Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SFT<br />

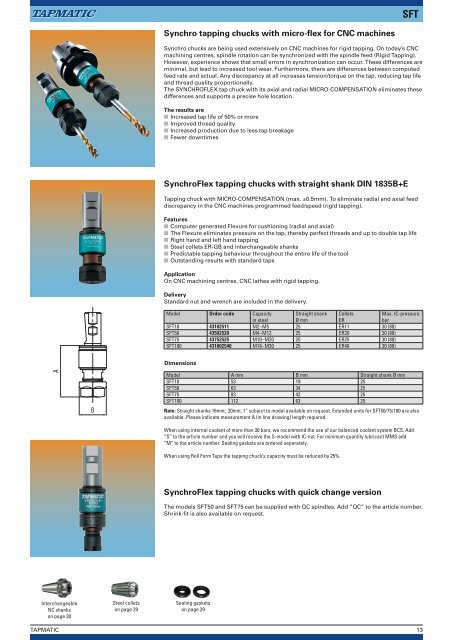

Syn<strong>ch</strong>ro tapping <strong>ch</strong>ucks with micro-flex for CNC ma<strong>ch</strong>ines<br />

Syn<strong>ch</strong>ro <strong>ch</strong>ucks are being used extensively on CNC ma<strong>ch</strong>ines for rigid tapping. On today’s CNC<br />

ma<strong>ch</strong>ining centres, spindle rotation can be syn<strong>ch</strong>ronized with the spindle feed (Rigid Tapping).<br />

However, experience shows that small errors in syn<strong>ch</strong>ronization can occur. These differences are<br />

minimal, but lead to increased tool wear. Furthermore, there are differences between computed<br />

feed rate and actual. Any discrepancy at all increases tension/torque on the tap, reducing tap life<br />

and thread quality proportionally.<br />

The SYNCHROFLEX tap <strong>ch</strong>uck with its axial and radial MICRO-COMPENSATION eliminates these<br />

differences and supports a precise hole location.<br />

The results are<br />

n Increased tap life of 50% or more<br />

n Improved thread quality<br />

n Increased production due to less tap breakage<br />

n Fewer downtimes<br />

Syn<strong>ch</strong>roFlex tapping <strong>ch</strong>ucks with straight shank DIN 1835B+E<br />

Tapping <strong>ch</strong>uck with MICRO-COMPENSATION (max. ±0.5mm). To eliminate radial and axial feed<br />

discrepancy in the CNC ma<strong>ch</strong>ines programmed feed/speed (rigid tapping).<br />

Features<br />

n Computer generated Flexure for cushioning (radial and axial)<br />

n The Flexure eliminates pressure on the tap, thereby perfect threads and up to double tap life<br />

n Right hand and left hand tapping<br />

n Steel collets ER-GB and inter<strong>ch</strong>angeable shanks<br />

n Predictable tapping behaviour throughout the entire life of the tool<br />

n Outstanding results with standard taps<br />

Application<br />

On CNC ma<strong>ch</strong>ining centres, CNC lathes with rigid tapping.<br />

Delivery<br />

Standard nut and wren<strong>ch</strong> are included in the delivery.<br />

Model Order code Capacity<br />

in steel<br />

Straight shank<br />

Ø mm<br />

Collets<br />

ER<br />

Max. IC-pressure<br />

bar<br />

SFT10 43102511 M2–M5 25 ER11 30 (80)<br />

SFT50 43502520 M4–M12 25 ER20 30 (80)<br />

SFT75 43752525 M10–M20 25 ER25 30 (80)<br />

SFT100 431002540 M18–M30 25 ER40 30 (80)<br />

Dimensions<br />

Model A mm B mm Straight shank Ø mm<br />

SFT10 53 19 25<br />

SFT50 63 34 25<br />

SFT75 83 42 25<br />

SFT100 112 63 25<br />

Note: Straight shanks 16mm; 20mm; 1“ subject to model available on request. Extended units for SFT50/75/100 are also<br />

available. Please indicate measurement A (in line drawing) length required.<br />

When using internal coolant of more than 30 bars, we recommend the use of our balanced coolant system BCS. Add<br />

“S” to the article number and you will receive the S-model with IC-nut. For minimum quantity lubricant MMS add<br />

“M” to the article number. Sealing gaskets are ordered separately.<br />

When using Roll Form Taps the tapping <strong>ch</strong>uck’s capacity must be reduced by 25%.<br />

Syn<strong>ch</strong>roFlex tapping <strong>ch</strong>ucks with quick <strong>ch</strong>ange version<br />

The models SFT50 and SFT75 can be supplied with QC spindles. Add “QC” to the article number.<br />

Shrink-fit is also available on request.<br />

Inter<strong>ch</strong>angeable<br />

NC shanks<br />

on page 30<br />

Steel collets<br />

on page 29<br />

Sealing gaskets<br />

on page 29<br />

TAPMATIC 13