You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Programming of the different models<br />

Model RDT and RDT-IC<br />

For efficient Tapping and production on CNC Ma<strong>ch</strong>ining Centre we<br />

recommend the writing of a subroutine with high speed retract. As an<br />

alternative a G85 boring cycle can be used. IMPORTANT NOTE at no<br />

time should the G code for Exact Stop or Ramp be used with TAPMATIC<br />

self-reversing Tapping Atta<strong>ch</strong>ments. They will cause the tapping cycle<br />

time to be significantly slower. We will gladly help with any programming<br />

computation.<br />

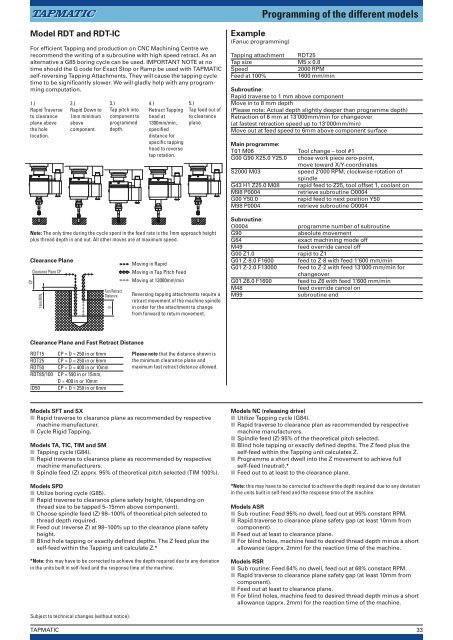

1.)<br />

Rapid Traverse<br />

to clearance<br />

plane above<br />

the hole<br />

location.<br />

2.)<br />

Rapid Down to<br />

1mm minimum<br />

above<br />

component.<br />

3.)<br />

Tap pit<strong>ch</strong> into<br />

component to<br />

programmed<br />

depth.<br />

4.)<br />

Retract Tapping<br />

head at<br />

1300mm/min,<br />

specified<br />

distance for<br />

specific tapping<br />

head to reverse<br />

tap rotation.<br />

5.)<br />

Tap feed out of<br />

to clearance<br />

plane.<br />

Example<br />

(Fanuc programming)<br />

Tapping atta<strong>ch</strong>ment RDT25<br />

Tap size M5 x 0.8<br />

Speed<br />

000 RPM<br />

Feed at 100%<br />

1600 mm/min<br />

Subroutine:<br />

Rapid traverse to 1 mm above component<br />

Move in to 8 mm depth<br />

(Please note: Actual depth slightly deeper than programme depth)<br />

Retraction of 6 mm at 13‘000mm/min for <strong>ch</strong>angeover<br />

(at fastest retraction speed up to 13‘000mm/min)<br />

Move out at feed speed to 6mm above component surface<br />

Main programme:<br />

T01 M06 Tool <strong>ch</strong>ange – tool #1<br />

G00 G90 X25.0 Y25.0 <strong>ch</strong>ose work piece zero-point,<br />

move toward X/Y-coordinates<br />

S2000 M03<br />

speed 2‘000 RPM, clockwise rotation of<br />

spindle<br />

G43 H1 Z25.0 M08 rapid feed to Z25, tool offset 1, coolant on<br />

M98 P0004<br />

retrieve subroutine O0004<br />

G00 Y50.0<br />

rapid feed to next position Y50<br />

M98 P0004<br />

retrieve subroutine O0004<br />

Note: The only time during the cycle spent in the feed rate is the 1mm approa<strong>ch</strong> height<br />

plus thread depth in and out. All other moves are at maximum speed.<br />

CP<br />

Clearance Plane<br />

Clearance Plane CP<br />

1 mm MIN.<br />

Fast Retract<br />

Distance<br />

D<br />

Moving in Rapid<br />

Moving in Tap Pit<strong>ch</strong> Feed<br />

Moving at 13000mm/min<br />

Reversing tapping atta<strong>ch</strong>ments require a<br />

retract movement of the ma<strong>ch</strong>ine spindle<br />

in order for the atta<strong>ch</strong>ment to <strong>ch</strong>ange<br />

from forward to return movement.<br />

Subroutine:<br />

O0004<br />

G90<br />

G64<br />

M49<br />

G00 Z1.0<br />

G01 Z-8.0 F1600<br />

G01 Z-2.0 F13000<br />

G01 Z6.0 F1600<br />

M48<br />

M99<br />

programme number of subroutine<br />

absolute movement<br />

exact ma<strong>ch</strong>ining mode off<br />

feed override cancel off<br />

rapid to Z1<br />

feed to Z-8 with feed 1‘600 mm/min<br />

feed to Z-2 with feed 13‘000 mm/min for<br />

<strong>ch</strong>angeover<br />

feed to Z6 with feed 1‘600 mm/min<br />

feed override cancel on<br />

subroutine end<br />

Clearance Plane and Fast Retract Distance<br />

RDT15<br />

RDT25<br />

RDT50<br />

RDT85/100<br />

ID50<br />

CP = D = 250 in or 6mm<br />

CP = D = 250 in or 6mm<br />

CP = D = 400 in or 10mm<br />

CP = 590 in or 15mm,<br />

D = 400 in or 10mm<br />

CP = D = 250 in or 6mm<br />

Please note that the distance shown is<br />

the minimum clearance plane and<br />

maximum fast retract distance allowed.<br />

Models SFT and SX<br />

n Rapid traverse to clearance plane as recommended by respective<br />

ma<strong>ch</strong>ine manufacturer.<br />

n Cycle Rigid Tapping.<br />

Models TA, TIC, TIM and SM<br />

n Tapping cycle (G84).<br />

n Rapid traverse to clearance plane as recommended by respective<br />

ma<strong>ch</strong>ine manufacturers.<br />

n Spindle feed (Z) apprx. 95% of theoretical pit<strong>ch</strong> selected (TIM 100%).<br />

Models SPD<br />

n Utilize boring cycle (G85).<br />

n Rapid traverse to clearance plane safety height, (depending on<br />

thread size to be tapped 5–15mm above component).<br />

n Choose spindle feed (Z) 98–100% of theoretical pit<strong>ch</strong> selected to<br />

thread depth required.<br />

n Feed out (reverse Z) at 98–100% up to the clearance plane safety<br />

height.<br />

n Blind hole tapping or exactly defined depths. The Z feed plus the<br />

self-feed within the Tapping unit calculate Z.*<br />

*Note: this may have to be corrected to a<strong>ch</strong>ieve the depth required due to any deviation<br />

in the units built in self-feed and the response time of the ma<strong>ch</strong>ine.<br />

Models NC (releasing drive)<br />

n Utilize Tapping cycle (G84).<br />

n Rapid traverse to clearance plan as recommended by respective<br />

ma<strong>ch</strong>ine manufacturers.<br />

n Spindle feed (Z) 95% of the theoretical pit<strong>ch</strong> selected.<br />

n Blind hole tapping or exactly defined depths. The Z feed plus the<br />

self-feed within the Tapping unit calculates Z.<br />

n Programme a short dwell into the Z movement to a<strong>ch</strong>ieve full<br />

self-feed (neutral).*<br />

n Feed out to at least to the clearance plane.<br />

*Note: this may have to be corrected to a<strong>ch</strong>ieve the depth required due to any deviation<br />

in the units built in self-feed and the response time of the ma<strong>ch</strong>ine.<br />

Models ASR<br />

n Sub routine: Feed 95% no dwell, feed out at 95% constant RPM.<br />

n Rapid traverse to clearance plane safety gap (at least 10mm from<br />

component).<br />

n Feed out at least to clearance plane.<br />

n For blind holes, ma<strong>ch</strong>ine feed to desired thread depth minus a short<br />

allowance (apprx. 2mm) for the reaction time of the ma<strong>ch</strong>ine.<br />

Models RSR<br />

n Sub routine: Feed 64% no dwell, feed out at 68% constant RPM.<br />

n Rapid traverse to clearance plane safety gap (at least 10mm from<br />

component).<br />

n Feed out at least to clearance plane.<br />

n For blind holes, ma<strong>ch</strong>ine feed to desired thread depth minus a short<br />

allowance (apprx. 2mm) for the reaction time of the ma<strong>ch</strong>ine.<br />

Subject to te<strong>ch</strong>nical <strong>ch</strong>anges (without notice).<br />

TAPMATIC 33