CONSTANT SPEED TAPPING

CONSTANT SPEED TAPPING

CONSTANT SPEED TAPPING

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NON REVERSING TOOLS<br />

<strong>CONSTANT</strong> <strong>SPEED</strong> <strong>TAPPING</strong><br />

For High-Production CNC Tapping<br />

Without Machine Reversal.<br />

Constant Speed Tapping relies on the<br />

compact tapping head to provide tap<br />

reversal. The machine spindle runs in<br />

one direction at the exact programmed<br />

speed and reversal occurs within the<br />

tapping head instantaneously upon machine<br />

retraction. Avoiding the RPM<br />

fluctuations,common to machine reversal<br />

tapping ensures these benefits:<br />

Reduces Cycle Time.<br />

Increases Tap Life.<br />

Improves<br />

Thread Quality.<br />

Eliminates Reversal<br />

Related Machine<br />

Wear & Tear<br />

Reduces<br />

Energy Costs.<br />

More Holes Per ISO 9001 Minute CERTIFIED: 802 CLEARWATER Than LOOP, POST Any FALLS, ID 83854, Other PHONE 800/854-6019, Tapping FAX: 208/773-3021, System.<br />

www.tapmatic.com<br />

15.

CST Provides Results Like This In Just 60 Seconds<br />

Even On A 15 Year Old Fadal VMC<br />

TAPMATIC<br />

Constant Speed Tapping<br />

Heads Produce More HPM<br />

Holes Per Minute And More<br />

HPT Holes Per Tap On<br />

Full Size Machining<br />

Centers Than Any<br />

Other Tapping<br />

Method.<br />

*For 7075 aluminum, tap<br />

manufacturers recommend<br />

90-100 SFM for cutting taps<br />

and 130 SFM for forming<br />

taps. Maximum<br />

recommended<br />

speeds were<br />

used in our<br />

tests.<br />

How Fast Can You Tap A Hole Using <strong>CONSTANT</strong> <strong>SPEED</strong> <strong>TAPPING</strong><br />

A<br />

Here Is A Simple Calculation You Can Make To See How Fast You Could Be Tapping.<br />

Seconds Per Hole Calculation F 2 x Depth x 60 secMmin.<br />

Feed Rate<br />

____________________________________________________________________________________________________________________<br />

Inch Taps Example Your Oob Metric Taps Example Your Oob<br />

____________________________________________________________________________________________________________________<br />

Tap Size F 1/4-20 ________ Tap Size F M6 x 1 ________<br />

Speed F 2500 RPM ________ Speed F 2500 RPM ________<br />

Feed Rate F 2500 : by 20 = 125 inch/min ________ Feed Rate F 2500 x 1 = 2500 mm/min ________<br />

Depth F .50 inch ________ Depth F 12mm ________<br />

Seconds Per Hole F .R8 seconds ________ Seconds Per Hole F .58 seconds ________<br />

Now calculate using your own specific applications and compare with your current tapping cycle time to see how much time you can save when<br />

you eliminate machine reversal.<br />

Note: Time estimate based on using Tapmatic’s recommended Reduced Cycle Time Programming shown on page 27.<br />

16.<br />

ISO 9001 CERTIFIED: 802 CLEARWATER LOOP, POST FALLS, ID 83854, PHONE 800/854-6019, FAX: 208/773-3021, www.tapmatic.com

NON REVERSING TOOLS<br />

Cut Cycle Times In Half & Increase Tap Life By 100%<br />

__________________________________________________________________________________<br />

REAL APPLICATION<br />

COST SAVINGS ANALYSIS<br />

______________________________________________<br />

Mr. Stefan Rolke, Owner, Firma Sted GmbH, Germany<br />

______________________________________________<br />

APPLICATIONV<br />

Work Piece Material<br />

Cast Iron<br />

Tap Size<br />

M6 x 1 HSS with TiN-Al coating<br />

Number of Holes Per Work PieceV 68<br />

_________________________________________________________________________________________<br />

1. 50Z Cycle Time Savings M Productivity Increased<br />

Or More<br />

Original Cycle Time w/ Rigid Tapping:<br />

6 minutes 34 seconds<br />

New Cycle Time Using RDTIC50:<br />

3 minutes 12 seconds<br />

Cycle Time Savings:<br />

202 seconds<br />

Machine Hourly Rate:<br />

$50.00 per hour<br />

202 Seconds Per Part Time Savings Means \2.80 Per Part Cost Savings ]\.0R per hole^<br />

________________________________________________________________________________________________________<br />

2. 300Z Longer Tap Life<br />

Original Tap Life with Rigid Tapping =<br />

3000 holes per tap<br />

68 Holes Per Work Piece = 44 parts per tap<br />

New Tap Life with Constant Speed Tapping<br />

9000 holes per tap<br />

68 Holes Per Work Piece = 132 parts per tap<br />

If Tap Cost Is $25.00, The Savings Is:<br />

With Rigid Tapping Tap Cost Is $25.00 divided by 44 =<br />

.56 per part tap cost.<br />

With Constant Speed Tapping Tap Cost Is $25.00 divided by 132 =. .19 per part tap cost<br />

Tap Cost Savings F<br />

\.37 per part ]\.005 per hole^<br />

________________________________________________________________________________________________________<br />

RDTIC50 ]Cost \2,10R.00^ Paid for Itself In<br />

66R Parts or R5,152 Holes<br />

_______________________________________________________________________________________________________<br />

3. Elimination Of Reversal Related Machine Spindle WearV Tapping is the only operation that requires reversal. Stopping and<br />

reversing your machine two times for every tapped hole will wear the spindle out more quickly. What does it cost to replace a<br />

machine spindleb What does it cost you in lost production time to have your machine downb<br />

Now Check Out How Quickly<br />

A Tapmatic Self-Reversing Head Will Pay For Itself<br />

_______________________________________________________________________________________________________<br />

RDT50 Example I Example II Example III<br />

_______________________________________________________________________________________________________<br />

Machine Hourly RateV $100.00 per hour $75.00 per hour $50.00 per hour<br />

Time Savings Per Tapped HoleV 2 seconds 1 second 1/2 second<br />

Shorter Time Cost Savings Per HoleV $.05 $.02 $.007<br />

Plus Tap Life Cost Savings $.01 per hole $.007 $.005<br />

Total RDT Savings Per Tapped HoleV \.06 \.027 \.012<br />

RDT ]Cost \1,759.00^ Pays For Itself InV 29,317 Holes 65,1R8 Holes 1R6,583 Holes<br />

ISO 9001 CERTIFIED: 802 CLEARWATER LOOP, POST FALLS, ID 83854, PHONE 800/854-6019, FAX: 208/773-3021, www.tapmatic.com<br />

17.

TOOL SELECTORV Constant Speed Tapping Attachments For<br />

PERFORMANCE ADVANTAGES<br />

❚❚<br />

❚❚<br />

❚❚<br />

❚❚<br />

❚❚<br />

❚❚<br />

Faster Cycle Time<br />

Longer Tap Life<br />

Reduced Energy Consumption<br />

Reduced Machine Spindle Wear<br />

Continuous dLike-Newd Performance<br />

Hard Start For Accurate<br />

Thread Depth Repeatability<br />

FAST And EASY INSTALLATION<br />

Compact Diameter<br />

Modular SystemV Straight shank design with angle flat<br />

permits easy adaptation to short length NC Arbors.<br />

Patented Features<br />

U.S. Patent #5,628, 293- Renewable Drive System:<br />

U.S. Patent #5,209,616- Dampened And Spring Biased Coupler:<br />

U.S. Patent #4,566,829- Integral orientation collar and stop arm<br />

US. Patent #5213453- RDTIC features patented Balanced High<br />

Pressure Internal Coolant System<br />

Unique Vacuum Suppressor prevents external coolant leakage into<br />

tapping head in flood conditions.<br />

Tapping spindle floats in ball and needle bearings reducing friction for<br />

smoother operation.<br />

For MACHINING CENTERS<br />

Available On Request<br />

Complete Tool Assemmblies For Popular Machines<br />

For 80mm Offset and CAT 50................. Steel Collet Chuck Spindle.<br />

For Haas VF1, VF2, VF3........................... Steel Collet Chuck Spindle<br />

For FADAL VMC20, R0, R020, 6030........ Steel Collet Chuck Spindle<br />

For 65mm Offset and CAT R0................. Steel Collet Chuck Spindle<br />

RDT<br />

RDTXT<br />

CAT50<br />

CATR0<br />

RDT<br />

RDTXT<br />

Pages 20 Page 21<br />

__________________________________________________________________________________________________________________<br />

RDT15 #0-#6 RDTXT50 #10-1/2"<br />

RDT25 #4-1/4"<br />

RDT50 #10-1/2"<br />

RDT85 1/2”-1”<br />

___________________________________________________________________________________________________________________<br />

Available On Request Page 38<br />

RSR<br />

VMC<br />

18.<br />

ISO 9001 CERTIFIED: 802 CLEARWATER LOOP, POST FALLS, ID 83854, PHONE 800/854-6019, FAX: 208/773-3021, www.tapmatic.com

NON REVERSING TOOLS<br />

High Production CNC Applications Without Machine Reversal<br />

Ask For RCT or RDTIC For Internal Coolant<br />

Balanced High Pressure Internal Coolant SystemV<br />

Delivers maximum volume at pressures up to 50 bar or 700 psi.<br />

Tapping head can be operated with or without internal coolant<br />

flow. If dirty coolant causes blockage, coolant tube can be<br />

removed and cleaned in minutes. US. Patent #5213453<br />

Minimum Quantity Lubrication Through The SpindleV<br />

If your machine uses MQL through the spindle, Tapmatic can<br />

deliver RDTIC tools especially made for these Near Dry<br />

Machining applications.<br />

Please contact our sales engineers at 800 854-6019<br />

RDTIC models come with standard nuts which allow some coolant flow through collet slots. To restrict flow to the coolant hole of the tap and seal the collet<br />

slots, the tools may also be ordered with a sealing disk nut. Please add "S" to the end of the order numbers shown below to specify tool with sealing disk<br />

nuts.<br />

For MACHINING CENTERS With INTERNAL COOLANT CAPABILITY<br />

New RCT- Reduced Cycle Time Tapping<br />

Coming In 2006<br />

NEW<br />

RCT-50 RDTIC RDTIC RDTICXT<br />

RCT RDTIC HSK RDTIC RDTICXT<br />

Pages 22-23 Page 25 Page 2R Page 26<br />

___________________________________________________________________________________________________________________<br />

RCT50 #10-1/2" RDTIC50 #10-1/2" RDTIC50 #10-1/2" RDTICXT50 #10-1/2"<br />

RDTIC75 3/8"-3/4"<br />

RDTIC85 1/2”-1”<br />

___________________________________________________________________________________________________________________<br />

_____________________________________________________________________________________________________________________________________________<br />

CST TOOL ORDERING INFORMATION. Order Separately:<br />

(A) Tapping Attachment. (B) Stop Arm. (C) NC ARBORS ER COLLETS Page 46<br />

See following pages. See following pages. Page 49 Use square drive collets whenever<br />

Please order by catalog # and tap size Special center distances or ready possible.<br />

capacity. Tool capacity must be reduced made stop arms to fit your machines<br />

by 25% when using roll form.<br />

are also available. Please consult factory.<br />

TAPMATIC Can Also Supply A Tool STOP BLOCKS INTERCHANGEABLE INSERTS<br />

Ready To Fit Your Machine For Your For RDTXT. Page 45<br />

See Page 28<br />

Machine<br />

Page 48-49<br />

_____________________________________________________________________________________________________________________________________________<br />

ISO 9001 CERTIFIED: 802 CLEARWATER LOOP, POST FALLS, ID 83854, PHONE 800/854-6019, FAX: 208/773-3021, www.tapmatic.com<br />

19.

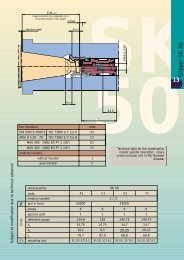

RDT15, 25, 50 & 85 With Steel Collet Chuck<br />

]A^_____________________________________________________________________________________________________________________________________________________________________________<br />

Capacity In Catalog Collet *Rec. Max.<br />

1010 Mild Steel Model Shank No. Series Speed Weight A B D N Q<br />

__________________________________________________________________________________________________________________________________________________________<br />

#0-#6 RDT-15HD 1d SS 391518HD #8 5000 RPM 3 lb. 2.250 .465 3.83 3.10 1.650<br />

M1-M3 Heavy Duty 25mm SS 3915258HD 1.4 Kg. 57.1mm 11.8mm 97mm 79m 42m<br />

__________________________________________________________________________________________________________________________________________________________<br />

#4-1/4" RDT-25HD 1d SS 3925111 #11 3500 RPM 3 lb. 2.250 .750 4.18 3.10 1.650<br />

M2.5-M6 Heavy Duty 25mm SS 39252511 1.4 Kg. 57.1mm 19mm 106mm 79mm 42mm<br />

Roll Form #10 Max<br />

__________________________________________________________________________________________________________________________________________________________<br />

#10-1/2" RDT-50HD 1d SS 3950116 #16 2000 RPM 6.4lb. 3.150 1.070 4.94 3.62 1.650<br />

M4.5-M12 Heavy Duty 25mm SS 39502516 2.9 Kg. 80mm 27mm 126mm 92mm 42mm<br />

Roll Form 3/8" Max<br />

NP 1/16", 1/8"<br />

____________________________________________________________________________________________________________________________________________________________<br />

]A^______________________________________________________________________________________________________________________________________________________<br />

Capacity In Catalog Collet *Rec. Max.<br />

1010 Mild Steel Model Shank No. Series Speed Weight A B D N Q<br />

_________________________________________________________________________________________________________________________________________________________<br />

7/16"-3/4" RDT-85HS 1d SS 3985125 #25 1500 RPM 8.7 Lb. 3.150 1.650 5.92 4.22 1.650<br />

M11-M20 High Speed 25mm SS 39852525 2.9 Kg. 80mm 42mm 150mm 107mm 42mm<br />

Roll Form 9/16" Max<br />

_________________________________________________________________________________________________________________________________________________________<br />

1/2"-1" RDT-85 1d SS 3985132 #32 1200 RPM 8.7 Lb. 3.150 1.960 6.18 4.22 1.650<br />

M12-M25 25mm SS 39852532 2.9 Kg. 80mm 50mm 157mm 107mm 42mm<br />

Roll Form 5/8" Max<br />

_______________________________________________________________________________________________________________________________<br />

20.<br />

ISO 9001 CERTIFIED: 802 CLEARWATER LOOP, POST FALLS, ID 83854, PHONE 800/854-6019, FAX: 208/773-3021, www.tapmatic.com

NON REVERSING TOOLS<br />

RDTXT50 Extended Length With Interchangeable Insert Spindle<br />

Order Insert Separately<br />

See page......45<br />

]A^_____________________________________________________________________________________________________________________________<br />

Capacity In Catalog *Rec. Max.<br />

1010 Mild Steel Model Shank No. Inserts Speed Weight A B D N Q<br />

_________________________________________________________________________________________________________________________________________________________<br />

#10-1/2" RDTXT50 1d SS 39501191 Order 2000 RPM 6.2 Lb. 3.150 1.365 7.53 3.62 1.650<br />

M4.5-M12 25mm SS 395025191 Separately 2.8 Kg. 80mm 35mm 191mm 92mm 42mm<br />

Roll Form 3/8" Max 1d SS 39501255 1800 RPM 6.3 Lb. 10.03<br />

NP 1/16", 1/8" 25mm SS 395025255 2.8 Kg. 255mm<br />

_________________________________________________________________________________________________________________________________________________________________<br />

*See recommended tapping speeds for specific tap size and work piece material. Charts included in instructions sheets. Do not exceed maximum speed.<br />

Please Note: For RDTXT & RDTICXT maximum speed with ER20 Insert is 1500 RPM.<br />

]B^____________________________________________________________________________________________________________________________________________________<br />

Stop Arm Assemblies<br />

_______________________________________________________________________________________________________________________________<br />

*Center Distance<br />

Q l R Catalog No. Catalog No. Catalog No. R S Q l S<br />

RDT 15 & 25 RDT 50 & 75 RDT85<br />

_____________________________________________________________________________<br />

55mm 392555 395055 .515 1.140 2.790<br />

13mm 29mm 71mm<br />

_____________________________________________________________________________<br />

65mm 392565 395065 398565 .909 1.534 3.184<br />

23mm 39mm 81mm<br />

______________________________________________________________________________<br />

80mm 392580 395080 398580 1.500 2.125 3.775<br />

80mm 65mm 55mm<br />

38mm 54mm 96mm<br />

Stop Arm Stop Arm Stop Arm<br />

______________________________________________________________________________________________________________________________<br />

*Special Center Distances also available.<br />

_____________________________________________________________________________________________________________________________________________<br />

CST TOOL ORDERING INFORMATION. Order Separately:<br />

(A) Tapping Attachment. This Page. (B) Stop Arm. This Page. (C) NC ARBORS ER COLLETS Page 46<br />

Please order by catalog and tap size Special center distances or ready Page 49 Use square drive collets whenever<br />

capacity. Tool capacity must be reduced made stop arms to fit your machines possible.<br />

by 25% when using roll form.<br />

are also available. Please consult factory.<br />

TAPMATIC Can Also Supply A Tool See alternative installation methods STOP BLOCKS INTERCHANGEABLE INSERT<br />

Ready To Fit Your Machine on page 49. For Your For RDTXT. Page 45<br />

See Page 28<br />

Machine<br />

Page 48-49<br />

_____________________________________________________________________________________________________________________________________________<br />

ISO 9001 CERTIFIED: 802 CLEARWATER LOOP, POST FALLS, ID 83854, PHONE 800/854-6019, FAX: 208/773-3021, www.tapmatic.com<br />

21.

Introducing The New RCT-50<br />

“Reduced Cycle Time” Tapping<br />

22.<br />

ISO 9001 CERTIFIED: 802 CLEARWATER LOOP, POST FALLS, ID 83854, PHONE 800/854-6019, FAX: 208/773-3021, www.tapmatic.com

NON REVERSING TOOLS<br />

New RCT50 With Inernal Coolant & ER Collet Chuck<br />

________________________________________________________________________________________________________________________________<br />

]A^_____________________________________________________________________________________________________________________________<br />

Capacity In Collet *Rec. Max.<br />

1010 Mild Steel Model Shank Catalog No. Series Speed Weight A B D N Q<br />

________________________________________________________________________________________________________________________________<br />

#10-1/2" RCT- 50 CATR0 0550CR016 #16 2500 RPM 8.0 Lb. 3.150 1.380 7.02 5.35 1.650<br />

M4.5-M12 3.6Kg. 80mm 35mm 178mm 136mm 42mm<br />

Roll form 3/8" Max CAT50 0550C5016 12.0 Lb. 7.02 5.35<br />

NP 1/16", 1/8" 5.4 Kg. 178mm 136mm<br />

BTR0 0550BR016 8.0 Lb. 7.02 5.35<br />

3.6 Kg. 178mm 136mm<br />

BT50 0550B5016 14.0 Lb. 7.47 5.80<br />

6.3. Kg. 190mm 147mm<br />

______________________________________________________________________________________________________________________________________________________________<br />

#10-1/2" RCT-50 HSK63A 0550H6316 #16 2500 RPM 10.0Lb. 3.150 1.380 7.38 5.71 1.650<br />

M4.5-M12 4.5Kg. 80mm 35mm 187mm 145mm 42mm<br />

Roll form 3/8" Max HSK100A 0550H10016 13.0 lb. 7.64 5.97<br />

NP 1/16", 1/8" 5.9 Kg. 194mm 152mm<br />

______________________________________________________________________________________________________________________________________________________________<br />

]B^________________________________________________________________________________________________________________________________________________________<br />

Stop Arm Assemblies<br />

____________________________________________________________________________<br />

Center Distance<br />

Q l R Catalog No. R S Q l S<br />

____________________________________________________________________________<br />

55mm 055055 .515 1.140 2.790<br />

13mm 29mm 71mm<br />

____________________________________________________________________________<br />

65mm 055065 .909 1.534 3.184<br />

23mm 39mm 81mm<br />

80mm 65mm 55mm<br />

____________________________________________________________________________<br />

Stop Arm Stop Arm Stop Arm<br />

80mm 055080 1.500 2.125 3.775<br />

38mm 54mm 96mm<br />

____________________________________________________________________________________________________________________________________________________________<br />

_____________________________________________________________________________________________________________________________________________<br />

CST TOOL ORDERING INFORMATION. Order Separately:<br />

(A) Tapping Attachment. This Page. (B) Stop Arm. This Page. ER COLLETS Page 46<br />

Please order by catalog and tap size Special center distances or ready Use square drive collets whenever<br />

capacity. Tool capacity must be reduced made stop arms to fit your machines possible.<br />

by 25% when using roll form.<br />

are also available. Please consult factory.<br />

TAPMATIC Can Also Supply A Tool STOP BLOCKS ER COLLET CHUCK<br />

Ready To Fit Your Machine For Your Page 45<br />

See Page 28<br />

Machine<br />

Page 48-49<br />

_____________________________________________________________________________________________________________________________________________<br />

ISO 9001 CERTIFIED: 802 CLEARWATER LOOP, POST FALLS, ID 83854, PHONE 800/854-6019, FAX: 208/773-3021, www.tapmatic.com<br />

23.

RDTIC50 & 85 With Internal Coolant & ER Collet Chuck<br />

]A^_____________________________________________________________________________________________________________________________<br />

Capacity In Model Catalog Collet *Rec. Max.<br />

1010 Mild Steel No. Shank No. Series Speed Weight A B D N Q<br />

____________________________________________________________________________________________________________________________________<br />

#10-1/2" RDTIC50HS 1d SS R0501LW16M #16 2300 RPM 6.4Lb. 3.150 .866 5.39 3.62 1.650<br />

M4.5-M12 Light Weight 25mm SS R05025LW16M 2.9Kg. 80mm 22mm 137mm 92mm 42mm<br />

Roll form 3/8" Max<br />

NP 1/16", 1/8"<br />

_______________________________________________________________________________________________________________________________<br />

Small capacity RDTIC25 also available on special request.<br />

ER20 and ER25 spindles also available on special request.<br />

________________________________________________________________________________________________________________________________<br />

]A^_____________________________________________________________________________________________________________________________<br />

Capacity In Catalog Collet *Rec. Max.<br />

1010 Mild Steel Model Shank No. Series Speed Weight A B D N Q<br />

__________________________________________________________________________________________________________________________________________________________<br />

7/16"-3/4" RDTIC85HS 1d SS R085125 #25 1500 RPM 8.7lb. 3.150 1.960 5.92 4.22 1.650<br />

M11-M20 Light Weight 25mm SS R0852525 2.9 Kg. 80mm 50mm 150mm 107mm 42mm<br />

Roll Form 9/16" Max Spindle<br />

__________________________________________________________________________________________________________________________________________________________<br />

1/2"-1" RDTIC85 1d SS R085132 #32 1200 RPM 9.4 Lb. 3.150 2.480 6.18 4.22 1.650.<br />

M12-M25 25mm SS R0852532 4.3 Kg. 80mm 63mm 157mm 107mm 42mm<br />

Roll Form 5/8" Max<br />

__________________________________________________________________________________________________________________________________________________________<br />

Seal Nut Option<br />

RDTIC models come with standard nuts which allow some coolant flow through collet slots. To restrict flow to the coolant hole of the tap and seal the collet slots,<br />

the tools may also be ordered with a sealing disk nut. Please add “S” to the end of the order numbers shown to specify tool with sealing disk nuts.<br />

24.<br />

ISO 9001 CERTIFIED: 802 CLEARWATER LOOP, POST FALLS, ID 83854, PHONE 800/854-6019, FAX: 208/773-3021, www.tapmatic.com

NON REVERSING TOOLS<br />

RDTIC50, 75 & 85 With Internal Coolant, Integral HSK Shank & ER Collet Chuck<br />

]A^_____________________________________________________________________________________________________________________________<br />

Capacity In Catalog Collet *Rec. Max.<br />

1010 Mild Steel Model Shank No. Series Speed Weight A B D N Q<br />

_________________________________________________________________________________________________________________________________.<br />

#10-1/2" RDTIC50HS HSK 63A R050H63LW16M #16 2300 RPM 7.8 Lb. 3.150 .866 7.33 5.56 1.650<br />

M4.5-M12 Light 3.5 Kg. 80mm 22mm 186mm 142mm 42mm<br />

Roll Form 3/8" Max. Weight HSK 80A R050H80LW16M 8.9 Lb. 7.51 5.74<br />

NP 1/16", 1/8" Spindle 4.0 Kg. 191mm 147mm<br />

HSK 100 A R050H100LW16M 11.2 Lb. 7.59 5.82<br />

5 Kg. 193mm 149mm<br />

________________________________________________________________________________________________________________________________<br />

ER20 and ER25 spindles available on special request.<br />

_________________________________________________________________________________________________________________________________<br />

]A^_____________________________________________________________________________________________________________________________<br />

Capacity In Catalog Collet *Rec. Max.<br />

1010 Mild Steel Model Shank No. Series Speed Weight A B D N Q<br />

________________________________________________________________________________________________________________________________<br />

7/16", -3/4" RDTIC85HS HSK63A R085H6325 #25 1500 RPM 10.1 Lb. 3.150 1.650 7.87 6.17 1.650<br />

M11-M20 3.5 Kg. 80mm 42mm 200mm 157mm 42mm<br />

Roll Form 9/16" Max HSK80A R085H8025 11.2 Lb. 8.05 6.35<br />

4.0 Kg. 204mm 161mm<br />

HSK100A R085H10025 13.5 Lb. 8.12 6.42<br />

5.0 Kg. 206mm 163mm<br />

_________________________________________________________________________________________________________________________________<br />

1/2", -1" RDTIC85 HSK63A R085H6332 #32 1200 RPM 10.1 Lb. 3.150 1.960 8.13 6.17 1.650<br />

M12-M25 3.5 Kg. 80mm 50mm 207mm 157mm 42mm<br />

Roll Form 5/8" Max HSK80A R085H8032 11.2 Lb. 8.31 6.35<br />

4.0 Kg. 211mm 161mm<br />

HSK100A R085H10032 13.5 Lb. 8.38 6.42<br />

5.0 Kg. 213mm 163mm<br />

_________________________________________________________________________________________________________________________________<br />

ISO 9001 CERTIFIED: 802 CLEARWATER LOOP, POST FALLS, ID 83854, PHONE 800/854-6019, FAX: 208/773-3021, www.tapmatic.com<br />

25.

RDTICXT 50 Extended Length With Internal Coolant & Interchangeable Insert Spindle<br />

]A^_______________________________________________________________________________________________________________________________<br />

Capacity In Catalog Insert *Rec. Max.<br />

1010 Mild Steel Model Shank No. Series Speed Weight A B D N Q<br />

___________________________________________________________________________________________________________________________________________________________<br />

#10-1/2" RDTICXT50 1d SS R0501191 Order 2000 RPM 6.2 Lb. 3.150 1.365 7.53 3.62 1.650<br />

M4.5-M12 25mm SS R05025191 Separately 2.8 Kg. 80mm 35mm 191 mm 92mm 42mm<br />

Roll Form 3/8" Max Page 45<br />

NP 1/16", 1/8" 1d SS R0501255 1800 RPM 6.3 Lb. 10.03<br />

25mm SS R05025255 2.8 Kg.. 255mm<br />

_____________________________________________________________________________________________________________________________________________________________<br />

NOTESV<br />

* See recommended tapping speeds for specific tap size and work piece material. Charts included in instruction sheets.<br />

Do not exceed maximum speed.<br />

Seal Nut Option<br />

RDTIC models come with standard nuts which allow some coolant flow through collet slots. To restrict flow to the coolant hole of the tap and seal the collet slots,<br />

the tools may also be ordered with a sealing disk nut. Please add “S” to the end of the order numbers shown to specify tool with sealing disk nuts.<br />

]B^____________________________________________________________________________________________________________________________________________________<br />

Stop Arm Assemblies<br />

____________________________________________________________________________________________________________________________________________________________<br />

Center Distance<br />

Q l R Catalog No. Catalog No. Catalog No. R S Q l S<br />

RDTIC 25 RDTIC 50 & 75 RDTIC 85<br />

___________________________________________________________________________________<br />

55mm 392555 395055 .515 1.140 2.790<br />

13mm 29mm 71mm<br />

___________________________________________________________________________________<br />

65mm 392565 395065 398565 .909 1.534 3.184<br />

23mm 39mm 81mm<br />

___________________________________________________________________________________ 80mm 65mm 55mm<br />

80mm 392580 395080 398580 1.500 2.125 3.775 Stop Arm Stop Arm Stop Arrm<br />

38mm 54mm 96mm<br />

____________________________________________________________________________________________________________________________________________________________<br />

_____________________________________________________________________________________________________________________________________________<br />

CST TOOL ORDERING INFORMATION. Order Separately:<br />

(A) Tapping Attachment. This Page. (B) Stop Arm. This Page. (C) NC ARBORS ER COLLETS Page 46<br />

Please order by catalog and tap size Special center distances or ready Page 49 Use square drive collets whenever<br />

capacity. Tool capacity must be reduced made stop arms to fit your machines possible.<br />

by 25% when using roll form.<br />

are also available. Please consult factory.<br />

TAPMATIC Can Also Supply A Tool STOP BLOCKS (D) INTERCHANGEABLE INSERTS<br />

Ready To Fit Your Machine For Your For RDTXT. Page 45<br />

See Page 28<br />

Machine<br />

Page 48-49<br />

_____________________________________________________________________________________________________________________________________________<br />

26.<br />

ISO 9001 CERTIFIED: 802 CLEARWATER LOOP, POST FALLS, ID 83854, PHONE 800/854-6019, FAX: 208/773-3021, www.tapmatic.com

NON REVERSING TOOLS<br />

Reduced Cycle Time Programming- The Fastest Way To Tap<br />

Clearance Plane<br />

Moving In Rapid<br />

Moving In Tap Pitch Feed<br />

Moving at 500 in/min or<br />

13000 mm/min Feed<br />

Axial movement is required with a selfreversing<br />

tapping head to move from<br />

engagement in forward drive to full<br />

engagement in reverse drive.<br />

* **<br />

1.) Rapid<br />

Traverse to<br />

clearance<br />

plane<br />

above hole<br />

location.<br />

2.) Rapid<br />

down to 1mm<br />

minimum<br />

above part.<br />

3.) Tap Pitch 4.) Retract tapping<br />

Feed in to part head at 500 in/min<br />

to program or 13000 mm/min<br />

depth. specified distance<br />

for specific tapping<br />

head to reverse tap<br />

rotation.<br />

FIG. 1<br />

5.) Tap Pitch<br />

Feed out of<br />

hole to<br />

clearance<br />

plane.<br />

RDT15-<br />

RDT25-<br />

RDT50-<br />

CLEARANCE PLANE AND FAST RETRACT DISTANCE<br />

CP=D= .250 in or 6mm Please note that the distance shown<br />

CP=D = .250 in or 6mm is the minimum clearance plane and<br />

CP=D = .400 in or 10mm maximum fast retract distance allowed.<br />

-<br />

NOTE: The only time during the cycle spent in the tap feed rate is the 1mm approach<br />

height plus thread depth in and out. All other moves are at maximum speed.<br />

EXAMPLE<br />

Tapping Unit: RDT25<br />

Tap Size #10-24<br />

100 SFM<br />

2000 RPM<br />

Feed Rate In @ 100% = 83.33 in/min<br />

RDT Reduced Cycle Time Programming Example<br />

Self-Reversing Tapping Unit Using G01 Code.<br />

Sub Routine:<br />

Rapid approach to 1mm or .040 above part.<br />

Feed in to depth .300 (note actual depth,<br />

slightly deeper than program depth)<br />

Retract .250 inch at 500 in/min to reverse tap. (Use maximum<br />

Feed Rate up to 500 in/min)<br />

Feed out to .250 clearance plane.<br />

VERY IMPORTANT NOTICE<br />

Regarding Ramp or Exact Stop: Please note<br />

that the G code for "Exact Stop" or "Ramp"<br />

should not be used with a Tapmatic selfreversing<br />

tapping attachment. Please be sure<br />

that these are not in effect when tapping<br />

because they will cause the tapping cycle time<br />

to be significantly slower and thread depth<br />

repeatability to be less accurate.<br />

Fadal Machines: Use G8 to cancel the Ramp<br />

for tapping. G9 will turn the Ramp on again if<br />

desired for other operations.<br />

Machines With Fanuc Controls and Haas Machines:<br />

Use G64 while tapping to eliminate the<br />

Exact Stop. G61 will make Exact Stop modal<br />

again for other operations if desired.<br />

MAIN PROGRAM<br />

M06 T6 Tool Change - Tool #6<br />

M00<br />

Program Stop<br />

M03 S2000 Spindle Forward ROTATION 2000 RPM.<br />

G8<br />

Ramp Off (or G64 eliminates exact stop)<br />

G00 G43 Z1.0 H06 M08 Rapid to Z1.0 Height Offset #6 coolant on.<br />

M49<br />

Spindle Speed and Feed Rate override cancel.<br />

G00 G90 X1.0 Y-1.0 Z.250 Rapid in absolute to hole position X1.0, Y-1.0 and Z.250 clearance plane.<br />

M98 P4 L1 Repeat sub program 04 one time.<br />

G00 Y-2.0 Rapid to next hole.<br />

M98 P4 L1 Repeat sub program 04 one time.<br />

Complete<br />

Programming<br />

Information<br />

Included With<br />

Each Tapping<br />

Attachment<br />

Sub Program<br />

0004<br />

G90<br />

Absolute movement.<br />

G00 Z.04 Rapid to .04 above hole<br />

G01 Z-.30 F83.33 Feed in to hole at 100% Feed Rate.<br />

G01 Z-.05 F 500.0 Retract .250 at 500 in/min to reverse tap.<br />

G01 Z.250 F83.33 Feed out of hole to .250 clearance plane.<br />

M99<br />

Return to main program<br />

ISO 9001 CERTIFIED: 802 CLEARWATER LOOP, POST FALLS, ID 83854, PHONE 800/854-6019, FAX: 208/773-3021, www.tapmatic.com<br />

27.

RDT, RDTIC & RCT Installation<br />

Tapmatic Can Supply Tools Ready To Fit Your Machine. RDT, RDTIC and RCT units take the burden of reversal away from the<br />

machine and therefore require a stop arm to activate their self-contained reversing mechanism. This arm must be positioned by the<br />

orientation collar to the exact location of the machine’s stop block then locked in place and fixed positively with the locking screw<br />

provided. Tapmatic has stop arms to fit most popular machines. Just give us your machine make and model #. If we have not already<br />

supplied tools for your machine, we may need the information shown below.<br />

If Your Machine Already Has A Stop Block We Will Need The Dimensions Shown Below To Prepare Your Tool.<br />

If we do not already have a custom stop<br />

arm available just provide the following<br />

information and we’ll make one for you.<br />

Installing an RDT, RDTIC or RCT on your<br />

machine is simple and Tapmatic<br />

experts are as near as your phone for any<br />

help you may require. Please contact our<br />

factory at 800 854-6019, FAX: 208/773-<br />

3021 and simply provide the dimensions<br />

requested. We will supply a tool modified<br />

to fit your machine.<br />

28.<br />

ISO 9001 CERTIFIED: 802 CLEARWATER LOOP, POST FALLS, ID 83854, PHONE 800/854-6019, FAX: 208/773-3021, www.tapmatic.com

NON REVERSING TOOLS<br />

RDT, RDTIC And RCT Installation<br />

If Your Machine Does Not Already Have A Stop Block Please Complete Either Spindle A or Spindle B Below.<br />

SPINDLE A<br />

SPINDLE B<br />

ISO 9001 CERTIFIED: 802 CLEARWATER LOOP, POST FALLS, ID 83854, PHONE 800/854-6019, FAX: 208/773-3021, www.tapmatic.com<br />

29.

More Reasons To Consider A Self-Reversing Tapping Head<br />

Turn Any VMCMHMC Into A High Speed Tapping<br />

Center Your older machining centers probably can’t<br />

match the rapid feed and traverse rates of a high<br />

speed tapping center but during the feed rate of the<br />

tapping cycle itself, Tapmatic’s Constant Speed more<br />

than makes up for this by eliminating two machine<br />

reversals per tapped hole. Avoiding the RPM<br />

fluctuations common to machine reversal tapping<br />

also increases tap life substantially.<br />

But Savings On Taps And Tapping Time Are Only<br />

Part Of The Story...<br />

Which Is Faster At The Same RPMb<br />

49.8 HPM*<br />

Sec.<br />

59.8 HPM*<br />

Sec.<br />

Hi-Speed Tapping Center<br />

Tapmatic & Machining Center<br />

TEST: (10) 6mm Roll Form Holes, 9mm Deep, 2500 RPM, 7075 Aluminum<br />

Even when the tapping center’s RPM was increased to 4000, it didn’t produce more<br />

*Holes Per Minute (HPM) than Tapmatic at 2500. SEND FOR COPY OF THIS VIDEO.<br />

CST permits your machines to operate at<br />

cruising speed in one direction and still produce<br />

more holes per minute than a high speed tapping<br />

center at higher RPM. This increases machine spindle<br />

life. Machine down time is a significant shop expense.<br />

By eliminating wear caused by machine reversal at<br />

high RPM some customers have saved as much<br />

as \20,000.00 on spindle replacements and down<br />

time annually.<br />

ACCESSORIESNON REVERSING TOOLS<br />

Power Consumption Costs Are Also ReducedV<br />

Tests Show CST Uses Only 1MRth As Much<br />

Electrical Power. In high production tapping this is a<br />

significant savings considering today’s energy costs.<br />

See For Yourself. Send For Free<br />

Better CNC Tapping CD<br />

And SwitchFaster<br />

Programming<br />

Instructions.<br />

ISO 9001 CERTIFIED: 802 CLEARWATER LOOP, POST FALLS, ID 83854, PHONE 800/854-6019, FAX: 208/773-3021, www.tapmatic.com