS KIT (KITSTA001.00)<br />

(for use with printer) for diagnosing A/C<br />

systems.<br />

THERMAL PRINTER (STM0006):<br />

provides a complete report of station<br />

operations.

Fully automatic single-gas station for<br />

recovering, recycling, and recharging R134<br />

refrigerant.<br />

ECK 1000<br />

AUTOMATIC FUNCTIONS:<br />

RECOVERY<br />

OIL<br />

DISCHARGE<br />

Vacuum<br />

TRACER<br />

optional<br />

OIL REINTE-<br />

GRATION<br />

GAS<br />

CHARGING<br />

STANDARD FEATURES<br />

• SERVICE ALARM: automatically informs the user when the filters require<br />

replacement.<br />

• SIMPLIFIED REFRIGERANT MANAGEMENT: by printing the report at the end of<br />

each recharging operation, the residual refrigerant in the bottle can be displayed<br />

for refrigerant transaction accounting<br />

• FLUSHING SOFTWARE for automatic flushing of series A/C systems. For use<br />

with AEK102-N7.<br />

• GUIDED LEAK TEST: permits programming a delay time after the vacuum phase<br />

to conduct visual inspection for leaks by checking the pressure gauges.<br />

• DISTRIBUTOR GROUP: built-in, patented unit optimized for top performance and<br />

dependability.<br />

• DATABASE BASIC for immediate availability of vehicle refrigerant capacity data.<br />

• USB PORT for software updates.<br />

OPTIONS<br />

SANIFLUX (SANI+): the first sanitizing<br />

system integrated in an A/C charging<br />

station.<br />

SANI<br />

<br />

FLUSHING KIT (AEK102-N7): for flushing<br />

the A/C system with refrigerant. External<br />

bottle and metal adapters included.<br />

A/C DIAGNOSIS MODULE (DIAKIT):<br />

integrated, for all types of A/C systems,<br />

featuring printout of diagnosis and<br />

problem solution.<br />

STATIC DIAGNOSIS KIT (KITSTA001.00)<br />

for diagnosing A/C systems.<br />

AUTOMATIC TRACER KIT (UVKIT-7)<br />

featuring collapsible cartridges for<br />

injecting a predetermined quantity of<br />

tracer.<br />

DATABASE ADVANCED (KITDB002.09):<br />

integrated database featuring the option<br />

of modifying user data.<br />

<br />

XK790B000000 STANDARD VERSION<br />

Type of refrigerant R134a<br />

Service procedure Fully automatic or manual<br />

Voltage<br />

220-240 V - 50/60 Hz<br />

Scale resolution 10 g<br />

Oil scale resolution 5 g<br />

Working temperature range 11/49°C<br />

Filter system 2 filters for humidity<br />

Vacuum pump 92 liter/min capacity, 0.1 mbar vacuum level<br />

Sealed compressor 12 cc, high-pressure<br />

Recovery speed 300 g/min in liquid phase<br />

Refrigerant bottle 12 litres, refillable<br />

Hoses<br />

3 metres<br />

Overall size<br />

55 x 60 x 105 cm<br />

Weight<br />

90 kg<br />

Thermal printer Standard equipment<br />

Pressure gauges Class 1<br />

Bottle pressure gauge Class 2.5<br />

Display<br />

LCD<br />

Bottle temperature sensor Integrated<br />

Bottle heater Automatic

ECK 750<br />

Automatic single-gas station for<br />

recovering, recycling, and recharging<br />

R134 refrigerant.<br />

AUTOMATIC FUNCTIONS:<br />

RECOVERY<br />

OIL<br />

DISCHARGE<br />

Vacuum<br />

GAS<br />

CHARGING<br />

STANDARD FEATURES<br />

• ALARMS: high pressure, full bottle, empty bottle.<br />

• SERVICE ALARM: acoustic and visual, for maintenance and filter<br />

replacement request.<br />

• SIMPLIFIED REFRIGERANT MANAGEMENT (for use with printer): by<br />

printing the report at the end of each recharging operation, the residual<br />

refrigerant in the bottle can be displayed for refrigerant transaction<br />

accounting<br />

• VACUUM PUMP: high performance, with acoustic signaling of end of<br />

vacuum.<br />

• DISTRIBUTOR GROUP: built-in, patented unit optimized for top performance<br />

and dependability.<br />

• SOFTWARE UPDATE: via Internet and RS-232 serial port.<br />

OPTIONS<br />

XK760B000000 STANDARD VERSION<br />

Type of refrigerant R134a<br />

Service procedure Automatic or manual<br />

Voltage<br />

220-240 V - 50/60 Hz<br />

Scale resolution 10 g<br />

Working temperature range 11/49°C<br />

Filter system 2 filters for humidity<br />

Vacuum pump 92 liter/min capacity, 0.1 mbar vacuum level<br />

Sealed compressor 12 cc, high-pressure<br />

Recovery speed 300 g/min in liquid phase<br />

Refrigerant bottle 12 litres, refillable<br />

Hoses<br />

3 metres<br />

Overall size<br />

55 x 60 x 105 cm<br />

Weight<br />

90 kg<br />

Thermal printer Optional<br />

Pressure gauges Class 1<br />

Bottle pressure gauge Class 2.5<br />

Display<br />

LED<br />

Bottle temperature sensor Integrated<br />

Bottle heater Automatic<br />

10<br />

DATABASE BASIC (KITDB001.09):<br />

Coded, integrated database for<br />

immediate availability of vehicle A/C<br />

system refrigerant capacity data.<br />

THERMAL PRINTER (STM0004):<br />

provides a complete report of station<br />

operations.

Fully automatic single-gas station for recovering,<br />

recycling, and recharging R134 refrigerant,<br />

for use with buses and industrial vehicles<br />

AUTOMATIC FUNCTIONS:<br />

ECK Truck<br />

Evolution<br />

RECOVERY<br />

OIL<br />

DISCHARGE<br />

Vacuum<br />

TRACER<br />

optional<br />

OIL REINTE-<br />

GRATION<br />

GAS<br />

CHARGING<br />

STANDARD FEATURES<br />

• ALARMS: high pressure, full bottle, empty bottle.<br />

• SERVICE ALARM: acoustic and visual, for maintenance and filter<br />

replacement request.<br />

• ONBOARD BOTTLE FILLING: automatic.<br />

• AUTOMATIC LEAK check during vacuum phase<br />

• DISTRIBUTOR GROUP: built-in, patented unit optimized for top performance<br />

and dependability.<br />

• AUTOMATIC DISCHARGE of non-condensable gases from the bottle.<br />

• GEAR PUMP for refrigerant charging.<br />

• SOFTWARE UPDATE: via Internet and RS-232 serial port.<br />

OPTIONS<br />

AUTOMATIC TRACER (UVKIT-4)<br />

AVAILABLE VERSION<br />

(XK150.000010)<br />

with external scale for 40-liter bottles<br />

XK150.000000 STANDARD VERSION<br />

Type of refrigerant R134a<br />

Service procedure Fully automatic or manual<br />

Voltage<br />

220-240 V - 50/60 Hz<br />

Scale resolution 20 g<br />

Oil scale resolution 5 g<br />

Working temperature range 11/49°C<br />

Filter system 2 filters for humidity<br />

Vacuum pump 170 liter/min capacity, 0.1 mbar vacuum level<br />

Sealed compressor 21 cc, high-pressure<br />

Gear pump<br />

1 kg/min capacity<br />

Refrigerant bottle 27 litres, refillable<br />

Hoses<br />

3 metres<br />

Overall size<br />

50 x 50 x 115 cm<br />

Weight<br />

100 kg<br />

Thermal printer Standard equipment<br />

Display<br />

LCD<br />

Bottle temperature sensor Integrated<br />

Pressure sensors Class 1<br />

Bottle heater Automatic<br />

11

ECK Truck CV-N8<br />

<br />

12

Sherlock 2000<br />

XS100.000000<br />

Data Base Online<br />

COD. DBK001<br />

A patented<br />

diagnostics system<br />

for determining<br />

the causes of<br />

malfunctions in<br />

any A/C system<br />

through analysis<br />

of pressures and<br />

temperatures.<br />

PATENTED<br />

TYPES OF REFRIGERANT R134a and R12<br />

TYPES OF SYSTEMS Traditional, flooded, and continual cutin<br />

flooded systems.<br />

2 MINUTES for results.<br />

DIAGNOSIS PRINTOUT complete with data, graphs, and<br />

solution for the problem.<br />

EXAMPLES OF DIAGNOSIS<br />

- No refrigerant in system<br />

- Defroster pressure switch<br />

- Clogged intake line<br />

- Refrigerant low<br />

- Capillary valve<br />

- Clogged condenser or hose<br />

- Air flow to evaporator<br />

- System OK<br />

- Excess refrigerant<br />

- Incorrect condenser airflow<br />

- Air in system<br />

- Check mixing door<br />

- High and low pressures inverted<br />

- Pulley does not engage<br />

- Replace compressor<br />

SOFTWARE UPDATES via Internet, RS232 serial port.<br />

All the advantages of the new Data Base<br />

Online service:<br />

• Up-to-the-minute data on refrigerant quantities, wiring<br />

diagrams, and the positions of service connections.<br />

• For any data not available, just send an update request:<br />

the requested datum will be made rapidly available on<br />

the website.<br />

• The data requested may be printed.<br />

• Easy to use.<br />

Refrigerant types<br />

Voltage<br />

Hoses<br />

Instrument dimensions<br />

Instrument weight<br />

Case dimensions<br />

Full case weight<br />

Data<br />

report<br />

Color<br />

graphics<br />

Diagnosis<br />

report<br />

Color print<br />

option<br />

R12 and R 134a<br />

12V (automobile battery)<br />

1,5 metres<br />

350 x 160 x 120 mm<br />

1,5 kg<br />

480 x 370 x 180 mm<br />

3 kg<br />

Sherlock PC – PC INTERFACE<br />

with the “Sherlock PC” program<br />

Data Base Basic<br />

COD. KITDB001.09<br />

Data Base Advanced<br />

13<br />

COD. KITDB002.09

Leak Detection Products & Consumables<br />

‹<br />

AEK203<br />

Cobra kit HD<br />

Leak detector kit<br />

for A/C circuits<br />

including: goggles,<br />

UV lamp,<br />

hermetic dye<br />

cartridge (55ml),<br />

injector.<br />

‹<br />

AEK107-3<br />

Electronic<br />

leak<br />

Detection:<br />

a single instrument<br />

for identifying<br />

all halogen<br />

gases, including<br />

CFC, HCFC, HFC<br />

‹<br />

AEK145-4<br />

COBRA BOTTLE<br />

KIT - Leak detection<br />

kit for A/C<br />

circuits, including:<br />

UV lamp, goggles,<br />

6 bottles (7.4 ml<br />

each) of tracer,<br />

injector, 1 bottle<br />

(120 ml) tracer dye<br />

cleaner liquid<br />

‹<br />

AEK107-6<br />

Electronic<br />

leak<br />

detector<br />

for combustible<br />

gases (50-1000<br />

ppm) ideal for<br />

Nitrogen +<br />

Hydrogen mix<br />

‹<br />

AEK145<br />

Cobra lamp +<br />

safety goggles<br />

‹<br />

AEK147<br />

Rechargeable<br />

UV lamp 12V,<br />

50W<br />

‹<br />

AEK146<br />

Tracer injection<br />

gun, including 1<br />

bottle of universal<br />

tracer (64<br />

applications), hose<br />

and connection for<br />

R134a, high-pressure<br />

adapter, air<br />

purge connector<br />

‹<br />

AEK160<br />

Air Fresh<br />

Deodorant spray<br />

Box of 5 sealed<br />

‹ bottles of tracer<br />

AEK203-C-5 (55 ml)<br />

‹<br />

AEK161<br />

DYE CLEANER<br />

Liquid detergent<br />

for tracer (474<br />

ml)<br />

Box of 6 bottles<br />

‹ of AC POE oil<br />

AEK125-1-6 (237 ml)<br />

‹<br />

AEK126-2<br />

350-ml bottle of<br />

universal tracer<br />

‹<br />

AEK204-H-5<br />

Box of 5 sealed<br />

bottles of oil for<br />

hybrid vehicles<br />

(55 ml)<br />

‹<br />

PMP 3330<br />

Oil for vacuum<br />

pump (350 ml)<br />

Box of 6 sealed<br />

‹ bottles of tracer<br />

AEK126-3-6 (125 ml)<br />

Saniflux liquid<br />

Box of 10 ‹<br />

AEK222-10 bottles (125 ml)<br />

‹<br />

AEK133<br />

Package of 12<br />

vials (7.4 ml<br />

each)

A/C Accessories<br />

‹<br />

XK183.000000<br />

EASYREC<br />

Refrigerant recovery unit<br />

- It works with all refrigerants<br />

- Compressor type: oil less<br />

- Air cooled<br />

- It works with gas and liquid refrigerant<br />

- Recovery rate (vapour): 17 kg/h<br />

- Recovery rate (liquid): 50 kg/h<br />

- Recovery rate (push-pull): 240 kg/h<br />

Easyrec plus<br />

Identical to Easyrec,<br />

‹ with carrycase<br />

XK183.000039 for hoses and couplings<br />

R12/R134a<br />

‹<br />

XA100.000000<br />

‹<br />

AEK204<br />

Vacuum and charging station<br />

- Vacuum and charging station<br />

designed and manufactured by<br />

Ecotechnics<br />

- Compact, easy to handle and to<br />

operate<br />

- Equipped with 4 wheels and a pocket<br />

for an electronic scale (not included)<br />

- 2 ways manifold<br />

- Large pressure gauges<br />

- 92 L/min vacuum pump<br />

Oil kit for hybrid<br />

vehicles<br />

including cartridge oil for<br />

hybrid vehicles (55 ml),<br />

injector<br />

‹<br />

CNT4010<br />

‹<br />

AEK120-E<br />

‹<br />

AEK221<br />

40-liter bottle for R134a,<br />

R22, R404a, R507,<br />

R407C<br />

Digital thermometer<br />

Laser thermometer<br />

‹<br />

AEK505<br />

Pressure-gauge group<br />

with 4-way diaphragm<br />

valve<br />

‹<br />

AEK220<br />

Digital thermometer<br />

with probe<br />

‹<br />

AEK500<br />

Pressure-gauge group<br />

with 2-way diaphragm<br />

valve<br />

‹<br />

AEK303<br />

Digital vacuum<br />

meter<br />

- Range 0-12000 microns<br />

+<br />

‹<br />

AEK515<br />

AEK525<br />

AEK535<br />

‹<br />

TUB1158<br />

‹<br />

TUB1168<br />

‹<br />

AEK114<br />

‹<br />

AEK116<br />

‹<br />

AEK116-1<br />

‹<br />

AEK118<br />

Set of flexible hoses<br />

90 cm<br />

150 cm<br />

180 cm<br />

6-m service hose,<br />

low pressure<br />

6-m service hose,<br />

high pressure<br />

Pair of retrofit adapters<br />

Reducer fitting for bottle<br />

ACME hose reducer<br />

fitting for bottle<br />

Compressor vane comb<br />

‹<br />

AEK302<br />

‹<br />

AEK214<br />

‹<br />

AEK215<br />

‹<br />

AEK211<br />

‹<br />

AEK109A<br />

‹<br />

AEK109B<br />

Electronic scale<br />

- LCD Display<br />

- Max capacity: 100 kg<br />

- Resolution: 10 g<br />

- Accurate charging of +/-<br />

10 g% of readings<br />

- Operating temperature:<br />

-10°C / +50°C<br />

Cutter for rubber hoses<br />

Valve-extractor<br />

screwdriver<br />

Special quick-connect<br />

coupling<br />

Terminal valve, high<br />

pressure<br />

Terminal valve, low<br />

pressure

Ecotechnics S.p.A - Via L. Longo, 21/23 - 50019 Sesto F.no (FI)<br />

Tel. +39 055 4207372 - Fax +39 055 4217972<br />

www.ecotechnics.com email: ecotechnics@ecotechnics.com