HAAKE RheoStress 600 - UPC

HAAKE RheoStress 600 - UPC

HAAKE RheoStress 600 - UPC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

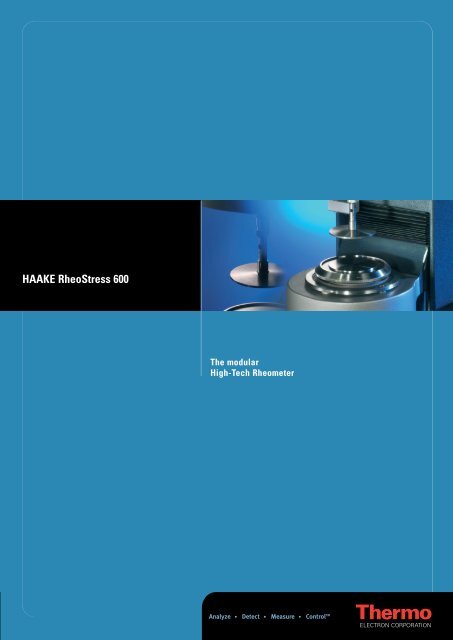

<strong>HAAKE</strong> <strong>RheoStress</strong> <strong>600</strong><br />

The modular<br />

High-Tech Rheometer<br />

Analyze • Detect • Measure • Control TM

<strong>HAAKE</strong> <strong>RheoStress</strong> <strong>600</strong><br />

What counts in<br />

Rheometry...<br />

VC-Motor<br />

VC Motor, powerful ... dynamic ... and extremely fast<br />

The proven VC motor of the RS300 has been further<br />

improved and sets new standards with:<br />

a 4 th generation diffusion air bearing<br />

high dynamic response due to digital adaptive<br />

control loops and an exemplary low inertia<br />

(1.1·10-5 kgm 2 )<br />

response times of 40 ms for shear rate<br />

and strain jumps<br />

a standard maximum torque of 200 mNm<br />

a minimum torque of 0.1µNm, realised with<br />

the new MSCplus (Micro Stress Control plus)<br />

The VC motor allows the simulation of extreme rheological<br />

processes – a rheologist’s dream comes true!<br />

Software modules<br />

Customize <strong>HAAKE</strong> RheoWin to your needs<br />

<strong>HAAKE</strong> RheoWin can be adapted to<br />

suit individual user requirements via<br />

special modules:<br />

snapshot for a quick characterization<br />

of an unknown sample<br />

RheoWizard ® ; the expert help<br />

system for creating new jobs<br />

Barcode control for workflow<br />

optimization (GLP)<br />

SAP interface for data exchange<br />

automatic comparisons with<br />

reference data / master curves<br />

polymer software <strong>HAAKE</strong> RheoSoft<br />

(WLF, Relaxation time spectra,<br />

molecular weight distribution)<br />

Tools for complying with the<br />

FDA 21 CFR part 11 requirements

CD-Mode<br />

True deformation control<br />

The new Controlled Deformation mode is<br />

available for rotational (strain-jump) as well<br />

as oscillatory measurements. In oscillation<br />

the desired deformation is attained at the<br />

first oscillation period, without iterations,<br />

in contrast to the AutoStrain functionality<br />

of classical CS-rheometers. Fast rheological<br />

processes, like chemical reactions, thermally<br />

induced hardening, gel formation kinetics,<br />

etc. can thus be recorded<br />

continuously.<br />

Data Recording<br />

Recording data right from the start<br />

Many visco-elastic samples e.g. polymers react to changes<br />

in shear stress with a characteristic time delay. Conclusions<br />

can be drawn from this with regard to the<br />

microstructure of the sample, provided that data is<br />

available over a wide range of time. With the 400 Hz<br />

sampling rate of the <strong>HAAKE</strong> <strong>RheoStress</strong> <strong>600</strong>, the first<br />

data point is measured after 2.5 ms. As a result the<br />

time dependent properties of visco-elastic substances<br />

can be characterized continuously.<br />

<strong>HAAKE</strong> RheoWin<br />

Measuring, evaluation and data export via Drag-&-Drop<br />

<strong>HAAKE</strong> RheoWin is a complete measuring and<br />

evaluation software for all measuring modes. It<br />

controls the <strong>HAAKE</strong> <strong>RheoStress</strong> <strong>600</strong> and handles<br />

the measured data either graphically or as a table.<br />

Some highlights are:<br />

definition of measuring and evaluation sequences<br />

(”Jobs”) using Drag-&-Drop<br />

fully automated measurement and evaluation in<br />

one job<br />

broad selection of rheological evaluation methods<br />

freely configurable ASCII data export<br />

automatic intermediate saving of measured data<br />

real multitasking; simultaneous measurements with<br />

multiple rheometers<br />

real 32-bit application for Windows ® 95/98/Me and<br />

NT/2000/XP<br />

highly configurable user managment system<br />

12 operating languages available<br />

Display/Control Unit<br />

Monitoring data on-line even without a PC<br />

The display/control unit of the <strong>HAAKE</strong> <strong>RheoStress</strong> <strong>600</strong> is<br />

used for manual operation of the lift and the gap setting.<br />

It is also used to set preselected shear rates and to intervene<br />

in PC-controlled measurements. The colour display<br />

monitors freely selectable rheological and instrument specific<br />

data online. Data can be displayed numerically as well<br />

as graphically. Complex measuring sequences are carried<br />

out ”at the touch of a button”, without using a PC.<br />

The display/control unit is part of the standard delivery of<br />

the <strong>HAAKE</strong> <strong>RheoStress</strong> <strong>600</strong> High Performance and an<br />

option for the <strong>HAAKE</strong> <strong>RheoStress</strong> <strong>600</strong>.

Modularity<br />

Trying out new ideas with the <strong>HAAKE</strong><br />

<strong>RheoStress</strong> <strong>600</strong>... acting flexibly<br />

The <strong>HAAKE</strong> <strong>RheoStress</strong> <strong>600</strong> is<br />

designed for the creative rheologist,<br />

who uses a rheometer for<br />

dedicated research. The instrument<br />

setup can be quickly adapted to<br />

suit a wide range of requirements<br />

due to its modular design.<br />

Temperature Control<br />

– Liquid temperature control,<br />

Peltier temperature control,<br />

electrical temperature control<br />

Special measuring sensors<br />

– High Temperature, Pressure,<br />

Electro-Rheology, UV-curing cell<br />

Options<br />

– High Shear, Normal Force<br />

<strong>HAAKE</strong> <strong>RheoStress</strong> <strong>600</strong><br />

Normal Force<br />

Rheometry not only in one direction<br />

Forces acting perpendicular to the direction of<br />

flow play an important role in many rheological<br />

applications. With the <strong>HAAKE</strong> <strong>RheoStress</strong> <strong>600</strong>,<br />

the normal force can be used as a set parameter<br />

as well as a measured variable.<br />

The normal stress differences induced by<br />

shearing a visco-elastic sample are measured<br />

by the normal force sensor which is integrated<br />

in the air-bearing, where it is shielded against<br />

mechanical and thermal influences. The new<br />

MFC (Micro Force Correction) extends the<br />

measurable force range down to 0.01 N.<br />

In the FCL mode (Force-Controlled-Loading)<br />

samples are loaded under a pre-set normal<br />

force in order to increase the reproducibility.<br />

With the <strong>HAAKE</strong> <strong>RheoStress</strong> <strong>600</strong> you can<br />

be sure that only the sample properties are<br />

measured.

<strong>HAAKE</strong> <strong>RheoStress</strong> <strong>600</strong><br />

<strong>HAAKE</strong> <strong>RheoStress</strong> <strong>600</strong> models and specifications<br />

<strong>HAAKE</strong> <strong>RheoStress</strong> <strong>600</strong> <strong>HAAKE</strong> <strong>RheoStress</strong> <strong>600</strong><br />

High Performance<br />

Max. Min. Max. Min.<br />

Angular resolution (micro rad) – 0.012 – 0.012<br />

Rotational speed CR-mode (min -1 ) 1500 0.001 1500 (4500*) 0.001<br />

Rotational speed CS-mode (min -1 ) 1500 1.0E-7 1500 1.0E-7<br />

Torque (Nm) 0.2 5.0E-7 0,2 1.0E-7<br />

Oscillation frequency (Hz) 100 0.0001 100 0.0001<br />

Normal force* (N) 30 0.01 30 0.01<br />

* optionally<br />

Temperature control devices<br />

Temp. Temp Heating Cooling<br />

min. max. rate rate<br />

(K/min) (K/min)<br />

Thermal fluid cylinder system -40 200 2 1<br />

Thermal fluid cone & plate system -80 350 3 2<br />

Electric heated cylinder system 30 200 8 1*<br />

Electric heated cone & plate system -80 500 15 2*<br />

Peltier controlled cone & system -60 185 40* 40*<br />

*depending on the properties and temperature of the cooling media<br />

Typical sensor systems<br />

Recommended<br />

Description Type Shear rate (s -1 ) Shear rate (s -1 ) viscosity range<br />

Standard High Shear option (mPas)<br />

Double gap cylinder system DG41 0,007 - 11 415 34 245 0,5 - 10 000<br />

Cylinder Ø 40 mm ISO 3219 Z40 DIN 0,001 - 1 931 5 793 5 - 100 000<br />

Cylinder Ø 20 mm ISO 3219 Z20 DIN 0,001 - 1 931 5 793 50 - 1 000 000<br />

Cylinder Ø 10 mm ISO 3219 Z10 DIN 0,001 - 1 931 5 793 500 - 10 000 000<br />

Cylinder Ø 41 mm DIN 53018 Z41 0,002 - 3 500 10 500 10 - 100 000<br />

Cylinder Ø 38 mm DIN 53018 Z38 0,001 - 1 400 4 200 30 - 500 000<br />

Cylinder Ø 31 mm DIN 53018 Z31 0,0005 - 660 1 980 50 - 1 000 000<br />

Profiled cylinder Ø 38 mm DIN 53018 Z38/S 0,001 - 1 500 4500 50 - 100 000<br />

Disposable cylinder Ø 41 mm ISO 3219 Z41DIN/E 0,001 - 1 931 5793 10 - 100 000<br />

Disposable cylinder Ø 25 mm ISO 3219 Z25DIN/E 0,001 - 1 931 5793 50 - 1 000 000<br />

High shear cylinder 25 µm gap HS25 0,1 - 69 200 207 <strong>600</strong> 5 - 100<br />

High shear cylinder 100 µm gap HS100 0,1 - 15 000 45 000 5 - 100<br />

Double cone Ø 60 mm, 1° angle DC60/1 0,006 - 9 000 27 000 1 - 50 000<br />

Cone Ø 60 mm, 1° angle * C60/1 0,006 - 9 000 27 000 2 - 100 000<br />

Cone Ø 35 mm, 1° angle * C35/1 0,006 - 9 000 27 000 100 - 1 000 000<br />

Cone Ø 20 mm, 1° angle * C20/1 0,006 - 9 000 27 000 1 000 - 1.0 E+08<br />

Plate Ø 60 mm PP60 0,003 - 4 700 14 100 2 - 100 000<br />

Plate Ø 35 mm PP35 0,002 - 2 700 8 100 100 - 1 000 000<br />

Plate Ø 20 mm PP20 0,001 - 1 570 4 710 1 000 - 1.0 E+08<br />

Plate Ø 35 mm serrated PP35/S 0,002 - 2 700 8 100 100 - 1 000 000<br />

Plate Ø 20 mm serrated PP20/S 0,001 - 1 570 4 710 1 000 - 1.0 E+08<br />

* Cones with angles of 0.5° and 2.0° are available as well

International/Germany<br />

Thermo Electron (Karlsruhe) GmbH<br />

Dieselstr. 4<br />

76227 Karlsruhe<br />

Tel. +49(0)721 40 94-444<br />

info.mc.de@thermo.com<br />

Benelux<br />

Thermo Electron B.V.<br />

Takkebijsters 1<br />

4817 BL Breda<br />

Tel. +31(0)76 5879888<br />

info.mc.nl@thermo.com<br />

France<br />

Thermo Electron S.A.<br />

16 Avenue du Québec - Silic 765<br />

91963 Courtaboeuf Cedex<br />

Tel. +33(0)1 60 92 48 00<br />

info.mc.fr@thermo.com<br />

United Kingdom<br />

Thermo Electron<br />

Emerald Way, Stone<br />

Staffordshire ST15 0SR<br />

Tel. +44(0)1785 813648<br />

info.mc.uk@thermo.com<br />

USA<br />

Thermo Electron<br />

25 Nimble Hill Rd.<br />

Newington, NH 03801<br />

Tel. 603-430-6329<br />

info.mc.us@thermo.com<br />

©MC / Dec. 2003 623-2055<br />

www.thermo.com/mc<br />

Analyze • Detect • Measure • Control TM