maintenance - Polaris

maintenance - Polaris

maintenance - Polaris

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

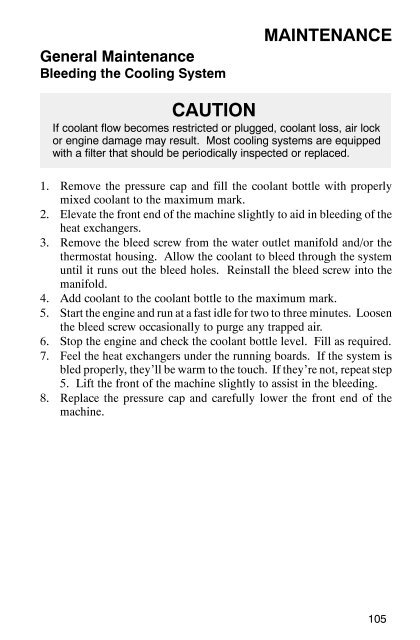

General Maintenance<br />

Bleeding the Cooling System<br />

MAINTENANCE<br />

CAUTION<br />

If coolant flow becomes restricted or plugged, coolant loss, air lock<br />

or engine damage may result. Most cooling systems are equipped<br />

with a filter that should be periodically inspected or replaced.<br />

1. Remove the pressure cap and fill the coolant bottle with properly<br />

mixed coolant to the maximum mark.<br />

2. Elevate the front end of the machine slightly to aid in bleeding of the<br />

heat exchangers.<br />

3. Remove the bleed screw from the water outlet manifold and/or the<br />

thermostat housing. Allow the coolant to bleed through the system<br />

until it runs out the bleed holes. Reinstall the bleed screw into the<br />

manifold.<br />

4. Add coolant to the coolant bottle to the maximum mark.<br />

5. Start the engine and run at a fast idle for two to three minutes. Loosen<br />

the bleed screw occasionally to purge any trapped air.<br />

6. Stop the engine and check the coolant bottle level. Fill as required.<br />

7. Feel the heat exchangers under the running boards. If the system is<br />

bled properly, they’ll be warm to the touch. If they’re not, repeat step<br />

5. Lift the front of the machine slightly to assist in the bleeding.<br />

8. Replace the pressure cap and carefully lower the front end of the<br />

machine.<br />

105