Vitocal 200-S Service and Installation10.8 MB - Viessmann

Vitocal 200-S Service and Installation10.8 MB - Viessmann

Vitocal 200-S Service and Installation10.8 MB - Viessmann

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

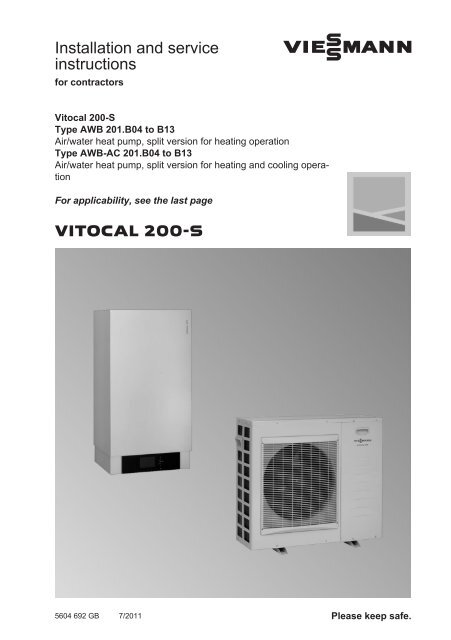

Installation <strong>and</strong> service<br />

instructions<br />

for contractors<br />

VIESMANN<br />

<strong>Vitocal</strong> <strong>200</strong>-S<br />

Type AWB 201.B04 to B13<br />

Air/water heat pump, split version for heating operation<br />

Type AWB-AC 201.B04 to B13<br />

Air/water heat pump, split version for heating <strong>and</strong> cooling operation<br />

For applicability, see the last page<br />

VITOCAL <strong>200</strong>-S<br />

5604 692 GB 7/2011 Please keep safe.

Safety instructions<br />

Safety instructions<br />

Please follow these safety instructions closely to prevent accidents <strong>and</strong> material<br />

losses.<br />

Safety instructions explained<br />

Danger<br />

This symbol warns against the<br />

risk of injury.<br />

!<br />

Please note<br />

This symbol warns against the<br />

risk of material losses <strong>and</strong> environmental<br />

pollution.<br />

Note<br />

Details identified by the word "Note" contain<br />

additional information.<br />

Target group<br />

These instructions are exclusively<br />

designed for qualified contractors.<br />

■ Work on the refrigerant circuit must<br />

only be carried out by qualified <strong>and</strong><br />

authorised refrigeration engineers<br />

■ Work on electrical equipment must<br />

only be carried out by a qualified electrician<br />

■ The system must be commissioned by<br />

the system installer or a qualified person<br />

authorised by the installer<br />

Regulations<br />

Observe the following when working on<br />

this system:<br />

■ National installation requirements<br />

■ Legal instructions regarding the prevention<br />

of accidents<br />

■ Legal instructions regarding environmental<br />

protection<br />

■ The Code of Practice of relevant trade<br />

associations<br />

■ All current safety regulations as<br />

defined by DIN, EN, DVGW, VDE <strong>and</strong><br />

all locally applicable st<strong>and</strong>ards<br />

a ÖNORM, EN <strong>and</strong> ÖVE<br />

c SEV, SUVA, SVTI <strong>and</strong> SWKI<br />

Working on the system<br />

■ Isolate the system from the power supply<br />

<strong>and</strong> check that it is no longer 'live',<br />

e.g. by removing the separate fuse or<br />

by means of a main isolator<br />

Note<br />

In addition to the control circuit, there<br />

may be several power circuits.<br />

Danger<br />

Contact with 'live' components<br />

can lead to severe injuries.<br />

Some components on the<br />

PCBs will remain 'live' even<br />

after the power supply has<br />

been switched off.<br />

Before removing covers from<br />

appliances, wait at least 4<br />

minutes for the power to dissipate.<br />

■ Safeguard the system against unauthorised<br />

reconnection<br />

5604 692 GB<br />

2

Safety instructions<br />

Safety instructions (cont.)<br />

!<br />

Please note<br />

Electronic assemblies can be<br />

damaged by electrostatic discharges.<br />

Before beginning work, touch<br />

earthed objects, such as heating<br />

or water pipes, to discharge static<br />

loads.<br />

Repair work<br />

!<br />

Please note<br />

Repairing components that fulfil a<br />

safety function can compromise<br />

the safe operation of your system.<br />

Replace faulty components only<br />

with original <strong>Viessmann</strong> spare<br />

parts.<br />

Auxiliary components, spare <strong>and</strong><br />

wearing parts<br />

Please note<br />

! Spare <strong>and</strong> wearing parts that<br />

have not been tested together<br />

with the system can compromise<br />

its function. Installing non-authorised<br />

components <strong>and</strong> making<br />

non-approved modifications or<br />

conversions can compromise<br />

safety <strong>and</strong> may invalidate our<br />

warranty.<br />

For replacements, use only original<br />

spare parts supplied or<br />

approved by <strong>Viessmann</strong>.<br />

5604 692 GB<br />

3

Index<br />

Installation instructions<br />

Preparing for installation<br />

Application............................................................................................................ 6<br />

Requirements for on-site connections.................................................................. 7<br />

Overview of possible system schemes................................................................ 9<br />

Designations in the system examples.................................................................. 11<br />

System example 1, ID: 4605169_1103_04.......................................................... 11<br />

System example 2, ID: 4605170_1103_04.......................................................... 19<br />

Installation sequence<br />

Installing the external unit..................................................................................... 27<br />

Installing the internal unit...................................................................................... 32<br />

Connecting the refrigerant lines........................................................................... 35<br />

Connecting a secondary circuit............................................................................ 41<br />

Connecting a cooling circuit if required................................................................ 42<br />

Electrical connections........................................................................................... 42<br />

Power supply........................................................................................................ 60<br />

Closing the heat pump......................................................................................... 66<br />

<strong>Service</strong> instructions<br />

Commissioning, inspection, maintenance<br />

Steps - commissioning, inspection <strong>and</strong> maintenance.......................................... 68<br />

Further details regarding the individual steps....................................................... 70<br />

Troubleshooting<br />

Repairs................................................................................................................. 88<br />

Internal unit parts lists<br />

Internal unit parts lists.......................................................................................... 99<br />

Overview of internal unit assemblies.................................................................... 100<br />

Internal unit parts not shown................................................................................ 101<br />

Casing, internal unit.............................................................................................. 101<br />

Electrical equipment, internal unit........................................................................ 103<br />

Hydraulics, internal unit, type AWB...................................................................... 105<br />

Hydraulics, internal unit, type AWB-AC................................................................ 107<br />

External unit parts lists<br />

External unit parts lists......................................................................................... 109<br />

External unit type AWB/AWB-AC 201.B04........................................................... 109<br />

External unit type AWB/AWB-AC 201.B07........................................................... 111<br />

Overview of the assemblies, external unit, type AWB/AWB-AC 201.B10, B13.... 113<br />

Casing, external unit, type AWB/AWB-AC 201.B10, B13.................................... 114<br />

4<br />

Index<br />

5604 692 GB

Index<br />

Index (cont.)<br />

Electrical equipment, external unit, type AWB/AWB-AC 201.B10, B13............... 116<br />

Hydraulics, external unit, type AWB/AWB-AC 201.B10, B13............................... 118<br />

Commissioning/service reports<br />

Hydraulic parameters report................................................................................. 120<br />

Control parameters report.................................................................................... 120<br />

Specification....................................................................................................... 125<br />

Appendix<br />

Heat pump commissioning order.......................................................................... 130<br />

Certificates<br />

Declaration of conformity...................................................................................... 131<br />

Keyword index.................................................................................................... 132<br />

5604 692 GB<br />

5

Preparing for installation<br />

Application<br />

The heat pumps <strong>Vitocal</strong> <strong>200</strong>-S,<br />

type AWB <strong>and</strong> AWB-AC can be used for<br />

the following purposes:<br />

■ Central heating via a heating system<br />

■ Central cooling (only type AWB-AC)<br />

via a heating system<br />

■ DHW heating<br />

Note<br />

<strong>Vitocal</strong> <strong>200</strong>-S is intended exclusively for<br />

domestic use, i.e. even people who have<br />

not had any instruction are able to operate<br />

the appliance safely.<br />

Any use that differs from or goes beyond<br />

this is not appropriate.<br />

5604 692 GB<br />

6

Preparing for installation<br />

Requirements for on-site connections<br />

Internal unit<br />

A B<br />

450<br />

360<br />

360<br />

58<br />

50<br />

40<br />

905<br />

150<br />

AB /<br />

960<br />

75<br />

147<br />

219<br />

294<br />

369<br />

+<br />

1105<br />

41<br />

5604 692 GB<br />

Installation<br />

7

Preparing for installation<br />

Requirements for on-site connections (cont.)<br />

Symbol Meaning Connection<br />

Refrigerant lines from/to the Type Pipe 7 UNF thread<br />

external unit:<br />

AWB/<br />

AWB-AC<br />

■ Hot gas line 201.B04 12 mm ⅞<br />

Reducer<br />

⅞ x ¾<br />

+<br />

201.B07<br />

201.B10<br />

201.B13<br />

16 mm<br />

16 mm<br />

16 mm<br />

■ Liquid line 201.B04 6 mm ⅝<br />

Reducer<br />

⅝ x ⁷⁄₁₆<br />

DHW cylinder flow (heating<br />

water side)<br />

Heating water return <strong>and</strong><br />

DHW cylinder return<br />

Heating water flow<br />

201.B07<br />

201.B10<br />

201.B13<br />

10 mm<br />

10 mm<br />

10 mm<br />

⅞<br />

⅞<br />

⅞<br />

⅝<br />

⅝<br />

⅝<br />

G 1¼<br />

G 1¼<br />

G 1¼<br />

A Cable entry 42 V<br />

1. Preparing connections on the heating<br />

water <strong>and</strong> the DHW side.<br />

Flush the heating system.<br />

2. Prepare the electrical connections.<br />

Note<br />

The internal/external unit BUS connecting<br />

cable can be routed along the<br />

refrigerant line <strong>and</strong> fixed to it.<br />

Cable lengths inside the internal/external unit plus wall clearance:<br />

Cables Internal unit External unit<br />

Power cables:<br />

Heat pump control unit (230 V~) 2.0 m —<br />

Compressor (230 V~) — 1.5 m<br />

Additional connecting cables:<br />

230 V~, e.g. for pumps 2.0 m —<br />

< 42 V, e.g. for sensors 2.0 m —<br />

8<br />

5604 692 GB

Preparing for installation<br />

Requirements for on-site connections (cont.)<br />

Cables Internal unit External unit<br />

Connecting cables between the internal/external units:<br />

12 V BUS 1.5 m 1.5 m<br />

43 V BUS 1.5 m 1.5 m<br />

Recommended power cables<br />

<strong>Vitocal</strong> <strong>200</strong>-S, type AWB, 201.B04 201.B07 201.B10 201.B13<br />

AWB-AC<br />

External unit (compressor)<br />

230 V~<br />

Cable cross-section 3 x 2.5 mm 2 3 x 2.5 mm 2 3 x 2.5 mm 2 3 x 4.0 mm 2<br />

Max. cable length 29 m 25 m 16 m 20 m<br />

or or<br />

Cable cross-section – – 3 x 4.0 mm 2 3 x 6.0 mm 2<br />

Max. cable length – – 26 m 30 m<br />

Heat pump control unit (internal<br />

unit) 230 V~<br />

Cable cross-section<br />

■ Without power-OFF 3 x 1.5 mm 2 3 x 1.5 mm 2 3 x 1.5 mm 2 3 x 1.5 mm 2<br />

■ With power-OFF 5 x 1.5 mm 2 5 x 1.5 mm 2 5 x 1.5 mm 2 5 x 1.5 mm 2<br />

Instantaneous heating water<br />

heater<br />

Cable cross-section<br />

■ 400 V~ 5 x 2.5 mm 2 5 x 2.5 mm 2 5 x 2.5 mm 2 5 x 2.5 mm 2<br />

■ 230 V~ 7 x 2.5 mm 2 7 x 2.5 mm 2 7 x 2.5 mm 2 7 x 2.5 mm 2<br />

Max. cable length 25 m 25 m 25 m 25 m<br />

Installation<br />

Overview of possible system schemes<br />

The following table provides an overview<br />

of all possible system schemes.<br />

5604 692 GB<br />

9

Preparing for installation<br />

Overview of possible system schemes (cont.)<br />

Components System scheme (parameter 7000)<br />

0 1 2 3 4 5 6<br />

Heating circuit<br />

A1/HC1 – X X – – X X<br />

M2/HC2 – – – X X X X<br />

DHW cylinder<br />

X – X – X – X<br />

Heating water buffer cylinder<br />

– 0 0 X X X X<br />

External heat source<br />

– 0 *1 0 *1 0 0 0 0<br />

Cooling<br />

A1/HC1 0 0 0 0<br />

M2/HC2 0 0 0 0<br />

Sep. cooling circuit 0 0 0 0 0 0 0<br />

X Component has been selected.<br />

0 Component can be added.<br />

*1<br />

Only in conjunction with a heating water buffer cylinder.<br />

5604 692 GB<br />

10

Preparing for installation<br />

Designations in the system examples<br />

oE<br />

--2/F14--<br />

oQ<br />

oW<br />

-2/145-<br />

A1<br />

2<br />

oE<br />

--2/F14--<br />

iE<br />

--2/X3.8;3.9--<br />

oR<br />

--2/211.2--<br />

oP<br />

Installation<br />

[H F<br />

[YF F<br />

--F6--<br />

--212.3--<br />

--F8--<br />

--F0--<br />

2<br />

--211.4--<br />

--211.2--<br />

--F14--<br />

--230V-- -KM BUS-<br />

-2/X3.8;3.9-<br />

System example 1, ID: 4605169_1103_04<br />

Setting system scheme 6<br />

■ Internal unit of the heat pump<br />

type AWB 201.B without instantaneous<br />

heating water heater or<br />

type AWB-AC 201.B with instantaneous<br />

heating water heater<br />

■ 1 radiator heating circuit without mixer<br />

A1/HC1<br />

■ 1 underfloor heating circuit with mixer<br />

M2/HC2<br />

■ DHW heating<br />

■ External heat source<br />

■ Heating water buffer cylinder<br />

Note<br />

This scheme is a basic example without<br />

shut-off devices or safety equipment.<br />

This does not replace the need for local<br />

engineering.<br />

5604 692 GB<br />

11

Preparing for installation<br />

System example 1, ID: 4605169_1103_04 (cont.)<br />

Hydraulic installation scheme<br />

--2--<br />

-KM BUS-<br />

105<br />

--20--<br />

-230V-<br />

91 -8/145- 71 -8/145-<br />

73<br />

--105/2--<br />

70<br />

90 -105/20--76-<br />

A1<br />

M2<br />

74<br />

--2/212.2--<br />

96<br />

--74/20--<br />

76<br />

77<br />

--105/52--<br />

62<br />

--2/F13--<br />

--2/F6--<br />

31<br />

WW<br />

37<br />

--2/212.3--<br />

52<br />

--2/224.7--<br />

53<br />

--2/F20--<br />

54<br />

--2/222.1;2--<br />

3<br />

--2/F0--<br />

29<br />

5<br />

1<br />

12<br />

13<br />

4<br />

6<br />

55<br />

-2/222.4--51-<br />

--2/F4--<br />

61<br />

KW<br />

30<br />

50<br />

14<br />

-2/211.2--14-<br />

60<br />

2<br />

--230V--<br />

--211.2--<br />

--212.3--<br />

--224.7--<br />

--222.1;2--<br />

--212.2--<br />

--222.4--<br />

--F6--<br />

--KM BUS--<br />

--F20--<br />

--F0--<br />

--F13--<br />

--F4--<br />

--52--<br />

27 28<br />

15<br />

-2/X3.3;3.4-<br />

--145--<br />

--145--<br />

--145--<br />

--145--<br />

8<br />

5604 692 GB<br />

--X3.3;3.4--<br />

12

System example 1, ID: 4605169_1103_04 (cont.)<br />

Preparing for installation<br />

Pos. Designation<br />

Heat source<br />

1 Internal unit, heat pump <strong>Vitocal</strong> <strong>200</strong>-S<br />

2 Heat pump control unit Vitotronic <strong>200</strong>, type WO1B<br />

3 Outside temperature sensor ATS<br />

4 Instantaneous heating water heater with control module<br />

(only for <strong>Vitocal</strong> <strong>200</strong>-S, type AWB-AC)<br />

5 3-way diverter valve for "Central heating/DHW heating"<br />

6 Secondary pump<br />

8 KM BUS distributor<br />

qE Heating circuit expansion vessel<br />

qT Flow switch<br />

Primary circuit<br />

wU Liquid line<br />

wI Hot gas line<br />

wO External unit of the heat pump <strong>Vitocal</strong> <strong>200</strong>-S<br />

DHW heating<br />

eP DHW cylinder (dual mode)<br />

eQ Cylinder temperature sensor STS<br />

eU DHW circulation pump ZP<br />

5604 692 GB<br />

Installation<br />

13

Preparing for installation<br />

System example 1, ID: 4605169_1103_04 (cont.)<br />

Pos.<br />

qR<br />

tP<br />

tQ<br />

tW<br />

tE<br />

tR<br />

tT<br />

zP<br />

zQ<br />

zW<br />

uP<br />

uQ<br />

uE<br />

uR<br />

uZ<br />

uU<br />

q-T<br />

oP<br />

oQ<br />

oZ<br />

Designation<br />

External heat source<br />

High limit safety cut-out for switching off the secondary pump<br />

External heat source, e.g. oil/gas boiler<br />

Dem<strong>and</strong> of external heat source (connection to heat pump control unit)<br />

Circulation pump for cylinder heating UPSB<br />

Boiler water temperature sensor KTS (for connection to the heat pump<br />

control unit):<br />

■ As contact temperature sensor<br />

or<br />

■ As immersion temperature sensor<br />

Mixer motor, directly controlled<br />

High limit safety cut-out STB 70 °C (to switch off the external heat<br />

source)<br />

Heating water buffer cylinder<br />

Buffer temperature sensor PTS<br />

System flow temperature sensor<br />

Heating circuit with mixer M2 (KM BUS)<br />

Underfloor heating circuit<br />

Vitotrol <strong>200</strong>A remote control<br />

Flow temperature sensor<br />

Temperature limiter to restrict the maximum temperature of underfloor<br />

heating systems<br />

■ As immersion thermostat<br />

or<br />

■ As contact thermostat<br />

Heating circuit pump<br />

3-way mixer, heating circuit<br />

Mixer motor in 3-way mixer<br />

Mixer extension kit<br />

Heating circuit without mixer A1<br />

Radiator heating circuit<br />

Vitotrol <strong>200</strong>A remote control<br />

Heating circuit pump<br />

Electrical installation scheme<br />

For an overview of the electrical connections<br />

<strong>and</strong> more information on the PCBs,<br />

see from page 45 <strong>and</strong> the separate<br />

service instructions for the heat pump<br />

control unit.<br />

For information regarding the power supply,<br />

see page 60.<br />

5604 692 GB<br />

14

System example 1, ID: 4605169_1103_04 (cont.)<br />

Preparing for installation<br />

2<br />

130W<br />

211.2<br />

X1. M<br />

1~ UP 6<br />

X2.N<br />

230 V/ 50 Hz<br />

X1.<br />

X2.N<br />

X1.<br />

X2.N<br />

211.4<br />

212.3<br />

ZP 37<br />

100W<br />

212.2<br />

X1. M<br />

1~ HK A1 96<br />

X2.N<br />

100W<br />

224.7<br />

X1. M<br />

1~ UPSB 52<br />

X2.N<br />

X3.1<br />

X1.<br />

X2.N<br />

X1.<br />

X2.N<br />

222.3<br />

222.4<br />

222.2<br />

222.1<br />

130W<br />

M<br />

1~<br />

50W<br />

M<br />

1~<br />

UV<br />

OPEN<br />

M<br />

1~<br />

CLOSED<br />

High limit safety 14cut-out<br />

5<br />

51<br />

High limit safety 55cut-out<br />

54<br />

Installation<br />

X2.N<br />

211.3<br />

224.4<br />

136<br />

L1<br />

L2<br />

L3<br />

N<br />

400 V, 50 Hz<br />

3 / N / PE<br />

4<br />

X3.3<br />

X3.4<br />

15<br />

8<br />

Low voltage<br />

145<br />

3<br />

2 2 145<br />

1<br />

1<br />

145<br />

145<br />

3<br />

2 145<br />

1<br />

3<br />

2<br />

1<br />

3<br />

2<br />

1<br />

2<br />

1 H1<br />

2<br />

1 H2<br />

HK A1<br />

HK M2<br />

91<br />

71<br />

105 HK M2<br />

40<br />

2<br />

20<br />

N<br />

L<br />

N<br />

74<br />

20<br />

N<br />

L<br />

M<br />

1~<br />

230 V/ 50 Hz<br />

1 / N / PE<br />

UP M2 76<br />

L<br />

N<br />

52<br />

M<br />

1~<br />

M2<br />

77<br />

1<br />

2<br />

2<br />

145<br />

2<br />

1<br />

NTC<br />

VTS M2<br />

73<br />

5604 692 GB<br />

15

Preparing for installation<br />

System example 1, ID: 4605169_1103_04 (cont.)<br />

Note<br />

The instantaneous heating water heater<br />

4, the 3-way diverter valve 5 <strong>and</strong> the<br />

secondary pump 6 are already installed<br />

<strong>and</strong> electrically connected.<br />

2<br />

PT500<br />

F6 STS 31<br />

PT500<br />

F4 PTS 61<br />

Low voltage<br />

F20<br />

F13<br />

PT500<br />

PT500<br />

KTS<br />

53<br />

VTS 62<br />

F0<br />

Ni500<br />

ATS<br />

3<br />

Power supplies for the internal unit<br />

<strong>and</strong> instantaneous heating water<br />

heater<br />

Note<br />

Instantaneous heating water heater only<br />

for <strong>Vitocal</strong> <strong>200</strong>-S, type AWB-AC.<br />

Power supply to heat pump control unit<br />

2<br />

F1 6.3 AH (slow)<br />

1 / N / PE<br />

230 V / 50 Hz<br />

L1<br />

N<br />

X40<br />

L1<br />

N<br />

Instantaneous heating water heater power supply<br />

1 / N / PE<br />

230 V/ 50 Hz<br />

L1<br />

L1<br />

L1<br />

N1<br />

N1<br />

N1<br />

4 230 V<br />

3 / N / PE<br />

400 V/ 50 Hz<br />

L3<br />

L2<br />

L1<br />

4 400 V<br />

N<br />

5604 692 GB<br />

16

System example 1, ID: 4605169_1103_04 (cont.)<br />

Preparing for installation<br />

Connections for the external unit<br />

4 kW 29<br />

C N L<br />

L1<br />

N<br />

1 / N / PE<br />

230 V/ 50 Hz<br />

2<br />

43 V<br />

COM<br />

> 42 V<br />

7 kW<br />

29<br />

COM Ni Li<br />

No Lo<br />

L1<br />

N<br />

1 / N / PE<br />

230 V/ 50 Hz<br />

Installation<br />

2<br />

43 V<br />

COM<br />

> 42 V<br />

10 / 13 kW<br />

29<br />

C2 C1<br />

N<br />

L<br />

N<br />

L<br />

L1<br />

N<br />

1 / N / PE<br />

230 V/ 50 Hz<br />

2<br />

12 V<br />

COM<br />

5604 692 GB<br />

< 42 V<br />

17

Preparing for installation<br />

System example 1, ID: 4605169_1103_04 (cont.)<br />

"Time program DHW circulation"<br />

(if a DHW circulation pump is installed)<br />

"DHW"<br />

■ "Enable booster heaters for DHW heating 6014" "1"<br />

■ "Enable electric heaters for DHW heating 6015" "1"<br />

Instantaneous heating water heater (if installed):<br />

"Electr booster heater"<br />

■ "Enable instantaneous heating water heater<br />

7900"<br />

Required parameter settings<br />

Parameter<br />

Setting<br />

"System definition"<br />

■ "System scheme 7000" "6"<br />

"Compressor"<br />

■ "Output compressor stage 5030"<br />

Type AWB/AWB-AC<br />

■ 201.B04: "4"<br />

■ 201.B07: "7"<br />

■ 201.B10: "10"<br />

■ 201.B13: "13"<br />

"External heat source"<br />

■ "Enable external heat source 7B00" "1"<br />

■ "Enable external heat source for DHW heating "1"<br />

7B0D"<br />

DHW heating:<br />

"Time program DHW heating"<br />

Set time program (see operating<br />

instructions)<br />

Set time program (see operating<br />

instructions)<br />

"1"<br />

■ "Enable instant. heating water heater for central "1"<br />

heating 7902"<br />

Remote controls (accessories):<br />

"Heating circuit 1"<br />

■ "Remote control <strong>200</strong>3" "1"<br />

"Heating circuit 2"<br />

■ "Remote control 3003" "1"<br />

To call up "Coding level 1" for setting<br />

the parameters, see the commissioning<br />

assistant on page 80 <strong>and</strong> page 8.<br />

5604 692 GB<br />

18

Preparing for installation<br />

System example 2, ID: 4605170_1103_04<br />

Setting system scheme 6<br />

■ Internal unit of heat pump<br />

type AWB-AC 201.B with instantaneous<br />

heating water heater<br />

■ 1 radiator heating circuit without mixer<br />

A1/HC1<br />

■ 1 underfloor heating circuit with mixer<br />

M2/HC2<br />

■ DHW heating<br />

■ External heat source<br />

■ Heating water buffer cylinder<br />

■ Cooling, heating circuit M2/HC2 via<br />

active cooling function<br />

Note<br />

This scheme is a basic example without<br />

shut-off devices or safety equipment.<br />

This does not replace the need for local<br />

engineering.<br />

5604 692 GB<br />

Installation<br />

19

Preparing for installation<br />

System example 2, ID: 4605170_1103_04 (cont.)<br />

Hydraulic installation scheme<br />

--2--<br />

-KM BUS-<br />

105<br />

--20--<br />

-230V-<br />

--52--<br />

91<br />

-8/145- 71 -8/145-<br />

83<br />

-2/X3.8;3.9-<br />

90<br />

A1<br />

--105/2-- 73<br />

-105/20--76-<br />

74<br />

70<br />

M2<br />

--2/212.2--<br />

96<br />

--74/20--<br />

76<br />

77<br />

--105/52--<br />

62<br />

--2/F13--<br />

--2/F6--<br />

31<br />

WW<br />

37<br />

--2/212.3--<br />

52<br />

--2/224.7--<br />

53<br />

--2/F20--<br />

54<br />

--2/222.1;2--<br />

3<br />

--2/F0--<br />

29<br />

5<br />

1<br />

89<br />

-2/211.5-<br />

4 6 13<br />

--2/F4--<br />

61<br />

89<br />

KW<br />

30<br />

50<br />

55<br />

-2/222.4--51-<br />

14<br />

-2/211.2--6-<br />

60<br />

2<br />

--212.3--<br />

--224.7--<br />

--222.1;2--<br />

--212.2--<br />

--222.4--<br />

--F6--<br />

--KM BUS--<br />

--F20--<br />

--F0--<br />

--230V--<br />

--211.2--<br />

--F13--<br />

--F4--<br />

--211.5--<br />

--X3.3;3.4--<br />

--2/211.5--<br />

27 28<br />

--2/X3.3;3.4--<br />

--2/X3.8;3.9--<br />

18<br />

--<br />

--145--<br />

--145--<br />

--145--<br />

--145--<br />

8<br />

--X3.8;3.9--<br />

-----<br />

12<br />

15<br />

Note<br />

In cooling mode, safeguard the minimum flow rate in the secondary circuit. Open<br />

valves on the heating circuit distributor or install an overflow valve.<br />

5604 692 GB<br />

20

System example 2, ID: 4605170_1103_04 (cont.)<br />

Preparing for installation<br />

Pos. Designation<br />

Heat source<br />

1 Internal unit, heat pump, <strong>Vitocal</strong> <strong>200</strong>-S, type AWB-AC<br />

2 Heat pump control unit Vitotronic <strong>200</strong>, type WO1B<br />

3 Outside temperature sensor ATS<br />

4 Instantaneous heating water heater with control module<br />

5 3-way diverter valve for "Central heating/DHW heating"<br />

6 Secondary pump<br />

8 KM BUS distributor<br />

qE Heating circuit expansion vessel<br />

qT Flow switch<br />

Primary circuit<br />

wU Liquid line<br />

wI Hot gas line<br />

wO External unit, heat pump <strong>Vitocal</strong> <strong>200</strong>-S<br />

DHW heating<br />

eP DHW cylinder (with internal indirect coil)<br />

eQ Cylinder temperature sensor STS<br />

eU DHW circulation pump ZP<br />

External heat source<br />

qR High limit safety cut-out for switching off the secondary pump<br />

tP External heat source, e.g. oil/gas boiler<br />

tQ Dem<strong>and</strong> of external heat source (connection to heat pump control unit)<br />

tW Circulation pump for cylinder heating UPSB<br />

tE Boiler water temperature sensor KTS (for connection to the heat pump<br />

control unit):<br />

■ As contact temperature sensor<br />

or<br />

■ As immersion temperature sensor<br />

tR Mixer motor directly controlled<br />

tT High limit safety cut-out STB 70 °C (to switch off the external heat<br />

source)<br />

5604 692 GB<br />

Installation<br />

21

Preparing for installation<br />

System example 2, ID: 4605170_1103_04 (cont.)<br />

Pos.<br />

zP<br />

zQ<br />

zW<br />

uP<br />

uQ<br />

uE<br />

uR<br />

uZ<br />

uU<br />

q-T<br />

iE<br />

iO<br />

oP<br />

oQ<br />

oZ<br />

Designation<br />

Heating water buffer cylinder<br />

Buffer temperature sensor<br />

System flow temperature sensor<br />

Heating circuit with mixer M2 (KM BUS)<br />

Underfloor heating circuit/cooling circuit<br />

Vitotrol <strong>200</strong>A remote control<br />

Flow temperature sensor<br />

Temperature limiter to restrict the maximum temperature of underfloor<br />

heating systems<br />

■ As immersion thermostat<br />

or<br />

■ As contact thermostat<br />

Heating circuit pump<br />

3-way mixer, heating circuit<br />

Mixer motor in 3-way mixer<br />

Extension kit, heating circuit with mixer<br />

Active cooling function (AC)<br />

Contact humidistat 230 V<br />

3-way diverter valve for "heating/cooling"<br />

Heating circuit without mixer A1<br />

Radiator heating circuit<br />

Vitotrol <strong>200</strong>A remote control<br />

Heating circuit pump<br />

Electrical installation scheme<br />

For an overview of the electrical connections<br />

<strong>and</strong> more information on the PCBs,<br />

see from page 45 <strong>and</strong> the separate<br />

service instructions for the heat pump<br />

control unit.<br />

For information regarding the power supply,<br />

see page 60.<br />

5604 692 GB<br />

22

System example 2, ID: 4605170_1103_04 (cont.)<br />

Preparing for installation<br />

2<br />

130W<br />

211.2<br />

X1. M<br />

1~ UP 6<br />

X2.N<br />

230 V/ 50 Hz<br />

X1.<br />

X2.N<br />

X1.<br />

X2.N<br />

211.4<br />

212.3<br />

ZP 37<br />

100W<br />

212.2<br />

X1. M<br />

1~ HK A1 96<br />

X2.N<br />

100W<br />

224.7<br />

X1. M<br />

1~ UPSB 52<br />

X2.N<br />

X3.1<br />

X1.<br />

X2.N<br />

X1.<br />

X2.N<br />

222.3<br />

222.4<br />

222.2<br />

222.1<br />

130W<br />

M<br />

1~<br />

50W<br />

M<br />

1~<br />

UV<br />

OPEN<br />

M<br />

1~<br />

CLOSED<br />

High limit safety 14cut-out<br />

5<br />

51<br />

High limit safety 55cut-out<br />

54<br />

Installation<br />

X2.N<br />

211.3<br />

224.4<br />

136<br />

L1<br />

L2<br />

L3<br />

N<br />

400 V, 50 Hz<br />

3 / N / PE<br />

4<br />

X3.3<br />

X3.4<br />

15<br />

8<br />

Low voltage<br />

145<br />

3<br />

2 2 145<br />

1<br />

1<br />

145<br />

145<br />

3<br />

2 145<br />

1<br />

3<br />

2<br />

1<br />

3<br />

2<br />

1<br />

2<br />

1 H1<br />

2<br />

1 H2<br />

HK A1<br />

HK M2<br />

91<br />

71<br />

105 HK M2<br />

40<br />

2<br />

20<br />

N<br />

L<br />

N<br />

74<br />

20<br />

N<br />

L<br />

M<br />

1~<br />

230 V/ 50 Hz<br />

1 / N / PE<br />

UP M2 76<br />

L<br />

N<br />

52<br />

M<br />

1~<br />

M2<br />

77<br />

1<br />

2<br />

2<br />

145<br />

2<br />

1<br />

NTC<br />

VTS M2<br />

73<br />

5604 692 GB<br />

23

Preparing for installation<br />

System example 2, ID: 4605170_1103_04 (cont.)<br />

Note<br />

The instantaneous heating water heater<br />

4, the 3-way diverter valve 5 <strong>and</strong> the<br />

secondary pump 6 are already installed<br />

<strong>and</strong> electrically connected.<br />

2<br />

211.5<br />

X1. M<br />

1~<br />

89<br />

X2.N<br />

M<br />

1~<br />

89<br />

230 V/ 50 Hz<br />

X3.3<br />

X3.4<br />

15<br />

18<br />

83<br />

X3.8<br />

X1.<br />

X3.9<br />

2<br />

PT500<br />

F6 STS 31<br />

PT500<br />

F4 PTS 61<br />

Low voltage<br />

F20<br />

F13<br />

PT500<br />

PT500<br />

KTS<br />

53<br />

VTS 62<br />

F0<br />

Ni500<br />

ATS<br />

3<br />

5604 692 GB<br />

24

System example 2, ID: 4605170_1103_04 (cont.)<br />

Preparing for installation<br />

Power supplies for the internal unit<br />

<strong>and</strong> instantaneous heating water<br />

heater<br />

Connections for the external unit<br />

4 kW 29<br />

C N L<br />

Power supply to heat pump control unit<br />

1 / N / PE<br />

230 V / 50 Hz<br />

L1<br />

N<br />

Instantaneous heating water heater power supply<br />

2 F1 6.3 AH (slow)<br />

X40<br />

L1<br />

N<br />

4 230 V<br />

L1<br />

N<br />

2<br />

43 V<br />

COM<br />

1 / N / PE<br />

230 V/ 50 Hz<br />

> 42 V<br />

L1<br />

1 / N / PE<br />

230 V/ 50 Hz<br />

L1<br />

L1<br />

N1<br />

N1<br />

N1<br />

7 kW<br />

29<br />

COM Ni Li<br />

No Lo<br />

L1<br />

N<br />

1 / N / PE<br />

230 V/ 50 Hz<br />

Installation<br />

4 400 V<br />

2<br />

3 / N / PE<br />

400 V/ 50 Hz<br />

L3<br />

L2<br />

L1<br />

N<br />

10 / 13 kW<br />

C2 C1<br />

N<br />

29<br />

L<br />

N<br />

L<br />

43 V<br />

COM<br />

> 42 V<br />

L1<br />

N<br />

1 / N / PE<br />

230 V/ 50 Hz<br />

2<br />

12 V<br />

COM<br />

5604 692 GB<br />

< 42 V<br />

25

Preparing for installation<br />

System example 2, ID: 4605170_1103_04 (cont.)<br />

"Time program DHW circulation"<br />

(if a DHW circulation pump is installed)<br />

"DHW"<br />

■ "Enable booster heaters for DHW heating 6014" "1"<br />

■ "Enable electric heaters for DHW heating 6015" "1"<br />

Instantaneous heating water heater (if installed):<br />

"Electr booster heater"<br />

■ "Enable instantaneous heating water heater<br />

7900"<br />

Required parameter settings<br />

Parameter<br />

Setting<br />

"System definition"<br />

■ "System scheme 7000" "6"<br />

"Compressor"<br />

■ "Output compressor stage 5030"<br />

Type AWB/AWB-AC<br />

■ 201.B04: "4"<br />

■ 201.B07: "7"<br />

■ 201.B10: "10"<br />

■ 201.B13: "13"<br />

"External heat source"<br />

■ "Enable external heat source 7B00" "1"<br />

■ "Enable external heat source for DHW heating "1"<br />

7B0D"<br />

DHW heating:<br />

"Time program DHW heating"<br />

Set time program (see operating<br />

instructions)<br />

Set time program (see operating<br />

instructions)<br />

"1"<br />

■ "Enable instant. heating water heater for central "1"<br />

heating 7902"<br />

"Cooling"<br />

■ "Cooling function 7100" "3"<br />

■ "Cooling circuit 7101" "2"<br />

Remote controls (if installed):<br />

"Heating circuit 1"<br />

■ "Remote control <strong>200</strong>3" "1"<br />

"Heating circuit 2"<br />

■ "Remote control 3003" "1"<br />

To call up "Coding level 1" for setting<br />

the parameters, see the commissioning<br />

assistant on page 80 <strong>and</strong> page 8.<br />

5604 692 GB<br />

26

Installation sequence<br />

Installing the external unit<br />

Please note<br />

! Avoid damaging the appliance<br />

during transportation.<br />

Never put weight on top of the<br />

appliance.<br />

Please note<br />

! If the compressor in the external<br />

unit is steeply angled, lubricant<br />

will enter the refrigerant circuit<br />

<strong>and</strong> damage the appliance.<br />

Compliance is required with the<br />

max. tilt angle according to the<br />

following table.<br />

Installation site requirements<br />

Installation location<br />

■ Select a location with good air circulation,<br />

so that the cooled air can dissipate<br />

<strong>and</strong> be replenished by warm air.<br />

■ Avoid direct insolation.<br />

Type<br />

Max. tilt angle<br />

AWB/AWB-AC<br />

201.B04 45°<br />

201.B07 45°<br />

201.B10 30°<br />

201.B13 30°<br />

■ When installing the unit where it is<br />

exposed to wind, ensure that the wind<br />

cannot influence the fan area. This<br />

might result in an "air short circuit"<br />

between the expelled <strong>and</strong> the inrushing<br />

air. Strong wind can have a negative<br />

influence on the evaporator ventilation.<br />

Please note<br />

! An "air short circuit" during<br />

heating operation will result in<br />

the cooled expelled air reentering<br />

the unit. This can lead<br />

to defrosting problems.<br />

Avoid "air short circuits".<br />

Installation<br />

5604 692 GB<br />

!<br />

Please note<br />

An "air short circuit" during<br />

cooling operation will result in<br />

the heated expelled air reentering<br />

the unit. This can lead<br />

to high pressure faults.<br />

Avoid "air short circuits".<br />

27

Installation sequence<br />

Installing the external unit (cont.)<br />

■ Take the lengths of the refrigerant<br />

lines into account (see "Connecting<br />

refrigerant lines").<br />

■ Select the installation site so that the<br />

evaporator cannot be blocked by<br />

leaves, snow etc.<br />

■ Select the installation site with due<br />

consideration of the statutory regulations<br />

on sound dissipation <strong>and</strong> reflections.<br />

Technical guide "Heat pump<br />

principles"<br />

■ Never site in the corners of rooms,<br />

recesses or between walls.<br />

■ Never install next to or below bedroom<br />

windows.<br />

■ Never install closer than 3 m from<br />

pathways, downpipes or sealed surfaces.<br />

The cooled air in the discharge<br />

area creates a risk of ice forming when<br />

outside temperatures are below<br />

10 °C.<br />

■ The installation site should be easily<br />

accessible, for example for maintenance<br />

work (see "Minimum clearances").<br />

Installation information<br />

■ Floor mounting:<br />

Use supports (accessories) for floor<br />

mounting.<br />

Where such supports cannot be used,<br />

install the external unit freest<strong>and</strong>ing on<br />

a solid base of at least 100 mm height.<br />

In difficult climatic circumstances<br />

(temperatures below zero, snow,<br />

humidity) install the appliance on a<br />

plinth of approx. 300 mm height.<br />

Take account of the weight of the<br />

external unit (see following table).<br />

■ Wall mounting:<br />

Use the wall mounting bracket set<br />

(accessory).<br />

■ Never install with the discharge side<br />

facing the main wind direction.<br />

■ Observe the wind loads when installing<br />

the unit on sites exposed to the<br />

wind.<br />

■ When mounting the unit on a wall, the<br />

wall must offer sufficient load-bearing<br />

capacity.<br />

■ Design wall outlets <strong>and</strong> protective<br />

pipes for the refrigerant lines <strong>and</strong> electrical<br />

cables without moulded parts<br />

<strong>and</strong> changes of direction.<br />

■ Incorporate the external unit into the<br />

lightning protection system.<br />

■ Consider the heat emitted by the unit<br />

when planning your weatherproofing<br />

measures or an enclosure.<br />

■ Ensure the condensate can drain<br />

freely, <strong>and</strong> create a permanent gravel<br />

bed below the external unit as a soakaway.<br />

5604 692 GB<br />

28

Installation sequence<br />

Installing the external unit (cont.)<br />

■ In regions with prolonged cold seasons<br />

(e.g. in Germany), provide an<br />

electric supplementary heating facility<br />

(accessory) for the condensate pan.<br />

■ For insulation of structure-borne noise<br />

<strong>and</strong> vibrations between the building<br />

<strong>and</strong> the external unit, consider the following<br />

measures:<br />

– Fit pipe bends to provide vibration<br />

compensation in refrigerant lines.<br />

– Route electrical cables/leads<br />

between the internal <strong>and</strong> external<br />

units free of stress.<br />

– Installation only on walls with high<br />

weight per area (> 250 kg/m 2 ), in<br />

other words not on lightweight walls,<br />

roof structure etc.<br />

– When mounting the unit on the floor,<br />

use only the rubber buffers supplied;<br />

for wall mounting use the anti-vibration<br />

mount supplied with the wall<br />

mounting bracket set; never use<br />

additional anti-vibration mounts,<br />

springs, rubber buffers etc.<br />

Weights of the external units<br />

Type<br />

Weight in kg<br />

AWB/AWB-AC<br />

201.B04 43<br />

201.B07 66<br />

201.B10 110<br />

201.B13 110<br />

5604 692 GB<br />

Installation<br />

29

Installation sequence<br />

Installing the external unit (cont.)<br />

Minimum clearances<br />

b<br />

A<br />

a<br />

c<br />

d<br />

B<br />

Example type AWB/AWB-AC 201.B04<br />

A Air intake<br />

B Air discharge<br />

Type AWB/AWB- Dimensions in mm<br />

AC<br />

a b c d<br />

201.B04 ≥ 100 ≥ 100 ≥ 300 ≥ 1000<br />

201.B07 ≥ 100 ≥ 100 ≥ 300 ≥ 1000<br />

201.B10 ≥ 100 ≥ <strong>200</strong> ≥ 300 ≥ 1000<br />

201.B13 ≥ 100 ≥ <strong>200</strong> ≥ 300 ≥ 1000<br />

5604 692 GB<br />

30

Installation sequence<br />

Installing the external unit (cont.)<br />

Floor mounting<br />

Installation<br />

2.<br />

4x<br />

D<br />

1.<br />

4x<br />

A<br />

B<br />

C<br />

5604 692 GB<br />

A Support for floor mounting (accessory)<br />

31

Installation sequence<br />

Installing the external unit (cont.)<br />

B Concrete foundations (see technical<br />

guide)<br />

C Gravel bed as condensate soakaway<br />

D Rubber buffers (supplied)<br />

Note<br />

We recommend letting condensate drain<br />

away freely (without condensate drain<br />

pipe).<br />

Wall mounting<br />

Installation must only be performed with<br />

the bracket set suitable for wall mounting<br />

(accessory).<br />

Separate installation instructions<br />

Installing the internal unit<br />

!<br />

Please note<br />

Avoid damaging the appliance<br />

during transportation.<br />

Never put weight on top of the<br />

appliance.<br />

Installation room requirements<br />

Please note<br />

! The installation room must be dry<br />

<strong>and</strong> free from the risk of frost.<br />

Ensure ambient temperatures of<br />

0 to 35 ºC.<br />

Please note<br />

! Avoid dust, gases <strong>and</strong> vapours<br />

due to a risk of explosion<br />

in the installation room.<br />

Minimum room volume (to<br />

DIN EN 378):<br />

Type AWB/AWB-<br />

AC<br />

Minimum room<br />

volume in m 3<br />

201.B04 2.7<br />

201.B07 4.8<br />

201.B10 6.7<br />

201.B13 6.7<br />

5604 692 GB<br />

32

Installation sequence<br />

Installing the internal unit (cont.)<br />

Minimum clearances<br />

A<br />

B<br />

100<br />

100<br />

1000<br />

A Cable entry 42 V<br />

5604 692 GB<br />

Installation<br />

33

Installation sequence<br />

Installing the internal unit (cont.)<br />

Fitting the internal unit to the wall<br />

5.<br />

3.<br />

1.<br />

4.<br />

2.<br />

2x<br />

5604 692 GB<br />

34

Installation sequence<br />

Connecting the refrigerant lines<br />

■ The external unit is pre-filled with<br />

refrigerant R410A.<br />

■ Install oil lift bends (see illustration)<br />

into the vertical lines in the following<br />

cases:<br />

– In heating mode, if the internal unit<br />

is installed higher than the external<br />

unit.<br />

– In cooling mode, if the internal unit is<br />

installed lower than the external unit.<br />

Routing refrigerant lines<br />

Type AWB/AWB-AC 201.B04 201.B07 201.B10 201.B13<br />

Refrigerant lines<br />

Min. line length 3 m 3 m 3 m 3 m<br />

Max. line length 20 m 30 m 30 m 30 m<br />

Max. height differential of internal<br />

unit – external unit<br />

10 m 15 m 15 m 15 m<br />

Note<br />

No topping up is required for line lengths<br />

between 3 <strong>and</strong> 12 m.<br />

A<br />

C Liquid line<br />

D Hot gas line<br />

E Oil lift bends<br />

, Flow direction for heating mode<br />

, Flow direction for cooling mode<br />

Installation<br />

B<br />

C<br />

E<br />

5000<br />

D<br />

5000<br />

Example type AWB/AWB-AC 201.B07<br />

A<br />

B<br />

Internal unit<br />

External unit<br />

5604 692 GB<br />

35

Installation sequence<br />

Connecting the refrigerant lines (cont.)<br />

Isolation of structure-borne sound <strong>and</strong> vibrations<br />

A<br />

B<br />

C<br />

D<br />

Note<br />

Route connecting cables <strong>and</strong> refrigerant lines separately.<br />

A Pipe bends as vibration compensators<br />

B Clips with EPDM lining<br />

C Wall outlet, e.g. drainage pipe with<br />

thermal insulation<br />

D Electrical cables/leads, internal/<br />

external unit<br />

5604 692 GB<br />

36

Installation sequence<br />

Connecting the refrigerant lines (cont.)<br />

Connection to the external unit<br />

1. Type AWB/AWB-AC 201.B04 <strong>and</strong><br />

201.B07:<br />

Remove the side cover; see<br />

page 58.<br />

2.<br />

D<br />

C<br />

3.<br />

2x<br />

Installation<br />

D<br />

C<br />

4.<br />

Example type AWB/AWB-AC 201.B04<br />

C Liquid line<br />

D Hot gas line<br />

5604 692 GB<br />

37

Installation sequence<br />

Connecting the refrigerant lines (cont.)<br />

2.<br />

!<br />

Please note<br />

No contamination (e.g. metal<br />

swarf) or moisture should<br />

enter the copper pipes.<br />

Therefore, hold the pipe openings<br />

down or plug them.<br />

3. Swage the pipe ends.<br />

4. Secure the pipes.<br />

Remove the nuts from connections<br />

C (liquid line) <strong>and</strong> D (hot gas line)<br />

of the refrigerant lines.<br />

Type AWB/AWB-AC 201.B04:<br />

Slide the nuts onto the refrigerant<br />

lines prepared on site.<br />

Type AWB/AWB-AC 201.B07,<br />

201.B10, 201.B13:<br />

Replace nuts with union nuts supplied<br />

(internal unit) (⅝ UNF for liquid<br />

line, ⅞ UNF for hot gas line).<br />

Tighten the nuts with the following torques:<br />

Type Line<br />

Connection to Torque in Nm<br />

AWB/<br />

AWB-AC<br />

external unit<br />

201.B04 Liquid line 7 6 mm ⁷⁄₁₆ UNF 14–18<br />

Hot gas line 7 12 mm ¾ UNF 50–62<br />

201.B07 Liquid line 7 10 mm ⅝ UNF 33–42<br />

Hot gas line 7 16 mm ⅞ UNF 63–77<br />

201.B10 Liquid line 7 10 mm ⅝ UNF 33–42<br />

Hot gas line 7 16 mm ⅞ UNF 63–77<br />

201.B13 Liquid line 7 10 mm ⅝ UNF 33–42<br />

Hot gas line 7 16 mm ⅞ UNF 63–77<br />

5604 692 GB<br />

38

Installation sequence<br />

Connecting the refrigerant lines (cont.)<br />

Connection to the internal unit<br />

2x<br />

2.<br />

D<br />

C<br />

Installation<br />

1.<br />

D<br />

C<br />

D<br />

C<br />

3.<br />

C Liquid line<br />

Please note<br />

! No contamination (e.g. metal<br />

swarf) or moisture should enter<br />

the copper pipes.<br />

Therefore, hold the pipe openings<br />

down or plug them.<br />

Note<br />

The refrigerant lines of the internal unit<br />

are filled with nitrogen, overpressure<br />

1 to 2 bar.<br />

D Hot gas line<br />

1. Remove the nuts from the refrigerant<br />

connections C <strong>and</strong> D.<br />

Type AWB/AWB-AC 201.B04:<br />

Replace nuts with union nuts supplied<br />

(⁷⁄₁₆ UNF for liquid line, ¾ UNF<br />

for hot gas line). Connect supplied<br />

reducer with copper sealing ring.<br />

Type AWB/AWB-AC 201.B07,<br />

201.B10, 201.B13:<br />

Push the nuts onto the associated<br />

refrigerant lines from the external<br />

unit.<br />

5604 692 GB<br />

39

Installation sequence<br />

Connecting the refrigerant lines (cont.)<br />

2. Swage the pipe ends of the refrigerant<br />

lines.<br />

Note<br />

If solder fittings are used, solder the<br />

fittings using an inert gas.<br />

3. Fit refrigerant lines <strong>and</strong> insulate them<br />

to provide protection from heat <strong>and</strong><br />

vapour diffusion.<br />

Tighten the nuts with the following torques:<br />

Type Line<br />

Connection to Torque in Nm<br />

AWB/<br />

AWB-AC<br />

internal unit<br />

201.B04 Liquid line 7 6 mm ⅝ UNF<br />

33–42<br />

with reducer<br />

⅝ x ⁷⁄₁₆ 14–18<br />

Hot gas line 7 12 mm ⅞ UNF<br />

63–77<br />

with reducer<br />

⅞ x ¾ 50–62<br />

201.B07 Liquid line 7 10 mm ⅝ UNF 33–42<br />

Hot gas line 7 16 mm ⅞ UNF 63–77<br />

201.B10 Liquid line 7 10 mm ⅝ UNF 33–42<br />

Hot gas line 7 16 mm ⅞ UNF 63–77<br />

201.B13 Liquid line 7 10 mm ⅝ UNF 33–42<br />

Hot gas line 7 16 mm ⅞ UNF 63–77<br />

5604 692 GB<br />

40

Installation sequence<br />

Connecting a secondary circuit<br />

+<br />

Installation<br />

Refrigerant lines from/to the external<br />

unit<br />

Symbol Meaning Connection<br />

DHW cylinder flow (heating water side)<br />

G 1¼<br />

+<br />

Heating water return <strong>and</strong> DHW cylinder<br />

return<br />

Heating water flow<br />

G 1¼<br />

G 1¼<br />

1. Equip the secondary circuit on site<br />

with an expansion vessel <strong>and</strong> safety<br />

assembly (in accordance with<br />

DIN 4757).<br />

Fit the safety assembly to the on-site<br />

line in the heating water return.<br />

2. Connect secondary lines to the heat<br />

pump.<br />

Please note<br />

! To prevent equipment damage,<br />

connect on-site secondary<br />

lines to the heat pump so that<br />

they are free of load <strong>and</strong> torque<br />

stresses.<br />

Make tight hydraulic connections<br />

on the secondary side.<br />

5604 692 GB<br />

3. Fill <strong>and</strong> vent secondary circuit.<br />

41

Installation sequence<br />

Connecting a secondary circuit (cont.)<br />

4. Thermally insulate pipes inside the<br />

building.<br />

5. Connect the drain hose to the safety<br />

valve.<br />

Connect the drain hose with a slope<br />

<strong>and</strong> a pipe vent to the public sewer.<br />

Note<br />

■ In underfloor heating circuits, install a<br />

temperature limiter to limit the maximum<br />

temperature for underfloor heating<br />

systems (see page 8)<br />

■ Safeguard minimum flow rate, e.g.<br />

with overflow valve (see Specification<br />

on page 125)<br />

Connecting a cooling circuit if required<br />

For area cooling systems (e.g. underfloor<br />

heating circuit, chilled ceiling), a<br />

contact humidistat (accessory) is<br />

required.<br />

Requirements for the contact humidistat:<br />

■ Electrical connection: 230 V~, 0.5 A<br />

■ Installation inside the room to be<br />

cooled at the cooling water flow<br />

(remove thermal insulation if required)<br />

■ If several rooms with different relative<br />

humidity are part of the cooling circuit,<br />

fit <strong>and</strong> connect several contact humidistats<br />

in series:<br />

Switching contacts as N/C contacts<br />

Electrical connections<br />

Routing electrical cables to the wiring chamber of the internal<br />

unit<br />

Danger<br />

Damaged cable insulation can<br />

cause injury <strong>and</strong> damage to the<br />

appliance.<br />

Route cables so that they cannot<br />

touch very hot, vibrating or sharpedged<br />

components.<br />

Danger<br />

Incorrectly routed wiring can lead<br />

to serious injury from electrical<br />

current <strong>and</strong> result in equipment<br />

damage.<br />

5604 692 GB<br />

42

Installation sequence<br />

Electrical connections (cont.)<br />

■ Route LV leads < 42 V <strong>and</strong><br />

cables > 42 V/230 V~/400 V~<br />

separately.<br />

■ Strip the insulation from the<br />

cables as close to the terminals<br />

as possible, <strong>and</strong> bundle tightly<br />

to the corresponding terminals.<br />

■ Secure cables with cable ties.<br />

This ensures that, should there<br />

be an error, for example when<br />

detaching a wire, the wires cannot<br />

drift into the adjacent voltage<br />

area.<br />

!<br />

Please note<br />

From a safety viewpoint, the BUS<br />

cable for the internal/external unit<br />

(12 V or 43 V) does not count as<br />

an LV lead.<br />

The BUS cable must be routed<br />

together with the 230 V cables.<br />

Note<br />

To ensure that the control panel can be<br />

placed in the service position (see<br />

page 90), all connections on the control<br />

panel (see page 45) must be made<br />

with flexible cables.<br />

5604 692 GB<br />

Installation<br />

43

Installation sequence<br />

Electrical connections (cont.)<br />

< 42V<br />

> 42V<br />

400V<br />

230V<br />

!<br />

B<br />

A<br />

A Type AWB/AWB-AC 201.B10 <strong>and</strong><br />

201.B13:<br />

12 V BUS cable: Routing in the<br />

230 V~ voltage area (for connection,<br />

see page 59)<br />

B Type AWB/AWB-AC 201.B04 <strong>and</strong><br />

201.B07:<br />

43 V BUS cable: Routing in the<br />

230 V~ voltage area (for connection,<br />

see page 59)<br />

5604 692 GB<br />

44

Installation sequence<br />

Electrical connections (cont.)<br />

Overview of connections: Internal unit<br />

Note<br />

■ Route 230 V~ cables <strong>and</strong> LV cables<br />

separately <strong>and</strong> bundle them tightly<br />

together at the terminals. This ensures<br />

that, in case of failure, for example<br />

when detaching a wire, the wires cannot<br />

drift into the adjacent voltage area.<br />

■ Strip the insulation as close to the terminals<br />

as possible.<br />

■ If two components are connected to<br />

the same terminal, press both wires<br />

together into a single wire ferrule.<br />

5604 692 GB<br />

Installation<br />

45

Installation sequence<br />

Electrical connections (cont.)<br />

F101<br />

A<br />

P202<br />

12V COM<br />

P203<br />

COM 43V<br />

B<br />

3.8 3.3<br />

X<br />

D<br />

3.9 3.4<br />

3.1 3.6 211.4<br />

3.7 211.2<br />

F1<br />

L1<br />

C<br />

N<br />

<br />

X1<br />

N 3 2 1<br />

X2<br />

aVG<br />

F0<br />

F6 F7 F4<br />

F14<br />

F13<br />

F16<br />

F21<br />

F18 F20<br />

F3<br />

212 211<br />

224 222<br />

F<br />

G<br />

E<br />

X31<br />

5604 692 GB<br />

46

Installation sequence<br />

Electrical connections (cont.)<br />

A AVI PCB (see page 57)<br />

F101 Fuse 1.0A (slow)<br />

B Control module <strong>and</strong> power supply<br />

for instantaneous heating water<br />

heater<br />

C Power supply 230 V~ (see<br />

pages 60)<br />

F1 Fuse 6.3A (slow)<br />

D Luster terminals (see page 54)<br />

E Controller <strong>and</strong> sensor PCB (see<br />

page 56)<br />

F Main PCB (see page 47)<br />

F3 Fuse 6.3A (slow)<br />

G Extension PCB on main PCB (see<br />

page 50)<br />

Main PCB (operating components 230 V~)<br />

Information regarding the connection<br />

values<br />

■ The output given is the recommended<br />

connected load.<br />

■ The total output of all components connected<br />

directly to the heat pump control<br />

unit must not exceed 1000 W (e.g.<br />

pumps, valves, message facilities,<br />

contactors).<br />

If the total output < 1000 W, the individual<br />

rating of a component (e.g.<br />

pump, valve, message facility, contactor)<br />

can be greater than specified.<br />

However, never exceed the breaking<br />

capacity of the corresponding relay.<br />

■ The stated current indicates the max.<br />

switching current of the switching contact<br />

(observe the total current of 5 A).<br />

■ Safety LV is unsuitable for controlling<br />

external heat sources.<br />

Set the required parameters during commissioning;<br />

see from page 80.<br />

Installation<br />

5604 692 GB<br />

Plug sYA<br />

Terminals Function Explanation<br />

211.5<br />

AC<br />

Type AWB-AC:<br />

Cooling control<br />

3-way diverter valves for<br />

heating water buffer cylinder<br />

bypass in cooling mode<br />

Connection values<br />

■ Max. output: 10 W<br />

■ Voltage: 230 V~<br />

■ Max. switching current: 4(2) A<br />

Connect the 3-way diverter valves for the<br />

bypass circuit in parallel.<br />

47

Installation sequence<br />

Electrical connections (cont.)<br />

Plug sYS<br />

Terminals Function Explanation<br />

212.2<br />

A1<br />

Heating circuit pump for<br />

heating circuit without mixer<br />

(A1)<br />

■ This pump is installed in addition to the<br />

secondary pump if a heating water buffer<br />

cylinder is connected.<br />

■ Connect temperature limiter as maximum<br />

temperature limiter for underfloor<br />

heating circuit (if installed) in series<br />

(see the following chapter)<br />

Connection values<br />

■ Output: 100 W<br />

■ Voltage: 230 V~<br />

■ Max. switching current: 4(2) A<br />

Connect on site.<br />

212.3 DHW circulation pump Connection values<br />

■ Output: 50 W<br />

■ Voltage: 230 V~<br />

■ Max. switching current: 4(2) A<br />

Connect on site.<br />

Connecting a temperature limiter as a maximum temperature limiter for underfloor<br />

heating<br />

Connecting a general temperature<br />

limiter B<br />

Connecting the temperature limiter,<br />

part no. 7151 728, 7151 729 B<br />

X2.N<br />

X1. <br />

A<br />

B<br />

X2.N<br />

X1. <br />

A<br />

B<br />

sÖ<br />

C<br />

M<br />

1~<br />

C<br />

M<br />

1~<br />

5604 692 GB<br />

48

Installation sequence<br />

Electrical connections (cont.)<br />

Heating circuit without mixer A1/<br />

HC1<br />

Connection Circulation pump C<br />

A to control<br />

unit<br />

211.2 Secondary pump<br />

■ Without heating water buffer cylinder<br />

■ With heating water buffer cylinder 212.2 Heating circuit pump A1/<br />

HC1<br />

Connecting the temperature limiter,<br />

part no. 7151 728, 7151 729 B to<br />

mixer extension kit<br />

A<br />

Installation<br />

sÖ<br />

B<br />

sÖ<br />

C<br />

M<br />

1~<br />

A Connect plug sÖ to mixer extension<br />

kit<br />

B Temperature limiter<br />

C Heating circuit pump for heating circuit<br />

with mixer<br />

5604 692 GB<br />

49

Installation sequence<br />

Electrical connections (cont.)<br />

Extension PCB on main PCB<br />

Information regarding the connection<br />

values<br />

■ The output given is the recommended<br />

connected load.<br />

■ The total output of all components connected<br />

directly to the heat pump control<br />

unit (e.g. pumps, valves, message<br />

facilities, contactors) must not exceed<br />

1000 W.<br />

If the total output is < 1000 W, the individual<br />

output of a component (e.g.<br />

pump, valve, messaging facility, contactor)<br />

may be selected larger than<br />

specified. However, the breaking<br />

capacity of the corresponding relay<br />

must not be exceeded.<br />

■ The stated current indicates the max.<br />

switching current of the switching contact<br />

(observe the total current of 5 A).<br />

■ Controls for external heat source <strong>and</strong><br />

central fault message are unsuitable<br />

for safety LV.<br />

Set the required parameters during commissioning;<br />

see from page 80.<br />

Function components 230 V~<br />

Plug sXS<br />

Terminals Function Explanation<br />

222.1 Mixer motor control for<br />

external heat source<br />

Signal mixer CLOSED<br />

Connection values:<br />

■ Output: 10 W<br />

■ Voltage: 230 V~<br />

■ Max. switching current: 0.2(0.1) A<br />

222.2 Mixer motor control for<br />

external heat source<br />

Signal mixer OPEN<br />

Connect on site.<br />

Connection values:<br />

■ Output: 10 W<br />

■ Voltage: 230 V~<br />

■ Max. switching current: 0.2(0.1) A<br />

Connect on site.<br />

5604 692 GB<br />

50

Installation sequence<br />

Electrical connections (cont.)<br />

Plug sXS<br />

Terminals Function Explanation<br />

222.3<br />

222.4<br />

Zero volt contact<br />

Switching external heat<br />

source with two high limit<br />

safety cut-outs (max. 70 °C)<br />

to protect the heat pump <strong>and</strong><br />

to stop the secondary pump<br />

Note<br />

■ The switching contact is a zero volt N/<br />

O contact that is closed when a heat<br />

dem<strong>and</strong> is issued.<br />

■ Never route low voltage via this contact;<br />

that requires an on-site relay.<br />

■ The boiler water temperature sensor in<br />

the external heat source (plug F20)<br />

must capture the average temperature<br />

of the external heat source.<br />

Connection values (contact loads):<br />

■ Voltage: 230 V~<br />

■ Max. switching current: 4(2) A<br />

Installation<br />

Connect the high limit safety cut-out on<br />

site:<br />

■ In series to the secondary pump (terminal<br />

211.2 on the main PCB).<br />

■ In series to the switching of external<br />

heat sources.<br />

5604 692 GB<br />

51

Installation sequence<br />

Electrical connections (cont.)<br />

High limit safety cut-out for heat<br />

pump in conjunction with an external<br />

heat source<br />

222.3<br />

222.4<br />

D<br />

A<br />

X3.1 B<br />

C<br />

C Connection on the external heat<br />

source at terminals for external<br />

dem<strong>and</strong><br />

D High limit safety cut-out (max. 70<br />

°C) as heat pump protection<br />

K1 Relay; sizing in accordance with the<br />

external heat source; observe<br />

safety instructions<br />

K1<br />

X2.N<br />

A Terminals on extension PCB<br />

B Move jumper from X3.1 to 222.3<br />

Plug sXF<br />

Terminals Function Explanation<br />

224.7 Circulation pump for DHW<br />

reheating<br />

or<br />

Connection values<br />

■ Max. output: 100 W<br />

■ Voltage: 230 V~<br />

■ Max. switching current: 4(2) A<br />

EHE immersion heater control<br />

(for connection, see the<br />

following diagram)<br />

Connect on site.<br />

5604 692 GB<br />

52

Installation sequence<br />

Electrical connections (cont.)<br />

Immersion heater (400 V~)<br />

L1 L2 L3 N <br />

224.7<br />

B<br />

X2.N<br />

A<br />

Installation<br />

A Immersion heater, power supply<br />

3/N/PE 400 V/50 Hz<br />

B Terminals of the heat pump control<br />

unit<br />

Immersion heater (230 V~, on site)<br />

L1 L1 L1 N N N <br />

224.7<br />

B<br />

X2.N<br />

A<br />

A Immersion heater, power supply<br />

1/N/PE 230 V/50 Hz<br />

B Terminals of the heat pump control<br />

unit<br />

5604 692 GB<br />

53

Installation sequence<br />

Electrical connections (cont.)<br />

Luster terminals<br />

Set the required parameters during commissioning;<br />

see from page 80.<br />

Message <strong>and</strong> safety connections<br />

Terminals Function Explanation<br />

F1 Fuse, heat pump control 6.3 A (slow)<br />

unit<br />

X3.1 Switched phase. Via control unit ON/OFF switch.<br />

Note<br />

Observe the total load (1000 W) of all connected<br />

components.<br />

X3.3<br />

X3.4<br />

X3.6<br />

X3.7<br />

G<br />

Flow switch, secondary<br />

circuit.<br />

Power-OFF (jumper fitted<br />

at the factory)<br />

Floating contact required:<br />

■ Closed: Heat pump in operation<br />

■ Open: Heat pump shut down<br />

■ Breaking capacity 230 V~, 0.15 A<br />

With a connected flow switch, no jumpers<br />

should be installed.<br />

Floating contact required:<br />

■ Closed: Heat pump in operation<br />

■ Open: Heat pump shut down<br />

■ Breaking capacity 230 V, 0.15 A<br />

Connect on site; remove jumper when connecting.<br />

5604 692 GB<br />

54

Installation sequence<br />

Electrical connections (cont.)<br />

Terminals Function Explanation<br />

Note<br />

■ No parameters need to be set.<br />

■ The compressor is "forced" off as soon<br />

as the contact opens.<br />

■ The supply voltage to the relevant components<br />

(subject to power supply utility)<br />

is switched off by the power-OFF contact<br />

signal.<br />

■ For the instantaneous heating water<br />

heater, the stages to be switched off can<br />

be selected (parameter "Output for<br />

instant. heating water heater at<br />

power-OFF 790A").<br />

■ The heat pump control unit power supply<br />

(3 x 1.5 mm 2 ) <strong>and</strong> the cable for the<br />

power-OFF signal can be combined in a<br />

5-core cable.<br />

■ For further information regarding power-<br />

OFF, see chapter "Power supply".<br />

Installation<br />

X3.8<br />

X3.9<br />

X40.L1<br />

■ Type AWB-AC:<br />

Contact humidistat <strong>and</strong>/<br />

or frost stat, cooling<br />

or<br />

Jumper<br />

■ Type AWB:<br />

Jumper<br />

Heat pump control unit<br />

power supply:<br />

Phase L1<br />

X40. Earth conductor<br />

connection<br />

X40.N Neutral conductor<br />

connection<br />

Floating contact required:<br />

■ Closed: Safety chain has continuity.<br />

■ Open: Safety chain interrupted; heat<br />

pump shut down.<br />

■ Breaking capacity 230 V~, 0.15 A<br />

Connect on site:<br />

■ Connected in series if both safety components<br />

are installed.<br />

■ Insert jumper if no safety components<br />

are installed.<br />

Connected to 230 V~ power supply on<br />

site.<br />

5604 692 GB<br />

55

Installation sequence<br />

Electrical connections (cont.)<br />

Terminals Function Explanation<br />

211.2 Secondary pump Connection values<br />

■ Max. output: 130 W<br />

■ Voltage: 230 V~<br />

■ Max. switching current: 4(2) A<br />

211.4<br />

r M<br />

M<br />

3-way diverter valve<br />

"Heating/DHW"<br />

In conjunction with the primary<br />

store system:<br />

■ Cylinder primary pump<br />

■ 2-way shut-off valve<br />

Connected at the factory.<br />

■ In systems without a heating water buffer<br />

cylinder, no other heating circuit<br />

pump is required (see terminal 212.2).<br />

■ Connect the temperature limiter as a<br />

maximum temperature limiter for underfloor<br />

heating circuit in series on site (see<br />

page 8).<br />

Connection values<br />

■ Max. output: 130 W<br />

■ Voltage: 230 V~<br />

■ Max. switching current: 4(2) A<br />

3-way diverter valve connected at the factory;<br />

connect the cylinder primary pump in<br />

parallel on site.<br />

Controller <strong>and</strong> sensor PCB<br />

Set the required parameters during commissioning;<br />

see from page 80.<br />

Note<br />

■ Plugs F11, F17:<br />

Nothing must be connected to plug<br />

F11 <strong>and</strong> F17 on site.<br />

Sensors<br />

Plugs Sensor Type<br />

F0 Outside temperature sensor; connect on site Ni 500<br />

(PTC)<br />

F4<br />

(X5.6/X5.7)<br />

Buffer temperature sensor, top; connect on site Pt 500<br />

(PTC)<br />

F6<br />

(X6.1/X6.2)<br />

Cylinder temperature sensor, top; connect on site Pt 500<br />

(PTC)<br />

5604 692 GB<br />

56

Installation sequence<br />

Electrical connections (cont.)<br />

Plugs Sensor Type<br />

F7<br />

(X6.1/X6.3)<br />

Cylinder temperature sensor, bottom; connect on site Pt 500<br />

(PTC)<br />

F13 System flow temperature sensor (with sensor well, downstream<br />

of heating water buffer cylinder); connect on site<br />

Pt 500<br />

(PTC)<br />

F14 Flow temperature sensor, cooling circuit (direct heating<br />

circuit A1/HC1 or separate cooling circuit); connect on<br />

site<br />

Ni 500<br />

(PTC)<br />

F16<br />

F20<br />