Prediction of Energy Intensity of Carbon Fiber Reinforced Plastics for ...

Prediction of Energy Intensity of Carbon Fiber Reinforced Plastics for ...

Prediction of Energy Intensity of Carbon Fiber Reinforced Plastics for ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

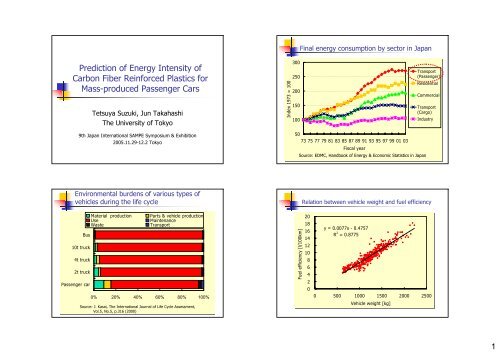

Final energy consumption by sector in Japan<br />

<strong>Prediction</strong> <strong>of</strong> <strong>Energy</strong> <strong>Intensity</strong> <strong>of</strong><br />

<strong>Carbon</strong> <strong>Fiber</strong> <strong>Rein<strong>for</strong>ced</strong> <strong>Plastics</strong> <strong>for</strong><br />

Mass-produced Passenger Cars<br />

Tetsuya Suzuki, Jun Takahashi<br />

The University <strong>of</strong> Tokyo<br />

Index 1973 = 100<br />

300<br />

250<br />

200<br />

150<br />

100<br />

Transport<br />

(Passenger)<br />

Residential<br />

Commercial<br />

Transport<br />

(Cargo)<br />

Industry<br />

9th Japan International SAMPE Symposium & Exhibition<br />

2005.11.29-12.2 Tokyo<br />

50<br />

73 75 77 79 81 83 85 87 89 91 93 95 97 99 01 03<br />

Fiscal year<br />

Source: EDMC, Handbook <strong>of</strong> <strong>Energy</strong> & Economic Statistics in Japan<br />

Environmental burdens <strong>of</strong> various types <strong>of</strong><br />

vehicles during the life cycle<br />

Relation between vehicle weight and fuel efficiency<br />

Bus<br />

10t truck<br />

4t truck<br />

2t truck<br />

Passenger car<br />

Material production<br />

Use<br />

Waste<br />

Parts & vehicle production<br />

Maintenance<br />

Transport<br />

0% 20% 40% 60% 80% 100%<br />

Source: J. Kasai, The International Journal <strong>of</strong> Life Cycle Assessment,<br />

Vol.5, No.5, p.316 (2000)<br />

Fuel efficiency [l/100km]<br />

20<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

y = 0.0077x - 0.4757<br />

R 2 = 0.8775<br />

0 500 1000 1500 2000 2500<br />

Vehicle weight [kg]<br />

1

Specific strength [σf/ρ]<br />

Specific strength [σf/ρ]<br />

Why carbon fiber rein<strong>for</strong>ced plastics (CFRP)<br />

50 50<br />

45 45<br />

40 40<br />

35 35<br />

30 30<br />

25 25<br />

20 20 Steel (1470MPa)<br />

15 15<br />

• TS: Thermosetting<br />

• TP: Thermoplastic<br />

• Vf: <strong>Fiber</strong> volume fraction<br />

10 10 Steel (780MPa)<br />

55<br />

Steel (440MPa)<br />

Steel (270MPa)<br />

00<br />

CFRTS (For airplanes)<br />

CFRTS (Rapid Molding)<br />

Titanium<br />

GFRP<br />

Aluminum<br />

Magnesium<br />

Vf=0.1<br />

Vf=0.6<br />

Vf=0.6<br />

Vf=0.5<br />

CFRTP<br />

0.00 0.05 0.10 0.15 0.20 0.25<br />

Specific rigidity [ 3 E/ρ]<br />

<strong>Energy</strong> intensity <strong>of</strong> steel and carbon fiber (CF)<br />

Raw material production<br />

Processing & assembly<br />

Total<br />

Steel *1<br />

[MJ/kg]<br />

-<br />

-<br />

33<br />

In 1999 *2<br />

42<br />

436<br />

478<br />

CF [MJ/kg]<br />

In 2004 *3<br />

39<br />

247<br />

286<br />

*1: Atushi Funazaki, Katsunori Taneda, “A Study <strong>of</strong> Inventories <strong>for</strong> Automobile LCA<br />

(3) – Iron and Steel Production –”, JARI ResearchJournalVol.23, No.2, 2001.2<br />

*2:Society <strong>of</strong> Japanese Aerospace Companies, “An investigation report about<br />

inventory data construction <strong>of</strong> a composite material”, 1997<br />

*3:METI, Global warming program, “Report <strong>of</strong> Research and development on carbon<br />

fiber rein<strong>for</strong>ced plastic <strong>for</strong> lightening automobiles”, 2004<br />

<strong>Energy</strong> intensity <strong>of</strong> matrix resins<br />

Decrease <strong>of</strong> energy intensity by removing <strong>of</strong> prepreg production<br />

Matrix<br />

Epoxy<br />

Unsaturated polyester<br />

Phenol<br />

Flexible polyurethane<br />

High-density polyethylene<br />

Polypropylene<br />

<strong>Energy</strong><br />

intensity<br />

[MJ/kg]<br />

76.0<br />

62.8<br />

32.9<br />

67.3<br />

20.3<br />

24.4<br />

CFRTS<br />

CFRTP<br />

Production process<br />

Resin blending<br />

Resin coating<br />

Resin impregnation<br />

Prepreg winding<br />

Atmosphere control<br />

Raw material storage<br />

Prepreg storage<br />

Release coated<br />

paper production<br />

Total<br />

<strong>Energy</strong><br />

intensity<br />

[MJ/kg]<br />

0.1<br />

1.4<br />

2.1<br />

0.2<br />

20.8<br />

11.5<br />

3.4<br />

0.5<br />

40.0<br />

Omission <strong>of</strong> prepreg<br />

production or integration<br />

into mass-production lines<br />

Dramatic reduction <strong>of</strong><br />

energy consumption<br />

0-4 MJ/kg<br />

2

<strong>Energy</strong> intensity <strong>of</strong> molding<br />

Relation between fiber volume fraction and structural index <strong>of</strong> CFRP<br />

Molding method<br />

Hand lay up<br />

Spray up<br />

RTM<br />

VARI<br />

Cold press<br />

Pre<strong>for</strong>m matched die<br />

SMC<br />

Filament winding<br />

Pultrusion<br />

<strong>Energy</strong><br />

intensity<br />

[MJ/kg]<br />

19.2<br />

14.9<br />

12.8<br />

10.2<br />

11.8<br />

10.1<br />

3.5<br />

2.7<br />

3.1<br />

CFRTS<br />

CFRTP<br />

Structual index [ 3 E/ρ] <strong>of</strong> CFRP<br />

3<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

PP<br />

PA<br />

PC<br />

UP<br />

Saturation <strong>of</strong> weight reduction in Vf=30-60%<br />

Magnesium: 2.01<br />

Aluminum: 1.49<br />

Steel: 0.76<br />

0 0.1 0.2 0.3 0.4 0.5 0.6<br />

<strong>Fiber</strong> volume fraction<br />

<strong>Energy</strong> intensity <strong>of</strong> CFRP <strong>for</strong> body<br />

Emphasis on rigidity<br />

<strong>Fiber</strong> volume fraction: 30%<br />

Matrix resin: Polypropylene (Thermoplastic)<br />

Weight reduction ratio: 65%<br />

<strong>Energy</strong> intensity <strong>of</strong> CFRP <strong>for</strong> chassis<br />

Emphasis on strength<br />

<strong>Fiber</strong> volume fraction: 60%<br />

Matrix resin: Epoxy (Thermosetting)<br />

Weight reduction ratio: 70%<br />

CF<br />

PP<br />

Pre<strong>for</strong>m<br />

matched die<br />

CFRP<br />

<strong>Energy</strong> intensity<br />

[MJ/kg]<br />

286<br />

24<br />

10<br />

155<br />

Weight<br />

[kg]<br />

0.462<br />

0.538<br />

1<br />

1<br />

<strong>Energy</strong> intensity<br />

[MJ/kg-CFRP]<br />

132<br />

13<br />

10<br />

155<br />

CF<br />

EP<br />

RTM<br />

CFRP<br />

<strong>Energy</strong> intensity<br />

[MJ/kg]<br />

286<br />

76<br />

13<br />

234<br />

Weight<br />

[kg]<br />

0.692<br />

0.308<br />

1<br />

1<br />

<strong>Energy</strong> intensity<br />

[MJ/kg-CFRP]<br />

198<br />

23<br />

13<br />

234<br />

3

Reuse and recycle flow <strong>of</strong> scrapped CFRP cars in the future<br />

Scrapped<br />

CFRP car<br />

Aged<br />

degradation<br />

Shortage <strong>of</strong><br />

fiber length<br />

Recycle<br />

Resin degradation<br />

by recycle<br />

Aged<br />

degradation<br />

1 st recycle 2 nd recycle 3 rd recycle<br />

Strength parts<br />

Reuse<br />

Reason <strong>for</strong><br />

property decrease<br />

Repeated weight<br />

by running<br />

Reason <strong>for</strong><br />

property decrease<br />

Non structural parts<br />

Property decrease<br />

Property decrease<br />

is dependent on<br />

resistance to fatigue<br />

CFRTS -> Only fiber<br />

CFRTP -> <strong>Fiber</strong> + Resin<br />

Thermal recycle<br />

Recovering energy<br />

as thermal<br />

No landfill<br />

CFRP after 3R<br />

• Reuse <strong>of</strong> CFRTS<br />

• Only<br />

• Only<br />

transportation<br />

transportation<br />

and<br />

and<br />

washing:<br />

washing -><br />

about<br />

about<br />

0 MJ/kg<br />

0 MJ/kg<br />

• Recycle<br />

• Recycle<br />

<strong>of</strong><br />

<strong>of</strong><br />

CFRTS<br />

CFRTS<br />

• <strong>Fiber</strong> volume fraction: 30%<br />

• Additional PP -> 13MJ/kg<br />

• Additional fresh PP: 13MJ/kg<br />

• Pre<strong>for</strong>med matched die -> 10MJ/kg<br />

• Pre<strong>for</strong>med matched die: 10MJ/kg<br />

• Separating and recovering <strong>of</strong> CF -> 10MJ/kg<br />

• Separating and recovering <strong>of</strong> CF: 10MJ/kg<br />

• Total -> 43MJ/kg<br />

• Total: 43MJ/kg<br />

• Recycle <strong>of</strong> CFRTP<br />

• Melt and remold CFRTP without adding fresh resin<br />

• Pre<strong>for</strong>med matched die -> 10MJ/kg<br />

• Recovering CFRTP -> 5MJ/kg<br />

• Total ->15MJ/kg<br />

Results<br />

Conclusion<br />

assembly, molding<br />

CF production<br />

Steel<br />

Fresh CFRTS<br />

Recycle CFRTS<br />

Fresh CFRTP<br />

Recycle CFRTP<br />

steel or matrix resin production<br />

materials recoverly<br />

• Effective combination <strong>of</strong> several technologies is<br />

needed in order to decrease energy intensity <strong>of</strong><br />

CFRP parts <strong>for</strong> mass-produced cars<br />

• In particular, 3R has a great effect because<br />

energy intensity <strong>of</strong> fresh CFRP is very large and<br />

the technological development is indispensable<br />

0 50 100 150 200 250<br />

<strong>Energy</strong> intensity [MJ/kg]<br />

4

For more in<strong>for</strong>mation..<br />

suzuki@sunshine.naoe.t.u-tokyo.ac.jp<br />

5