Good Engineering Practice for Northern Water and Sewer Systems

Good Engineering Practice for Northern Water and Sewer Systems

Good Engineering Practice for Northern Water and Sewer Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

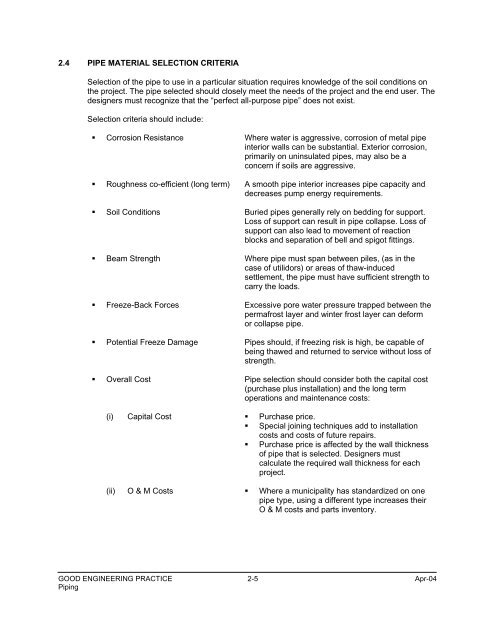

2.4 PIPE MATERIAL SELECTION CRITERIA<br />

Selection of the pipe to use in a particular situation requires knowledge of the soil conditions on<br />

the project. The pipe selected should closely meet the needs of the project <strong>and</strong> the end user. The<br />

designers must recognize that the “perfect all-purpose pipe” does not exist.<br />

Selection criteria should include:<br />

• Corrosion Resistance Where water is aggressive, corrosion of metal pipe<br />

interior walls can be substantial. Exterior corrosion,<br />

primarily on uninsulated pipes, may also be a<br />

concern if soils are aggressive.<br />

• Roughness co-efficient (long term) A smooth pipe interior increases pipe capacity <strong>and</strong><br />

decreases pump energy requirements.<br />

• Soil Conditions Buried pipes generally rely on bedding <strong>for</strong> support.<br />

Loss of support can result in pipe collapse. Loss of<br />

support can also lead to movement of reaction<br />

blocks <strong>and</strong> separation of bell <strong>and</strong> spigot fittings.<br />

• Beam Strength Where pipe must span between piles, (as in the<br />

case of utilidors) or areas of thaw-induced<br />

settlement, the pipe must have sufficient strength to<br />

carry the loads.<br />

• Freeze-Back Forces Excessive pore water pressure trapped between the<br />

permafrost layer <strong>and</strong> winter frost layer can de<strong>for</strong>m<br />

or collapse pipe.<br />

• Potential Freeze Damage Pipes should, if freezing risk is high, be capable of<br />

being thawed <strong>and</strong> returned to service without loss of<br />

strength.<br />

• Overall Cost<br />

Pipe selection should consider both the capital cost<br />

(purchase plus installation) <strong>and</strong> the long term<br />

operations <strong>and</strong> maintenance costs:<br />

(i)<br />

(ii)<br />

Capital Cost<br />

O & M Costs<br />

• Purchase price.<br />

• Special joining techniques add to installation<br />

costs <strong>and</strong> costs of future repairs.<br />

• Purchase price is affected by the wall thickness<br />

of pipe that is selected. Designers must<br />

calculate the required wall thickness <strong>for</strong> each<br />

project.<br />

• Where a municipality has st<strong>and</strong>ardized on one<br />

pipe type, using a different type increases their<br />

O & M costs <strong>and</strong> parts inventory.<br />

GOOD ENGINEERING PRACTICE 2-5 Apr-04<br />

Piping