September 2009 - AFMA

September 2009 - AFMA

September 2009 - AFMA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

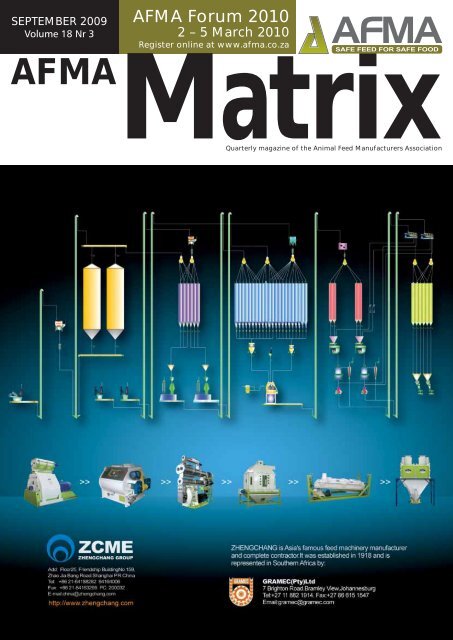

SEPTEMBER <strong>2009</strong><br />

Volume 18 Nr 3<br />

<strong>AFMA</strong><br />

<strong>AFMA</strong> Forum 2010<br />

2 – 5 March 2010<br />

Register online at www.afma.co.za<br />

Matrix<br />

Quarterly magazine of the Animal Feed Manufacturers Association

XX<br />

<strong>AFMA</strong><br />

Matrix<br />

CONTENTS<br />

SEPTEMBER <strong>2009</strong><br />

Volume 18 Nr 3<br />

EDITORIAL OFFICE<br />

Embankment Park, 194 Kwikkie Crescent,<br />

Centurion 0157<br />

Tel: +27 12 663 9097<br />

Tel: +27 12 663 9361<br />

Fax: +27 12 663 9612<br />

E-mail: admin@afma.co.za<br />

Website: www.afma.co.za<br />

PUBLISHER<br />

<strong>AFMA</strong><br />

PO Box 8144 Centurion 0046<br />

Embankment Park, 194 Kwikkie Crescent,<br />

Centurion 0157<br />

Tel: +27 12 663 9097<br />

Tel: +27 12 663 9361<br />

Fax: +27 12 663 9612<br />

E-mail: admin@afma.co.za<br />

Website: www.afma.co.za<br />

ADVERTISEMENTS<br />

<strong>AFMA</strong><br />

PO Box 8144 Centurion 0046<br />

Embankment Park, 194 Kwikkie Crescent,<br />

Centurion 0157<br />

Tel: +27 12 663 9097<br />

Tel: +27 12 663 9361<br />

Fax: +27 12 663 9612<br />

E-mail: admin@afma.co.za<br />

Website: www.afma.co.za<br />

DESIGN & LAYOUT<br />

Gecko Communications<br />

PO Box 11436 Erasmuskloof 0048<br />

Centurion Office Park, Block A, Ground Floor,<br />

Embankment Road, Centurion 0157<br />

Tel: +27 12 683 0231<br />

Fax: +27 86 626 7701<br />

E-mail: studio@geckocom.co.za<br />

Website: www.geckocom.co.za<br />

PRINTERS<br />

Beria Printers-Publishers<br />

PO Box 48078 Hercules 0030<br />

30 Jacaranda Street, Dirk Smit Industrial Park,<br />

Section 8 & 9, Hennopspark X35,<br />

Centurion 0157<br />

Tel: +27 12 653 2941<br />

Fax: +27 12 653 3487<br />

Opinions expressed in articles are not<br />

necessarily endorsed by <strong>AFMA</strong>.<br />

© Copyright. Articles may be used with the<br />

necessary acknow ledgement to the author<br />

and <strong>AFMA</strong> MATRIX.<br />

2 Preface: Facing the Feed Industry Challenges<br />

By Brett Roosendaal – National Feed Technical Manager, Epol<br />

4 Clay minerals to fight footpad lesions<br />

By Arno van der Aa – Technical Manager, Orffa Additives<br />

12 Correct particle size benefits animal performance<br />

By Dick Ziggers<br />

24 Industry News<br />

• AFGRI - first in <strong>AFMA</strong> Code of Conduct certification<br />

26 Does your finished product shrink or grow<br />

By Ian Buick – Operations Management Services Ltd, UK<br />

32 Industry News<br />

• New Managing Director for Astral Foods:<br />

Feed Division<br />

• Mario le Roux new MD of Nutri Feeds (Pty) Ltd<br />

• Cuthbert Mambolo joins Bedson Africa<br />

34 Stool management in sows: keep the GI tract<br />

By Ernst-Günther Hellwig and Dr Heinrich Kleine Klausing<br />

41 Basic principles for finishing lambs in a feedlot<br />

By Dr Conrad Coetzer – Director: Technological<br />

Development, AFGRI Animal Feeds<br />

42 Industry News<br />

• The Oceana Group<br />

44 Coming events<br />

<strong>September</strong> <strong>2009</strong> <strong>AFMA</strong> MATRIX 1

PREFACE<br />

Facing the Feed<br />

Industry Challenges<br />

By Brett Roosendaal – National Feed Technical Manager, Epol<br />

The last quarter of 2008 will be<br />

remembered as one of the most<br />

tumultuous periods in the history<br />

of modern capital markets, and its<br />

first anniversary is upon us. Do<br />

we need to be reminded that global<br />

equity markets collapsed by over<br />

40%, credit markets froze, housing<br />

prices declined and central bankers<br />

extended their lending facilities<br />

beyond the imaginable. South<br />

Africa to a large extent escaped<br />

the direct impact of this financial<br />

market turmoil. The indirect effects<br />

of the global recession have become<br />

evident however, with amongst<br />

others, softening in animal protein<br />

demand and a consequent decline in<br />

prime lending rates.<br />

Feed raw material prices peaked<br />

at historically high levels during<br />

the past twelve months and have<br />

remained exceptionally volatile.<br />

Record high prices across all<br />

commodities were attained, followed<br />

by the credit crunch and then, more<br />

recently, a rapid fall in commodity<br />

prices. The foregoing together<br />

with exchange rate volatility has<br />

translated into significant challenges<br />

for raw material procurement and<br />

has placed feed companies’ margins<br />

at risk. These challenges have been<br />

compounded by extra feed milling<br />

capacity being created by new<br />

entrants into the market and by the<br />

expansion of existing companies.<br />

Feed margins are going to be under<br />

pressure for the foreseeable future<br />

and will return to more moderate<br />

levels in the short term as<br />

supply and demand economics<br />

dictate.<br />

The local chicken market is<br />

estimated to have grown in rand<br />

value by 10% in the past twelve<br />

months to R17,7 billion as meat<br />

substitution shifts the priority away<br />

from beef and pork. Meat demand<br />

is expected to keep on increasing<br />

due to more South Africans having<br />

larger disposable incomes and<br />

moving into higher socio-economic<br />

groups.<br />

Taking account of the context<br />

portrayed above the Congress<br />

Committee has crafted the 8th<br />

International Congress for the<br />

Feed Industry to address a number<br />

of these imminent challenges by<br />

internationally renowned experts.<br />

Topics include the “Global Financial<br />

and Economic Situation, Global<br />

Feed Situation, and Global Raw<br />

Material Situation”. Global Feed<br />

Safety and the European Regulatory<br />

environment will also be defined<br />

in a paper presented by The<br />

European Feed Safety Authority.<br />

The role of the nutritionist will<br />

receive attention in a paper called<br />

“Businessman Nutritionist – The<br />

nutritionist’s role in cost efficient<br />

feeding”. Current “buzz” topics are<br />

also covered, namely the advent<br />

of AGP-free nutrition and gut<br />

health. Recent advances in specie<br />

specific nutritional topics will be<br />

presented by speakers such as Steve<br />

Leeson, Lourens Erasmus, Simon<br />

Tibble, and Merryl Webster on mill<br />

optimization. Vitamin and mineral<br />

nutrition as well as mill hygiene<br />

and energy efficiency in the<br />

feedmill are topics that will receive<br />

airtime.<br />

The overriding flavour of the<br />

International Congress is one where<br />

we find ourselves in a global context<br />

and in what way we can endeavour<br />

to build demand and produce more<br />

cost efficiently through the animal<br />

protein value chain. Delegates<br />

should experience profound<br />

intellectual enrichment with<br />

practical and commercial take-out<br />

to advance their business interests<br />

in the feed and animal protein<br />

production industries.<br />

A number of support industries to<br />

the feed industry will be present<br />

in the exhibitors hall to showcase<br />

their recent developments and will<br />

include Buhler, Kemin, Novus and<br />

ADDCON. Apart from the formal<br />

presentations, a further major<br />

benefit will be the networking<br />

opportunity the Congress will<br />

provide as it attracts interested<br />

parties from the sub-region, the<br />

continent, surrounding islands<br />

and from overseas. The venue<br />

is Sun City with its world-class<br />

facilities in terms of entertainment,<br />

restaurants, accommodation and the<br />

game reserve close by. I hope the<br />

program will act as a sweetener and<br />

entice you to join <strong>AFMA</strong> in hosting<br />

the 8 th International Congress<br />

for the Feed Industry in southern<br />

Africa.<br />

2 <strong>AFMA</strong> MATRIX <strong>September</strong> <strong>2009</strong>

NUTRITION<br />

Clay minerals<br />

to fight footpad<br />

lesions<br />

Footpad lesions in poultry are an indicator of animal welfare<br />

standards. Footpad burns often indicate that the animals are not<br />

properly housed and fed. Arno van der Aa explains how clay<br />

minerals in the diet can help prevent these painful foot conditions.<br />

By Arno van der Aa – Technical Manager, Orffa Additives<br />

The implementation of welfare<br />

measurements for broilers in recently<br />

approved legislation has put the<br />

importance of preventing footpad<br />

lesions in a new perspective. In June<br />

2007 EU Directive 2007-43-EC<br />

became effective and implementation<br />

is due on 30 th June, 2010. During<br />

the long negotiations the uptake of<br />

footpad lesions has been in and out of<br />

this Directive. It was finally decided<br />

not to include footpad lesions as an<br />

effective parameter in the Directive.<br />

However, it was noted that at the<br />

evaluation of this directive in 2012<br />

this parameter would be revisited.<br />

Clinoptilolites are specially selected clay<br />

minerals, known for their typical structure<br />

which enables the clay mineral to bind<br />

ammonia.<br />

Importance of the issue<br />

Concurrently, the discussion also<br />

continues on a national level. In the<br />

Netherlands, for example, footpad<br />

lesions were still planned to be taken<br />

up by the national implementation<br />

of the EU Directive 2007-43-EC.<br />

This would mean that the incidence<br />

of footpad lesions would become a<br />

tool to define the density of birds<br />

a poultry farmer is allowed to keep,<br />

which has a direct bearing on the<br />

economical results. Just before<br />

governmental approval in July 2008,<br />

footpad lesions were (again) left out<br />

of the Dutch regulation. But the<br />

government agreed with the poultry<br />

industry to investigate possibilities<br />

for monitoring and addressing the<br />

problem of footpad lesions. This again<br />

indicates the importance of footpad<br />

lesions, and moreover the difficulty<br />

for governments to effectively include<br />

this parameter in their legislation.<br />

In some countries footpad lesions<br />

have already had a direct effect on<br />

farmers’ income. Sweden already<br />

started in 1994 with the “broiler foot<br />

health programme”. In Denmark<br />

footpad lesions are measured in the<br />

slaughterhouse and farmers are<br />

awarded for good results. It is very<br />

likely that more countries will soon<br />

follow this kind of practice, or that<br />

retail and/or NGO’s become driving<br />

forces to fulfill consumer demands.<br />

For the benefit of the poultry<br />

industry a pro-active approach seems<br />

advisable.<br />

Multiple factors<br />

Footpad lesions are a multifactorial<br />

disease and are influenced by internal<br />

and external factors. Internal factors<br />

of influence can be categorised as sex,<br />

breed, age, pressure, daily growth,<br />

and animal health. External factors<br />

include water supply, litter type, litter<br />

height, top dressing of litter, climate,<br />

season, light, bird density, faeces<br />

distribution and last but certainly not<br />

least, feed composition (Veldkamp<br />

2007). Within this article mainly the<br />

effect of feed measurements, but more<br />

particularly the use of clinoptilolite<br />

(clay minerals) will be discussed.<br />

Feed measurements and footpad<br />

lesions<br />

There are several ways to manage<br />

litter quality and footpad lesions by<br />

means of feed strategies. The levels<br />

of sodium and potassium in the feed<br />

may affect water uptake and thereby<br />

lead to wet litter problems. Some feed<br />

ingredients such as soy and tapioca<br />

have high potassium levels and also<br />

high levels of certain feed ingredients<br />

that may affect litter quality. High<br />

levels of crude protein are also<br />

known to have a negative effect on<br />

><br />

4 <strong>AFMA</strong> MATRIX <strong>September</strong> <strong>2009</strong>

NUTRITION<br />

litter quality. High protein levels<br />

cause high levels of uric acid to be<br />

formed in the liver and excreted by<br />

the kidneys. It furthermore stimulates<br />

water uptake and wet droppings. To<br />

prevent footpad lesions, the inclusion<br />

levels of biotin may be of importance.<br />

Biotin improves the formation and<br />

development of the upper skin.<br />

Earlier reports have shown that biotin<br />

deficiencies increase footpad lesions<br />

(Mayne, 2005).<br />

Importance of litter quality<br />

Litter quality is an important<br />

parameter regarding the incidence<br />

and severity of footpad lesions.<br />

Moisture content is important, since<br />

wet litter is known to influence the<br />

occurrence of footpad lesions in<br />

broilers and turkeys (Mayne, 2005).<br />

But especially the occurence of<br />

wet litter combined with nitrogen<br />

components like ammonia is an<br />

irritant to footpads. The combination<br />

of wet litter and high ammonia<br />

content can affect the footpad, which<br />

results in colourisation of the skin,<br />

and ultimately ulcerations. Damaged<br />

footpads give lee way for fungi or<br />

bacteria to cause secondary infections,<br />

which may even lead to condemnation<br />

of the carcass (Ekstrand ea, 1997).<br />

Broilers affected by footpad lesions<br />

will experience pain and therefore<br />

reduced mobility, leading to lower<br />

feed intake and growth.<br />

Clay minerals and litter quality<br />

Clinoptilolites are specially selected<br />

clay minerals, known for their typical<br />

structure which enables the clay<br />

mineral to bind ammonia (Suchy et<br />

al., 2006). As a result gut health is<br />

improved, since ammonia is toxic to<br />

the gut wall. As an additional effect,<br />

a reduction of footpad lesions may be<br />

expected because ammonia bound to<br />

clinoptilolite causes less irritation to<br />

the footpads. In 2001 the binding of<br />

ammonia by clinoptilolite was tested<br />

in pigs by the University of Gent,<br />

Belgium. They found that 32% of<br />

total ammonia was bound within diets<br />

that contained clinoptilolite, compared<br />

to only 1% with bounded ammonia<br />

in the control treatment. Results<br />

Table 1: Experimental setup<br />

Treatment Additive Starter Grower Finisher<br />

1 Control - - -<br />

2 Clinoptilolite 0,5% 1,0% 1,5%<br />

A negative control group against a treatment with Clinoptilolite (AmmoMIN, Orffa Additives) added to<br />

the diet. The procental addition of Clinoptilolite is a dilution of the diet.<br />

Table 2: Effects of clinoptilolite on litter quality and footpad lesions<br />

Control<br />

Clinoptilolite<br />

Growth (0-35d) gr 2 116 2 170<br />

Feed intake (0-35d) gr 3 457 3 611<br />

Corrected FCR (0-35d) 1,621 1,629<br />

Litter score<br />

Day 7 1 1<br />

Day 14 2 2<br />

Day 21 2,8 2,3<br />

Day 27 3,5 3<br />

Day 31 4 3,5<br />

Day 35 4,3 4<br />

Footpad lesion scores*<br />

Day 28 1,7 1,5<br />

Day 35 1,3 1,1<br />

1<br />

Corrected FCR (0-35d.)<br />

FCR corrected to 2132 grams at day 35, -0,01 for each additional 25 grams of body weight.<br />

*0= No lesions, no discolouration or scars. 1= Mild lesions, parts of the footpad is discoloured to light<br />

brown 2= Larger or multiple tumours, discolouration of the footpad to dark brown 3= Severe lesions;<br />

deep lesions, ulcers, and scabs<br />

from several trials have shown that<br />

the inclusion of clinoptilolite in the<br />

diet reduces water excretion and thus<br />

improves litter quality. As a result of<br />

ammonia binding in the gut, technical<br />

performance is also improved. In the<br />

following sections different trials are<br />

discussed.<br />

Balance trial in Belgium<br />

In 2005 a trial was performed at CLO-<br />

DVV (Melle, Belgium) to measure<br />

the bio-efficacy of clinoptilolites in<br />

three different dosages. The trial was<br />

set up as a balance trial with male<br />

Ross-308 broilers according to the<br />

EU Reference method (Bourdillon<br />

et al., 1990). Three different dosages<br />

of clinoptilolite (1%, 2% and 3%<br />

inclusion) were compared with a<br />

negative control group. There was a<br />

7 days adaptation period (day 14-21<br />

days of age) and the trial lasted from<br />

21 to 24 days. For every treatment<br />

six replicates of 4 male broilers were<br />

used. Feed and nutrient intake, water<br />

excretion, dry matter of excretion,<br />

total excretion, fat digestibility and<br />

Nitrogen retention were measured.<br />

The dry matter content of the<br />

manure was significantly increased;<br />

see the results shown in Figure 1.<br />

Water excretion (H 2<br />

O/feed intake)<br />

decreases with the inclusion of<br />

clinoptilolite. Further results showed<br />

that the inclusion of up to 2% of<br />

clinoptilolite in the ration had no<br />

effect on the feed intake, energy value<br />

of the diet, or Nitrogen retention.<br />

This means that dilution of the diet<br />

up to 2% is possible while maintaining<br />

the performance. This is explained<br />

by improved fat digestibility and<br />

improved usage of protein sources.<br />

Using a dilution strategy including<br />

clinoptilolite can be a successful tool<br />

to lower feeding costs.<br />

Field trials in Germany<br />

In 2003 a field trial was performed<br />

in Germany on a farm with two<br />

identical stables containing 26 500<br />

birds each. The effects of additional<br />

clinoptilolites were determined, using<br />

inclusion levels of 0,5%, 1,0% and<br />

1,5% in starter, grower and finisher<br />

diets respectively. Litter quality<br />

improved numerically at days 14, 21<br />

and 28 with 0,5 (scale 1 to 6). The<br />

trial was repeated in 2005 with an<br />

addition of 1,0% clinoptilolites in<br />

all phases. Litter quality improved<br />

numerically by 0,67 on average at days<br />

><br />

6 <strong>AFMA</strong> MATRIX <strong>September</strong> <strong>2009</strong>

NUTRITION<br />

9, 21 and 28 (scale 1 to 6). Footpad<br />

lesions were scored in 994 birds,<br />

on scale 1 (no lesions) to 4 (severe<br />

lesions). Results are given in Figure<br />

2. Scores tended to be positively<br />

influenced by the clinoptilolite versus<br />

control diets: score 1 (8,4% vs 4,2%),<br />

score 2 (24,0% vs 22,0%), score 3<br />

(60,8% vs 66,8%) and score 4 (6,9%<br />

vs 7,0%). In both trials economic<br />

results improved, by 23% and 41%<br />

respectively. Interestingly, both trials<br />

resulted in an improvement in losses<br />

at the slaughterhouse.<br />

Research trial in The Netherlands<br />

To improve litter quality and reduce<br />

footpad lesion prevalence and<br />

severity, a trial was performed in<br />

2007 at Provimi Research Station<br />

“De Viersprong” in Velddriel, The<br />

Netherlands. In this trial the effects<br />

of clinoptilolite (AmmoMIN, Orffa<br />

Additives BV) inclusion in the diet<br />

were measured. The feed composition<br />

was formulated in such a way<br />

that wet litter was expected, this<br />

to see clear effects on litter quality<br />

and footpad lesions. Birds were fed a<br />

control diet or a diet with an addition<br />

of 0,5%, 1,0% and 1,5% clinoptilolite<br />

in starter, grower and finisher diets<br />

respectively. This means that clinoptilolite<br />

replaces other ingredients,<br />

leading to a nutritional dilution. Both<br />

treatments contained 120 male birds<br />

divided over 6 replicates. Results of<br />

this trial are shown in Table 2. Birds<br />

fed clinoptilolite tended to grow<br />

faster (+54 grams) from day 0 to 35,<br />

although not significantly (P> 0,05,<br />

ANOVA using GENSTAT). No differences<br />

were found in Corrected Feed<br />

Conversion. These results show that<br />

at least similar results on performance<br />

can be obtained, with a tendency to<br />

increased growth, even with a dilution<br />

of the diets by adding clinoptilolites.<br />

This can be explained by the binding<br />

of ammonia in the gut. The dilution<br />

of the diet with clinoptilolite may<br />

reduce the cost price of the formulation.<br />

Litter scores were measured<br />

weekly on a scale from 1 (dry) to 5<br />

(wet). From day 21 onwards, litter<br />

scores improved numerically for birds<br />

fed clinoptilolite. Footpad lesions<br />

Figure 1: Dry matter content of manure at different inclusion rates of clinoptilolite in the<br />

broiler diet<br />

26,5 (%)<br />

26<br />

25,5<br />

25<br />

24,5<br />

24<br />

23,5<br />

23,3<br />

23<br />

22,5<br />

22<br />

were scored from 1 (no lesions) to 4<br />

(severe lesions) per bird at days 28<br />

and 35. According to trial protocol,<br />

fresh wood shavings were added to<br />

cages when litter scores became too<br />

high (> 4). Adding clinoptilolite to<br />

broiler diets numerically reduced<br />

average footpad lesions, from 1,7 to<br />

1,5 at day 28 and from 1,3 to 1,1 at<br />

day 35 for control and clinoptilolite<br />

diets respectively. It should be noted<br />

that even four out of six replicates<br />

of the control group required extra<br />

wood shavings compared to only two<br />

clinoptilolite replicates. Extra addition<br />

of wood shavings is known to reduce<br />

the incidence of footpad lesions. In<br />

practice, extra addition of wood shavings<br />

is not common; therefore, the<br />

effects on footpad lesions may even<br />

be higher than recorded. Experiences<br />

from other trials teach us that dry<br />

matter of the faeces may increase due<br />

to clinoptilolite addition.<br />

Conclusions<br />

It seems that footpad lesions in the<br />

24,6<br />

25,6<br />

25,9<br />

Control 1% Clinop. 2% Clinop. 3% Clinop.<br />

Figure 2: Effect of clinoptilolite on lesion severity, German field trial 2005<br />

% DISTRIBUTION<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Score 1 Score 2 Score 3 Score 4<br />

LESION SEVERITY<br />

Control<br />

poultry industry are becoming<br />

increasingly important. Not only does<br />

one have to keep in mind that animal<br />

welfare is important for the image of<br />

the poultry meat industry; footpad<br />

lesions can also impact on performance<br />

due to low mobility of the<br />

birds. It will also become increasingly<br />

important in terms of legislation,<br />

although in many countries so far,<br />

practical implementation seems to be<br />

at a bottleneck.<br />

Inclusion of clinoptilolite in broiler<br />

diets has several advantages. First of<br />

all it can be used as an assurance to<br />

prevent wet litter and reduce severity<br />

of footpad lesions. Secondly, it is a<br />

cost price reducing measurement,<br />

while performance will be equal or<br />

may even improve, in cases where the<br />

product is used to dilute the diet.<br />

References are available on request.<br />

Clinoptilolite<br />

With acknowledgement to FEED MIX<br />

magazine.<br />

10 <strong>AFMA</strong> MATRIX <strong>September</strong> <strong>2009</strong>

NUTRITION<br />

Correct particle size benefits<br />

animal performance<br />

Feed producers should be concerned about the composition of the cereal grains in the feed and<br />

also closely manage the feed processing steps so that the animals may fully utilise the nutrients.<br />

Particle size reduction is an aspect that is of major importance, since it increases the surface area<br />

of the grain and thus allows for greater interaction with digestive enzymes. It has been studied<br />

for many years now, but still new data become available.<br />

By Dick Ziggers<br />

techniques which can be used on-line.<br />

Most of the feed ingredients used in feed<br />

manufacturing are subjected to particle<br />

size reduction either within the feed plant<br />

or prior to reception. The most important<br />

benefits from particle size reduction in<br />

feed manufacturing processes are related<br />

to:<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

Larger surface area for faster<br />

digestion<br />

Improving ease of handling of some<br />

ingredients<br />

Improving mixing characteristics of<br />

ingredients<br />

Increasing pelleting efficiency and<br />

pellet quality<br />

Meeting customer performance for<br />

feeds<br />

Studying the influence of particle size on animal performance is complicated due to the<br />

indirect effects on nutritional value of other steps in processing, such as mixing and<br />

pelleting.<br />

Particle size analysis is the study of<br />

the size distribution of the particles<br />

of a powdery material and is closely<br />

related to key processes such as grinding,<br />

fractionation and mixing. In addition,<br />

size distribution is related to feeding<br />

behaviour and digestion of the feed<br />

particles by animals.<br />

Since the particles have irregular shapes,<br />

size measurement is defined as the<br />

diameter of the theoretical sphere whose<br />

behaviour is similar to that of the real<br />

particle. The distribution is then fitted<br />

on theoretical laws. The fineness of the<br />

meal is described by the mean diameter<br />

and the heterogeneity of the distribution<br />

by the standard deviation. Among the<br />

main techniques commonly used are<br />

sieving (in dry or wet conditions), laser<br />

light diffraction, and imaging. These last<br />

two techniques are non-invasive and fast<br />

Much energy has been put into particle<br />

size research in pigs at Kansas State<br />

University (KSU) in the beginning of<br />

this century. It was found here, that the<br />

young pig does a better job of chewing<br />

its feed than growing-finishing pigs.<br />

The largest potential for fine grinding<br />

to improve feed efficiency will be for<br />

finishing pigs. Nonetheless, fine grinding<br />

or rolling will improve feed efficiency<br />

regardless of age. This improved feed<br />

efficiency appears to be a result of<br />

improved nutrient digestibility. Average<br />

daily gain does not seem to be effected<br />

by reduced particle size. Usually feed<br />

intake is reduced with reduced particle<br />

size. However, there seems to be an<br />

optimum particle size between 500 and<br />

700 microns. Pigs fed grain ground to<br />

500 microns had a 6% improvement in<br />

feed efficiency compared to pigs fed<br />

diets containing grain ground to 900<br />

microns. On the other hand production<br />

rate in the mill is reduced when particle<br />

><br />

12 <strong>AFMA</strong> MATRIX <strong>September</strong> <strong>2009</strong>

XX NUTRITION<br />

sizes is decreased from e.g. 700 to 500<br />

microns. The decision on optimum diet<br />

particle size needs to include assessment<br />

of improvements in feed efficiency versus<br />

reduction in milling production. KSU<br />

researchers suggest a diet particle<br />

size of app. 700 microns to optimise<br />

both pig performance and milling<br />

efficiency.<br />

Type of grain counts<br />

Not all grains should be reduced to the<br />

same particle size. Studies with high-fibre<br />

cereals such as barley indicate that fine<br />

grinding of these ingredients may greatly<br />

improve their feeding value. Research<br />

data indicate that grinding of fibrous<br />

feed ingredients to approximately 700<br />

microns improves their feeding value<br />

and may make them more attractive as<br />

substitutes for corn and sorghum.<br />

Wheat needs to be treated slightly<br />

differently. Because of its high protein<br />

content and propensity to become floury,<br />

it presents some unique processing<br />

problems. If ground too fine, wheat can<br />

reduce feed intake. Therefore in pig diets<br />

wheat should be ground coarser than<br />

corn or sorghum, between 800 and 900<br />

microns.<br />

One of the known disadvantages of fine<br />

grinding is the increased incidence of<br />

gastric ulcers. The frequency of ulceration<br />

increases when particle size drops below<br />

500 microns. Other disadvantages of fine<br />

grinding include bridging problems in<br />

bulk bins and feeders as well as increased<br />

dustiness of the feed.<br />

Particle size in practice<br />

KSU studies in the US showed that<br />

two-thirds of compound feeds sampled<br />

were in the recommended 600-800<br />

micron range. Similar research was<br />

conducted by an Ohio State University<br />

(OSU) who found that the average<br />

micron size of feed ground in a hammer<br />

mill was 916 microns. Roller mills<br />

averaged 720 microns. The location of<br />

feed manufacture was also significant.<br />

On-farm processing yielded an average<br />

of 881 microns. Feed mill processed<br />

feed averaged 755 microns. On-farm<br />

hammer mills produced a wide range<br />

of particle sizes. There was also a<br />

significant difference in average particle<br />

size of feed from on-farm or feed mill<br />

operated hammer mills. On-farm grinding<br />

averaged 1 029 microns and the feed<br />

mills averaged 730 microns.<br />

The economic impact of particle size can<br />

be significant. If a 100-sow farrow-tofinish<br />

operation has an average diet cost<br />

of $130 per tonne and reduces particle<br />

size from 1 100 to 750 microns, this<br />

would result in a saving of approximately<br />

$4 750 per year based on improved feed<br />

efficiency.<br />

Researchers in Denmark investigated the<br />

effect of particle size (fine and coarse)<br />

and feed processing (pelleted vs. nonpelleted)<br />

on the villi in the intestines<br />

and the adhesion of Salmonella enteric<br />

Typhimurium DT12 to the intestines<br />

of pigs. They found that the effects of<br />

particle size and feed processing on<br />

villus height and crypt depth in the small<br />

intestine were minor. Feeding coarse diets<br />

increased the crypt depth in the colon.<br />

Using a pig intestine organ culture model,<br />

Salmonella adhered less (60%) to the ileal<br />

tissue of pigs fed the non-pelleted diets<br />

than to those fed pelleted diets. Their<br />

general conclusion was that pigs fed a<br />

non-pelleted diet are better protected<br />

against Salmonella infections than pigs<br />

fed a pelleted diet.<br />

Researchers in Tarragona, Spain looked<br />

at feed preferences in pigs and its<br />

correlation with feed particle size and<br />

texture. They concluded that the texture<br />

properties of the feed could explain in<br />

part the feed preferences observed in<br />

pigs, whereas particle size characteristics<br />

appeared less important.<br />

Particle size relevance<br />

Guillou and Landeau from French<br />

cooperative Ucaab, compiled a<br />

quantitative database with data from 23<br />

scientific papers and internal reports, in<br />

order to derive response laws to particle<br />

size variation for nutritional value.<br />

General conclusions from their survey:<br />

in growing swine (weaned piglets and<br />

growing-finishing pigs) energy faecal<br />

digestibility is reduced by 0,6 unit and<br />

nitrogen faecal digestibility by 0,8 unit<br />

when particle size increases by 100 μm<br />

(micron). Among technical parameters,<br />

only feed conversion (FCR) of piglets<br />

is related to particle size: +100 μm<br />

in average particle size increased FCR<br />

with 0,03 unit. These ranges are low<br />

compared with other sources of variation<br />

in digestive or metabolic use of diets.<br />

Poultry prefer larger particles<br />

Day-old chicks learn to associate<br />

nutritional effects with the sensorial<br />

characteristics of feed particles, thanks<br />

to a precise visual observation of details<br />

and specific tactile capacities of the beak.<br />

Selection of feed particles is fast and<br />

accurate. However, this selection may<br />

vary according to the sensorial experience<br />

of the bird concerning the feed. Eating<br />

rate depends on the size and hardness of<br />

the pecked particles.<br />

In poultry diets the effects of particle size<br />

appear to be puzzled with complexity of<br />

the diet as well as further processing such<br />

as pelleting or crumbling. The response<br />

to reduced particle size (600 to 500<br />

microns) in broiler chicks appears to be<br />

greatest when fed simple (corn-soybean)<br />

diets in meal form. Feeding a complex<br />

diet in crumbled form did not appear to<br />

require particle size below 1 000 microns.<br />

Studies with laying hens suggest that<br />

there is no advantage in reducing particle<br />

size below 800 microns.<br />

In New Zealand Amerah et al. (2007)<br />

studied the influence of feed particle<br />

size and feed form in broilers. Bird<br />

performance was superior in birds fed<br />

pelleted diets compared with those on<br />

mash diets. Pelleting evened out the<br />

differences in particle size distribution<br />

between treatments and, as a result,<br />

wheat particle size had no effect on the<br />

performance of broilers fed pelleted<br />

diets.<br />

In mash diets, coarse grinding of wheat<br />

improved weight gain and feed:gain<br />

compared with medium grinding.<br />

Pelleting had a negative effect on<br />

Apparent Metbolizable Energy (AME(n)).<br />

Overall, the results showed that feed<br />

form had a greater influence on the<br />

different measured parameters than did<br />

particle size.<br />

In an additional study Amerah et. al<br />

(2008) found that differences in particle<br />

size distribution still existed between<br />

diets (corn or wheat-based) after<br />

pelleting, especially in the proportion<br />

of coarse particles (1 mm and over).<br />

In corn-based diets, coarse grinding<br />

improved weight gains compared with<br />

fine grinding, but this particle size effect<br />

was not observed in wheat-based diets.<br />

In both diets, coarse grinding lowered<br />

feed:gain of broilers compared with fine<br />

grinding. In wheat-based diets, coarse<br />

grinding improved AME(n) compared<br />

with fine grinding. Heavier gizzard<br />

><br />

14 <strong>AFMA</strong> MATRIX <strong>September</strong> <strong>2009</strong>

NUTRITION<br />

Table 1: Effect of different wheat particle sizes on egg production and quality<br />

Parameter<br />

Whole wheat<br />

+ balancer<br />

2mm particle<br />

size<br />

5mm particle<br />

size<br />

8mm particle<br />

size<br />

Feed intake (g per d on dry<br />

matter basis)<br />

81,4 87,8 92,1 99,1<br />

Daily egg production 0,96 0,92 0,93 0,84<br />

Egg weight (g) 60,4 59,3 58,6 53,3<br />

Yolk colour index 4,59 4,59 4,70 4,67<br />

Percentage shell (%) 8,73 9,23 9,06 9,80<br />

Feed cost (£ per tonne) 277 317 302 299<br />

Feed cost per 100 eggs (£) 2,35 3,03 2,99 3,53<br />

weights were observed in birds fed coarse<br />

corn-based diets. This effect was not<br />

present in birds fed coarse wheat-based<br />

diets. Overall the researchers concluded<br />

that the effect of feed particle size varies<br />

according to grain type.<br />

Gizzard effect<br />

Although it is assumed that fine grinding<br />

increases particle surface and thus<br />

increases availability for enzymatic<br />

digestion, there is evidence that coarser<br />

grinding to a more uniform particle<br />

size improves the performance of birds<br />

maintained on mash diets. This counterintuitive<br />

effect may result from the<br />

positive effect of feed particle size on<br />

gizzard development. A more developed<br />

gizzard is associated with increased<br />

grinding activity, resulting in increased<br />

gut motility and improved digestion of<br />

nutrients.<br />

Although grinding to fine particle size is<br />

thought to improve pellet quality, it will<br />

markedly increase energy consumption<br />

during milling. Systematic investigations<br />

on the relationships of feed particle<br />

size and diet uniformity with bird<br />

performance, gut health and pellet<br />

quality are warranted if efficiency is to<br />

be optimised in respect of the energy<br />

expenditure of grinding.<br />

Indian research at CCS Haryana<br />

Agricultural University investigated the<br />

effects of five different particle sizes<br />

(2-6 mm hammer mill screens) in broiler<br />

feeds. The general conclusion was that<br />

feed particle size resulting from the 5mm<br />

screen (868 micron) hammer mill was<br />

most efficiently utilised by the broilers,<br />

as it resulted in improved FCR, reduced<br />

electricity consumption for grinding and<br />

better body weight gains in birds.<br />

Laying hen studies<br />

Little work has been carried out in laying<br />

hens regarding particle sizes in the<br />

diet. A recent study conducted by Dr<br />

Marian Scott at the University of Belfast,<br />

North Ireland, has evaluated the effect<br />

of particle size and feed form on egg<br />

production and egg quality parameters.<br />

The treatments included a whole-wheat<br />

ration plus balancer, wheat ground<br />

through three particle sizes (2, 5 and<br />

8mm) and formulated into diets offered<br />

in three forms (pellets, crumbs and mash)<br />

to laying hens. Performance of the hens<br />

is summarised in Table 1. The effect of<br />

feed form is not reflected in this table,<br />

although this had no significant effect<br />

on egg production or egg quality, but<br />

crumbed diets reduced feed cost per<br />

100 eggs. The finer particle size (2mm)<br />

resulted in better performance than<br />

coarser particle sizes. However, overall<br />

optimum performance was achieved<br />

when the whole-wheat plus balancer<br />

ration was given to hens. Offering feeds<br />

in such a form would also reduce diet<br />

costs per 100 eggs produced and in<br />

addition, reduce the energy required for<br />

diet production. However, this would<br />

need extra investments in the feeding<br />

system for feeding the wheat whole.<br />

Research at the Polytechnical University<br />

of Madrid, Spain, investigated the effect<br />

of the main cereal of the diet and particle<br />

size in young brown layers. The only<br />

significant effect detected was that feed<br />

intake was greater for hens fed coarseground<br />

cereals (10mm screen) than<br />

for hens fed medium and fine-ground<br />

cereals (8 or 6mm screen). None of the<br />

egg quality parameters studied were<br />

influenced by dietary treatment. Neither<br />

type of cereal nor particle size affected<br />

productive performance or egg quality of<br />

young brown hens.<br />

Studying the influence of particle size<br />

is complicated by the integration of<br />

indirect effects on nutritional value,<br />

such as mix stability, or by interactions<br />

with elementary steps of the process<br />

In pigs the recommended particle size is<br />

between 700 and 800 microns. Smaller<br />

particles could give better results, but<br />

have detrimental effects on the animal’s<br />

digestive system.<br />

Poultry are somewhat indifferent to particle<br />

size, however, they prefer particles coarser<br />

than pigs do for optimal performance.<br />

other than grinding (such as pelleting).<br />

Moreover, optimal particle size<br />

selection depends on factors other than<br />

nutritional-like flowing properties of the<br />

meal: feed restriction due to poor flowing<br />

properties is still a real concern. Technical<br />

constraints nowadays still override<br />

nutritional benefits in the decisionmaking<br />

process for high quality meal.<br />

With acknowledgement to FEED TECH<br />

magazine.<br />

18 <strong>AFMA</strong> MATRIX <strong>September</strong> <strong>2009</strong>

INDUSTRY NEWS<br />

AFGRI - first in <strong>AFMA</strong> Code<br />

of Conduct certification<br />

AFGRI Animal Feeds was the first <strong>AFMA</strong> member to be awarded<br />

the <strong>AFMA</strong> Code of Conduct certification, done on all their branches<br />

which include: Bethlehem; Eloff; Isando; Kinross; Klipheuwel;<br />

Patterson and its Head Office.<br />

The <strong>AFMA</strong> Code of Conduct was developed by industry for<br />

industry, to ensure the adherence to all the legislative requirements<br />

as well as regulations pertaining to feed legislation. The Code<br />

however specifically focuses on all the requirements pertaining to<br />

the Animal Feeds and Animal Health Act.<br />

Additional to the <strong>AFMA</strong> Code of Conduct Certification, AFGRI was<br />

also awarded the AFRI Compliance Platinum Award, which focuses<br />

on food safety, bio-safety and quality in the manufacturing. This<br />

prestigious Platinum Award can only be made to an <strong>AFMA</strong> member<br />

after completing the AFRI Compliance Audit as well as the <strong>AFMA</strong><br />

Code of Conduct Audit.<br />

From left to right: De Wet Boshoff (Executive Director,<br />

<strong>AFMA</strong>), Joe Hanekom (Managing Director, Afri<br />

Compliance), Herman van Zyl (Executive Portfolio<br />

Manager, Afri Compliance) and Henry Cottle (Managing<br />

Director, Afgri Animal Feeds).<br />

Being the first recipient of the <strong>AFMA</strong> Code of Conduct, AFGRI<br />

hereby once again confirms its commitment to excellence and the<br />

pursuing of its objective to produce safe feed to its clients.<br />

Afgri Trading can bring benefit and value to our customers<br />

by supplying quality raw materials in a cost effective<br />

manner making use of our extensive resources in farmer<br />

contracts, finance packages, storage capabilities, logistics<br />

and hedging strategies.<br />

Our range of raw materials include:<br />

Maize, milling by-products, oilseeds, oilseed meals,<br />

other proteins, minerals and amino acids.<br />

Contact:<br />

Erhard Briedenhann 012 683 5349 / 082 551 1634<br />

erhardb@afgri.co.za<br />

Tania Erwee 012 643 8196 / 083 994 5592<br />

Tanya.erwee@afgri.co.za<br />

Francois Smit 012 683 5354 / 083 629 8324<br />

fsmit@afgri.co.za<br />

AFGRI Trading (Pty) Ltd • Reg no. 1963/007478/07 • 267B West<br />

Avenue, 1st Floor, Centurion, Pretoria • P O Box 11054, Centurion<br />

0046, Gauteng South Africa

MANAGEMENT<br />

Ian<br />

Bu<br />

ick<br />

is direc<br />

tor<br />

of Opera<br />

tions<br />

Man<br />

age<br />

men<br />

tS<br />

Serv<br />

ice<br />

ces Ltd,<br />

a UK bas<br />

sed<br />

Int<br />

tern<br />

ernati<br />

ationa<br />

lFeed<br />

ed<br />

Mi<br />

llil ng con<br />

sultan<br />

cy<br />

provid<br />

ding<br />

a ful<br />

l rang<br />

nge eo<br />

f prod<br />

uction<br />

an<br />

d<br />

eng<br />

ine<br />

eri<br />

ng<br />

ser<br />

vic<br />

es to the<br />

indus<br />

try since<br />

1999.<br />

9.<br />

An<br />

engine<br />

neer<br />

er<br />

and me<br />

mber ro<br />

ft he UK<br />

Cha<br />

rte<br />

red<br />

Manag<br />

nageme<br />

ement<br />

Ins<br />

nstit<br />

ute, Ian<br />

has<br />

mor<br />

et<br />

han<br />

34 years<br />

exper<br />

perien<br />

ence<br />

in eve<br />

very<br />

asp<br />

ect<br />

of mill<br />

operat<br />

ratio<br />

ion<br />

s.<br />

Matching weight volumes of incoming raw materials<br />

and outgoing complete feed can save a lot of money.<br />

Does your finished<br />

product shrink or grow<br />

By Ian Buick – Operations Management Services Ltd, UK<br />

Do you know the key<br />

performance indicator<br />

which identifies the<br />

variation in tonnes of<br />

finished product leaving<br />

the mill, when compared<br />

with the tonnage of raw<br />

material which originally<br />

arrived This is one vital<br />

question which far too<br />

many managers responsible<br />

for managing feed mills<br />

cannot answer accurately.<br />

When 100 tonnes raw materials arrive at<br />

the plant and 1% is lost in the process it<br />

means that only 99 tonnes leave. So why<br />

is it happening, how can it be identified<br />

and how can it be corrected There can<br />

be a number of reasons why a mill loses<br />

stock or suffers shrink:<br />

• Losses due to moisture reduction in<br />

processing;<br />

• Unauthorised removal of feed from<br />

site;<br />

• Failure to account for movements of<br />

material properly;<br />

• Material being spoilt and thrown<br />

away;<br />

• Dust emissions from inefficient control<br />

equipment.<br />

The last four can be dealt with through<br />

good management of maintenance,<br />

production and administration. Moisture<br />

loss, the most significant factor, is more<br />

complex and needs further explanation.<br />

None of them, however, will be obvious,<br />

unless the overall reconciliation of<br />

material movements is done on a regular<br />

basis.<br />

Moisture loss<br />

If moisture changes during production<br />

are examined, it is possible to create<br />

profiles for feed through the process.<br />

Figure 1 shows a typical feed passing<br />

though the feed production process<br />

><br />

26 <strong>AFMA</strong> MATRIX <strong>September</strong> <strong>2009</strong>

MANAGEMENT<br />

and indicates the main points at which<br />

moisture changes. Without corrective<br />

action, mills can suffer between 0,5 and<br />

1,5% moisture losses. With net profit<br />

margins in some feed companies being as<br />

low as 1 to 2 %, this factor alone could<br />

influence whether or not that company<br />

returns a profit or loss, so it really is a<br />

vital part of mill management control.<br />

The diagram highlights the effects of<br />

grinding and cooling on moisture losses.<br />

The first is almost impossible to prevent.<br />

It can be reduced by maintaining grinder<br />

beaters, screens and the air system in<br />

good condition, but losses will still be<br />

experienced. Cooling is an evaporative<br />

process, so moisture reduction is<br />

essential, but there may be times when<br />

cooling is too efficient and overdrying is<br />

experienced.<br />

Figure 1: A typical moisture profile during production with no extra water added<br />

% MOISTURE<br />

14<br />

13<br />

12<br />

11<br />

10<br />

Raw material Grinding Conditioning Cooling<br />

The only way to fully correct this effect<br />

is to add water. The difficult part is<br />

to ensure that the water is retained,<br />

and that the pellet press is capable of<br />

pelleting the higher moisture material.<br />

Since the late 1990’s the Akzo Nobel<br />

emulsifier Bredol has been used to<br />

assist in correcting the problem, in<br />

addition to providing other significant<br />

production benefits. It not only allows<br />

the retention of higher moisture than<br />

pure water, it also allows the addition<br />

of more water, than the press would<br />

normally be able to handle. This is<br />

particularly important in hot dry climates.<br />

One recent full-scale production trial<br />

in Australia demonstrated that if water<br />

levels as high as 3% were added with<br />

emulsifier, the pellet press could easily<br />

process the material, and the subsequent<br />

evaporation of excess water actually<br />

cooled the product below the ambient<br />

air temperature by 2°C. The end product<br />

moisture was then slightly higher than<br />

><br />

GAIN<br />

LOSS<br />

Breakeven<br />

Point<br />

Only<br />

steam<br />

added<br />

Moisture<br />

Target<br />

Finished<br />

Product<br />

28 <strong>AFMA</strong> MATRIX <strong>September</strong> <strong>2009</strong>

MANAGEMENT<br />

the calculated target from raw material<br />

moisture levels.<br />

Figure 2 shows the progression which can<br />

be achieved from zero water addition,<br />

pure water addition and increased water<br />

addition + emulsifier.<br />

Figure 2: Showing the different effects possible with the use of an emulsifier<br />

Moisture %<br />

Normal<br />

Production<br />

Only using steam<br />

Raw material<br />

12%<br />

Grinding<br />

11%<br />

Mixing and<br />

Conditioning<br />

14%<br />

Cooling<br />

11%<br />

Result<br />

Loss 1%<br />

Balancing the differences<br />

So how does a mill identify the balance<br />

of gains and losses in a mill Primarily, if<br />

a mill wishes to simply look at moisture<br />

variations, then the testing of raw<br />

material and finished product moistures<br />

can provide results which would indicate<br />

the trend in gains or losses. There<br />

are, however, serious issues related to<br />

moisture testing. When a mill is looking<br />

for movements of 0,5 to 1%, the only<br />

truly reliable method is to oven test<br />

samples.<br />

Quick testing methods are a valuable<br />

indicator, particularly in live production<br />

testing – however, NIR, NIT, Capacitance<br />

and Microwave testing are only as<br />

good as their calibration set up. When<br />

compared with oven tests it is sometimes<br />

possible to experience variations as large<br />

as 1%. Results like these can hide the<br />

trends being looked for. Quick testing<br />

heat balances have an even larger<br />

potential variance where repeated tests<br />

are carried out before the equipment<br />

cools down. Loading a small sample<br />

carefully onto the plate takes time. The<br />

sample is also drying rapidly during this<br />

loading operation. The end result is that<br />

the sample may be compromised before<br />

the test begins. In this case sample<br />

preparation should be done on the plate<br />

away from the machine after it has been<br />

zeroed.<br />

Correct sampling<br />

No moisture results can be representative<br />

unless the sampling procedure is carried<br />

out correctly. The only sample which<br />

will deliver accurate information is one<br />

which has been taken once the cooler has<br />

discharged its own maximum volume and<br />

optimum conditioning is taking place.<br />

Samples which are taken too early in the<br />

production run will always deliver a low<br />

moisture result. If different operators<br />

regularly take samples at different stages<br />

of the run, the end result will be variable<br />

moisture results.<br />

Some mill computer systems have<br />

the capacity to track despatched feed<br />

volumes and relate this back to raw<br />

Steam plus<br />

1,5% water<br />

Steam plus<br />

1,5% water<br />

and emulsifier<br />

Steam plus<br />

3% water and<br />

emulsifier<br />

12%<br />

12%<br />

12%<br />

material weighing records. In this way<br />

any variation resulting from the process<br />

will be identified. Care has to be taken if<br />

the product is screened at loading, as this<br />

will clearly affect the quantity available<br />

for despatch.<br />

The simplest and most basic method<br />

of monitoring looks at raw materials<br />

received at a mill, the quantity in stock<br />

and finished products being dispatched.<br />

It is relatively easy to monitor if you are<br />

measuring all incoming materials over<br />

a weighbridge and sending finished<br />

products out in the same way. The only<br />

remaining factor is the starting and<br />

finishing stock of materials in the mill.<br />

This is potentially a variable area as you<br />

need to measure the contents of bulk<br />

bins, but given an experienced operator<br />

and some degree of measurement, which<br />

can be as simple as a tape measure<br />

with a weight at the end, this will<br />

provide reliable information. Monthly<br />

reconciliation is the longest interval<br />

which should be used as figures can be<br />

investigated and acted upon quickly. The<br />

best mills do it on a weekly basis. The<br />

calculation looks like this:<br />

Opening stock + Received goods<br />

Closing stock + Dispatched goods –<br />

Stock gained or lost<br />

11%<br />

11%<br />

11%<br />

Changing nutritional values<br />

Some parties argue that, instead of<br />

looking at stock variations, raw material<br />

nutritional values can be changed to<br />

factor out moisture losses. This is a very<br />

risky strategy. If an overall approach is<br />

taken, it assumes that all raw materials<br />

will lose moisture at the same rate during<br />

15,5%<br />

15,5%<br />

17%<br />

11,5%<br />

12%<br />

13%<br />

Loss 0,5%<br />

Break even<br />

Gain 1%<br />

grinding. Raw material properties and<br />

financial values are then changed in the<br />

formulation computer to allow for this.<br />

The reality is that materials behave in<br />

different ways during grinding, and<br />

some will lose moisture more readily<br />

than others. Even if materials are treated<br />

separately, separate deliveries can behave<br />

differently during grinding. For example,<br />

hard and soft wheats or sorghum with<br />

the same moisture level will grind<br />

differently and release more or less<br />

moisture. Generally feed grains are not<br />

differentiated, so any figures to correct<br />

moisture losses are likely to be guesswork.<br />

The only way to arrive at a close finished<br />

product nutritional result which matches<br />

the target based on analysis of incoming<br />

raw materials, is to bring the moisture<br />

back to it’s target level. If 100 tonnes<br />

arrives at a mill, 100 tonnes should<br />

leave.<br />

The calculation is very simple. For<br />

example, every 100 000 tonnes produced<br />

in a mill with average raw material cost<br />

at 100 Euro per tonne, a 1% loss in<br />

moisture represents a profit reduction of<br />

100 000 Euro. Despite this many mills<br />

either do not pay attention to this factor<br />

at all and the losses are hidden. Others<br />

will reconcile once or twice each year.<br />

This simply reveals that you have had<br />

a long term problem and it is now too<br />

late to correct it. Regular checks and fast<br />

action will provide a big benefit to your<br />

company’s profit line.<br />

With acknowledgement to FEED TECH<br />

magazine.<br />

30 <strong>AFMA</strong> MATRIX <strong>September</strong> <strong>2009</strong>

YOUR PARTNER IN<br />

FEED PRODUCTION<br />

Graintech Milling Systems (Pty) Ltd and<br />

Makeway Engineering Co (Pty) Ltd are<br />

uniquely versatile organisations, providing a<br />

comprehensive range of services, expertise<br />

and equipment to a diversity of customers.<br />

The guiding principles behind each and every<br />

Graintech and Makeway project are quality,<br />

reliability, accuracy, timeliness and good<br />

return on capital invested.<br />

Scope of services:<br />

- Turnkey material handling projects<br />

- Engineering services<br />

- Total project management<br />

- Total turnkey projects<br />

- Conceptual engineering and feasibility studies<br />

- Detail engineering and design<br />

- Detail draughting<br />

- Shop detailing<br />

- Project procurement<br />

- Construction and commissioning<br />

Areas of specialisation (applications):<br />

- Flour mills and feed mills<br />

- Maize milling<br />

- Flour milling<br />

- Wheat milling<br />

- Sorghum milling<br />

- Soya milling<br />

- Maize degermination<br />

- Animal feed milling<br />

- Animal feed pelleting<br />

- Biomass processing and pelleting<br />

- Animal feed mixing and blending<br />

- Roughage grinding<br />

- Lucerne drying, grinding and pelleting<br />

- Molasses supplementation<br />

- Maize silos<br />

- Sunfl ower silos<br />

- Wheat silos<br />

- Malt handling<br />

- Starch handling<br />

- Pneumatic fl our handling<br />

- Pro-nutro weighing and mixing<br />

- Sugar conditioning and handling<br />

- Bulk materials handling systems<br />

- Batch houses and cullet treatment systems for the<br />

glass industry<br />

- Batch weighing and continuous weighing systems<br />

Contact: Jan Kminek | 68 Fourth Street, Booysens Reserve, Johannesburg 2091 | Tel: +27 11 835-2064 | Fax: +27 11 835-2816<br />

E-mail: info@graintech-makeway.com | Website: www.graintech-makeway.com

INDUSTRY NEWS<br />

New Managing Director<br />

Astral Foods: Feed Division<br />

Roedolf Steenkamp was appointed<br />

to the position of Managing<br />

Director: Feed Division of Astral<br />

Foods on 4 June <strong>2009</strong>, replacing<br />

Chris Schutte, who was promoted<br />

to CEO of Astral Foods. Roedolf<br />

joined the company on 2 April 2002<br />

as General Manager of the Group’s<br />

feed milling operations in Zambia<br />

and Zimbabwe. In November 2005,<br />

he was promoted to Chief Operating Officer – Africa.<br />

Roedolf Steenkamp holds the position of Managing<br />

Director for the Astral Foods Feed Division (8 local<br />

feed mills) and also serves on the Boards of Africa Feeds<br />

Limited, trading as Tiger Animal Feeds and Progressive<br />

Poultry Limited, both Zambian operations as well as<br />

Meadow Mozambique Limitada in Mozambique. Astral’s<br />

Central Analytical Laboratories (CAL) also report to<br />

him.<br />

Roedolf Steenkamp also serves as an Executive Director<br />

on the Board of Astral Operations Limited.<br />

Mario le Roux new MD<br />

of Nutri Feeds (Pty) Ltd<br />

Mario le Roux is the newly appointed Managing<br />

Director of Nutri Feeds replacing Chris van<br />

Niekerk. Mr le Roux is a qualified C.A (SA), RA.<br />

This highly successful individual made his way<br />

up from S.A.R.S where he was director of special<br />

investigations in Cape Town. He first became<br />

involved in the business world in Johannesburg<br />

as an assistant financial manager at Macsteel<br />

International.<br />

He became financial manager for Barlows Equipment Company and<br />

formed part of a team establishing the Caterpillar brand in Angola,<br />

Zambia, Malawi and Mozambique. After Barlows he became the<br />

Managing Director Tiger Animal Feeds (Zambia), Director Meadow<br />

Feeds (Malawi) and Financial Director Meadow Feeds (RSA).<br />

Before joining Nutri Feeds he was involved at Afgri Operations Limited<br />

where he was Managing Director of the Clark Cotton Group of<br />

Companies and director of Afgri Operations Limited.<br />

Mario can best be described as a corporate problem solver and<br />

Business Expander.<br />

Nutri Feeds is fortunate to have this young business executive as<br />

part of the team on the eve of Nutri’s planned expansion and market<br />

repositioning in Southern Africa.<br />

Cuthbert Mambolo<br />

joins Bedson Africa<br />

Cuthbert Mamabolo formerly Operational Nutritionist<br />

of AFGRI Animal Feeds has been appointed as<br />

Technical Marketing Manager at Bedson Africa in May<br />

<strong>2009</strong> and will be responsible for the Feed Division’s<br />

products which include mycotoxin management, gut<br />

health and in-feed performance enhancers.<br />

Cuthbert holds an MSc (Agric) from University of<br />

Pretoria and Post Graduate Diploma in Business<br />

Administration (PDBA) from GIBS. He has experience<br />

in feed formulation and technical support to key<br />

customers. Bedson Africa<br />

(Pty) Ltd is a market leader<br />

in the supply and marketing<br />

of top quality animal health<br />

and production-enhancement<br />

products. For more information<br />

please contact Cuthbert on<br />

012 803 4376 or cuthbert.<br />

mamabolo@bedson.co.za.<br />

32 <strong>AFMA</strong> MATRIX <strong>September</strong> <strong>2009</strong>

NUTRITION<br />

Stool management<br />

in sows: keep the GI<br />

tract moving<br />

The performance of sows in north-western Europe has increased<br />

dramatically over the past 10 years. The overall benchmark now is<br />

to produce 30 pigs/sow/year. To achieve this, the GI tract has to<br />

be supported and working well to optimally supply the uterus with<br />

nutrients and guarantee high performance.<br />

By Ernst-Günther Hellwig and Dr Heinrich Kleine Klausing*<br />

The gastro-intestinal (GI) tract is<br />

one of the most sensitive systems<br />

in the pig. The intestine is in direct<br />

contact with the environment and<br />

has the task to enzymatically digest<br />

(small intestine) or bacterially digest<br />

(large intestine) feed that is processed<br />

and moved onward by peristaltic<br />

movement. Through this process<br />

pathogenic bacteria can be ingested<br />

and/or a non-pathogenic load of<br />

bacteria are constantly present in the<br />

GI tract. As long as the system “GI<br />

tract” is working there will be no<br />

apparent clinical symptoms or disease.<br />

If the system is disturbed – and sows<br />

often suffer from constipation during<br />

critical phases, for instance around<br />

birth or during lactation – pathogenic<br />

bacteria reproduce very quickly<br />

(clostridia) or ubiquitous gram<br />

negative E.coli die in large amounts<br />

and their cell wall fractions flood the<br />

sow’s metabolism with endotoxins.<br />

Today’s feeds are specifically<br />

formulated for this critical phase<br />

around birth, which amongst other<br />

tasks will keep the sow’s stool from<br />

firming. However, this does not mean<br />

that all feeding phases should not<br />

facilitate normal peristaltic movement.<br />

Diarrhoea can occasionally be<br />

observed in sows. Oftentimes bacteria<br />

like lawsonia and brachyspirus will<br />

be the cause of this (less frequently,<br />

Salmonella). Of course, there are<br />

many other causes for diarrhoea<br />

which can be identified via dissection<br />

or individual analytical stool samples.<br />

While we have been breeding for pig<br />

numbers over the years there is no<br />

positive correlation between uterus<br />

lengths, needed for pig numbers, and<br />

intestinal length. This means that<br />

the intestine has to work much more<br />

efficiently at 16-18 foetuses in late<br />

gestation, than if the sow were only<br />

to carry 7-9 foetuses. As a result we<br />

have to pay much more attention<br />

with modern sow lines, not only to<br />

the farrowing process and rearing<br />

but also to the way in which we<br />

manage the stool consistency around<br />

farrowing and during lactation. We<br />

could call this an optimisation of stool<br />

management.<br />

Positively influencing gut microflora<br />

It is paramount to maintain intestinal<br />

peristalsis so that constipation does<br />

not occur and that health problems<br />

and performance reduction are not<br />

experienced. Especially around<br />

farrowing and during lactation but<br />

also during gestation it remains<br />

important to maintain good stool.<br />

The most important influence on<br />

the gut peristalsis will be the ration<br />

and the correct fibrous structure<br />

of the feed (expandable, absorptive<br />

components with fermentable<br />

substances – see Table 1). Mycotoxins<br />

need to be watched by applying<br />

thorough quality control measures<br />

of raw materials. Equally important,<br />

a clean water supply with low iron<br />

and manganese levels, a neutral<br />

pH without toxins (biofilm), and<br />

chlorinated.<br />

Stabilising the gut microflora and<br />

a reduction of gut pathogens and<br />

their metabolic by-products and<br />

endotoxins can be achieved by using<br />

acids, prebiotics, probiotics and other<br />

additives. Antibacterial plant extracts<br />

and herbal oils are being used more<br />

and more.<br />

The addition of acids (formic-, lactic-,<br />

citric-,propionic and benzoic acid)<br />

will strategically reduce the pH value<br />

in the stomach. This allows for a<br />

><br />

34 <strong>AFMA</strong> MATRIX <strong>September</strong> <strong>2009</strong>

NUTRITION<br />

Stool consistency acceptable but fibres not fully degraded.<br />

Feed ingredients have been well fermented, which is reflected in a<br />

smooth consistency.<br />

very pH consistent digesta entering<br />

the small intestine and alkalinity is<br />

avoided – an important prerequisite<br />

for the reduction of microbial<br />

colonisation of the gut. Acids will<br />

discourage orally ingested bacteria<br />

from multiplying in the stomach.<br />

Prebiotics are especially effective in<br />

the gut. They will be bacterially<br />

digested and produce short-chain<br />

fatty acids that will affect the pH<br />

value and at the same time represent<br />

an energy source for enterocytes<br />

and the animal itself. Prebiotics are<br />

represented by fructooligosaccharides,<br />

mannanoligosaccharides, lactulose,<br />

xylooligosaccharides, etc.<br />

Probiotics have the task of “occupying<br />

spaces” that would otherwise be taken<br />

up by pathogenic bacteria (e.g. E.coli).<br />

Probiotics will also induce the release<br />

of endogeneous enzymes which will<br />

result in a better digestion and less<br />

food for pathogenic bacteria in the<br />

small intestine. Probiotic bacteria<br />

stimulate the innate lactobacillus in<br />

the mucous membrane and immune<br />

competence of the protective barrier<br />

of the intestine.<br />

Ion exchange materials such as<br />

aluminosilicates and bentonite are<br />

able to bind charged metabolic byproducts<br />

like ammonia and detoxify<br />

the body. Plant-derived materials as<br />

well as herbs and herbal oils will have<br />

an antibacterial and antioxidative<br />

effect on the gut microflora.<br />

Increased vitamin doses above<br />

nutritional requirements will also<br />

show positive results. Particularly<br />

vitamin E, vitamin C and vitamin<br />

B have proved to be very useful in<br />

practice.<br />

...and in practice...<br />

During practical routine diagnosis in<br />

farrowing operations the following<br />

symptoms may be observed:<br />

• Units have problems with<br />

constipation starting in gestation;<br />

• Hard stool starting before but also<br />

after birth continuing into the<br />

suckling period (2 nd - 3 rd week) in a<br />

large portion of the sows;<br />

• Reduced feed intake in lactating<br />

sows;<br />

• Reduced milking in the important<br />

first days of lactation up to about<br />

14 days post farrowing;<br />

• Uneven development of the piglets<br />

in the affected litters, diarrhoea<br />

starting as early as the first few<br />

days, higher mortality (smothering,<br />

diarrhoea, starve-outs from<br />

insufficient milk).<br />

Feed requirements around<br />

farrowing<br />

What can be done from a feeding<br />

aspect and how can the sows be<br />

assisted Extremely important: Check<br />

the water supply! Lactating sows have<br />

a daily requirement of up to 40 litres.<br />

Are the sows being brought into the<br />

farrowing house early enough It<br />

is required at least 7 days prior to<br />

farrowing. If the time is shorter and<br />

the feed is changed when moving<br />

the sow into the farrowing house<br />

(gestation feed to lactation feed) it<br />

can be useful to continue feeding the<br />

gestation diet up to two to three days<br />

after farrowing.<br />

If feeding the lactation diet causes<br />

constipation, the nutritional state<br />

is always worse than if the sow<br />

continues to eat a gestation diet which<br />

is consumed and digested properly.<br />

The alternative is to use special<br />

products that will significantly reduce<br />

the risk of constipation.<br />

If sows are kept on straw it makes<br />

sense to take them off the straw<br />

14 days prior to farrowing. Sows<br />

will eat straw and straw can lead to<br />

constipation stressing the system;<br />

straw will not swell and absorb<br />

moisture. For this reason the sow’s<br />

intestinal tract should be free from<br />

straw around farrowing.<br />

If an energy dense lactation diet<br />

is being fed (13,4 MJ ME/kg and<br />

higher) the use of fibrous materials<br />

will be limited. In such cases it is<br />

advisable to use a lower energy<br />

lactation diet (12,8-13,0 MJ ME per<br />

kg). Fibre content should be at least<br />

5% and expandable fibre sources such<br />

as wheat bran and sugar beet pulp<br />

><br />

36 <strong>AFMA</strong> MATRIX <strong>September</strong> <strong>2009</strong>

NUTRITION<br />

Feed structure and crude fibre<br />

Feed materials that are highly fermentable by bacteria (functional dietary components) are cereal roughage (like wheat bran),<br />

sugar beet pulp, maize and wheat feed as well as canola and sunflower extraction meals. Functional dietary components play an<br />

important role in the intestine. They improve gut motility and as a result passage rates which in turn result in a reduced incidence<br />