service manual 55a four marine diesel engine - Westerbeke

service manual 55a four marine diesel engine - Westerbeke

service manual 55a four marine diesel engine - Westerbeke

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

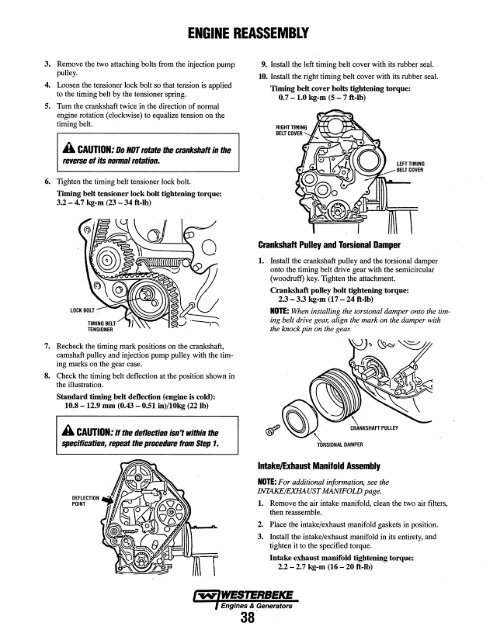

ENGINE REASSEMBLY<br />

3. Remove the two attaching bolts from the injection pump<br />

pulley.<br />

4. Loosen the tensioner lock bolt so that tension is applied<br />

to the timing belt by the tensioner spring.<br />

5. Tum the crankshaft twice in the direction of normal<br />

<strong>engine</strong> rotation (clockwise) to equalize tension on the<br />

timing belt.<br />

9. Install the left timing belt cover with its rubber seal.<br />

10. Install the right timing belt cover with its rubber seal.<br />

TIming belt cover bolts tightening torque:<br />

0.7 -1.0 kg-m (5 -7 ft-Ib)<br />

A CAUTION: Do NOT rotate the crankshaft in the<br />

reverse of its nonnal rotation.<br />

6. Tighten the timing belt tensioner lock bolt.<br />

TIming belt tensioner lock bolt tightening torque:<br />

3.2 - 4.7 kg-m (23 - 34 ft-Ib)<br />

Crankshaft Pulley and Torsional Damper<br />

1. Install the crankshaft pulley and the torsional damper<br />

onto the timing belt drive gear with the semicircular<br />

(woodruff) key. Tighten the attachment.<br />

Crankshaft pulley bolt tightening torque:<br />

2.3 - 3.3 kg-m (17 - 24 ft-Ib)<br />

NOTE: When installing the torsional damper onto the timing<br />

belt drive gear, align the mark on the damper with<br />

the knock pin on the gear.<br />

7. Recheck the timing mark positions on the crankshaft,<br />

camshaft pulley and injection pump pulley with the timing<br />

marks on the gear case.<br />

8. Check the timing belt deflection at the position shown in<br />

the illustration.<br />

Standard timing belt deflection (<strong>engine</strong> is cold):<br />

10.8 -12.9 mm (0.43 - 0.51 in)/10kg (22 Ib)<br />

A CAUTION: If the deflection isn't within the<br />

specification, repeat the procedure from Step 1.<br />

CRANKSHAFT PULLEY<br />

Intake/Exhaust Manifold Assembly<br />

NOTE: For additional information, see the<br />

INTAKE/EXHAUST MANIFOW page.<br />

1. Remove the air intake manifold, clean the two air filters,<br />

then reassemble.<br />

2. Place the intake/exhaust manifold gaskets in position.<br />

3. Install the intake/exhaust manifold in its entirety, and<br />

tighten it to the specified torque.<br />

Intake exhaust manifold tightening torque:<br />

2.2 - 2.7 kg-m (16 - 20 ft-Ib)<br />

Engines & Generators<br />

3S'