Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SFT Syn<strong>ch</strong>roFlex-tap <strong>ch</strong>ucks<br />

Highest thread quality with Syn<strong>ch</strong>roFlex-tap <strong>ch</strong>ucks<br />

General information<br />

On today‘s CNC ma<strong>ch</strong>ining centres, spindle rotation can be syn<strong>ch</strong>ronized<br />

with the spindle feed (Rigid Tapping). However, experience shows<br />

that small errors in syn<strong>ch</strong>ronization can occur. These differences are<br />

minimal, but lead to increased tool wear.<br />

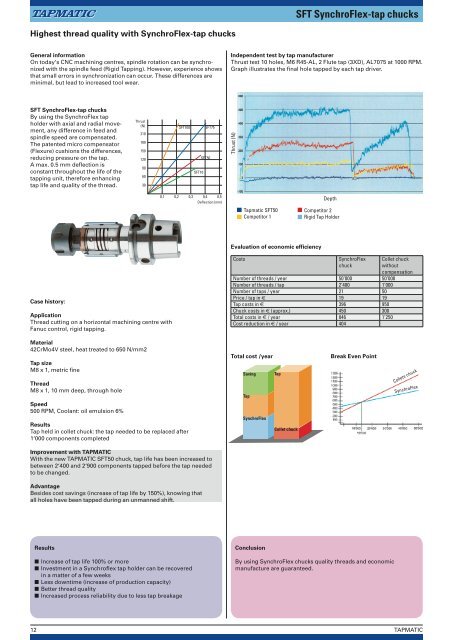

Independent test by tap manufacturer<br />

Thrust test 10 holes, M6 R45-AL, 2 Flute tap (3XD), AL7075 at 1000 RPM.<br />

Graph illustrates the final hole tapped by ea<strong>ch</strong> tap driver.<br />

SFT Syn<strong>ch</strong>roFlex-tap <strong>ch</strong>ucks<br />

By using the Syn<strong>ch</strong>roFlex tap<br />

holder with axial and radial movement,<br />

any difference in feed and<br />

spindle speed are compensated.<br />

The patented micro compensator<br />

(Flexure) cushions the differences,<br />

reducing pressure on the tap.<br />

A max. 0.5 mm deflection is<br />

constant throughout the life of the<br />

tapping unit, therefore enhancing<br />

tap life and quality of the thread.<br />

Thrust<br />

(N)<br />

210<br />

180<br />

150<br />

120<br />

90<br />

60<br />

30<br />

SFT100<br />

SFT10<br />

SFT75<br />

SFT50<br />

Thrust (N)<br />

0,1 0,2 0,3 0,4 0,5<br />

Deflection (mm)<br />

Tapmatic SFT50<br />

Competitor 1<br />

Depth<br />

Competitor 2<br />

Rigid Tap Holder<br />

Evaluation of economic efficiency<br />

Case history:<br />

Application<br />

Thread cutting on a horizontal ma<strong>ch</strong>ining centre with<br />

Fanuc control, rigid tapping.<br />

Costs<br />

Syn<strong>ch</strong>roFlex<br />

<strong>ch</strong>uck<br />

Number of threads / year 50’000 50’000<br />

Number of threads / tap 2’400 1’000<br />

Number of taps / year 21 50<br />

Price / tap in 19 19<br />

Tap costs in 396 950<br />

Chuck costs in (approx.) 450 300<br />

Total costs in / year 846 1’250<br />

Cost reduction in / year 404<br />

Collet <strong>ch</strong>uck<br />

without<br />

compensation<br />

Material<br />

42CrMo4V steel, heat treated to 650 N/mm2<br />

Tap size<br />

M8 x 1, metric fine<br />

Thread<br />

M8 x 1, 10 mm deep, through hole<br />

Speed<br />

500 RPM, Coolant: oil emulsion 6%<br />

Results<br />

Tap held in collet <strong>ch</strong>uck: the tap needed to be replaced after<br />

1‘000 components completed<br />

Total cost /year<br />

Saving Tap<br />

Tap<br />

Syn<strong>ch</strong>roFlex<br />

Collet <strong>ch</strong>uck<br />

Break Even Point<br />

Collets <strong>ch</strong>uck<br />

Syn<strong>ch</strong>roFlex<br />

Improvement with TAPMATIC<br />

With the new TAPMATIC SFT50 <strong>ch</strong>uck, tap life has been increased to<br />

between 2‘400 and 2‘900 components tapped before the tap needed<br />

to be <strong>ch</strong>anged.<br />

Advantage<br />

Besides cost savings (increase of tap life by 150%), knowing that<br />

all holes have been tapped during an unmanned shift.<br />

Results<br />

Conclusion<br />

n Increase of tap life 100% or more<br />

n Investment in a Syn<strong>ch</strong>roflex tap holder can be recovered<br />

in a matter of a few weeks<br />

n Less downtime (increase of production capacity)<br />

n Better thread quality<br />

n Increased process reliability due to less tap breakage<br />

By using Syn<strong>ch</strong>roFlex <strong>ch</strong>ucks quality threads and economic<br />

manufacture are guaranteed.<br />

12 TAPMATIC