You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

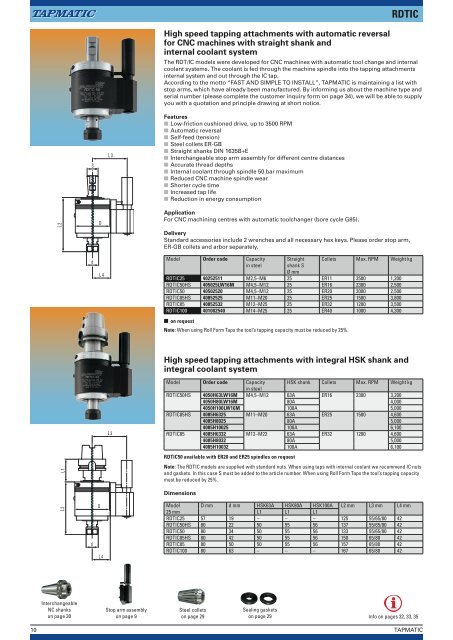

High speed tapping atta<strong>ch</strong>ments with automatic reversal<br />

for CNC ma<strong>ch</strong>ines with straight shank and<br />

internal coolant system<br />

The RDT/IC models were developed for CNC ma<strong>ch</strong>ines with automatic tool <strong>ch</strong>ange and internal<br />

coolant systems. The coolant is fed through the ma<strong>ch</strong>ine spindle into the tapping atta<strong>ch</strong>ments<br />

internal system and out through the IC tap.<br />

According to the motto “FAST AND SIMPLE TO INSTALL”, TAPMATIC is maintaining a list with<br />

stop arms, whi<strong>ch</strong> have already been manufactured. By informing us about the ma<strong>ch</strong>ine type and<br />

serial number (please complete the customer inquiry form on page 34), we will be able to supply<br />

you with a quotation and principle drawing at short notice.<br />

Features<br />

n Low-friction cushioned drive, up to 3500 RPM<br />

n Automatic reversal<br />

n Self-feed (tension)<br />

n Steel collets ER-GB<br />

n Straight shanks DIN 1635B+E<br />

n Inter<strong>ch</strong>angeable stop arm assembly for different centre distances<br />

n Accurate thread depths<br />

n Internal coolant through spindle 50 bar maximum<br />

n Reduced CNC ma<strong>ch</strong>ine spindle wear<br />

n Shorter cycle time<br />

n Increased tap life<br />

n Reduction in energy consumption<br />

Application<br />

For CNC ma<strong>ch</strong>ining centres with automatic tool<strong>ch</strong>anger (bore cycle G85).<br />

Delivery<br />

Standard accessories include 2 wren<strong>ch</strong>es and all necessary hex keys. Please order stop arm,<br />

ER-GB collets and arbor separately.<br />

Model Order code Capacity<br />

in steel<br />

Straight<br />

shank S<br />

Ø mm<br />

n on request<br />

Note: When using Roll Form Taps the tool’s tapping capacity must be reduced by 25%.<br />

RDTIC<br />

Collets Max. RPM Weight kg<br />

RDTIC25 40252511 M2,5–M6 25 ER11 3500 1,200<br />

RDTIC50HS 405025LW16M M4,5–M12 25 ER16 2300 2,500<br />

RDTIC50 40502520 M4,5–M12 25 ER20 2000 2,500<br />

RDTIC85HS 40852525 M11–M20 25 ER25 1500 3,800<br />

RDTIC85 40852532 M12–M25 25 ER32 1200 3,500<br />

RDTIC100 401002540 M14–M25 25 ER40 1000 4,300<br />

High speed tapping atta<strong>ch</strong>ments with integral HSK shank and<br />

integral coolant system<br />

Model Order code Capacity HSK shank Collets Max. RPM Weight kg<br />

in steel<br />

RDTIC50HS 4050H63LW16M M4,5–M12 63A ER16 2300 3,200<br />

4050H80LW16M 80A 4,000<br />

4050H100LW16M 100A 5,000<br />

RDTIC85HS 4085H6325 M11–M20 63A ER25 1500 4,600<br />

4085H8025 80A 5,000<br />

4085H10025 100A 6,100<br />

RDTIC85 4085H6332 M12–M22 63A ER32 1200 4,600<br />

4085H8032 80A 5,000<br />

4085H10032 100A 6,100<br />

RDTIC50 available with ER20 and ER25 spindles on request<br />

Note: The RDTIC models are supplied with standard nuts. When using taps with internal coolant we recommend IC nuts<br />

and gaskets. In this case S must be added to the article number. When using Roll Form Taps the tool’s tapping capacity<br />

must be reduced by 25%.<br />

Dimensions<br />

Model D mm d mm HSK63A HSK80A HSK100A L2 mm L3 mm L4 mm<br />

25 mm<br />

L1 L1 L1<br />

RDTIC25 57 19 – – – 125 55/65/80 42<br />

RDTIC50HS 80 22 50 55 56 137 55/65/80 42<br />

RDTIC50 80 34 50 55 56 133 55/65/80 42<br />

RDTIC85HS 80 42 50 55 56 150 65/80 42<br />

RDTIC85 80 50 50 55 56 157 65/80 42<br />

RDTIC100 80 63 – – – 167 65/80 42<br />

Inter<strong>ch</strong>angeable<br />

NC shanks<br />

on page 30<br />

Stop arm assembly<br />

on page 9<br />

Steel collets<br />

on page 29<br />

Sealing gaskets<br />

on page 29<br />

Info on pages 32, 33, 35<br />

10 TAPMATIC