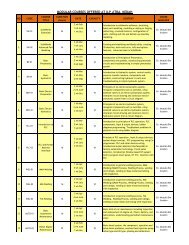

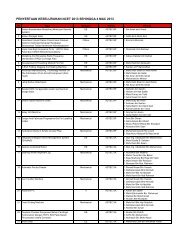

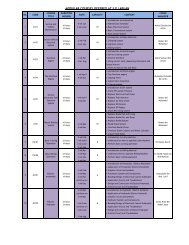

MODULAR COURSES OFFERED AT ILP KANGAR, PERLIS

MODULAR COURSES OFFERED AT ILP KANGAR, PERLIS

MODULAR COURSES OFFERED AT ILP KANGAR, PERLIS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>MODULAR</strong> <strong>COURSES</strong> <strong>OFFERED</strong> <strong>AT</strong> <strong>ILP</strong> <strong>KANGAR</strong>, <strong>PERLIS</strong><br />

BIL<br />

CODE<br />

COURSE<br />

TITLE<br />

DUR<strong>AT</strong>ION D<strong>AT</strong>E CAPACITY CONTENT<br />

COURSE<br />

MANAGER<br />

1 AP-01<br />

Basic<br />

Pneumatic<br />

16<br />

2nd wk Jan<br />

1st wk Mar<br />

1st wk May<br />

2nd wk July<br />

1st wk Sept<br />

1st wk Nov<br />

10<br />

Introduction to Pneumatic system, introduction to various part of<br />

pneumatic equipment, production of compressed air, sign and<br />

symbol used for pneumatic component. Symbol and schematric<br />

diagram for pneumatic component and their user. Function and<br />

working principle of various type of valve, cylinder and other<br />

accessories.<br />

HEAD OF<br />

ELECTRICAL<br />

DEPARTMENT<br />

2 AP-02<br />

Basic Electro-<br />

Pneumatic<br />

16<br />

2nd wk Feb<br />

2nd wk Apr<br />

2nd wk June<br />

1st wk Aug<br />

1st wk Oct<br />

1st wk Dec<br />

10<br />

Introduction to electro-pneumatic system: Introduction to various<br />

part of electro-pneumatic equipment, production of compressed<br />

air, sign and symbol used for electro-pneumatic components:<br />

Symbol and schematic diagram for piston and cylinder, control<br />

valve etc, designation symbol for component, electro-pneumatic<br />

component and their uses: Function and working principle of<br />

various type of valve, cylinder and other accessories, pneumatic<br />

component and their uses: Function and working principle of<br />

various type of valve, cylinder and other accessories.<br />

HEAD OF<br />

ELECTRICAL<br />

DEPARTMENT<br />

3 AP-03 Basic Hydraulic 16<br />

3rd wk Jan<br />

2nd wk Mar<br />

2nd wk May<br />

3rd wk July<br />

2nd wk Sept<br />

2nd wk Nov<br />

10<br />

Introduction to hydraulics, hydraulics power system: Power pack<br />

system, hydraulic fluids properties and uses, hydraulics power<br />

system: Power pack system, hydraulic fluids properties and uses,<br />

element and standard symbol of hydraulics system, hydraulics<br />

accessories: Type and uses of hydraulics equipment and<br />

component, basic hydraulics circuit: Development of basic<br />

hydraulics for controlling hydraulics cylinder, motors and other<br />

actuators, development of simple hydraulics diagrams, basic<br />

hydraulics practical: Setting up simple hydraulic circuit according<br />

to diagrams.<br />

HEAD OF<br />

ELECTRICAL<br />

DEPARTMENT<br />

4 AP-04<br />

Basic Electro-<br />

Hydraulic<br />

16<br />

3rd wk Feb<br />

3rd wk Apr<br />

3rd wk June<br />

2nd wk Aug<br />

2nd wk Oct<br />

2nd wk Dec<br />

10<br />

Introduction to electro-hydraulics, electro-hydraulics power<br />

system: Power pack system, electro-hydraulic fluids properties<br />

and uses, electro-hydraulics power system: Power pack system,<br />

electro-hydraulic fluids properties and uses, element and standard<br />

symbol of electro-hydraulics system, electro-hydraulics<br />

accessories: Type and uses of electro-hydraulics equipment and<br />

component, basic electro-hydraulics circuit: Development of basic<br />

electro-hydraulics for controlling electro-hydraulics cylinder,<br />

motors and other actuators, development of simple electrohydraulics<br />

diagrams, basic electro-hydraulics practical: Setting up<br />

simple electro-hydraulic circuit according to diagrams.<br />

HEAD OF<br />

ELECTRICAL<br />

DEPARTMENT<br />

5 AP-05<br />

Programmable<br />

Logic Control -<br />

Part 1<br />

16<br />

4th wk Jan<br />

3rd wk Mar<br />

3rd wk May<br />

4th wk July<br />

4th wk Sept<br />

3rd wk Nov<br />

10<br />

Introduction to PLC, function and use of PLC component, circuit<br />

development and circuit diagram design, documentation and<br />

software management, communication between personal<br />

computers and PLC, programming in ladder diagrams and<br />

troubleshooting problem and basic control system.<br />

HEAD OF<br />

ELECTRICAL<br />

DEPARTMENT

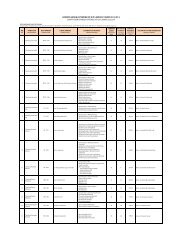

BIL<br />

CODE<br />

COURSE<br />

TITLE<br />

DUR<strong>AT</strong>ION D<strong>AT</strong>E CAPACITY CONTENT<br />

COURSE<br />

MANAGER<br />

6 AP-06<br />

Programmable<br />

Logic Control -<br />

Part 2<br />

16<br />

4th wk Feb<br />

4th wk Apr<br />

4th wk June<br />

4th wk Aug<br />

3rd wk Oct<br />

3rd wk Dec<br />

10<br />

Advantages of PLC, function and use of PLC component,<br />

commissioning of a PLC, criteria for use of mechanical, optical<br />

cacitive and inductive proximity sensors, circuit development,<br />

circuit diagram design, documentation and software management,<br />

communiczation between oersonal computers and PLCs,<br />

programming in ladder diagrams, function chart and ststement<br />

list, development of squence and logic control system, defining<br />

appropriate control systems for a given control task,<br />

mnodification of programs by inserting or deleting control<br />

command.<br />

HEAD OF<br />

ELECTRICAL<br />

DEPARTMENT<br />

7 AP-07<br />

PC Maintenance<br />

And Servicing -<br />

Part 1<br />

16<br />

2nd wk Jan<br />

4th wk Mar<br />

4th wk May<br />

5th wk July<br />

5th wk Sept<br />

4th wk Nov<br />

12<br />

Introduction to personal computer, familiarizing with PC<br />

components, central processing unit, motherboard, storage media<br />

installation, multimedia components installation, memory<br />

installation, modem installations, putting PC components<br />

together.<br />

HEAD OF<br />

ELECTRICAL<br />

DEPARTMENT<br />

8 AP-08<br />

PC Maintenance<br />

And Servicing -<br />

Part 2<br />

16<br />

2nd wk Feb<br />

5th wk Apr<br />

2nd wk June<br />

2nd wk Aug<br />

2nd wk Oct<br />

4th wk Dec<br />

12<br />

Introduction to software, setup Bios.Create partation and format,<br />

install windows, antivirus, automation office and basic network.<br />

HEAD OF<br />

ELECTRICAL<br />

DEPARTMENT<br />

9 EP-01 Basic Electronic 20<br />

1 & 2 wk Jan<br />

2 & 3 wk Feb<br />

1 & 2 wk Mar<br />

1 & 2 wk May<br />

2 & 3 wk June<br />

1 & 2 wk July<br />

1 & 2 wk Sept<br />

1 & 2 wk Oct<br />

1 & 2 wk Nov<br />

8<br />

Introduction to basic electricity, electronics and digital logic,<br />

operation of the devices, schematic diagram and perform test and<br />

measurement with a VOM, oscilloscope and signal generator.<br />

HEAD OF<br />

ELECTRONIC<br />

DEPARTMENT<br />

10 EP-02<br />

Basic<br />

Programmable<br />

Logic Controller<br />

20<br />

2 & 3 wk Feb<br />

3 & 4 wk Mar<br />

2 & 3 wk Apr<br />

4 & 5 wk June<br />

3 & 4 wk July<br />

1 & 2 wk Aug<br />

2 & 3 wk Oct<br />

3 & 4 wk Nov<br />

1 & 2 wk Dec<br />

8<br />

To understand the basic operation and mechanism of PLC.<br />

Learn some basic PLC Programming. Basic mechanism of PLC.<br />

Basic operation of programmable console. Some application of<br />

basic execution commands. Learn simple operation of<br />

programming.<br />

HEAD OF<br />

ELECTRONIC<br />

DEPARTMENT<br />

11 EP-03<br />

Basic Of Control<br />

Motor Curcuit<br />

16<br />

5th wk Jan<br />

5 th wk Apr<br />

4th wk May<br />

4th wk Aug<br />

5th wk Sept<br />

3rd wk Dec<br />

8<br />

To perform basic of the principles, types and function of Three<br />

Phase Inductor Motor Starter components.<br />

HEAD OF<br />

ELECTRONIC<br />

DEPARTMENT<br />

12 IP-01<br />

Maintain Safe<br />

Guarding<br />

System<br />

16<br />

3rd wk Jan<br />

2nd wk Feb<br />

2nd wk Mar<br />

2nd wk Apr<br />

1st wk May<br />

2nd wk June<br />

2nd wk July<br />

1st wk Aug<br />

2nd wk Sept<br />

1st wk Oct<br />

1st wk Nov<br />

2nd wk Dec<br />

10<br />

Calibrate temperature switch using temperature probe, calibrator<br />

and multimeter so that the set point of the switch meets process<br />

specification. Calibrate level switch using level stand pipe<br />

indicator and multimeter so that the set point of the switch<br />

meets process specification. Functional check on flow switch<br />

using simulated flow and multimeter so that the flow switch is<br />

functioning as per specification. Functional check on solenoid<br />

valve using air/power supply source and pressure gAuge so that<br />

the solenoid valve is functioning to specification<br />

HEAD OF<br />

ELECTRONIC<br />

DEPARTMENT

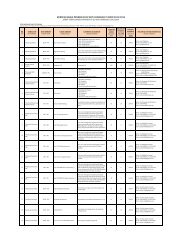

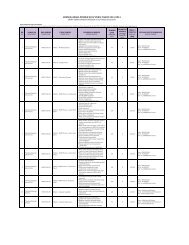

BIL<br />

CODE<br />

COURSE<br />

TITLE<br />

DUR<strong>AT</strong>ION D<strong>AT</strong>E CAPACITY CONTENT<br />

COURSE<br />

MANAGER<br />

13 IP-02<br />

Maintain<br />

Auxiliary<br />

Instrument<br />

Devices<br />

24<br />

3 & 4 wk Feb<br />

4 & 5 wk Mar<br />

4 & 5 wk Apr<br />

3 & 4 wk May<br />

4 & 5 wk June<br />

4 & 5 wk July<br />

2 & 3 wk Aug<br />

4 & 5 wk Sept<br />

2 & 3 wk Oct<br />

3 & 4 wk Nov<br />

3 & 4 wk Dec<br />

6<br />

Install pneumatic transmition lines and components using hook-up<br />

diagram, tubing bender, cutter and leak detection solution so that<br />

it provides air supply to the transmitter for signal transmition.<br />

Install electrical signal transmition lines and components using<br />

wiring diagram, hand tools and multimeter so that it provides<br />

electrical power and signal transmition to the instruments.<br />

Calibrate pressure gAuge using pressure calibrator and hand tools<br />

so thet the acuracy of the reading meets manufacturer's<br />

specification. Functional check on limit switch appropriate<br />

triggering devices and multimeter so that function as per plant<br />

requirement. Service process regulator using pressure gAuge and<br />

hand tools so thet the process regulator is in working condition<br />

dan meets manufacturer's specification.<br />

HEAD OF<br />

ELECTRONIC<br />

DEPARTMENT<br />

14 FL-01<br />

Basic Arc<br />

Welding<br />

16<br />

2nd wk Jan<br />

1st wk May<br />

1st wk Sept<br />

1st wk Dec<br />

12<br />

Fundamental of arc welding-safety procedures setting up and<br />

operation procedure of arc welding machines, identification and<br />

selection of electrodes and their applications in welding work,<br />

welding technique-beading, padding on flat and round bar.<br />

Welding of lap, corner and tee fillet welds, testing weldsdestructive<br />

and non-destructive testing .<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT<br />

15 FL-02<br />

Intermediate<br />

Arc Welding<br />

16<br />

2nd wk Feb<br />

2nd wk June<br />

1st wk Oct<br />

12<br />

Welding variable and techniques beading in horizontal and vertical<br />

up, type of butt-weld, edge preparation and vertical up, meaning<br />

of arc blow and polarity, welding of butt-joints in 1G, 2G and 3G (<br />

flat, horizontal - vertical and vertical-up position), testing weldsdestructive<br />

testing .<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT<br />

16 FL-03<br />

Basic Metal<br />

Fabrication<br />

16<br />

1st wk Mar<br />

2nd wk July<br />

1st wk Nov<br />

12<br />

Introduction to metal fabrication practices and safety<br />

precautions. Layout procedures, selection and use of shop tools<br />

and fabrication machinery including shears, hand, grinders, etc.<br />

Set up operations of oxy-acetylene welding/cutting equipments.<br />

Set up and operations of arc-welding machine. Welding and flame<br />

cutting, development drawings. Fabrication of workpieces by<br />

using templates, such as cone hopper, square and round elbow<br />

and T-joint.<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT<br />

17 FL-04<br />

Intermediate<br />

Metal<br />

Fabrication<br />

16<br />

2nd wk Apr<br />

1st wk Aug<br />

1st wk Dec<br />

12<br />

Set up and operation of oxy-acetylene welding/cutting<br />

equipment's and arc welding machine, development drawing.<br />

Preparation of templates, fabrication work: Fabrication of square<br />

to round shape workpiece, joining pipes in 90 degrees three pitch<br />

turn and y-branch, fabricating three-piece rectangular to round<br />

elbow .<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT<br />

18 FL-05<br />

Advanced Metal<br />

Fabrication<br />

16<br />

1st wk May<br />

1st wk Sept<br />

3rd wk Dec<br />

12<br />

Type of butt-joints and edge preparation, techniques of pipe<br />

welding, welding of rotated pipe in, horizontal (1G) position,<br />

welding of pipe in vertical (2G) position, welding of fix pipe in,<br />

horizontal (5G) positions, types of weld defects and weld test .<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT<br />

19 FL-06<br />

AutoCAD 2007 -<br />

Part 1<br />

16<br />

3rd wk Jan<br />

3rd wk Apr<br />

3rd wk July<br />

2nd wk Oct<br />

12<br />

Getting started, display commands, CAD Tools & drawing setup,<br />

basic drawing command, basic edit commands, layers, CAD<br />

construction techniques, creating text & defining styles, blocks &<br />

drawing import/export options dimensions, crosshatching,<br />

printing & ploting basics, introduction to paper space .<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT

BIL<br />

CODE<br />

COURSE<br />

TITLE<br />

DUR<strong>AT</strong>ION D<strong>AT</strong>E CAPACITY CONTENT<br />

COURSE<br />

MANAGER<br />

20 FL-07<br />

AutoCAD 2007-<br />

Part 2<br />

16<br />

3rd wk Feb<br />

2nd wk May<br />

2rd wk Aug<br />

2nd wk Nov<br />

12<br />

Advanced drawing techniques, managing your system, inserting<br />

graphics, working with attributes, advanced dimensioning, paper<br />

space and plotting, introduction to customization, introduction to<br />

3D .<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT<br />

21 FL-08<br />

AutoCAD 2007 -<br />

3D<br />

16<br />

2nd wk Mar<br />

3rd wk June<br />

2nd wk Sept<br />

2nd wk Dec<br />

12<br />

AutoCAD 3D productivity, basic 3D concepts, coordinate system &<br />

viewing, entities in 3D space, surfaces, creating 3D solids, editing<br />

& analyzing 3D solids, model space & paper space, concepts<br />

visualing the finishing model.<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT<br />

22 FL-09<br />

Oxy-Acetylene<br />

Welding Cutting<br />

16<br />

3rd wk Mar<br />

4th wk Apr<br />

4th wk July<br />

4th wk Sept<br />

3rd wk Dec<br />

16<br />

Work on the steel plate with a several thickness, groove weld in:<br />

Horizontal position, vertical position, uphill position cutting<br />

straight/round on plate, work on the steel pipe with several<br />

diameters and thickness, groove weld in rotation, vertical position<br />

and all position, preparation before welding, defect and remedy<br />

and welding control.<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT<br />

23 FL-10<br />

Blue Print<br />

Reading<br />

16<br />

5th wk Jan<br />

3rd wk May<br />

3rd wk Oct<br />

12<br />

Introduction to blue print, the alphabet of line, types of lines and<br />

their uses, lettering and dimensioning, freehand sketches,<br />

principles of projection drawing, pictorial drawing, sectional<br />

views, title block, list of material, drawing notes, drawing<br />

changes, thread representation/specification, specification and<br />

call-out for machine processes. Broken out, partial, removed and<br />

revolved sections, tolerances, allowances and dimensioning,<br />

limits and fits, geometric tolerancing, auxiliary views, welding<br />

symbols and castings, Irrelationship and sequence of components<br />

in assembly and sub assembly procedure, basic AutoCAD 2D .<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT<br />

24 FL-11<br />

Gas Tungsten<br />

Arc Welding -<br />

Carbon Steel<br />

16<br />

4th wk Feb<br />

4th wk June<br />

3rd wk Nov<br />

9<br />

Material: Carbon steel position: 1F1G or/ and 2F2G or/ and 3F3G<br />

theoretical : Introduction to gas metal arc welding, safety and<br />

health of welders, selecting the equipment and material, set up<br />

operation and shut down procedure, practical : Exercise on fillet<br />

joint and single V butt joint in vertical position, material<br />

positioning and tack weld, perform fillet joint and single V butt<br />

joint, test and visual inspections, in accordance with the position<br />

required by the company.<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT<br />

25 FL-12<br />

Gas Tungsten<br />

Arc Welding -<br />

Stainless Steel<br />

16<br />

4th wk Mar<br />

4th wk Aug<br />

4th wk Dec<br />

9<br />

Position: 1F/1G or 2F/2G and 3F/3G, theoretical: Introduction to<br />

GTAW (only for 1F/1G course ), the welding characteristics of<br />

carbon steel, safety and health of welders, selecting the<br />

equiment and meterial, set up operation and shut down<br />

procedure, practical, stringer bead without and with filler metal<br />

on 1.5mm D20 carbon steel in flat/ horizontal/ vertical position,<br />

fillet weld lap joint without and with filler metal on 1.5mm low<br />

carbon steel plate (for 1G and 2G), fillet weld T-joint without and<br />

with filler metalon 1.5mm low carbon steel plate in the position<br />

required by the company, fillet weld outside corner joint without<br />

and with filler metal on 1.5mm low carbon steel plate in flat<br />

position (only for 1F), groove weld single V butt joint on 6mm low<br />

carbon steel plate in vertical position (3G) (root and hot pass<br />

only), groove weld square butt joint with filler metal on 1.5mm<br />

low carbon steel plate in the required position, inspection and<br />

testing welds, report, in accordance with the position required<br />

by the company.<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT

BIL<br />

CODE<br />

COURSE<br />

TITLE<br />

DUR<strong>AT</strong>ION D<strong>AT</strong>E CAPACITY CONTENT<br />

COURSE<br />

MANAGER<br />

26 FL-13<br />

Gas Tungsten<br />

Arc Welding -<br />

Aluminium<br />

16<br />

5th wk Apr<br />

5th wk July<br />

4th wk Nov<br />

9<br />

Material: Aluminium position: 1G and 2G theoretical: Safety and<br />

health of welders, selecting the equipment and materials, set up<br />

operation shut down procedure, the joint designs for pipe welding<br />

and pipe welds quality, practical, square butt joint on diameter<br />

50mm sch. 10 aluminium pipe in 1G position, groove weld single V<br />

butt joint on diameter 50mm sch. 40 aluminium pipe in 1G<br />

position, square butt joint on diameter 50mm sch.10 aluminium<br />

pipe in 2G position, groove weld single V butt joint on diameter<br />

50mm sch. 40 aluminium pipe in 2G position, inspection and<br />

testing welds and report.<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT<br />

27 FL-14<br />

Gas Metal Arc<br />

Welding -<br />

Carbon Steel<br />

16<br />

2nd wk Jan<br />

1st wk Mar<br />

4th wk May<br />

1st wk Aug<br />

1st wk Oct<br />

9<br />

Material: Carbon steel position: 1F1G or/ and 2F2G or/ and 3F3G<br />

theoretical : Introduction to gas metal arc welding, safety and<br />

health of welders, selecting the equipment and material, set up<br />

operation and shut down procedure, practical : Exercise on fillet<br />

joint and single V butt joint in vertical position, material<br />

positioning and tack weld, perform fillet joint and single V butt<br />

joint, test and visual inspections, in accordance with the position<br />

required by the company.<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT<br />

28 FL-15<br />

Gas Metal Arc<br />

Welding -<br />

Stainless Steel<br />

16<br />

2nd wk Feb<br />

2nd wk Apr<br />

2nd wk June<br />

1st wk Dec<br />

9<br />

Position: 1F/1G or/ and 2F/2G or/ and 3F/3G, theoretical:<br />

Introduction to GMAW (only for 1F/1G course ), the welding<br />

characteristics of carbon steel, safety and health of welders,<br />

selecting the equiment and material, set up operation and shut<br />

down procedure, practical, stringer bead without and with filler<br />

metal on 1.5mm low carbon steel in flat/ horizontal/ vertical<br />

position, fillet weld lap joint without and with filler metal on<br />

1.5mm low carbon steel plate (for 1G and 2G), fillet weld tee<br />

joint without and with filler wire metal on 5mm low carbon steel<br />

plate in the position required by the company, fillet weld outside<br />

corner joint without and with filler metal on 5mm low thickness<br />

low carbon steel plate in flat position (only for 1F), Groove weld<br />

single V butt joint on 6mm low carbon steel plate in vertitcal<br />

position (3G) (root and hot pass only), groove weld square butt<br />

joint with filler wire metal on 5mm low carbon steel plate in the<br />

required position, inspection and testing welds, report,in<br />

accordance with the position required by the company.<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT<br />

29 FL-16<br />

Development<br />

Drawing<br />

16<br />

2nd wk Mar<br />

2nd wk July<br />

1st wk Nov<br />

12<br />

How to use radial line to develop template, knowledge<br />

mechanical drawing, using of drawing tools, method of<br />

developments, preparation templates . How to use trigulation<br />

method to develop template, knowledge mechanical drawing,<br />

using of drawing tools, method of developments, preparation<br />

templates .<br />

HEAD OF<br />

PRODUCTION<br />

DEPARTMENT<br />

30 CNC-01<br />

Perform Milling<br />

Operation<br />

32<br />

3 & 4 wk Feb<br />

2 & 3 wk Apr<br />

2 & 3 wk June<br />

1 & 2 wk Aug<br />

1 & 2 wk Oct<br />

10<br />

This course is designed to enable participants to acquire<br />

knowledge and skill in operation of vertical Milling Machine.<br />

Participants will be thAught theory and practical skill of various<br />

milling techniques.<br />

CONTENT; Workshop safety. Operation of machine. Rough and<br />

finish milling a blank with six surface. Milling slot, step, shoulder<br />

and grove. Pocket milling. Inspection and maintenance. Assemble<br />

part techniques.<br />

HEAD OF<br />

MECHANICAL<br />

DEPARTMENT<br />

31 CNC-02 CNC Milling 40<br />

1 ~ 3 wk Mar<br />

1 ~ 3 wk Sept<br />

10<br />

Overview: Features and component of CNC Milling. Workpiece<br />

clamping system and tool clamping system. Type of cutting tool<br />

used in CNC Milling. The controller of CNC Miliing.<br />

Programming: Introduction to the programming codes. The<br />

program structure and machining sequence. Write a simple CNC<br />

Milling program refering to part drawing given.<br />

Application: Tool setting on the machine. Program editing on the<br />

machine. Workpiece machining.<br />

HEAD OF<br />

MECHANICAL<br />

DEPARTMENT

BIL<br />

CODE<br />

COURSE<br />

TITLE<br />

DUR<strong>AT</strong>ION D<strong>AT</strong>E CAPACITY CONTENT<br />

COURSE<br />

MANAGER<br />

32 CNC-03 CNC Turning 40 1 ~ 3 wk May 10<br />

Overview: Features and component of CNC Turning. Workpiece<br />

clamping system and tool clamping system. Type of cutting tool<br />

used in CNC Turning. The controller of CNC Turning.<br />

Programming: Introduction to the programming codes. The<br />

program structure and machining sequence. Write a simple CNC<br />

Turning program refering to part drawing given.<br />

Application: Tool setting on the machine. Program editing on the<br />

machine. Workpiece machining.<br />

HEAD OF<br />

MECHANICAL<br />

DEPARTMENT<br />

33 CNC-04 CNC Wire Cut 40<br />

2 ~ 4 wk July<br />

1 ~ 3 wk Dec<br />

10<br />

Overview: Features and component of CNC Wire Cut . Knowledge<br />

on type of wire, installation and setting CNC Wire Cut. Workpiece<br />

setting. The controller of CNC Wire Cut.<br />

Programming: Introduction to the programming codes. The<br />

program structure and machining sequence. Write a simple CNC<br />

Wire Cut program refering to part drawing given.<br />

Application: Wire setting on the machine. Program editing on the<br />

machine. Workpiece machining.<br />

HEAD OF<br />

MECHANICAL<br />

DEPARTMENT<br />

34 CNC-05 CNC Die Sinking 40 1 ~ 3 wk Nov 10<br />

Knowledge on type of electrode. Knowledge on type of electrode<br />

holding devices. Knowledge on operational feature of EDM Die<br />

Sinking Machine and function. Practical exercise on Die Sinking.<br />

HEAD OF<br />

MECHANICAL<br />

DEPARTMENT<br />

35 TM-01<br />

Microsoft Word -<br />

Part 1<br />

16<br />

2nd wk Jan<br />

2nd wk Feb<br />

1st wk MAC<br />

2nd wk Apr<br />

1st wk May<br />

2nd wk June<br />

2nd wk July<br />

1st wk Aug<br />

1st wk Sept<br />

1st wk Oct<br />

1st wk Nov<br />

1st wk Dec<br />

15<br />

Introduction to ms-word, editing document, bullets, auto<br />

numbering and multilevel, formatting document, table, columns<br />

and border, columns, setting on word 2000, insert picture,<br />

printing document, merging document.<br />

HEAD OF<br />

RESOURCE CENTRE<br />

AND COMPUTER<br />

DEPARTMENT<br />

36 TM-02<br />

Microsoft Excel -<br />

Part 1<br />

16<br />

3rd wk Jan<br />

3rd wk Feb<br />

2nd wk Mar<br />

3rd wk Apr<br />

2nd wk May<br />

3rd wk June<br />

3rd wk July<br />

2nd wk Aug<br />

2nd wk Sept<br />

2nd wk Oct<br />

2nd wk Nov<br />

2nd wk Dec<br />

15<br />

Introduction to ms-excel 2000, building a worksheet, correcting<br />

data and using help, adding formulas, cut, copy and paste, More<br />

on summation, inserting and deleting rows and columns,<br />

formatting a worksheet, printing a worksheet, working with<br />

charts, pivot table, sorting data.<br />

HEAD OF<br />

RESOURCE CENTRE<br />

AND COMPUTER<br />

DEPARTMENT<br />

37 TM-03<br />

Microsoft<br />

Powerpoint -<br />

Part 1<br />

16<br />

5th wk Jan<br />

4th wk Feb<br />

3rd wk Mar<br />

4th wk Apr<br />

3rd wk May<br />

4th wk June<br />

4th wk July<br />

4th wk Aug<br />

4th wk Sept<br />

3rd wk Oct<br />

3rd wk Nov<br />

3rd wk Dec<br />

15<br />

Introduction to ms- power point 2000, creating a new<br />

presentation, entering and adding text to your presentation,<br />

moving text and objects, changing text attributes, save, undo and<br />

redo your presentation, add, delete and move slides, viewing your<br />

slide show, creating a new presentation using the auto wizard,<br />

opening and printing presentation, adding clip-art, working with<br />

slide and layout, drawing objects, working with draw objects,<br />

slide transitions, adding animation and sound.<br />

HEAD OF<br />

RESOURCE CENTRE<br />

AND COMPUTER<br />

DEPARTMENT

BIL<br />

CODE<br />

COURSE<br />

TITLE<br />

DUR<strong>AT</strong>ION D<strong>AT</strong>E CAPACITY CONTENT<br />

COURSE<br />

MANAGER<br />

38 TM-04<br />

PC Assembly -<br />

Part 1<br />

16<br />

2nd wk Jan<br />

2nd wk Feb<br />

4th wk MAC<br />

5th wk Apr<br />

4th wk May<br />

2nd wk June<br />

5th wk July<br />

1st wk Aug<br />

5th wk Sept<br />

1st wk Oct<br />

4th wk Nov<br />

4th wk Dec<br />

15<br />

Introduction to PC Component and hardware. Theory on hardware<br />

assembly technique. Practice on assemble hardware for Personal<br />

Computer and basic installation of Operating System<br />

HEAD OF<br />

RESOURCE CENTRE<br />

AND COMPUTER<br />

DEPARTMENT<br />

39 TM-05 Basic Internet 16<br />

3rd wk Jan<br />

3rd wk Feb<br />

1st wk Mar<br />

2rd wk Apr<br />

1st wk May<br />

3rd wk June<br />

2nd wk July<br />

2nd wk Aug<br />

1st wk Sept<br />

2nd wk Oct<br />

1st wk Nov<br />

5th wk Dec<br />

15<br />

Introduction to the internet. Getting connected to the internet.<br />

Internet application and understanding the World Wide Web.<br />

HEAD OF<br />

RESOURCE CENTRE<br />

AND COMPUTER<br />

DEPARTMENT<br />

40 MI-01<br />

Perform Turning<br />

Operation<br />

32<br />

3 & 4 wk Feb<br />

3 & 4 wk Apr<br />

3 & 4 wk June<br />

1 & 2 wk Aug<br />

2 & 3 wk Oct<br />

2 & 3 wk Dec<br />

10<br />

This course is designed to enable participants to acquire<br />

knowledge and skill in operation of Lathe Machine. Participants<br />

will be thAught theory and practical skill of turning techniques.<br />

CONTENT; Workshop safety. Part and function of lathe machine.<br />

Facing, longitudinal step turning. Drilling, boring. Taper turning.<br />

Thread cutting. Knurling, Grooving, Chamfering and Parting off.<br />

Assemble part techniques.<br />

HEAD OF<br />

MECHANICAL<br />

DEPARTMENT