You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

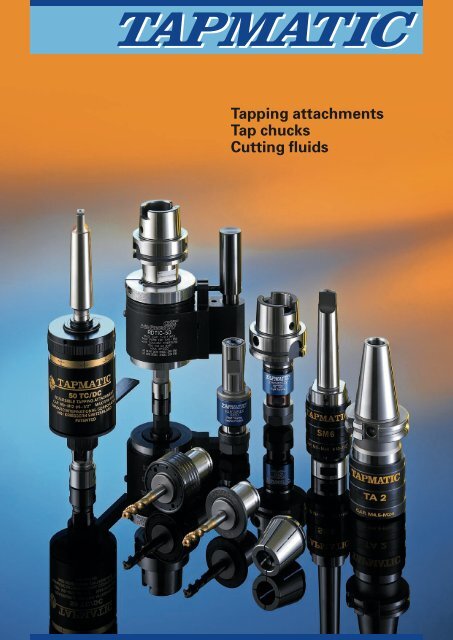

Tapping atta<strong>ch</strong>ments<br />

Tap <strong>ch</strong>ucks<br />

Cutting fluids

TAPMATIC –<br />

The tapping specialists<br />

TAPMATIC has for over 50 years manufactured tapping atta<strong>ch</strong>ments of<br />

the highest quality. Generous investment in resear<strong>ch</strong> and development<br />

has created and maintained a leading market position worldwide in the<br />

field of integrated reversing tapping atta<strong>ch</strong>ments.TAPMATIC tapping<br />

atta<strong>ch</strong>ments can be used on all ma<strong>ch</strong>ine tools from the manually<br />

operated to the most sophisticated CNC ma<strong>ch</strong>ining centre. In 1981<br />

TAPMATIC (Kriessern) in Switzerland opened their own manufacturing<br />

plant, who‘s primary responsibility is to supply the European market.<br />

All tapping heads and spare parts are available from this central plant<br />

in Kriessern. TAPMATIC have their own distribution companies in all<br />

major countries throughout Europe. TAPMATIC also has stockists with<br />

trained representatives in more than 50 industrial countries world-wide<br />

ensuring the best possible service. Cutting fluids are a further product<br />

of TAPMATIC. They enable perfect threads to be cut, of the highest<br />

precision and surface finish including very difficult materials.<br />

Ea<strong>ch</strong> tapping unit goes through practical test runs and has a one year<br />

guarantee, according to our certified quality standard ISO 9001:2000.<br />

The advantages of<br />

TAPMATIC tapping heads<br />

TAPMATIC‘s self-reversing atta<strong>ch</strong>ments keep a constant tapping speed<br />

for optimum tap life.<br />

This means<br />

n Ideal <strong>ch</strong>ip flow = perfect thread surface<br />

n Constant high RPM up to 5000<br />

n Shorter ma<strong>ch</strong>ining time, due to saving two spindle reversals per<br />

tapped hole.<br />

n Therefore reduced wear to expensive CNC ma<strong>ch</strong>ines<br />

n In most cases a 50% to 100% increased tap life<br />

Self-feed<br />

Permits the tap to act as its own lead screw. The self-feed accommodates<br />

any differences between thread pit<strong>ch</strong> and ma<strong>ch</strong>ine feed<br />

control. The tap is propelled by rotation only and cuts a thread without<br />

pressure; this guarantees a thread of high quality, whi<strong>ch</strong> is as accurate<br />

as the tap itself.<br />

Patented ball drive<br />

TAPMATIC‘s spring biased rolling ball design transmits rotational<br />

power to the tap. The ball disengages smoothly and silently after<br />

rea<strong>ch</strong>ing the thread depth swit<strong>ch</strong>ing to the reverse mode.<br />

Collets<br />

TAPMATIC tapping atta<strong>ch</strong>ments use multi-range Rubber-Flex collets<br />

or steel collet ER type, preferably ER-GB. Usually no more than two<br />

Rubber-Flex collets are required to cover a unit‘s capacity range.<br />

Modular systems<br />

The straight shank design with Weldon type flats to DIN1835B+E<br />

permits easy adaption to standard tool holders.<br />

TAPMATIC Kriessern, Switzerland<br />

Thread depth accuracy<br />

TAPMATIC tapping atta<strong>ch</strong>ments disengage after rea<strong>ch</strong>ing their<br />

pre-selected thread depth, irrespective of any ma<strong>ch</strong>ine spindle lag. The<br />

depth is equal to the feed set on the ma<strong>ch</strong>ine plus the self-feed in the<br />

unit.<br />

Adjustable slipping clut<strong>ch</strong><br />

The manual type TAPMATIC heads are fitted with a safety clut<strong>ch</strong>,<br />

whi<strong>ch</strong> guards against tap breakage. This clut<strong>ch</strong> design is intended as a<br />

safety device only and a ma<strong>ch</strong>ine stop should be set to allow the tap to<br />

release before bottoming whenever possible.<br />

TAPMATIC Post Falls, USA<br />

Internal coolant system<br />

Some TAPMATIC tapping atta<strong>ch</strong>ments are designed with internal<br />

coolant systems capable of a supply up to 80 bar. Ideal lubrication<br />

is a<strong>ch</strong>ieved by supplying coolant within or alongside the tool shank,<br />

thereby thread quality is improved. Furthermore this can be cost-effective<br />

as tap life is increased by washing away swarf from the core hole.<br />

Hard start<br />

Because of its unique design, the hard start guarantees the tap will cut<br />

at the same point ea<strong>ch</strong> time without compression, even at high RPMs.<br />

Front release<br />

This protects the tap <strong>ch</strong>uck, tap adapter, tap and work piece from<br />

damage.This can occur when the length compensation is exceeded<br />

(tension) e.g. because the ma<strong>ch</strong>ine spindle lags in the <strong>ch</strong>ange from<br />

forward to reverse or a rapid spindle movement backwards before the<br />

tap is completely out of the component. In these situations the quick<br />

<strong>ch</strong>ange tap adapter disengages from the tap holder automatically and<br />

avoids expensive damage.<br />

<br />

TAPMATIC

Product line index<br />

Description Model Page<br />

Self-reversing tapping atta<strong>ch</strong>ments<br />

Automatic reverse with increased reverse ratio.<br />

For manually operated drilling and milling<br />

ma<strong>ch</strong>ines.<br />

X<br />

TC / DC<br />

RX<br />

6<br />

7<br />

7<br />

Heavy duty self-reversing tapping atta<strong>ch</strong>ment<br />

for ma<strong>ch</strong>ines with automatic feed<br />

1:1 Reverse Ratio<br />

SPD / SPD-QC<br />

8<br />

CNC tapping atta<strong>ch</strong>ments with<br />

straight shanks<br />

For vertical and horizontal CNC ma<strong>ch</strong>ining centres,<br />

for continuous production. Extended spindles and<br />

inter<strong>ch</strong>angeable shanks available.<br />

RDT<br />

RDT-IC<br />

RDTXT<br />

RDTICXT<br />

9<br />

10<br />

11<br />

11<br />

Syn<strong>ch</strong>roFlex with straight shanks to DIN 1853B+E,<br />

HSK, ISO, BT<br />

For rigid tapping on CNC ma<strong>ch</strong>ines with/without<br />

internal coolant, ER-GB or QC-collets.<br />

SFT<br />

SX<br />

13<br />

14<br />

15<br />

16<br />

Tap <strong>ch</strong>ucks with straight shanks DIN 1835B+E or<br />

morse taper<br />

For use on NC ma<strong>ch</strong>ining centres or NC centre<br />

lathes and all ma<strong>ch</strong>ines with controlled feed.<br />

SM 17<br />

Tap <strong>ch</strong>ucks with quick-<strong>ch</strong>ange adapters to<br />

DIN 1835B+E<br />

With tension/compression, for rigid tapping,<br />

without internal coolant, front release, for use on<br />

all ma<strong>ch</strong>ines with controlled feed.<br />

TA 18<br />

19<br />

Tap <strong>ch</strong>ucks with quick-<strong>ch</strong>ange adapters,<br />

with internal coolant to DIN 69893A, DIN 1835B+E<br />

With tension/compression, for rigid tapping, with<br />

internal coolant, with quick-<strong>ch</strong>ange tap adapters<br />

steel or rubber.<br />

TIC 20<br />

21<br />

Various accessories<br />

suitable for tapping atta<strong>ch</strong>ments tapping <strong>ch</strong>ucks<br />

and ma<strong>ch</strong>ine spindles.<br />

Quick-<strong>ch</strong>ange<br />

tap adapters<br />

Collets<br />

Clamping nuts/<br />

sealing gaskets<br />

Arbors<br />

24–27<br />

28–29<br />

29<br />

30<br />

Cutting fluids<br />

FERROFLUID for steel and stainless steel,<br />

ALUFLUID for aluminium. MINIFLUID for difficult<br />

materials, application by drop.<br />

FERROFLUID<br />

ALUFLUID<br />

MINIFLUID<br />

31<br />

TAPMATIC

Tapping atta<strong>ch</strong>ments –<br />

selector <strong>ch</strong>art<br />

Series X TC/DC RX SPD RDT RDT-IC ASR / RSR<br />

Capacity in steel M0,5 – M30 M1,4 – M18 M1,4 – M18 M1,4 – M42 M1 – M25 M2,5 – M25 M2 – M16<br />

max. RPM 2000 2000 2000 2000 6000 3500 3000<br />

For use on<br />

Manual ma<strong>ch</strong>ines • • •<br />

CNC ma<strong>ch</strong>ines<br />

•<br />

CNC ma<strong>ch</strong>ining centres • • •<br />

CNC lathes<br />

•<br />

Features<br />

Automatic reverse • • • • • • •<br />

Constant tapping speed • • • • • • •<br />

Adjustable slipping cluts<strong>ch</strong> • • •<br />

Release to neutral • • • • • • •<br />

For right and left hand tapping<br />

Integral stop arm • • •<br />

Internal coolant system (max. 50 bar)<br />

•<br />

Extended length<br />

•<br />

Collets and adapters<br />

Multi-range collets RF • • • •<br />

Steel collets ER / ER-GB • • •<br />

Quick <strong>ch</strong>ange tap adapters:<br />

•<br />

T positive drive •<br />

TC adjustable torque control •<br />

D die holders •<br />

E / TF collet holders<br />

•<br />

Atta<strong>ch</strong>ment mounts<br />

Internal taper • • • •<br />

Internal thread • • • •<br />

Straight shank DIN 1835B+E • •<br />

Shank HSK<br />

•<br />

Shank VDI 3425 (DIN 69880)<br />

•<br />

Modification Possible<br />

Tap <strong>ch</strong>ucks –<br />

selector <strong>ch</strong>art<br />

Series SFT SX SM TA TIC TIM NC<br />

Capacity in steel M2 – M30 M2 – M20 M1,4 – M30 M1 – M48 M3 – M24 M7 – M24 M1,4 – M22<br />

For use on<br />

Manual ma<strong>ch</strong>ines • • •<br />

CNC ma<strong>ch</strong>ines • • • • •<br />

CNC ma<strong>ch</strong>ining centres • • • • • • •<br />

CNC lathes • • • • • • •<br />

Features<br />

Self-feed (tension/compression) • • • • • • •<br />

Front release • • • •<br />

Hard start • • • •<br />

Release to neutral<br />

•<br />

For right and left hand tapping • • • • • •<br />

Internal coolant system • • • •<br />

–10 bar minimum quantity lubrication •<br />

–50 bar • • •<br />

–80 bar • •<br />

Collets and adapters<br />

Multi-range collets RF<br />

•<br />

Steel collets ER / ER-GB • •<br />

Quick <strong>ch</strong>ange tap adapters: • • • • •<br />

T positive drive • • • • •<br />

TC adjustable torque control • • • •<br />

T-IK positive drive, internal coolant (for taps without internal coolant) • •<br />

TC-IK torque control, internal coolant (for taps without internal coolant) • •<br />

D die holders • • •<br />

E / TF collet holders • • • •<br />

ER collet adapter USA •<br />

Shrink Fit Adapters • • •<br />

Tap <strong>ch</strong>uck mounts<br />

Straight shank DIN 1835B+E • • • • • • •<br />

Morse taper arbor DIN 228B • •<br />

Shank HSK DIN 69893A • • • • •<br />

Shank DIN 69871A, A / D, B • • •<br />

Shank MAS-BT (JIS B6339) • •<br />

Shank DIN 2080 • •<br />

Shank VDI 3425 (DIN 69880) • • •<br />

Shank ABS (system KOMET) • • •<br />

<br />

TAPMATIC

Advantages of tapping atta<strong>ch</strong>ments with automatic reversal<br />

X | RDT | RDT-IC tapping atta<strong>ch</strong>ment<br />

General Information<br />

Thread cutting is the only ma<strong>ch</strong>ining operation whi<strong>ch</strong> requires a<br />

<strong>ch</strong>ange of direction for the return of the tool. This can be laborious, it<br />

also causes wear and is a costly procedure for any ma<strong>ch</strong>ine.<br />

RDT / RDT-IC tapping atta<strong>ch</strong>ment<br />

RDT and RDT-IC reversing tapping atta<strong>ch</strong>ments are specially designed<br />

for fastest thread manufacturing on CNC ma<strong>ch</strong>ining centres. They also<br />

eliminate reversal related ma<strong>ch</strong>ine wear and tear and reduce energy<br />

consumption. The patented ball drive with integrated planet gear<br />

for automatic reversal creates an almost constant cutting speed and<br />

eliminates the need to start the ma<strong>ch</strong>ine spindle twice per thread.<br />

By using the RDT tapping atta<strong>ch</strong>ments the cycle time is reduced and<br />

the life of the tap is increased. The IC-version allows coolant to flow<br />

directly through the tapping head.<br />

Case history:<br />

Constant speed tapping –<br />

the secret of longer tap life<br />

RPM<br />

Tapping with an atta<strong>ch</strong>ement<br />

Reversal<br />

Feed in<br />

Feed out<br />

Time<br />

Tapping with a ma<strong>ch</strong>ine spindle reversal<br />

Reversal<br />

Feed in<br />

Feed out<br />

Application<br />

Thread cutting on a horizontal ma<strong>ch</strong>ining centre Fritz Werner<br />

TC800 with internal cooling.<br />

RPM<br />

Material<br />

GG20<br />

Time<br />

Tap<br />

M6 standard thread HSS with TIN-AL coating<br />

Power consumption for 144 threads M8<br />

Thread<br />

M6 standard thread, 9 mm deep, tapping drill ø 5.05 and 12.5 mm deep<br />

Speed<br />

Rigid tapping with spindle reversal, programmed speed 1‘200 RPM<br />

(ø RPM rea<strong>ch</strong>ed: 513)<br />

Results<br />

Cycle time of 6 min 34 sec for 68 threads<br />

Change with TAPMATIC<br />

Using a TAPMATIC tapping atta<strong>ch</strong>ment RDT-IC50 with ER16<br />

spindle, programmed speed 1‘800 RPM.<br />

KW<br />

Ma<strong>ch</strong>ine reversal<br />

1500 UpM<br />

TAPMATIC<br />

1500 UpM<br />

TAPMATIC<br />

2500 UpM<br />

Minutes<br />

Evaluation of economic efficiency<br />

Energy cost saving of 75%<br />

Not only is the shorter cycle time of<br />

importance, but also the constant<br />

spindle direction. By <strong>ch</strong>anging the<br />

direction (decelerating and<br />

accelerating) of the spindle, higher<br />

spikes of power are needed, whi<strong>ch</strong><br />

can be prevented by constant<br />

spindle rotation.<br />

Improvement<br />

Cycle time reduced to 3 min 22 sec for 68 threads, tap life tripled.<br />

Advantage<br />

Besides reducing the cycle time, tap life was considerably increased<br />

Costs<br />

Tapping<br />

atta<strong>ch</strong>ment<br />

RDT-IC<br />

Number of threads/part 68 68<br />

Number of parts 400 400<br />

Cycle time per part/min 3.36 6.56<br />

Cycle time in hours 22.4 43.7<br />

Ma<strong>ch</strong>ine hourly rate in 70 70<br />

Number of taps 22 65<br />

Tap costs in 275 813<br />

Production costs in 1‘568 3‘061<br />

Chuck costs in (approx.) 1‘500 450<br />

Total costs in 3‘343 4‘324<br />

Cost reduction in 981<br />

Collets <strong>ch</strong>uck<br />

with<br />

compensation<br />

Total cost / year<br />

Break Even Point<br />

Saving<br />

Tap<br />

Tap<br />

collet <strong>ch</strong>uck<br />

RDT-IC<br />

RDT-IC<br />

Collest<br />

<strong>ch</strong>uck<br />

Results<br />

n Reduction of cycle time by 50%<br />

n Increase of production capacity<br />

n Tap life tripled<br />

n Less ma<strong>ch</strong>ine wear (no spindle reversals)<br />

n Roughly 75% energy savings by constant speed tapping<br />

Conclusion<br />

With the use of tapping atta<strong>ch</strong>ments, the cycle time is less, whi<strong>ch</strong><br />

also increases productivity. Additionally, ma<strong>ch</strong>ine repair / downtime<br />

is reduced, also tap and energy costs.<br />

TAPMATIC

Self-reversing tapping atta<strong>ch</strong>ments with high-speed return and<br />

adjustable slipping clut<strong>ch</strong><br />

The compact build and simple handling, together with multiplicity of inter<strong>ch</strong>angeable arbors<br />

used with these units, makes them first <strong>ch</strong>oice in 75% of all thread cutting operations. The spring<br />

bias drive permits smooth tapping speeds up to 2000 RPM.<br />

Features<br />

n Adjustable slipping clut<strong>ch</strong> (discs)<br />

n Automatic reversal<br />

n Self-feed (tension-compression)<br />

n Re-entry cushion<br />

n Right hand tapping (Left hand on request)<br />

n Multi-range collets (RF)<br />

n High-speed return 1.75 : 1<br />

n Inter<strong>ch</strong>angeable arbors<br />

Application<br />

For all manually operated drilling and milling ma<strong>ch</strong>ines.<br />

Delivery<br />

Standard accessories include 2 wren<strong>ch</strong>es, all necessary hex keys and one stop arm. Please order<br />

the necessary 2 multi-range collets and arbor separately.<br />

X<br />

L<br />

D<br />

Model Order code Capacity Max. RPM Mounts S L mm Collets RF<br />

in steel<br />

Taper mounts Thread. mounts<br />

100XB 16101 M0,5–M2 2000 JT1 94 117XB7<br />

30X 10306 M1,4–M7 2000 JT6 113 J116<br />

10312 B12<br />

J117<br />

10316 B16<br />

10333 JT33<br />

10331 5/16"–24 104<br />

10337 3/8"–24<br />

10350 1/2"–20 113<br />

10362 5/8"–16<br />

10375 3/4"–16<br />

50X 10506 M3–M12 1500 JT6 153 J421<br />

10516 B16<br />

J422<br />

10533 JT33<br />

10537 3/8"–24 148<br />

10550 1/2"–20<br />

10562 5/8"–16<br />

10575 3/4"–16<br />

70X 10703 M5–M18 1200 JT3 176 J443<br />

10718 B18<br />

J440<br />

10750 1/2"–20<br />

10762 5/8"–16<br />

10775 3/4"–16<br />

10787 7/8"–20<br />

90X 10904 M10–M30 600 JT4 219 J461<br />

10915 1.1/2"–18<br />

J462<br />

Note: When using Roll Form Taps the tool’s tapping capacity must be reduced by 25%.<br />

Rubber Flex collets page 29. Inter<strong>ch</strong>angeable shanks page 30.<br />

Dimensions<br />

Model D mm d mm Self-feed mm T Weight kg<br />

100XB 33 9 5 0.200<br />

30X 48 19 3.5 0.500<br />

50X 70 27 6 1.400<br />

70X 76 36 9 2.100<br />

90X 105 57 13 5.000<br />

Order information:<br />

Order code 10516 (50X-B16) + J421, J422 (standard collets) + MK2-B16 (arbor)<br />

Collets RF<br />

on page 29<br />

Arbors<br />

on page 30<br />

Info on pages 33, 35<br />

<br />

TAPMATIC

TC/DC | RX<br />

Self-reversing tapping atta<strong>ch</strong>ments with high-speed return,<br />

adjustable slipping clut<strong>ch</strong> and depth control<br />

The TC/DC models are identical to the X models, however they have the additional feature of<br />

depth control, thus the self-feed can be reduced.<br />

Application<br />

For all manually operated drilling and milling ma<strong>ch</strong>ines where tapping short blind holes is<br />

required.<br />

Delivery<br />

Standard accessories include 2 wren<strong>ch</strong>es, all necessary hex keys and one stop arm. Please order<br />

the necessary 2 multi-range collets and arbor separately.<br />

Model Order code Capacity Max. RPM Mounts S L mm Collets RF<br />

in steel<br />

Taper mounts Thread. mounts<br />

30TC/DC 14306 M1,4–M7 2000 JT6 122 J116<br />

14312 B12<br />

J116<br />

14316 B16<br />

14333 JT33<br />

14331 5/16"–24 113<br />

14337 3/8"–24<br />

14350 1/2"–20 122<br />

14362 5/8"–16<br />

50TC/DC 14506 M3–M12 1500 JT6 169 J421<br />

14516 B16<br />

J422<br />

14533 JT33<br />

14537 3/8"–24<br />

14550 1/2"–20<br />

14562 5/8"–16<br />

70TC/DC 14703 M5–M18 1200 JT3 191 J443<br />

14718 B18<br />

J440<br />

14750 1/2"–20<br />

14762 5/8"–16<br />

14787 7/8"–20<br />

Universal self-reversing tapping atta<strong>ch</strong>ments with<br />

high-speed return<br />

A robust head for volume production and performance, suitable for roll tapping. A higher degree<br />

of torque is transferred through the heavy-duty ball clut<strong>ch</strong> (slipping) to the tap, making it a very<br />

durable unit.<br />

Application<br />

For all manually operated drilling and milling ma<strong>ch</strong>ines.<br />

Delivery<br />

Standard accessories include 2 wren<strong>ch</strong>es, all necessary hex keys and one stop arm. Please order<br />

the necessary 2 multi-range collets and arbor separately.<br />

L<br />

D<br />

Model Order code Capacity Max. RPM Mounts S Collets RF<br />

in steel<br />

Taper mounts Thread. mounts<br />

RX 30 013006 M1,4–M7 2000 JT6 J116<br />

013016 B16<br />

J117<br />

013033 JT33<br />

30337 3/8"–24<br />

30350 1/2"–20<br />

RX 50 015006 M3–M12 1500 JT6 J421<br />

015016 B16<br />

J422<br />

015033 JT33<br />

015050 1/2"–20<br />

RX 70 017006 M5–M18 750 JT3 J443<br />

017087 7/8"–20 J440<br />

Note: When using Roll Form Taps the tool’s tapping capacity must be reduced by 25%.<br />

Rubber Flex collets page 29. Inter<strong>ch</strong>angeable shanks page 30.<br />

Dimensions<br />

d<br />

Model D mm d mm Self-feed mm T Weight kg<br />

RX30 53 19 6 0,700<br />

RX50 76 27 10 1,800<br />

RX70 88 36 10 3,000<br />

Collets RF<br />

Arbors<br />

on page 29 on page 30<br />

Info on pages 33, 35<br />

TAPMATIC

Self-reversing tapping atta<strong>ch</strong>ments for ma<strong>ch</strong>ines with<br />

automatic feed<br />

A short durable tapping atta<strong>ch</strong>ment with a 1:1 reverse ratio, suitable particularly for difficult<br />

applications su<strong>ch</strong> as combination drill taps and roll form tapping.<br />

Features<br />

n Direct drive 1:1 ratio<br />

n Automatic reversal<br />

n Self-feed (tension-compression)<br />

n Re-entry cushion (Hard start available on request)<br />

n Multi-range collets (RF) or quick-<strong>ch</strong>ange collets (steel)<br />

n Inter<strong>ch</strong>angeable arbors<br />

Application<br />

For turret drill ma<strong>ch</strong>ines, pneumatic/hydraulic operated<br />

and electro-drill units.<br />

SPD | SPD-QC<br />

Delivery<br />

Standard accessories include 2 wren<strong>ch</strong>es, all necessary hex keys and one stop arm.<br />

Please order the necessary 2 multi-range collets and arbor separately.<br />

Model Order code Max. RPM Capacity Mounts S L mm Collets<br />

in steel<br />

Taper mounts Thread. mounts<br />

SPD-3 18316 2000 M1,4–M7 B16 118 J116<br />

18333 JT33<br />

J117<br />

18337 3/8"–24 105<br />

18350 1/2"–20 113<br />

18362 5/8"–16 <br />

18375 3/4"–16 118<br />

SPD-5 18516 1500 M3–M12 B16 148 J421<br />

18533 JT33<br />

J422<br />

10537 3/8"–24 138<br />

10550 1/2"–20<br />

18562 5/8"–16<br />

18575 3/4"–16<br />

18587 7/8"–20 148<br />

SPD-7 18703 1200 M5–M18 JT3 175 J443<br />

18750 1/2"–20 162<br />

J440<br />

18762 5/8"–16<br />

18787 7/8"–20 175<br />

SPD-9A 17904 600 M10–M30 JT4 228 J461<br />

17915 1.1/2"–18 200<br />

J462<br />

Quick-<strong>ch</strong>ange version<br />

Model Order code Max. RPM Capacity Mounts S L mm Tap adapters<br />

in steel<br />

Taper mounts Thread. mounts<br />

SPD-3 QC 18216 2000 M1,4–M7 B16 109 0<br />

18233 JT33<br />

T0<br />

18237 3/8"–24 96<br />

TC0<br />

18250 1/2"–20 104<br />

18262 5/8"–16<br />

18275 3/4"–16 109<br />

SPD-5 QC 18416 1500 M3–M12 B16 130 1<br />

18433 JT33<br />

T1<br />

18450 1/2"–20 122<br />

TC1<br />

18462 5/8"–16<br />

18489 7/8"–20 130<br />

SPD-7 QC 18603 1200 M5–M18 JT3 159 2<br />

18650 1/2"–20 147<br />

T2<br />

18662 5/8"–16<br />

TC2<br />

18687 7/8"–20 159<br />

SPD-7 QC 17804 600 M10–M30 JT4 217 3, T3<br />

17815 1.1/2"–18 189<br />

TC3<br />

SPD-11 QC 18100 400 M22–M42 2.1/4"–10 236 T4, TC4<br />

Note: When using Roll Form Taps the tool’s tapping capacity must be reduced by 25%.<br />

Rubber Flex collets page 29. Inter<strong>ch</strong>angeable shanks page 30.<br />

Dimensions<br />

Model D mm d mm Self-feed mm Weight kg<br />

SPD-3 53 19 3 0,5<br />

SPD-5 69 27 5 1,4<br />

SPD-7 76 36 7 2,1<br />

SPD-9A 103 57 10 5,0<br />

SPD-3 QC 53 28 3 0,5<br />

SPD-5 QC 69 36 5 1,4<br />

SPD-7 QC 76 54 7 2,1<br />

SPD-9A QC 103 76 10 5,0<br />

SPD-11 QC 146 90 13 14,0<br />

Collets RF<br />

Shanks<br />

Arbors<br />

Tap adapters<br />

on page 29 on page 30<br />

on page 30<br />

on pages 24–27<br />

Info on pges 33, 35<br />

<br />

TAPMATIC

High speed tapping atta<strong>ch</strong>ments with automatic reversal for<br />

CNC ma<strong>ch</strong>ines with straight shank<br />

These tapping atta<strong>ch</strong>ments are of extremely compact build. The stop arm prevents any rotation<br />

in the tool magazine and serves as a torque bar when the head is loaded in the ma<strong>ch</strong>ine spindle.<br />

According to the motto “FAST AND SIMPLE TO INSTALL”, TAPMATIC is maintaining a list with<br />

stop arms, whi<strong>ch</strong> have already been manufactured. By informing us about the ma<strong>ch</strong>ine type and<br />

serial number (please complete the customer inquiry form on page 34), we will be able to supply<br />

you with a quotation and principle drawing at short notice.<br />

Features<br />

n Low-friction cushioned drive, up to 5000 RPM<br />

n Automatic reversal<br />

n Self-feed (tension)<br />

n Steel collets ER-GB<br />

n Straight shanks DIN 1635B+E<br />

n Inter<strong>ch</strong>angeable stop arm assembly for different centre distances<br />

n Accurate thread depths<br />

n Reduced CNC ma<strong>ch</strong>ine spindle wear<br />

n Shorter cycle time<br />

n Increased tap life<br />

n Reduction in energy consumption<br />

Application<br />

For CNC ma<strong>ch</strong>ining centres with automatic tool<strong>ch</strong>anger (bore cycle G85).<br />

Delivery<br />

Standard accessories include 2 wren<strong>ch</strong>es and all necessary hex keys. Please order stop arm,<br />

ER-GB collets and arbor separately.<br />

Model Order code Capacity<br />

Straight shank S Collets<br />

Max. RPM<br />

in steel<br />

Ø mm<br />

RDT15 3915258 M1 – M3 25 ER8 5000<br />

RDT25 39252511 M2,5 – M6 25 ER11 3500<br />

RDT50 39502516 M4,5 – M12 25 ER16 2300<br />

RDT85 HS 39852525 M11 – M20 25 ER25 1500<br />

RDT85 39852532 M12 – M25 25 ER32 1200<br />

RDT100 391002540 M14 – M25 25 ER40 1000<br />

n on request<br />

Note: When using Roll Form Taps the tool’s tapping capacity must be reduced by 25%.<br />

Steel collets page 29. Inter<strong>ch</strong>angeable shanks page 30.<br />

Dimensions<br />

Model D mm d mm L2 mm L3 mm L4 mm Weight kg<br />

RDT15 57 12 97 55/65/80 42 1,400<br />

RDT25 57 19 106 55/65/80 42 1,400<br />

RDT50 80 27 126 55/65/80 42 2,900<br />

RDT75 80 42 133 55/65/80 42 3,000<br />

RDT85 HS 80 42 150 65/80 42 3,400<br />

RDT85 80 50 157 65/80 42 3,500<br />

RDT100 80 63 167 65/80 42 4,300<br />

RDT<br />

Stop arm assemblies for models RDT and RDT/IC<br />

CNC tapping atta<strong>ch</strong>ment RDT and RDT/IC are supplied as standard without stop arms.<br />

Depending upon the centre distance (see L3 above, centre of the ma<strong>ch</strong>ine spindle to the centre<br />

of the stop pin) stop arm assemblies are available with a 55mm, 60mm or 80mm centre distance.<br />

They are atta<strong>ch</strong>ed to the tapping atta<strong>ch</strong>ment via 4 fixing bolts. Other distances are obtainable by<br />

using spacers.<br />

Suitable head<br />

Model<br />

RDT15<br />

RDT25<br />

RDTIC25<br />

RDT50<br />

RDTXT50<br />

RDTIC50<br />

RDTICXT50<br />

RDT85,<br />

RDT85 HS<br />

RDT100<br />

RDTIC85<br />

RDTIC85 HS<br />

RDTIC100<br />

Order code Centre distance Dimensions<br />

L4 + R mm R mm S mm L4 + S mm<br />

392555 55 13 29 71<br />

392565 65 23 39 81<br />

392580 80 38 54 96<br />

395055 55 13 29 71<br />

395065 65 23 39 81<br />

395080 80 38 54 96<br />

398565 65 23 39 81<br />

398580 80 38 54 96<br />

Note: An alternative universal stop arm assembly is available on page 32.<br />

Steel collets<br />

on page 28<br />

TAPMATIC<br />

Inter<strong>ch</strong>angeable<br />

NC shanks<br />

on page 30 Info on pages 32, 33, 35

High speed tapping atta<strong>ch</strong>ments with automatic reversal<br />

for CNC ma<strong>ch</strong>ines with straight shank and<br />

internal coolant system<br />

The RDT/IC models were developed for CNC ma<strong>ch</strong>ines with automatic tool <strong>ch</strong>ange and internal<br />

coolant systems. The coolant is fed through the ma<strong>ch</strong>ine spindle into the tapping atta<strong>ch</strong>ments<br />

internal system and out through the IC tap.<br />

According to the motto “FAST AND SIMPLE TO INSTALL”, TAPMATIC is maintaining a list with<br />

stop arms, whi<strong>ch</strong> have already been manufactured. By informing us about the ma<strong>ch</strong>ine type and<br />

serial number (please complete the customer inquiry form on page 34), we will be able to supply<br />

you with a quotation and principle drawing at short notice.<br />

Features<br />

n Low-friction cushioned drive, up to 3500 RPM<br />

n Automatic reversal<br />

n Self-feed (tension)<br />

n Steel collets ER-GB<br />

n Straight shanks DIN 1635B+E<br />

n Inter<strong>ch</strong>angeable stop arm assembly for different centre distances<br />

n Accurate thread depths<br />

n Internal coolant through spindle 50 bar maximum<br />

n Reduced CNC ma<strong>ch</strong>ine spindle wear<br />

n Shorter cycle time<br />

n Increased tap life<br />

n Reduction in energy consumption<br />

Application<br />

For CNC ma<strong>ch</strong>ining centres with automatic tool<strong>ch</strong>anger (bore cycle G85).<br />

Delivery<br />

Standard accessories include 2 wren<strong>ch</strong>es and all necessary hex keys. Please order stop arm,<br />

ER-GB collets and arbor separately.<br />

Model Order code Capacity<br />

in steel<br />

Straight<br />

shank S<br />

Ø mm<br />

n on request<br />

Note: When using Roll Form Taps the tool’s tapping capacity must be reduced by 25%.<br />

RDTIC<br />

Collets Max. RPM Weight kg<br />

RDTIC25 40252511 M2,5–M6 25 ER11 3500 1,200<br />

RDTIC50HS 405025LW16M M4,5–M12 25 ER16 2300 2,500<br />

RDTIC50 40502520 M4,5–M12 25 ER20 2000 2,500<br />

RDTIC85HS 40852525 M11–M20 25 ER25 1500 3,800<br />

RDTIC85 40852532 M12–M25 25 ER32 1200 3,500<br />

RDTIC100 401002540 M14–M25 25 ER40 1000 4,300<br />

High speed tapping atta<strong>ch</strong>ments with integral HSK shank and<br />

integral coolant system<br />

Model Order code Capacity HSK shank Collets Max. RPM Weight kg<br />

in steel<br />

RDTIC50HS 4050H63LW16M M4,5–M12 63A ER16 2300 3,200<br />

4050H80LW16M 80A 4,000<br />

4050H100LW16M 100A 5,000<br />

RDTIC85HS 4085H6325 M11–M20 63A ER25 1500 4,600<br />

4085H8025 80A 5,000<br />

4085H10025 100A 6,100<br />

RDTIC85 4085H6332 M12–M22 63A ER32 1200 4,600<br />

4085H8032 80A 5,000<br />

4085H10032 100A 6,100<br />

RDTIC50 available with ER20 and ER25 spindles on request<br />

Note: The RDTIC models are supplied with standard nuts. When using taps with internal coolant we recommend IC nuts<br />

and gaskets. In this case S must be added to the article number. When using Roll Form Taps the tool’s tapping capacity<br />

must be reduced by 25%.<br />

Dimensions<br />

Model D mm d mm HSK63A HSK80A HSK100A L2 mm L3 mm L4 mm<br />

25 mm<br />

L1 L1 L1<br />

RDTIC25 57 19 – – – 125 55/65/80 42<br />

RDTIC50HS 80 22 50 55 56 137 55/65/80 42<br />

RDTIC50 80 34 50 55 56 133 55/65/80 42<br />

RDTIC85HS 80 42 50 55 56 150 65/80 42<br />

RDTIC85 80 50 50 55 56 157 65/80 42<br />

RDTIC100 80 63 – – – 167 65/80 42<br />

Inter<strong>ch</strong>angeable<br />

NC shanks<br />

on page 30<br />

Stop arm assembly<br />

on page 9<br />

Steel collets<br />

on page 29<br />

Sealing gaskets<br />

on page 29<br />

Info on pages 32, 33, 35<br />

10 TAPMATIC

RDTXT/IC<br />

Tapping atta<strong>ch</strong>ments with automatic reversal, extended length,<br />

with straight shank<br />

The RDTXT and RDTICXT models with their extended spindles were developed to allow you to<br />

tap those difficult to rea<strong>ch</strong> holes, on CNC ma<strong>ch</strong>ines with automatic tool <strong>ch</strong>ange.<br />

According to the motto “FAST AND SIMPLE TO INSTALL”, TAPMATIC is maintaining a list with<br />

stop arms, whi<strong>ch</strong> have already been manufactured. By informing us about the ma<strong>ch</strong>ine type and<br />

serial number (please complete the customer inquiry form on page 34), we will be able to supply<br />

you with a quotation and principle drawing at short notice.<br />

Features<br />

n Low-friction cushioned drive up to 2000 RPM<br />

n Automatic reversal<br />

n Self-feed (tension)<br />

n Steel collets ER-GB<br />

n Straight shanks DIN1835B+E<br />

n Inter<strong>ch</strong>angeable stop arms assembly for different centre distances<br />

n Internal coolant through the spindle 50 bar maximum<br />

n Accurate thread depths<br />

n Reduced CNC ma<strong>ch</strong>ine spindle wear<br />

n Shorter cycle times<br />

n Increased tap life<br />

n Reduction in energy consumption<br />

Application<br />

For CNC ma<strong>ch</strong>ining centres with automatic tool<strong>ch</strong>anger (bore cycle G85)<br />

Delivery<br />

Standard accessories include 2 wren<strong>ch</strong>es and all necessary hex keys. Please order stop arm,<br />

ER-GB collets and arbor separately.<br />

Standard version<br />

Model Order code Capacity<br />

Straght shank S Steel collets Max. RPM*<br />

in steel<br />

Ø mm<br />

adapters<br />

RDTXT50 395025191 M4,5–M12 25 ER16/ER20 2000<br />

395025255 1800<br />

* Maximum speed with ER20 insert is 1500 RPM.<br />

Version with internal coolant system<br />

Model Order code Capacity<br />

Straght shank S Steel collets Max. RPM *<br />

in steel<br />

Ø mm<br />

adapters<br />

RDTICXT50 405025191 M4,5–M12 25 ER16/ER20 2000<br />

405025255 1800<br />

* Maximum speed with ER20 insert is 1500 RPM<br />

Dimensions<br />

Model D mm d mm L2 mm L3 mm L4 mm Weight kg<br />

RDTXT50 80 35 191 55/65/80 42 2,800<br />

255 2,800<br />

RDTICXT50 80 35 191 55/65/80 42 2,800<br />

255 2,800<br />

Note: When using internal coolant system we recommend the use of the IC nuts with gaskets, in this case S must be<br />

added to the article number. When using Roll Form Taps the heads tapping capacity must be reduced by 25%.<br />

ER collets page 29. Inter<strong>ch</strong>angeable arbors page 30.<br />

HSK shanks on request.<br />

Inter<strong>ch</strong>angeable<br />

NC shanks<br />

on page 30<br />

Stop arm assembly<br />

on page 9<br />

Steel collets<br />

on page 29<br />

Sealing gaskets<br />

on page 29<br />

Info on pages 32, 33, 35<br />

TAPMATIC 11

SFT Syn<strong>ch</strong>roFlex-tap <strong>ch</strong>ucks<br />

Highest thread quality with Syn<strong>ch</strong>roFlex-tap <strong>ch</strong>ucks<br />

General information<br />

On today‘s CNC ma<strong>ch</strong>ining centres, spindle rotation can be syn<strong>ch</strong>ronized<br />

with the spindle feed (Rigid Tapping). However, experience shows<br />

that small errors in syn<strong>ch</strong>ronization can occur. These differences are<br />

minimal, but lead to increased tool wear.<br />

Independent test by tap manufacturer<br />

Thrust test 10 holes, M6 R45-AL, 2 Flute tap (3XD), AL7075 at 1000 RPM.<br />

Graph illustrates the final hole tapped by ea<strong>ch</strong> tap driver.<br />

SFT Syn<strong>ch</strong>roFlex-tap <strong>ch</strong>ucks<br />

By using the Syn<strong>ch</strong>roFlex tap<br />

holder with axial and radial movement,<br />

any difference in feed and<br />

spindle speed are compensated.<br />

The patented micro compensator<br />

(Flexure) cushions the differences,<br />

reducing pressure on the tap.<br />

A max. 0.5 mm deflection is<br />

constant throughout the life of the<br />

tapping unit, therefore enhancing<br />

tap life and quality of the thread.<br />

Thrust<br />

(N)<br />

210<br />

180<br />

150<br />

120<br />

90<br />

60<br />

30<br />

SFT100<br />

SFT10<br />

SFT75<br />

SFT50<br />

Thrust (N)<br />

0,1 0,2 0,3 0,4 0,5<br />

Deflection (mm)<br />

Tapmatic SFT50<br />

Competitor 1<br />

Depth<br />

Competitor 2<br />

Rigid Tap Holder<br />

Evaluation of economic efficiency<br />

Case history:<br />

Application<br />

Thread cutting on a horizontal ma<strong>ch</strong>ining centre with<br />

Fanuc control, rigid tapping.<br />

Costs<br />

Syn<strong>ch</strong>roFlex<br />

<strong>ch</strong>uck<br />

Number of threads / year 50’000 50’000<br />

Number of threads / tap 2’400 1’000<br />

Number of taps / year 21 50<br />

Price / tap in 19 19<br />

Tap costs in 396 950<br />

Chuck costs in (approx.) 450 300<br />

Total costs in / year 846 1’250<br />

Cost reduction in / year 404<br />

Collet <strong>ch</strong>uck<br />

without<br />

compensation<br />

Material<br />

42CrMo4V steel, heat treated to 650 N/mm2<br />

Tap size<br />

M8 x 1, metric fine<br />

Thread<br />

M8 x 1, 10 mm deep, through hole<br />

Speed<br />

500 RPM, Coolant: oil emulsion 6%<br />

Results<br />

Tap held in collet <strong>ch</strong>uck: the tap needed to be replaced after<br />

1‘000 components completed<br />

Total cost /year<br />

Saving Tap<br />

Tap<br />

Syn<strong>ch</strong>roFlex<br />

Collet <strong>ch</strong>uck<br />

Break Even Point<br />

Collets <strong>ch</strong>uck<br />

Syn<strong>ch</strong>roFlex<br />

Improvement with TAPMATIC<br />

With the new TAPMATIC SFT50 <strong>ch</strong>uck, tap life has been increased to<br />

between 2‘400 and 2‘900 components tapped before the tap needed<br />

to be <strong>ch</strong>anged.<br />

Advantage<br />

Besides cost savings (increase of tap life by 150%), knowing that<br />

all holes have been tapped during an unmanned shift.<br />

Results<br />

Conclusion<br />

n Increase of tap life 100% or more<br />

n Investment in a Syn<strong>ch</strong>roflex tap holder can be recovered<br />

in a matter of a few weeks<br />

n Less downtime (increase of production capacity)<br />

n Better thread quality<br />

n Increased process reliability due to less tap breakage<br />

By using Syn<strong>ch</strong>roFlex <strong>ch</strong>ucks quality threads and economic<br />

manufacture are guaranteed.<br />

12 TAPMATIC

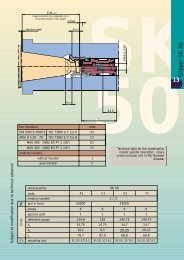

SFT<br />

Syn<strong>ch</strong>ro tapping <strong>ch</strong>ucks with micro-flex for CNC ma<strong>ch</strong>ines<br />

Syn<strong>ch</strong>ro <strong>ch</strong>ucks are being used extensively on CNC ma<strong>ch</strong>ines for rigid tapping. On today’s CNC<br />

ma<strong>ch</strong>ining centres, spindle rotation can be syn<strong>ch</strong>ronized with the spindle feed (Rigid Tapping).<br />

However, experience shows that small errors in syn<strong>ch</strong>ronization can occur. These differences are<br />

minimal, but lead to increased tool wear. Furthermore, there are differences between computed<br />

feed rate and actual. Any discrepancy at all increases tension/torque on the tap, reducing tap life<br />

and thread quality proportionally.<br />

The SYNCHROFLEX tap <strong>ch</strong>uck with its axial and radial MICRO-COMPENSATION eliminates these<br />

differences and supports a precise hole location.<br />

The results are<br />

n Increased tap life of 50% or more<br />

n Improved thread quality<br />

n Increased production due to less tap breakage<br />

n Fewer downtimes<br />

Syn<strong>ch</strong>roFlex tapping <strong>ch</strong>ucks with straight shank DIN 1835B+E<br />

Tapping <strong>ch</strong>uck with MICRO-COMPENSATION (max. ±0.5mm). To eliminate radial and axial feed<br />

discrepancy in the CNC ma<strong>ch</strong>ines programmed feed/speed (rigid tapping).<br />

Features<br />

n Computer generated Flexure for cushioning (radial and axial)<br />

n The Flexure eliminates pressure on the tap, thereby perfect threads and up to double tap life<br />

n Right hand and left hand tapping<br />

n Steel collets ER-GB and inter<strong>ch</strong>angeable shanks<br />

n Predictable tapping behaviour throughout the entire life of the tool<br />

n Outstanding results with standard taps<br />

Application<br />

On CNC ma<strong>ch</strong>ining centres, CNC lathes with rigid tapping.<br />

Delivery<br />

Standard nut and wren<strong>ch</strong> are included in the delivery.<br />

Model Order code Capacity<br />

in steel<br />

Straight shank<br />

Ø mm<br />

Collets<br />

ER<br />

Max. IC-pressure<br />

bar<br />

SFT10 43102511 M2–M5 25 ER11 30 (80)<br />

SFT50 43502520 M4–M12 25 ER20 30 (80)<br />

SFT75 43752525 M10–M20 25 ER25 30 (80)<br />

SFT100 431002540 M18–M30 25 ER40 30 (80)<br />

Dimensions<br />

Model A mm B mm Straight shank Ø mm<br />

SFT10 53 19 25<br />

SFT50 63 34 25<br />

SFT75 83 42 25<br />

SFT100 112 63 25<br />

Note: Straight shanks 16mm; 20mm; 1“ subject to model available on request. Extended units for SFT50/75/100 are also<br />

available. Please indicate measurement A (in line drawing) length required.<br />

When using internal coolant of more than 30 bars, we recommend the use of our balanced coolant system BCS. Add<br />

“S” to the article number and you will receive the S-model with IC-nut. For minimum quantity lubricant MMS add<br />

“M” to the article number. Sealing gaskets are ordered separately.<br />

When using Roll Form Taps the tapping <strong>ch</strong>uck’s capacity must be reduced by 25%.<br />

Syn<strong>ch</strong>roFlex tapping <strong>ch</strong>ucks with quick <strong>ch</strong>ange version<br />

The models SFT50 and SFT75 can be supplied with QC spindles. Add “QC” to the article number.<br />

Shrink-fit is also available on request.<br />

Inter<strong>ch</strong>angeable<br />

NC shanks<br />

on page 30<br />

Steel collets<br />

on page 29<br />

Sealing gaskets<br />

on page 29<br />

TAPMATIC 13

SFT<br />

Syn<strong>ch</strong>roFlex tapping <strong>ch</strong>ucks with HSK shank<br />

Tapping <strong>ch</strong>uck with MICRO-COMPENSATION (max. ±0.5mm). To eliminate radial and axial feed<br />

discrepancy in the CNC ma<strong>ch</strong>ines programmed feed/speed (rigid tapping).<br />

Features<br />

n Computer generated Flexure for cushioning (radial and axial)<br />

n The Flexure eliminates pressure on the tap, thereby perfect threads and up to double tap life<br />

n Right hand and left hand tapping<br />

n Steel collets ER-GB, inter<strong>ch</strong>angeable shanks<br />

n Predictable tapping behaviour throughout the entire life of the tool<br />

n Outstanding results with standard taps<br />

n Internal coolant system up to 30 bar (version S for up to 80 bar)<br />

n Integrated short design<br />

Application<br />

On CNC ma<strong>ch</strong>ining centres, CNC lathes with rigid tapping.<br />

Delivery<br />

Standard nut and wren<strong>ch</strong> are included in the delivery.<br />

Model Order code Capacity<br />

in steel<br />

Shank HSK-A Collets ER Max. IC-pressure<br />

bar<br />

SFT50 4350H5020 M4–M12 50 ER20 30 (80)<br />

4350H6320 63 30 (80)<br />

4350H10020 100 30 (80)<br />

SFT75 4375H5025 M10–M20 50 ER25 30 (80)<br />

4375H6325 63 30 (80)<br />

4375H10025 100 30 (80)<br />

SFT100 43100H6340 M18–M30 63 ER40 30 (80)<br />

43100H10040 100 30 (80)<br />

Note: When using internal coolant of more than 30 bars, we recommend the use of our balanced coolant system BCS.<br />

Add “S” to the article number and you will receive the S-model with IC-nut. For minimum quantity lubricant MMS add<br />

“M” to the article number. Sealing gaskets are ordered separately.<br />

The models SFT50 and SFT75 can be supplied with QC spindles. Add “QC” to the article number. Shrink-fit is also<br />

available on request.<br />

Extended units are also available please indicate measurement A (in line drawing) length required.<br />

When using Roll Form Taps the <strong>ch</strong>uck’s tapping capacity must be reduced by 25%.<br />

Dimensions<br />

Model A (HSK 50A) mm A (HSK 63A) mm A (HSK 100A) mm B mm<br />

SFT50 102 102 109 34<br />

SFT75 122 122 129 40<br />

SFT100 – 151 158 63<br />

Syn<strong>ch</strong>roFlex tapping <strong>ch</strong>ucks with Capto ® shank<br />

Syn<strong>ch</strong>roFlex tapping <strong>ch</strong>ucks are also available with Capto ® shanks C4, C5, C6 and C8 upon<br />

request.<br />

Steel collets<br />

on page 29<br />

Sealing gaskets<br />

on page 29<br />

14 TAPMATIC

SFT<br />

Syn<strong>ch</strong>roFlex tapping <strong>ch</strong>ucks with DIN 69871 A/D shank<br />

Tapping <strong>ch</strong>uck with MICRO-COMPENSATION (max. ±0.5mm). To eliminate radial and axial feed<br />

discrepancy in the CNC ma<strong>ch</strong>ines programmed feed/speed (rigid tapping).<br />

Features<br />

n Computer generated Flexure for cushioning (radial and axial)<br />

n The Flexure eliminates pressure on the tap, thereby perfect threads and up to double tap life<br />

n Right hand and left hand tapping<br />

n Steel collets ER-GB, inter<strong>ch</strong>angeable shanks<br />

n Predictable tapping behaviour throughout the entire life of the tool<br />

n Outstanding results with standard taps<br />

n Integrated short design<br />

Application<br />

On CNC ma<strong>ch</strong>ining centres, CNC lathes with rigid tapping.<br />

Delivery<br />

Standard nut and wren<strong>ch</strong> are included in the delivery.<br />

Model Order code Capacity<br />

in steel<br />

Shank<br />

DIN 69871A/D<br />

Collets ER Max. IC-pressure<br />

bar<br />

SFT50 4350A4020 M4–M12 SK 40 ER20 30 (80)<br />

4350A5020 SK 50<br />

SFT75 4375A4025 M10–M20 SK 40 ER25 30 (80)<br />

4375A5025 SK 50<br />

Dimensions<br />

Model A mm B mm<br />

SFT50 98 34<br />

SFT75 118 40<br />

Syn<strong>ch</strong>roFlex tapping <strong>ch</strong>uck with MAS BT shanks<br />

Model Order code Capacity<br />

in steel<br />

Shank BT Collets ER Max. IC-pressure<br />

bar<br />

SFT50 4350B4020 M4–M12 BT40 ER20 30 (80)<br />

4350B5020<br />

BT50<br />

SFT75 4375B4025 M10–M20 BT40 ER25 30 (80)<br />

4375B5025<br />

BT50<br />

Dimensions<br />

Model A mm B mm Shank BT<br />

SFT50 90 34 40<br />

101 50<br />

SFT75 110 40 40<br />

121 50<br />

Note: When using internal coolant of more than 30 bars, we recommend the use of our balanced coolant system BCS.<br />

Add “S” to the article number and you will receive the S-model with IC-nut. For minimum quantity lubricant MMS add<br />

“M” to the article number. Sealing gaskets are ordered separately.<br />

When using Roll Form Taps the <strong>ch</strong>uck’s tapping capacity must be reduced by 25%.<br />

The models SFT50 and SFT75 can be supplied with QC spindles. Add “QC” to the article number. Shrink-fit is also<br />

available on request.<br />

Steel collets<br />

on page 29<br />

Sealing gaskets<br />

on page 29<br />

TAPMATIC 15

SX<br />

SelectaFlex-syn<strong>ch</strong>ro tapping <strong>ch</strong>ucks with straight shank<br />

DIN1835B+E (adjustable)<br />

Tapping <strong>ch</strong>uck with MICRO-COMPENSATION (max. ±0.5mm) to eliminate radial and axial feed<br />

discrepancy in the CNC ma<strong>ch</strong>ine programme feed/speed (rigid tapping).<br />

Features<br />

n The microcompensator eliminates pressure on the tap, thereby perfect threads and up to<br />

double tap life<br />

n Adjustable thrust for difficult materials or Roll Tapping<br />

n Right hand and left hand tapping<br />

n Steel collets ER-GB, inter<strong>ch</strong>angeable shanks<br />

n Internal coolant system up to 30 bar (version S for up to 80 bar)<br />

Application<br />

On CNC ma<strong>ch</strong>ining centres, CNC lathes with rigid tapping.<br />

Delivery<br />

Standard nut and wren<strong>ch</strong> are included in the delivery.<br />

Model Order code Capacity<br />

in steel<br />

Straight<br />

shank S<br />

Ø mm<br />

Collets ER<br />

Max.<br />

IC-pressure<br />

bar<br />

SX10 44102511 M2–M5 25 ER11 30 (80) 0.4<br />

SX50 44502520 M4–M12 25 ER20 30 (80) 0.5<br />

SX75 44752525 M10–M20 25 ER25 30 (80) 1.0<br />

Weight kg<br />

Dimensions<br />

Model A mm B mm Straight shank Ø mm<br />

SX10 51 19 25<br />

SX50 63 34 25<br />

SX75 83 42 25<br />

Note: When using internal coolant of more than 30 bars, we recommend the use of our balanced coolant system BCS.<br />

Add “S” to the article number and you will receive the S-model with IC-nut. Sealing gaskets are ordered separately.<br />

When using Roll Form Taps the <strong>ch</strong>uck’s tapping capacity must be reduced by 25%.<br />

Adjustable thrust<br />

These units have the additional feature of adjustable thrust. They can be adjusted ± to give<br />

optimal production and exact thread depth in difficult/special materials, this applies particularly<br />

to Roll Form Tapping.<br />

Steel collets<br />

on page 29<br />

Inter<strong>ch</strong>angeable<br />

NC shanks<br />

on page 30<br />

Sealing gaskets<br />

on page 29<br />

16 TAPMATIC

SM<br />

Tapping <strong>ch</strong>ucks with straight shank DIN 1835B+E<br />

for multi-range collets (RF)<br />

The tension and compression in the SM units is increased to accommodate excessive syn<strong>ch</strong>ronization<br />

inaccuracies. The <strong>ch</strong>ucks are non-reversing, <strong>ch</strong>ange of tapping direction is done by<br />

ma<strong>ch</strong>ine spindle (G84 tapping cycle).<br />

Features<br />

n Increased tension compression<br />

n Adjustable hard start<br />

n Right hand and left hand tapping<br />

n Multi-range collets (RF), adjustable back jaw<br />

Application<br />

On NC ma<strong>ch</strong>ines, lathes as well as all ma<strong>ch</strong>ines with controlled feed.<br />

Delivery<br />

Standard accessories include 2 wren<strong>ch</strong>es, all necessary hex keys and one stop arm. Please order<br />

the necessary 2 multi-range collets and arbor separately.<br />

Model Order code Capacity Straight shank Collets Self-feed mm<br />

in steel Ø mm<br />

Rubber Flex Tension T Compress. H<br />

SM2-016 23216 M1,4–M7 16 J116, J117 4.5 5<br />

SM2-020 23220 20<br />

SM4-016 23416 M3–M12 16 J421, J422 7 7<br />

SM4-020 23420 20<br />

SM4-025 23425 25<br />

SM6-020 23620 M5–M18 20 J440, J443 11 11<br />

SM6-025 23625 25<br />

SM8-025 23825 M10–M30 25 J461, J462 17 17<br />

Dimensions<br />

Model D mm d mm L1 mm L2 mm L3 mm Weight kg<br />

SM2-016 27 19 48 53 26 0,200<br />

SM2-020 50<br />

SM4-016 38 27 48 71 36 0,400<br />

SM4-020 50<br />

SM4-025 56<br />

SM6-020 47.5 37 50 96 56 0,800<br />

SM6-025 56<br />

SM8-025 63.5 57 56 128 78 2,000<br />

Tapping <strong>ch</strong>ucks with morse taper arbor DIN 228B<br />

for multi-range collets (RF)<br />

The tension and compression in the SM units is increased to accommodate excessive syn<strong>ch</strong>ronisation<br />

inaccuracies. The <strong>ch</strong>ucks are non-reversing, <strong>ch</strong>ange of tapping direction done is by<br />

ma<strong>ch</strong>ine spindle (G84 tapping cycle).<br />

Features<br />

n Increased tension compression<br />

n Adjustable hard start<br />

n Right hand and left hand tapping<br />

n Multi-range collets (RF), adjustable back jaw<br />

Application<br />

On NC ma<strong>ch</strong>ines, lathes as well as all ma<strong>ch</strong>ines with controlled feed.<br />

Delivery<br />

Standard accessories include 2 wren<strong>ch</strong>es, all necessary hex keys and one stop arm. Please order<br />

the necessary 2 multi-range collets and arbor separately.<br />

Model Order code Capacity Morse taper Collets Self-feed mm<br />

in steel MT<br />

Rubber Flex Tension T Compress. H<br />

SM2-002 23202 M1,4–M7 2 J116, J117 4.5 5<br />

SM4-002 23402 M3–M12 2 J421, J422 7 7<br />

SM6-003 23603 M5–M18 3 J440, J443 11 11<br />

SM8-004 23804 M10–M30 4 J461, J462 17 17<br />

Dimensions<br />

Model D mm d mm L1 mm L2 mm L3 mm Weight kg<br />

SM2-002 27.0 19 80 57.5 26 0,200<br />

SM4-002 38.0 27 80 74 36 0,400<br />

SM6-003 47.5 37 99 99 56 0,900<br />

SM8-004 63.5 57 124 134 78 2,300<br />

Collets RF<br />

on page 29<br />

TAPMATIC 17

Tapping <strong>ch</strong>ucks with straight shank DIN 1835B+E<br />

quick-<strong>ch</strong>ange version<br />

The TA tapping <strong>ch</strong>uck has tension/compression and adjustable hard start, with its quick <strong>ch</strong>ange<br />

spindle the taps can be <strong>ch</strong>anged in seconds.<br />

Features<br />

n Self-feed (tension/compression)<br />

n Adjustable hard start<br />

n Right hand and left hand tapping<br />

n Quick-<strong>ch</strong>ange spindle<br />

n Short construction<br />

Model Order code Capacity<br />

in steel<br />

Straight<br />

shank<br />

Tap adapters Self-feed mm Front<br />

release<br />

Ø mm<br />

Tension T Compress. H Z mm<br />

TA0-016 15016 M1–M10 16 T0, TC0, E0, TF0 7.5 5 1,7<br />

TA0-020 15020 M1–M10 20 T0, TC0, E0, TF0 7.5 5 1,7<br />

TA1-016 15116 M3–M14 16 T1, TC1, E1, D1, TF1 8 5 2,1<br />

TA1-020 15120 M3–M14 20 T1, TC1, E1, D1, TF1 8 5 2,1<br />

TA1-025 15125 M3–M14 25 T1, TC1, E1, D1, TF1 8 5 2,1<br />

TA2-025 15225 M4,5–M24 25 T2, TC2, E2, D2, TF2 15 8.5 2,8<br />

TA2-032 15232 M4,5–M24 32 T2, TC2, E2, D2, TF2 15 8,5 2,8<br />

TA3-032 15332 M14–M36 32 T3, TC3, D3, TF3 23.5 15 4,1<br />

TA4-040 15440 M22–M48 40 T4, TC4 25 16.5 5,7<br />

TA<br />

Application<br />

On all ma<strong>ch</strong>ine-tools with controlled feed,<br />

especially on CNC ma<strong>ch</strong>ining centres and<br />

lathes.<br />

Note: When using Roll Form Taps the <strong>ch</strong>uck’s tapping<br />

capacity must be reduced by 25%.<br />

The quick-<strong>ch</strong>ange adapters are ordered separately, see<br />

pages 24–27.<br />

Dimensions<br />

Model D mm d mm L1 mm L2 mm<br />

TA0-016 29 13 48 38.0<br />

TA0-020 50<br />

TA1-016 39 19 49 39.0<br />

TA1-020 51<br />

TA1-025 57<br />

TA2-025 56 31 57 63.0<br />

TA2-032<br />

TA3-032 81 48 61 124.0<br />

TA4-040 99 60 71 135.5<br />

Tapping <strong>ch</strong>ucks with HSK shank DIN 69893A<br />

quick <strong>ch</strong>ange version<br />

The TA tapping <strong>ch</strong>uck with HSK DIN69893A has tension/compression and adjustable hard start,<br />

with its quick <strong>ch</strong>ange spindle the taps can be <strong>ch</strong>anged in seconds.<br />

Features<br />

n Self-feed (tension/compression)<br />

n Adjustable hard start<br />

n Right hand and left hand tapping<br />

n Quick-<strong>ch</strong>ange spindle<br />

n Integral HSK spindle<br />

n Short construction<br />

Model Order code Capacity<br />

in steel<br />

Shank S<br />

HSK-A<br />

Tap adapters Self-feed Front<br />

release<br />

Tension T Compress. H Z mm<br />

TA1-HSK50A 15150 M3–M14 50 T1, TC1 8 5 2.1<br />

TA1-HSK63A 15163 63<br />

E1, D1, TF1<br />

TA1-HSK80A 15180 80<br />

TA1-HSK100A 15100 100<br />

TA2-HSK50A 15250 M4,5–M24 50 T2, TC2 15 8.5 2.8<br />

TA2-HSK63A 15263 63<br />

E2, D2, TF2<br />

TA2-HSK80A 15280 80<br />

TA2-HSK100A 15200 100<br />

TA3-HSK63A 15363 M14–M36 63 T3, TC3, 23.5 15 4.1<br />

TA3-HSK80A 15380 80<br />

D3, TF3<br />

TA3-HSK100A 15300 100<br />

TA4-HSK80A 15480 M22–M48 80 T4, TC4 25 16.5 5.7<br />

TA4-HSK100A 15400 100<br />

Inter<strong>ch</strong>angeable<br />

NC shanks<br />

on page 30<br />

Tap adapters<br />

on pages 24–27<br />

Application<br />

On ma<strong>ch</strong>ining centres with HSK adaption.<br />

Note: When using Roll Form Taps the <strong>ch</strong>uck’s tapping<br />

capacity must be reduced by 25%.<br />

The quick-<strong>ch</strong>ange adapters are ordered separately, see<br />

pages 24–27.<br />

Dimensions<br />

Model D mm d mm L1 mm L2 mm<br />

TA1-HSK50A 39 19 25 77<br />

TA1-HSK63A 32 79<br />

TA1-HSK80A 40 83.5<br />

TA1-HSK100A 50 85.5<br />

TA2-HSK50A 56 31 25 111<br />

TA2-HSK63A 32 113<br />

TA2-HSK80A 40 117.5<br />

TA2-HSK100A 50 119.5<br />

TA3-HSK63A 81 48 32 164<br />

TA3-HSK80A 40 168.5<br />

TA3-HSK100A 50 170.5<br />

TA4-HSK80A 99 60 40 203<br />

TA4-HSK100A 50 205<br />

18 TAPMATIC

TA<br />

Tapping <strong>ch</strong>ucks with to DIN 69871A quick <strong>ch</strong>ange version<br />

The TA tapping <strong>ch</strong>uck to DIN 69871A has tension/compression and adjustable hard start, with its<br />

quick-<strong>ch</strong>ange spindle the tap can be <strong>ch</strong>anged in seconds.<br />

Features<br />

n Self-feed (tension/compression)<br />

n Adjustable hard start<br />

n Right hand and left hand tapping<br />

n Quick-<strong>ch</strong>ange spindle<br />

n Integral Shank DIN 69871A<br />

n Short construction<br />

Application<br />

Especially on ma<strong>ch</strong>ining centres with adaption acc. to DIN 69871A.<br />

Model Order code Capacity<br />

in steel<br />

Shank Tap adapters Self-feed mm Front<br />

release<br />

Tension T Compress. H Z mm<br />

TA1-DIN40 15142 M3–M14 40 T1, TC1, E1 8 5 2.1<br />

TA1-DIN50 15152 50<br />

D1, TF1<br />

TA2-DIN40 15242 M4,5–M24 40 T2, TC2, E2 15 8.5 2.8<br />

TA2-DIN50 15252 50<br />

D2, TF2<br />

TA3-DIN40 15342 M14–M36 40 T3, TC3 23.5 15 4.1<br />

TA3-DIN50 15352 50<br />

D3, TF3<br />

TA4-DIN40 15442 M22–M48 40 T4, TC4 25 16.5 5.7<br />

TA4-DIN50 15452 50<br />

Dimensions<br />

Model D mm d mm L1 mm L2 mm<br />

TA1-DIN40 39 19 68.25 74<br />

TA1-DIN50 101.6<br />

TA2-DIN40 56 31 68.25 98<br />

TA2-DIN50 101.6<br />

TA3-DIN40 81 48 68.25 147<br />

TA3-DIN50 101.6 159<br />

TA4-DIN40 99 60 68.25 160<br />

TA4-DIN50 101.6<br />

Note: When using Roll Form Taps the <strong>ch</strong>uck’s tapping capacity must be reduced by 25%.<br />

The quick-<strong>ch</strong>ange adapters are ordered separately, see pages 24–27.<br />

Tapping <strong>ch</strong>ucks with morse taper shank DIN 228B quick <strong>ch</strong>ange version<br />

The TA tapping <strong>ch</strong>uck with morse taper shank DIN228B has tension/compression and adjustable<br />

hard start, with its quick-<strong>ch</strong>ange spindle the tap can be <strong>ch</strong>anged in seconds.<br />

Features<br />

n Self-feed (tension/compression)<br />

n Adjustable hard start<br />

n Right hand and left hand tapping<br />

n Quick-<strong>ch</strong>ange spindle<br />

n Integral shank morse taper shank DIN228B<br />

n Short construction<br />

Application<br />

On ma<strong>ch</strong>ine-tools with controlled feed, especially on ma<strong>ch</strong>ining centres, lathes and column drill<br />

presses.<br />

Model Order code Capacity<br />

in steel<br />

Morse taper<br />

MT<br />

Tap adapters Self-feed mm Front<br />

release<br />

Tension T Compress. H Z mm<br />

TA0-MT1 15001 M1–M10 1 T0, TC0 7.5 5 1.7<br />

TA0-MT2 15002 2<br />

E0, TF0<br />

TA1-MT2 15102 M3–M14 2 T1, TC1 8 5 2.1<br />

TA1-MT3 15103 3<br />

E1, D1, TF1<br />

TA2-MT3 15203 M4,5–M24 3 T2, TC2 15 8.5 2.8<br />

TA2-MT4 15204 4<br />

E2, D2, TF2<br />

TA2-MT5 15205 5<br />

TA3-MT4 15304 M14–M36 4 T3, TC3 23.5 15 4.1<br />

TA3-MT5 15305 5<br />

D3, TF3<br />

TA4-MT5 15405 M22–M48 5 T4, TC4 25 16.5 5.7<br />

TA4-MT6 15406 6<br />

Dimensions<br />

Model D mm d mm L1 mm L2 mm<br />

TA0-MT1 29 13 62.0 43.5<br />

TA0-MT2 29 13 75.0 45.0<br />

TA1-MT2 39 19 75.0 47.0<br />

TA2-MT3 56 31 94.0 71.0<br />

TA3-MT4 81 48 117.5 105.0<br />

TA4-MT5 99 60 149.5 116.5<br />

Tap adapters<br />

on pages 24–27<br />

Note: When using Roll Form Taps the <strong>ch</strong>uck’s tapping capacity must be reduced by 25%.<br />

The quick-<strong>ch</strong>ange adapters are ordered separately, see pages 24–27.<br />

TAPMATIC 19

TIC<br />

Tapping <strong>ch</strong>ucks with straight shank to DIN 1835B+E<br />

internal coolant system, quick <strong>ch</strong>ange version<br />

The TIC tapping <strong>ch</strong>uck has an internal coolant system, tension/compression and adjustable hard<br />

start, with its quick-<strong>ch</strong>ange spindle the tap can be <strong>ch</strong>anged in seconds.<br />

Features<br />

n Self-feed (tension/compression)<br />

n Adjustable hard start<br />

n Right hand and left hand tapping<br />

n Quick-<strong>ch</strong>ange spindle<br />

n Internal coolant system (max. 50 bar)<br />

n Short construction<br />

Application<br />

On all ma<strong>ch</strong>ine-tools with internal coolant system, especially on lathes and ma<strong>ch</strong>ining centres.<br />

Model Order code Capacity<br />

in steel<br />

Straight<br />

shank<br />

Ø mm<br />

TIC1-025 16125 M3–M14 25 T1, T1-IK<br />

TC1, TC1-IK<br />

E1, D1<br />

TIC2-025 16225 M4,5–M24 25 T2, T2-IK<br />

TC2, TC2-IK<br />

E2, D2<br />

Tap adapters Self-feed mm Front<br />

release<br />

Tension T Compress. H Z mm<br />

7.5 5 2.5<br />

10 7 3<br />

Dimensions<br />

Model D mm d mm L1 mm L2 mm<br />

TIC1-025 43 19 57 62<br />

TIC2-025 59 31 57 98<br />

Note: When using Roll Form Taps the <strong>ch</strong>uck’s tapping capacity must be reduced by 25%.<br />

The quick-<strong>ch</strong>ange adapters are ordered separately, see pages 24–27.<br />

Tapping <strong>ch</strong>ucks with HSK DIN 69893A<br />

internal coolant system, quick <strong>ch</strong>ange version<br />

The TIC tapping <strong>ch</strong>uck has an internal coolant system, tension/compression and adjustable hard<br />

start, with its quick-<strong>ch</strong>ange spindle the tap can be <strong>ch</strong>anged in seconds with a perfect seal.<br />

Features<br />

n Self-feed (tension/compression)<br />

n Adjustable hard start<br />

n Right hand and left hand tapping<br />

n Quick-<strong>ch</strong>ange spindle<br />

n Internal coolant system (max. 50 bar)<br />

n Integral HSK Shank<br />

n Short construction<br />

Application<br />

On all ma<strong>ch</strong>ine-tools with internal coolant system, especially on lathes and ma<strong>ch</strong>ining centres.<br />

Model Order code Capacity<br />

in steel<br />

Shank S<br />

HSK-A<br />

Tap adapters Self-feed mm Front<br />

release<br />

Tension T Compress. H Z mm<br />

TIC1-HSK50A 16150 M3–M14 50 T1, T1-IK 7.5 5 2.5<br />

TIC1-HSK63A 16163 63<br />

TC1, TC1-IK<br />

TIC1-HSK80A 16180 80<br />

E1, D1<br />

TIC1-HSK100A 16100 100<br />

TIC2-HSK50A 16250 M4,5–M24 50 T2, T2-IK 10 7 3<br />

TIC2-HSK63A 16263 63<br />

TIC2-HSK80A 16280 80<br />

TIC2-HSK100A 16200 100<br />

TC2, TC2-IK<br />

E2, D2<br />

Dimensions<br />

Model D mm d mm L1 mm L2 mm<br />

TIC1-HSK50A 43 19 25 91<br />

TIC1-HSK63A 32 93<br />

TIC1-HSK80A 40 97<br />

TIC1-HSK100A 50 98<br />

TIC2-HSK50A 59 31 25 140<br />

TIC2-HSK63A 32 130<br />

TIC2-HSK80A 40 133<br />

TIC2-HSK100A 50 135<br />

Tap adapters<br />

on pages 24–27<br />

Note: When using Roll Form Taps the <strong>ch</strong>uck’s tapping capacity must be reduced by 25%.<br />

The quick-<strong>ch</strong>ange adapters are ordered separately, see pages 24–27.<br />

20 TAPMATIC

Tapping <strong>ch</strong>ucks with shank DIN 69871 A/D or B<br />

internal coolant system quick <strong>ch</strong>ange version<br />

The TIC tapping <strong>ch</strong>uck has an internal coolant system, tension/compression and adjustable hard<br />

start, with its quick-<strong>ch</strong>ange spindle the tap can be <strong>ch</strong>anged in seconds.<br />

Features<br />

n Self-feed (tension/compression)<br />

n Adjustable hard start<br />

n Right hand and left hand tapping<br />

n Quick-<strong>ch</strong>ange spindle<br />

n Internal coolant system (max. 50 bar)<br />

n Integral shank DIN 69871A/D or B<br />

n Short construction<br />

Application<br />

Especially on ma<strong>ch</strong>ining centres with adaption acc. to DIN 69871A/D or B.<br />

Model Order code Capacity<br />

in steel<br />

Shank Tap adapters Self-feed mm Front<br />

release<br />

Tension T Compress. H Z mm<br />

TIC1-DIN40AD 16142 M3–M14 40A/D T1,T1-IK 7.5 5 2.5<br />

TIC1-DIN40B 16143 40B TCI, TC1-IK<br />

TIC1-DIN50AD 16152 50A/D E1, D1<br />

TIC1-DIN50B 16153 50B<br />

TIC2-DIN40AD 16242 M4,5–M24 40A/D T2, T2-IK 10 7 3<br />

TIC2-DIN40B 16243 40B<br />

TIC2-DIN50AD 16252 50A/D<br />

TIC2-DIN50B 16253 50B<br />

TC2,TC2-IK<br />

E2, D2<br />

TIC<br />

Dimensions<br />

Model D mm d mm L1 mm L2 mm<br />

TIC1-DIN40AD 43 19 68.4 97<br />

TIC1-DIN40B<br />

TIC1-DIN50AD 101.8<br />

TIC1-DIN50B<br />

TIC2-DIN40AD 59 31 68.4 133<br />

TIC2-DIN40B<br />

TIC2-DIN50AD 101.8<br />

TIC2-DIN50B<br />

Note: When using Roll Form Taps the <strong>ch</strong>uck’s tapping capacity must be reduced by 25%.<br />

The quick-<strong>ch</strong>ange adapters are ordered separately, see pages 24–27.<br />

Further shank versions as DIN 69880 (VDI 3425), ABS (System Komet) available on request.<br />

Tap adapters<br />

on pages 24–27<br />

TAPMATIC 21

Special models on request<br />

High speed tapping atta<strong>ch</strong>ments with automatic reversal for<br />

CNC ma<strong>ch</strong>ines<br />

The ID models are particularly suitable for CNC ma<strong>ch</strong>ines with limited space in the tool<br />

magazine. With its outside diameter of only 65mm the unit occupies only one station in the tool<br />

<strong>ch</strong>ange magazine.<br />

Features<br />

n Low-friction cushioned drive up to 2500 RPM<br />

n Self-feed (tension)<br />

n Accurate thread depths<br />

n Steel collets ER-GB<br />

n Straight shanks, inter<strong>ch</strong>angeable shanks available (HSK)<br />

n Renewable drive systems<br />

n Internal coolant system (max. 50 bar)<br />

n Reduced ma<strong>ch</strong>ine spindle wear<br />

n Shorter cycle time<br />

n Increased tap life<br />

n Reduction in energy consumption<br />

Application<br />

On CNC ma<strong>ch</strong>ining centres with automatic tool <strong>ch</strong>anger (bore cycle G85) or modified and<br />

efficient sub routine.<br />

Delivery<br />

Standard accessories include 2 wren<strong>ch</strong>es and all necessary hex keys. The required stop arm,<br />

sealing gaskets as well as ER-GB (ER) steel collets are ordered separately.<br />

Model Order code Capacity<br />

in steel<br />

Max. RPM<br />

Straight<br />

shank S<br />

Ø mm<br />

Collets<br />

ID50 38642 M4,5–M12 2500 25 ER20 2,5<br />

Note: When using Roll Form Taps the <strong>ch</strong>uck’s tapping capacity must be reduced by 25%.<br />

Several models with HSK shank on request.<br />

Weight kg<br />

Tapping atta<strong>ch</strong>ments for CNC centre lathes with VDI shank<br />

Features<br />

n Automatic reversal<br />

n Self-feed (tension)<br />

n Steel collets ER-GB<br />

n Modular VDI shank DIN 69880 (VDI3425)<br />

Application<br />

On CNC-lathes with activated tools and VDI shank.<br />

Radial self-reversing tapping atta<strong>ch</strong>ment RSR<br />

Model Order code Capacity in steel Collets Max. RPM<br />

RSR50 37014 M4,5–M12 ER16 2500<br />

Model RSR<br />

Axial self-reversing tapping atta<strong>ch</strong>ment ASR<br />

Model Order code Capacity in steel Collets Max. RPM<br />

ASR50 37030 M2,5–M7 ER11 3000<br />

ASA50 37034 M4,5–M12 ER16 2500<br />

ASA65 37038 M6–M16 ER20 1500<br />

Note: When using Roll Form Taps the <strong>ch</strong>uck’s tapping capacity must be reduced by 25%.<br />

Steel collets and VDI shank are ordered separately. The VDI shank is manufactured individually for your lathe.<br />

Dimensions for the atta<strong>ch</strong>ments available on request.<br />

Model ASR<br />

Steel collets<br />

on page 28<br />

22 TAPMATIC

D<br />

S<br />

L 1<br />

Tapping <strong>ch</strong>ucks with straight shank DIN 1835B+E<br />

quick <strong>ch</strong>ange version<br />

Features<br />

n Self-feed (tension/compression)<br />

n Releasable hard start<br />

n Short construction<br />

n Right hand tapping<br />

n Neutral position<br />

n Quick <strong>ch</strong>ange spindle T, TC, TF, D, E<br />

n Inter<strong>ch</strong>angeable shanks<br />

Special models on request<br />

H<br />

T<br />

L 2<br />

Application<br />

On ma<strong>ch</strong>ine-tools with controlled feed, especially on CNC ma<strong>ch</strong>ining centres and CNC lathes.<br />

Model Order code Capacity in steel Straight shank S Tap adapters<br />

mm<br />

NC-0 34002 M1,4–M6 20 T0, TC0, TF0, D0, E0<br />

NC-1 34012 M3–M12 25 T1, TC1, TF1, D1, E1<br />

NC-2S 34022S M5–M22 25 T2, TC2, TF2, D2, E2<br />

Tapping <strong>ch</strong>ucks with straight shank DIN 1835B+E<br />

quick <strong>ch</strong>ange for minimal coolant<br />

Features<br />

n Self-feed (tension/compression)<br />

n Hard start<br />

n Front release<br />

n Internal coolant system (Minimum quantity lubrication up to max. 10 bar)<br />

n Short construction<br />

n Quick-<strong>ch</strong>ange spindle<br />

n Inter<strong>ch</strong>angeable shanks<br />

Application<br />

Especially on CNC ma<strong>ch</strong>ining centres.<br />

Model Order code Capacity in steel Straight shank S Tap adapters<br />

mm<br />

TIM1-025 17125 M7–M14 25 T1<br />

TIM2-025 17225 M7–M24 25 T2<br />

Further shank versions on request.<br />

Syn<strong>ch</strong>ro tapping <strong>ch</strong>ucks without length compensation<br />

multi-range collets (RF)<br />

Features<br />

n Rigid without tension/compression<br />

n Multi-range collets (RF)<br />

n Adjustable back jaw to drive tap<br />

n Inter<strong>ch</strong>angeable shanks<br />

Application<br />

Especially on CNC ma<strong>ch</strong>ining centres with syn<strong>ch</strong>ronous control.<br />

Model Order code Capacity in steel Taper mount Collets<br />

DIN 238<br />

JACOBS<br />

SM41-JT1 24101 M1,4–M7 JT1 J116, J117<br />

SM42-B12 24212 M3–M12 B12 J421, J422<br />

SM42-JT1 24201 JT1<br />

SM42-JT2 24202 JT2<br />

SM44-B16 24416 M5–M18 B16 J443, J440<br />

SM44-JT2 24402 JT2<br />

SM44-JT6 24406 JT6<br />

Tap adapters<br />

on pages 24–27<br />

Inter<strong>ch</strong>angeable<br />

NC shanks<br />

on page 30<br />

Collets RF<br />

on page 29<br />

Arbors<br />

on page 30<br />

TAPMATIC 23

T<br />

Quick-<strong>ch</strong>ange tap adapters DIN/ISO positive drive<br />

For tap <strong>ch</strong>ucks TA, TIC, TIM and NC.<br />

Features<br />

n Positive drive<br />

n Right and left hand tapping<br />

n Internal coolant system through the tap<br />

Model Tap size Seize Dimensions<br />

d mm L1 mm D mm L2 mm<br />

T0 M1–M10 0 13 26.5 22 7<br />

T1 M3–M14 1 19 28.5 30 7<br />

T2 M4,5–M24 2 31 46.5 48 11<br />

T3 M14–M36 3 48 68.5 70 14<br />

T4 M22–M48 4 60 105.0 92 42<br />

Product range – Adapters<br />

Tap Shank<br />

Ø<br />

Square<br />

mm<br />

Order code<br />

T0<br />

Order code<br />

T1<br />

Order code<br />

T2<br />

Order code<br />

T3<br />

Order code<br />

T4<br />

M1 2.5 2.1 T0-025021<br />

M2 2.8 2.1 T0-028021<br />

M2,5 2.8 2.1 T0-028021<br />

M2,6 2.8 2.24 T0-028022<br />

M3 2.24 1.8 T0-022018<br />

M3 3.15 2.5 T0-0315025<br />

M3 3.5 2.7 T0-035027<br />

M3,5 3.55 2.8 T0-035028 T1-035028<br />

M3,5 4 3 T0-040030 T1-040030<br />

M4 2.8 2.1 T0-028021 –<br />

M4 4 3.15 T0-040031 T1-040031<br />

M4 4.5 3.4 T0-045034 T1-045034<br />