Design Services - Progress Rail Services

Design Services - Progress Rail Services

Design Services - Progress Rail Services

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Vehicle & General Engineering Castings<br />

Permanent Way Track Materials<br />

Permanent Way Trackwork<br />

Cast Manganese Products<br />

<strong>Design</strong> <strong>Services</strong><br />

<strong>Design</strong>, Manufacture,<br />

Project Management and<br />

Global Supply Capability<br />

Switches & Crossings<br />

Permanent Way Switch Systems<br />

<strong>Design</strong> <strong>Services</strong><br />

Permanent Way Catenary Structures

Switches, Crossings and Turnout <strong>Design</strong><br />

We have a dedicated team of graduate and Chartered Engineers from<br />

mechanical, metallurgical and electrical backgrounds. We support our<br />

engineers in their membership of the IMechE and industry specific<br />

professional bodies<br />

Mechanical Analysis<br />

We assess product life cycle and expected performance, operation and<br />

maintenance requirements using a combination of classical mechanical<br />

analysis, Finite Element Analysis (FEA), practical testing and empirical<br />

data from over 100 years of manufacturing experience<br />

We undertake work for our own process and product development, but<br />

also deliver commissioned work for various clients in the UK and overseas<br />

We consider risk management a fundamental aspect of good design and<br />

follow ‘yellow book’ engineering safety management principles at the<br />

appropriate level for all product developments<br />

We design products using state-of-the-art 3D CAD software, considering<br />

mechanical integrity, potential failure modes and human interaction<br />

aspects before progressing to prototyping and testing<br />

Switch Performance Optimisation<br />

Our in house analysis tools allow us to fine tune the flexural behaviour of<br />

switches, minimising the thrust requirements and optimising the location<br />

and quantity of drive points. This process minimises the work done by the<br />

points operating equipment whilst ensuring closed switch fit and free wheel<br />

clearance are satisfactory under all operating conditions<br />

We also model customer’s current problems and derive mathematical<br />

models demonstrating the root causes and the potential remedies<br />

All of our products are supplied with operation and maintenance<br />

guidelines, developed with the end user in mind<br />

New Product Development<br />

The demands on the rail infrastructure continue to increase with faster trains and increased occupancy. To support this we are constantly driving ourselves<br />

to develop new products and allow our customers to meet these demands

<strong>Design</strong> <strong>Services</strong><br />

Visit us online at:<br />

www.progressrail.com<br />

Cast Manganese Products Modelling,<br />

Methods and Metallurgy<br />

3D modelling and FEA allow us to engineer all of our products more<br />

efficiently. From CNC controlled pattern making for cast manganese<br />

crossings (frogs) to Failure Mode and Effect Analysis (FMEA) to determine<br />

weaknesses in design<br />

Our current engineering processes revolve around 3D modelling to<br />

generate LEAN products with highly analysed performance characteristics<br />

3D modelling interfaces directly with our Computer Numerical Controlled<br />

(CNC) machines to offer a superior and repeatable quality product<br />

The casting process itself is a well established and highly controlled<br />

process. This control stems, in part, from 3D modelling the molten shape<br />

and the molten metal flow to ensure cooling rates and other parameters<br />

are within known tolerances to produce a high quality product<br />

Within our South Queensferry and Midland foundries we have qualified<br />

metallurgical engineers and are members of the Cast Metal Federation<br />

Complex Cast Manganese Solutions<br />

Our design engineers are qualified to high standards and are able to<br />

solve complex geometrical alignment problems facing many of the<br />

world’s railways<br />

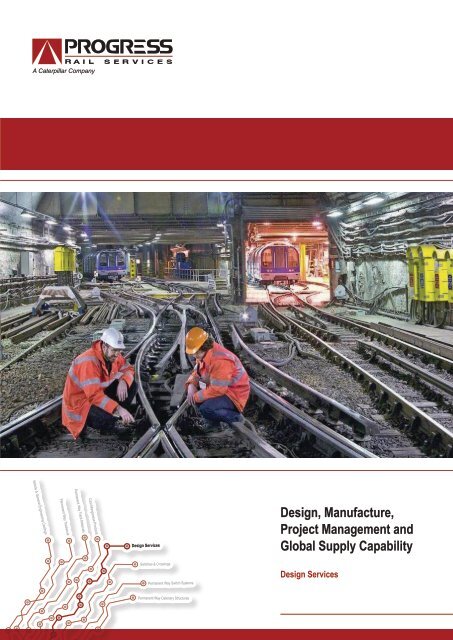

We undertake work regularly for London Underground and have also<br />

worked for various subterranean rail systems around the world where<br />

alignment is paramount. We have been involved in tunnel wall studies<br />

and modelling train paths to ensure clearance is within permitted levels<br />

Geometrical data is used to develop 3D models of cast manganese<br />

products and these models are used to create the wooden patterns used<br />

in the production of sand moulds for the casting process<br />

Molten Metal Modelling using Magma 5 Software<br />

Using Magma 5 software we simulate mould filling, solidification and<br />

cooling rates for different shape and complexity patterns<br />

This state-of-the-art analysis tool ensures that the molten metal witnesses<br />

directional solidification in order to eliminate the formation of shrinkage<br />

cavities within the casting<br />

We are also able to simulate metal entering the mould cavity using<br />

particle tracers, which move just like metal flow, allowing the identification<br />

and elimination of high and low velocities during mould filling which can<br />

lead to the formation of casting defects , oxide films and inclusions<br />

References<br />

Our <strong>Design</strong> <strong>Services</strong> team have undertaken work for customers in:<br />

• Commissioned <strong>Design</strong> and Standards work in the UK, USA and Australia<br />

• Trackwork and Cast Manganese Crossings (Frogs) designed and supplied to worldwide customers

Visit us online at:<br />

www.progressrail.com<br />

DET NORSKE VERITAS AUDITED<br />

• ISO 9001-2008<br />

• ISO14001-2004<br />

• ISO18001-2007<br />

<strong>Progress</strong> <strong>Rail</strong> <strong>Services</strong> UK Ltd Sites<br />

South Queensferry<br />

Headrig Road, South<br />

Queensferry, Scotland<br />

Closest Airport : Edinburgh (EDI)<br />

- 7 Miles from site<br />

Darlington<br />

Dumfries Street,<br />

Darlington, England<br />

Closest Airport : Durham Tees (MME)<br />

- 6 Miles from site<br />

Sheffield<br />

Shepcote Lane,<br />

Sheffield, England<br />

Closest Airport: Robin Hood<br />

Doncaster Sheffield (DSA)<br />

- 20 Miles from site<br />

Sandiacre and Beeston<br />

Osmaston Street, Sandiacre,<br />

Nottingham, England<br />

Closest Airport : East Midlands (EMA)<br />

- 10 Miles from site<br />

Regions supplied:<br />

Please contact us for further information:<br />

David Evans<br />

Head of Sales & Marketing<br />

<strong>Progress</strong> <strong>Rail</strong> <strong>Services</strong> UK Ltd<br />

Osmaston Street, Sandiacre, Nottingham, NG10 5AN, UK<br />

devans@progressrail.com<br />

Tel: +44 (0) 115 921 8218 | Mob: +44 (0) 752 738 8803 | Fax: +44 (0) 115 921 8219<br />

Copyright © 2013 <strong>Progress</strong> <strong>Rail</strong> <strong>Services</strong> UK Ltd. All Rights Reserved. No part of this publication may be reproduced without the permission of <strong>Progress</strong> <strong>Rail</strong> <strong>Services</strong> UK Ltd.<br />

Brochure: PRSUK_<strong>Design</strong> <strong>Services</strong>_revision1_April 2013