Combustion in CI Engines & Gas Turbines

Combustion in CI Engines & Gas Turbines

Combustion in CI Engines & Gas Turbines

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Combustion</strong> <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

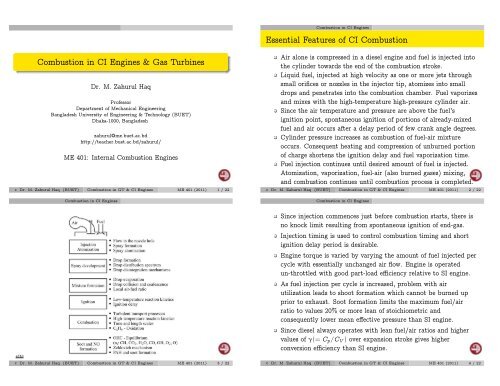

Essential Features of <strong>CI</strong> <strong>Combustion</strong><br />

<strong>Combustion</strong> <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es & <strong>Gas</strong> Turb<strong>in</strong>es<br />

Dr. M. Zahurul Haq<br />

Professor<br />

Department of Mechanical Eng<strong>in</strong>eer<strong>in</strong>g<br />

Bangladesh University of Eng<strong>in</strong>eer<strong>in</strong>g & Technology (BUET)<br />

Dhaka-1000, Bangladesh<br />

zahurul@me.buet.ac.bd<br />

http://teacher.buet.ac.bd/zahurul/<br />

ME 401: Internal <strong>Combustion</strong> Eng<strong>in</strong>es<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 1 / 22<br />

<strong>Combustion</strong> <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

Air alone is compressed <strong>in</strong> a diesel eng<strong>in</strong>e and fuel is <strong>in</strong>jected <strong>in</strong>to<br />

the cyl<strong>in</strong>der towards the end of the combustion stroke.<br />

Liquid fuel, <strong>in</strong>jected at high velocity as one or more jets through<br />

small orifices or nozzles <strong>in</strong> the <strong>in</strong>jector tip, atomizes <strong>in</strong>to small<br />

drops and penetrates <strong>in</strong>to the combustion chamber. Fuel vaporizes<br />

and mixes with the high-temperature high-pressure cyl<strong>in</strong>der air.<br />

S<strong>in</strong>ce the air temperature and pressure are above the fuel’s<br />

ignition po<strong>in</strong>t, spontaneous ignition of portions of already-mixed<br />

fuel and air occurs after a delay period of few crank angle degrees.<br />

Cyl<strong>in</strong>der pressure <strong>in</strong>creases as combustion of fuel-air mixture<br />

occurs. Consequent heat<strong>in</strong>g and compression of unburned portion<br />

of charge shortens the ignition delay and fuel vaporization time.<br />

Fuel <strong>in</strong>jection cont<strong>in</strong>ues until desired amount of fuel is <strong>in</strong>jected.<br />

Atomization, vaporization, fuel-air (also burned gases) mix<strong>in</strong>g,<br />

and combustion cont<strong>in</strong>ues until combustion process is completed.<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 2 / 22<br />

<strong>Combustion</strong> <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

e740<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 3 / 22<br />

S<strong>in</strong>ce <strong>in</strong>jection commences just before combustion starts, there is<br />

no knock limit result<strong>in</strong>g from spontaneous ignition of end-gas.<br />

Injection tim<strong>in</strong>g is used to control combustion tim<strong>in</strong>g and short<br />

ignition delay period is desirable.<br />

Eng<strong>in</strong>e torque is varied by vary<strong>in</strong>g the amount of fuel <strong>in</strong>jected per<br />

cycle with essentially unchanged air flow. Eng<strong>in</strong>e is operated<br />

un-throttled with good part-load efficiency relative to SI eng<strong>in</strong>e.<br />

As fuel <strong>in</strong>jection per cycle is <strong>in</strong>creased, problem with air<br />

utilization leads to shoot formation which cannot be burned up<br />

prior to exhaust. Soot formation limits the maximum fuel/air<br />

ratio to values 20% or more lean of stoichiometric and<br />

consequently lower mean effective pressure than SI eng<strong>in</strong>e.<br />

S<strong>in</strong>ce diesel always operates with lean fuel/air ratios and higher<br />

values of γ(= C p /C V ) over expansion stroke gives higher<br />

conversion efficiency than SI eng<strong>in</strong>e.<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 4 / 22

<strong>Combustion</strong> <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

Two Categories of Diesel <strong>Combustion</strong> Systems<br />

<strong>Combustion</strong> <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

Direct Injection (DI) Systems<br />

1 Direct-<strong>in</strong>jection (DI) Eng<strong>in</strong>es<br />

2 Indirect-<strong>in</strong>jection (IDI) Eng<strong>in</strong>es<br />

e743<br />

e742<br />

⊙ IDI eng<strong>in</strong>e designs are only used <strong>in</strong> the smallest eng<strong>in</strong>e sizes.<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 5 / 22<br />

<strong>Combustion</strong> <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

(a) quiescent chamber with multi-hole nozzle typical of larger eng<strong>in</strong>es;<br />

(b) bowl-<strong>in</strong>-piston chamber with swirl and multi-hole nozzle;<br />

(c) bowl-<strong>in</strong>-piston chamber with swirl and s<strong>in</strong>gle-hole nozzle.<br />

(b) and (c) used <strong>in</strong> medium to small DI eng<strong>in</strong>e range.<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 6 / 22<br />

<strong>Combustion</strong> <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

Phases of a DI Eng<strong>in</strong>e <strong>Combustion</strong><br />

Air alone is compressed and raised to a high temperature on the<br />

compression stroke. One or more jets of fuels, compressed to a<br />

pressure of 100-2000 bar is <strong>in</strong>jected <strong>in</strong>to the eng<strong>in</strong>e cyl<strong>in</strong>der.<br />

Physical Delay: Fuel jet dis<strong>in</strong>tegrates <strong>in</strong>to a core of fuel<br />

surrounded by a spray envelope created by atomization and<br />

vaporization of fuel. At some location <strong>in</strong> the spray envelope a<br />

mixture of air and fuel will form and oxidation becomes imm<strong>in</strong>ent.<br />

e744<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 7 / 22<br />

e700<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 8 / 22

<strong>Combustion</strong> <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

<strong>Combustion</strong> <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

Chemical Delay: Reaction starts slowly and then accelerates<br />

until <strong>in</strong>flammation or ignition takes place.<br />

Ignition Delay = Physical Delay + Chemical Delay.<br />

Rapid pressure rise occurs because of the myriad ignition po<strong>in</strong>ts<br />

and the accumulation of fuel <strong>in</strong> the delay period. Follow<strong>in</strong>g the<br />

stage, the f<strong>in</strong>al portion of the fuel are <strong>in</strong>jected and consequently<br />

combustion is regulated by the <strong>in</strong>jection rate. S<strong>in</strong>ce the process is<br />

far from homogeneous, combustion cont<strong>in</strong>ues when the expansion<br />

stroke is well under way.<br />

e701<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 9 / 22<br />

<strong>Combustion</strong> <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

Indirect-Injection (IDI) Systems<br />

IDI systems have divided combustion chamber and rich mixtures <strong>in</strong> the<br />

auxiliary chamber with relatively lean charges <strong>in</strong> the ma<strong>in</strong> chamber are<br />

used to achieve extremely low NOx and HC emissions.<br />

e745<br />

(a) Swirl chamber system (b) Pre-chamber system<br />

Swirl chambers rely on the ordered motion to raise combustion speed,<br />

and pre-chambers rely on turbulence to <strong>in</strong>crease combustion speed.<br />

Both types uses heat-resistant <strong>in</strong>serts which is quickly heated up by<br />

the combustion process, and then helps to reduce ignition delay.<br />

e746<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 11 / 22<br />

e741<br />

1 Ignition Delay (ab)<br />

2 Premixed or Rapid Burn<strong>in</strong>g Phase (bc)<br />

3 Mix<strong>in</strong>g Controlled <strong>Combustion</strong> Phase (cd)<br />

4 Late <strong>Combustion</strong> Phase (de)<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 10 / 22<br />

Knock <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

Knock <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

The problem of knock <strong>in</strong> <strong>CI</strong> eng<strong>in</strong>e is complicated by the added<br />

complexity of the physical delay period which is <strong>in</strong>fluenced by:<br />

1 the density and temperature of air <strong>in</strong> the cyl<strong>in</strong>der<br />

2 the atomization, penetration and shape of the spray<br />

3 the properties of the fuel, such as volatility and viscosity, which<br />

affect the spray characteristics<br />

4 the turbulence of air, which promotes mix<strong>in</strong>g.<br />

To reduce the possibility of knock <strong>in</strong> <strong>CI</strong> eng<strong>in</strong>es, fuel/air should have:<br />

A high temperature<br />

A high density<br />

A short delay<br />

A reactive mixture<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 12 / 22

Knock <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

Temperature Factors <strong>in</strong> Reduc<strong>in</strong>g <strong>CI</strong> Knock<br />

Knock <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

Density Factors <strong>in</strong> Reduc<strong>in</strong>g <strong>CI</strong> Knock<br />

Decreas<strong>in</strong>g the temperature of the <strong>in</strong>itially formed mixture by any of<br />

the follow<strong>in</strong>g methods will <strong>in</strong>crease the possibility of knock:<br />

Lower<strong>in</strong>g the compression ratio<br />

Lower<strong>in</strong>g the <strong>in</strong>let air temperature<br />

Lower<strong>in</strong>g the coolant temperature<br />

Lower<strong>in</strong>g the cyl<strong>in</strong>der and cyl<strong>in</strong>der walls temperature<br />

Advanc<strong>in</strong>g or retard<strong>in</strong>g the start of <strong>in</strong>jection<br />

⊙ Injection of fuel after TDC will reduce knock (and power) because<br />

Decreas<strong>in</strong>g the temperature of the <strong>in</strong>itially formed mixture by any of<br />

the follow<strong>in</strong>g methods will <strong>in</strong>crease the possibility of knock:<br />

Decreas<strong>in</strong>g the <strong>in</strong>let air pressure<br />

Decreas<strong>in</strong>g the compression ratio<br />

Thus rais<strong>in</strong>g the compression ratio and supercharg<strong>in</strong>g the <strong>CI</strong> eng<strong>in</strong>e,<br />

unlike <strong>in</strong> the SI eng<strong>in</strong>e, tends to reduce knock.<br />

of the pressure impact is relieved by the expansion stroke.<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 13 / 22<br />

Knock <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

Time Factors <strong>in</strong> Reduc<strong>in</strong>g <strong>CI</strong> Knock<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 14 / 22<br />

Knock <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

Composition Factors <strong>in</strong> Reduc<strong>in</strong>g <strong>CI</strong> Knock<br />

Increas<strong>in</strong>g the amount of fuel <strong>in</strong> the <strong>in</strong>itially formed mixture, or<br />

<strong>in</strong>creas<strong>in</strong>g the time for form<strong>in</strong>g a homogeneous mixture, by any of the<br />

follow<strong>in</strong>g methods will <strong>in</strong>crease the possibility of knock:<br />

Decreas<strong>in</strong>g the turbulence of the compressed air<br />

Increas<strong>in</strong>g the speed of the eng<strong>in</strong>e<br />

Decreas<strong>in</strong>g the <strong>in</strong>jection pressure<br />

Increas<strong>in</strong>g the rate of <strong>in</strong>jection<br />

The possibility of knock <strong>in</strong> <strong>CI</strong> eng<strong>in</strong>e is decreased by the follow<strong>in</strong>g<br />

factors:<br />

Rais<strong>in</strong>g the cetane rat<strong>in</strong>g of the fuel (decreas<strong>in</strong>g chemical delay)<br />

Increas<strong>in</strong>g the volatility of the fuel (decreas<strong>in</strong>g physical delay)<br />

Decreas<strong>in</strong>g the viscosity of the fuel (promot<strong>in</strong>g mix<strong>in</strong>g and<br />

therefore decreas<strong>in</strong>g physical delay).<br />

⊙ Fuels with high cetane rat<strong>in</strong>g may be undesirable for particular<br />

eng<strong>in</strong>e s<strong>in</strong>ce the rise of combustion may be too gradual. Thus, cetane<br />

rat<strong>in</strong>g of 40-60 are usually specified. If the cetane rat<strong>in</strong>g is too low,<br />

start<strong>in</strong>g of the eng<strong>in</strong>e may be difficult. With high cetane values, the<br />

ignition delay may be too short to allow the adequate mix<strong>in</strong>g of fuel<br />

with air, and <strong>in</strong>complete combustion may result.<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 15 / 22<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 16 / 22

Knock <strong>in</strong> <strong>CI</strong> Eng<strong>in</strong>es<br />

<strong>Combustion</strong> <strong>in</strong> <strong>Gas</strong> Turb<strong>in</strong>es<br />

GT Operat<strong>in</strong>g Parameters<br />

e751<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 17 / 22<br />

<strong>Combustion</strong> <strong>in</strong> <strong>Gas</strong> Turb<strong>in</strong>es<br />

GT combustors operates at pressures of 3 atm for small eng<strong>in</strong>es to<br />

as high as 40 atm for advanced eng<strong>in</strong>es. Aircraft eng<strong>in</strong>es operate<br />

at compression ratios of 20/1 to 40/1, while stationary units<br />

operate at 10 to 15 atm.<br />

Combustor outlet temperatures are set by the metallurgical<br />

requirements of the turb<strong>in</strong>e blades and range from 1300 to 1700 o C<br />

for aircraft turb<strong>in</strong>es and 1000 to 1500 o C for stationary turb<strong>in</strong>es.<br />

Combustor <strong>in</strong>let temperature depends on the compressor pressure<br />

ratio and ranges from 200 to 500 o C. The highest cycle efficiency is<br />

achieved with the highest feasible turb<strong>in</strong>e <strong>in</strong>let temperature.<br />

S<strong>in</strong>ce the stoichiometric flame temperatures of GT fuels is 2000 o C<br />

or more, 100 to 150% excess air is used to cool the combustor l<strong>in</strong>er<br />

to a suitable operat<strong>in</strong>g temperature around 800 o C.<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 18 / 22<br />

<strong>Combustion</strong> <strong>in</strong> GT<br />

<strong>Combustion</strong> <strong>in</strong> <strong>Gas</strong> Turb<strong>in</strong>es<br />

Fuel <strong>in</strong> GT is burned almost stoichiometrically with 25 to 35% of the<br />

air enter<strong>in</strong>g the combustor. The combustion products mix with the<br />

rema<strong>in</strong><strong>in</strong>g air to arrive at a suitable temperature for the turb<strong>in</strong>e. All<br />

combustors have the follow<strong>in</strong>g three zones:<br />

1 Recirculation zone: fuel is evaporated and partially burned.<br />

2 Burn<strong>in</strong>g zone: fuel air mixture burn<strong>in</strong>g is completed.<br />

3 Dilution zone: dilution air is mixed with hot gas.<br />

e747<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 19 / 22<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 20 / 22

<strong>Combustion</strong> <strong>in</strong> <strong>Gas</strong> Turb<strong>in</strong>es<br />

<strong>Combustion</strong> <strong>in</strong> <strong>Gas</strong> Turb<strong>in</strong>es<br />

e748<br />

e752<br />

e749<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 21 / 22<br />

c Dr. M. Zahurul Haq (BUET) <strong>Combustion</strong> <strong>in</strong> GT & <strong>CI</strong> Eng<strong>in</strong>es ME 401 (2011) 22 / 22