Focus on Best Practice and Customized Product ... - Tenaris

Focus on Best Practice and Customized Product ... - Tenaris

Focus on Best Practice and Customized Product ... - Tenaris

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3 Sharing Knowledge Crucial to the Automotive Sector<br />

5 Qualificati<strong>on</strong> Keeps Pace with Growth in Airbag Market<br />

6 Working under Pressure<br />

7 The Tor<strong>on</strong>to Office: Strengthening a Firm Customer Base<br />

8 A Machinability Rating Indicator for Tubes for Mechanical Applicati<strong>on</strong>s<br />

10 Taking Part in Turin 2006 Winter Olympic Games<br />

6/o6<br />

8th Issue<br />

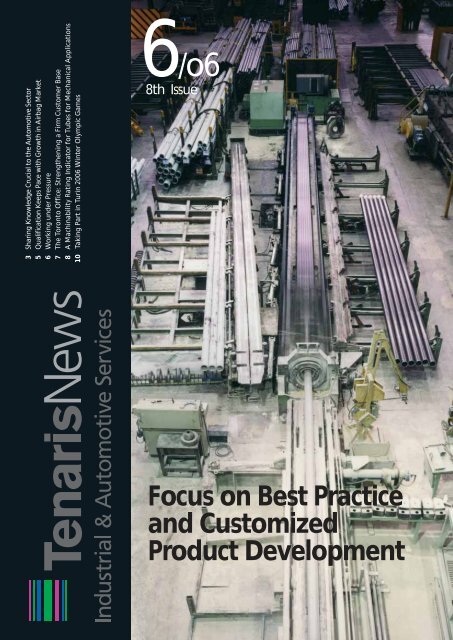

<str<strong>on</strong>g>Focus</str<strong>on</strong>g> <strong>on</strong> <strong>Best</strong> <strong>Practice</strong><br />

<strong>and</strong> <strong>Customized</strong><br />

<strong>Product</strong> Development

Know-how in product development<br />

<strong>and</strong> processes shared at a<br />

global level al<strong>on</strong>g with a direct<br />

relati<strong>on</strong>ship with the client are<br />

at the heart of the relati<strong>on</strong>ship<br />

with automotive customers.<br />

2 <strong>Tenaris</strong> News

Sharing Knowledge Crucial<br />

to the Automotive Sector<br />

After a stalled 2005, slight growth in the European auto market was seen in the<br />

sec<strong>on</strong>d half of the year, above all in Italy, France, Spain <strong>and</strong> Germany <strong>and</strong> a stable<br />

US market with a significant change in market share am<strong>on</strong>g the Big 3 <strong>and</strong> the<br />

Japanese auto makers.<br />

Dem<strong>and</strong> is ever more oriented towards supplying tubes<br />

according to complex client specificati<strong>on</strong>s <strong>and</strong> supplying<br />

semi-finished products, like tubes cut-to-length or with<br />

additi<strong>on</strong>al special operati<strong>on</strong>s, all the way to the request<br />

for complete comp<strong>on</strong>ents.<br />

With high request for pipes in the oil&gas market, the seamless<br />

tube business in the industrial sector finds itself facing capacity<br />

c<strong>on</strong>straints, <strong>and</strong> is therefore looking for ever greater efficiency<br />

<strong>and</strong> globalizati<strong>on</strong> of offers for added-value products. We spoke<br />

to Ricardo Perugini, resp<strong>on</strong>sible for special product business in<br />

the European market. Prior to looking after this market Perugini<br />

was, in 1998, the commercial manager for the automotive market<br />

in Nafta, <strong>and</strong> subsequently headed the new automotive comp<strong>on</strong>ent<br />

center in Veracruz, Mexico.<br />

<strong>Tenaris</strong> News 3

“The cycle to setup <strong>and</strong> homologate tubes for manufacture of, for<br />

example, c<strong>on</strong>stant-velocity joints for heavy vehicles <strong>and</strong> drive<br />

shafts – Perugini explains – is rather l<strong>on</strong>g <strong>and</strong> complex.<br />

Furthermore, the automotive manufacturers are going through a<br />

phase of profound reorganizati<strong>on</strong> in which, in the quest for maximum<br />

efficiency, they have established centralized hubs for design<br />

<strong>and</strong> comp<strong>on</strong>ent purchasing <strong>and</strong> have relocated producti<strong>on</strong> units<br />

in the markets with the greatest potential for development.<br />

In this sense <strong>Tenaris</strong> has followed the same development model,<br />

strengthening its presence in Eastern Europe <strong>and</strong> now in China,<br />

establishing a global R&D functi<strong>on</strong> coordinated centrally, setting<br />

up the technical <strong>and</strong> quality requisites of the product, through to<br />

supplying a package of services that facilitate integrati<strong>on</strong> into<br />

their supply chain.<br />

In fact, it’s in the airbag market where we’re starting to see the<br />

most centralized development models, which we are moving to<br />

emulate. The global presence of <strong>Tenaris</strong> is a str<strong>on</strong>g point in as<br />

much as it allows dialogue with the client, guaranteeing the same<br />

technical <strong>and</strong> commercial levels in all the principal markets,<br />

focusing particularly <strong>on</strong> Europe, Nafta <strong>and</strong> Mercosur.”<br />

4 <strong>Tenaris</strong>News<br />

It’s in the airbag<br />

market where we’re<br />

starting to see the<br />

most centralized<br />

development models.<br />

In a c<strong>on</strong>stant effort to achieve efficiency <strong>and</strong> cost<br />

reducti<strong>on</strong>, we share experience in product <strong>and</strong><br />

process development.<br />

Sharing know-how<br />

“In a c<strong>on</strong>stant effort to achieve internal efficiency <strong>and</strong> cost reducti<strong>on</strong>s<br />

– Perugini adds – we transfer experience gained in development<br />

of a product <strong>and</strong> process to the plants involved in producing<br />

the same product.”<br />

For example, the know-how acquired in ring gear products initially<br />

gained in the AlgomaTubes plant, was subsequently enlarged to<br />

include the Tamsa plant <strong>and</strong> now there are plans to transfer part<br />

of the producti<strong>on</strong> to the Italian facility. In particular, in the latter<br />

plant, various qualificati<strong>on</strong> trials were c<strong>on</strong>cluded involving four<br />

new steel types <strong>and</strong> about ten different part numbers.<br />

The quenched <strong>and</strong> tempered airbag product has also followed a<br />

similar path: initial development at Siderca was then exp<strong>and</strong>ed to<br />

the Tamsa mill, <strong>and</strong> now the comp<strong>on</strong>ent center at Costa Volpino,<br />

already the principal reference point for the European market, is<br />

working <strong>on</strong> qualificati<strong>on</strong> of beveled tubes in the high-resistance<br />

<strong>Tenaris</strong> UHSS-145 grade to meet the increase in dem<strong>and</strong> <strong>and</strong><br />

design characteristics in the US <strong>and</strong> European markets for curtain<br />

airbag inflators <strong>and</strong> passenger hybrid inflators.

Qualificati<strong>on</strong> Keeps Pace<br />

with Growth in Airbag Market<br />

Trial planning <strong>and</strong> interfuncti<strong>on</strong>al teamwork - <strong>Product</strong>, Quality, Logistics<br />

<strong>and</strong> <strong>Product</strong> Development - were crucial.<br />

Following qualificati<strong>on</strong> of the<br />

<strong>Tenaris</strong>Dalmine Costa Volpino colddrawing<br />

plant for tubes for Q&T<br />

airbag vessels in late 2004, the Dalmine<br />

steelworks <strong>and</strong> small diameter tube<br />

hot-rolling plant have also gained PPAP<br />

(<strong>Product</strong>i<strong>on</strong> Part Approval Process)<br />

qualificati<strong>on</strong>.<br />

In line with the approach of knowledge<br />

sharing within the industrial system, hollows<br />

previously coming just from the<br />

Siderca facility, Argentina, to Italy for<br />

Q&T to be then shipped to the comp<strong>on</strong>ent<br />

center in Veracruz, Mexico, to form<br />

the air bag inflator, are now also being<br />

produced at the Dalmine mill.<br />

Eduardo Altschuler, resp<strong>on</strong>sible for product<br />

development for the automotive sector<br />

in Europe, explains why qualificati<strong>on</strong><br />

of all <strong>Tenaris</strong> facilities in Italy was necessary:<br />

“The airbag market is growing very<br />

rapidly in terms of annual volumes -<br />

more cars are being made, there are more<br />

airbags per car <strong>and</strong> <strong>Tenaris</strong>’s market share<br />

is increasing - so in order to keep pace we<br />

need to qualify different mills.<br />

<strong>Product</strong>i<strong>on</strong> started at <strong>Tenaris</strong>Dalmine in<br />

2005, with hollows coming out of the<br />

Siderca mill <strong>and</strong> the Veracruz Comp<strong>on</strong>ent<br />

Center producing about 800,000 airbag<br />

inflators annually.<br />

As a result, we’ve been able to increase<br />

producti<strong>on</strong> to keep pace with the market:<br />

the Costa Volpino facility, for instance,<br />

has increased its orders for air bag inflators<br />

four times in the last two years. In<br />

order to optimize logistics for this product<br />

it was critical to qualify the route with<br />

Dalmine steel.”<br />

In additi<strong>on</strong> to supplying Veracruz, the<br />

same product is now being supplied to<br />

an airbag manufacturer in Europe,<br />

although in relatively small quantities.<br />

This step does, however, indicate the<br />

efforts <strong>Tenaris</strong> is making to develop the<br />

European market to achieve a similar<br />

presence to the <strong>on</strong>e gained in Nafta.<br />

Additi<strong>on</strong>ally, projects are underway with<br />

all the main European airbag producers.<br />

The qualificati<strong>on</strong> process<br />

“It was a very interesting project<br />

because it involved several manufactur -<br />

ing facilities. – Altschuler c<strong>on</strong>tinues -<br />

The steel shop had to manufacture a<br />

particular steel for the first time, a SAE<br />

1510-modified steel type for airbags.<br />

Then the small diameter tube<br />

hot-rolling mill manufactured the mother<br />

tubes, the hollows, for Costa Volpino,<br />

which dem<strong>and</strong>ed, am<strong>on</strong>g other critical<br />

characteristics, a very good surface quality.”<br />

In fact the principal focus for this<br />

qualificati<strong>on</strong> centered <strong>on</strong> the small diameter<br />

tube hot-rolling plant.<br />

Trial planning <strong>and</strong> interfuncti<strong>on</strong>al teamwork<br />

between <strong>Product</strong>i<strong>on</strong>, Quality,<br />

Logistics, <strong>and</strong> <strong>Product</strong> departments were<br />

some of the keys to gaining PPAP<br />

approval.<br />

Renato Demarchi worked as Project<br />

Leader, helping to identify <strong>and</strong> keep<br />

critical process parameters under c<strong>on</strong>trol:<br />

“We had to make sure we were complying<br />

with the tough n<strong>on</strong>-destructive test<br />

requirements for this product, implementing<br />

very strict c<strong>on</strong>trols throughout,<br />

both <strong>on</strong> the hot rolled hollows <strong>and</strong> <strong>on</strong><br />

the cold drawing.” Demarchi’s activity<br />

was crucial, ensuring that Costa Volpino<br />

received a hollow ready for cold drawing<br />

that met all the critical requisites in terms<br />

of surface quality.<br />

The steel shop had to manufacture a<br />

particular steel for the first time,<br />

a SAE 15-10-modified for airbags.<br />

<strong>Tenaris</strong> News 5

Working under Pressure<br />

Chesterfield Special Cylinders Ltd <strong>and</strong> <strong>Tenaris</strong> join forces to supply air<br />

pressure vessels to the offshore industry.<br />

<strong>Tenaris</strong> has recently been awarded<br />

significant orders for semi-finished<br />

cylinders by Chesterfield Special<br />

Cylinders Ltd, the UK based specialist<br />

high-pressure cylinder manufacturer.<br />

Originally formed in 1897, Chesterfield<br />

has acquired over a century of knowhow<br />

applied to its design <strong>and</strong><br />

manufacture of high-pressure seamless<br />

steel gas cylinders <strong>and</strong> related services.<br />

Chesterfield Special Cylinders is the<br />

world’s largest supplier of APV’s (air<br />

pressure vessels) for floating offshore<br />

platforms <strong>and</strong> it is for this product line<br />

with cylinders up to 310 bar working<br />

pressure that the two companies have<br />

recently teamed up.<br />

The tubes destined for the offshore oildrilling<br />

sector will find an applicati<strong>on</strong> in<br />

drilling system moti<strong>on</strong> compensators.<br />

Surface drill string moti<strong>on</strong> compensators<br />

fitted to offshore rigs enable the drill<br />

string to be raised or lowered as the rig<br />

moves up <strong>and</strong> down, thereby maintaining<br />

6 <strong>Tenaris</strong> News<br />

a near c<strong>on</strong>stant weight <strong>on</strong> the bit. This is<br />

achieved by compressed fluid being fed<br />

from reservoir cylinders to cylinders<br />

which then operate pist<strong>on</strong>s. As the fluid<br />

pressure acts <strong>on</strong> the pist<strong>on</strong>s a proporti<strong>on</strong><br />

of the weight of the drill string is lifted,<br />

supporting as much of the string’s weight<br />

as necessary to maintain the desired<br />

weight <strong>on</strong> the bit. These surface moti<strong>on</strong><br />

compensators play a significant role in<br />

modern offshore marine drilling, allowing<br />

the weight <strong>on</strong> the bit to be varied when<br />

drilling through various types of<br />

formati<strong>on</strong>s, for example. Additi<strong>on</strong>al<br />

benefits include increasing service life <strong>and</strong><br />

penetrati<strong>on</strong>, <strong>and</strong> saving time that would<br />

otherwise need to be spent carrying out<br />

repairs or changing damaged bits.<br />

The tubes will be forged <strong>and</strong> heat-treated<br />

at the Dalmine mill before being shipped<br />

to Chesterfield Special Cylinders’<br />

Sheffield site for machining, hydrostatic<br />

<strong>and</strong> ultras<strong>on</strong>ic testing, final inspecti<strong>on</strong>,<br />

painting <strong>and</strong> fitting up into assemblies.<br />

This producti<strong>on</strong> route takes advantage of<br />

the most efficient processes in each<br />

<strong>Product</strong>i<strong>on</strong> route for the drilling system<br />

moti<strong>on</strong> compensator tubes takes<br />

advantage of <strong>Tenaris</strong>’s capabilities<br />

in forging <strong>and</strong> heat treating <strong>and</strong><br />

Chesterfield’s in finishing.<br />

company, i.e. <strong>Tenaris</strong> in forging <strong>and</strong><br />

heat treating <strong>and</strong> Chesterfield in<br />

finishing.<br />

Current <strong>and</strong> medium term prospects for<br />

this product are extremely buoyant due<br />

to the investment being channelled into<br />

oil explorati<strong>on</strong> <strong>and</strong> producti<strong>on</strong> by the<br />

major oil companies in their attempts to<br />

satisfy the world’s increasing dem<strong>and</strong><br />

for oil related products.<br />

With this in mind, <strong>Tenaris</strong> <strong>and</strong><br />

Chesterfield are working closely<br />

together to ensure c<strong>on</strong>tinuity of supply<br />

to satisfy Chesterfield’s exacting<br />

customers operating in this field.<br />

Chesterfield chose to work with <strong>Tenaris</strong><br />

<strong>on</strong> the basis of their quality of product,<br />

service, delivery performance <strong>on</strong> recent<br />

related c<strong>on</strong>tracts <strong>and</strong> price, <strong>and</strong> look<br />

forward to an <strong>on</strong>going <strong>and</strong> successful<br />

relati<strong>on</strong>ship in this <strong>and</strong> other market<br />

sectors.

The Tor<strong>on</strong>to Office: Strengthening<br />

a Firm Customer Base<br />

While the introducti<strong>on</strong> of new framework agreements looks set to<br />

improve established business, the Tor<strong>on</strong>to sales office sets its sights <strong>on</strong> a<br />

broader range of seamless tube opportunities.<br />

George Nogalo, Automotive Sales Manager<br />

for Canada.<br />

Set up in August 2003, the Tor<strong>on</strong>to Bay<br />

Street office has been able to strengthen<br />

its working relati<strong>on</strong>ship with automotive<br />

customers based in Canada <strong>and</strong> nearby<br />

US states. George Nogalo, Automotive<br />

Regi<strong>on</strong>al Sales Manager for the area,<br />

gives a snapshot of current automotive<br />

business <strong>and</strong> some pointers <strong>on</strong> the directi<strong>on</strong><br />

the office is taking in order to diversify<br />

its seamless product offering in the<br />

regi<strong>on</strong>.<br />

Improving automotive business<br />

Nogalo highlights the relati<strong>on</strong>ship with<br />

two established customers in particular<br />

to illustrate the activities of the Tor<strong>on</strong>to<br />

office: Dana Corporati<strong>on</strong>’s Commercial<br />

Vehicle Systems plant in Barrie, Ontario,<br />

with its sister plant in Lugoff, South<br />

Carolina, USA <strong>and</strong> IMT, with operati<strong>on</strong>s<br />

located two hours west of Tor<strong>on</strong>to. Both<br />

customers buy cut-to-length, Q&T<br />

tubes for axle applicati<strong>on</strong>s coming out of<br />

the AlgomaTubes plant in Sault Ste<br />

Marie. Both Dana <strong>and</strong> IMT supply to a<br />

global customer base <strong>and</strong> both have<br />

recently c<strong>on</strong>cluded framework agreements,<br />

which, by defining pricing, product,<br />

delivery, forecasting <strong>and</strong> releasing<br />

terms, are making already existing business<br />

better.<br />

Nogalo explains the thinking behind<br />

these framework agreements: “We’ve<br />

really knit together an agreement which<br />

will benefit the relati<strong>on</strong>ship, clarifying<br />

terms <strong>and</strong> c<strong>on</strong>diti<strong>on</strong>s to avoid misunderst<strong>and</strong>ings.”<br />

The agreement includes an<br />

annual forecast to help ensure steel is<br />

always in the supply chain <strong>and</strong> then a 24week<br />

rolling forecast, with early weeks<br />

firm <strong>and</strong> future weeks for planning,<br />

allowing for some flexibility. “The problem<br />

with the commercial vehicle sector is<br />

it really is ‘feast or famine’ – Nogalo<br />

c<strong>on</strong>tinues – <strong>and</strong> these spikes put a lot of<br />

heavy dem<strong>and</strong>s <strong>on</strong> our ability to supply,<br />

hence the forecasts are necessary to<br />

avoid outages.”<br />

Both Dana <strong>and</strong> IMT order seamless<br />

tubing to SAE 1527 Q&T specificati<strong>on</strong><br />

for its axle manufacture. <strong>Tenaris</strong> supplies<br />

not <strong>on</strong>ly the tube but also h<strong>and</strong>les<br />

the cutting operati<strong>on</strong>s. The advantages<br />

for them include proximity <strong>and</strong> the ‘<strong>on</strong>e<br />

stop’ JIT service, meaning a better supply<br />

chain <strong>and</strong> greater cost effectiveness.<br />

C<strong>on</strong>sequently the customer no l<strong>on</strong>ger<br />

needs to hold an inventory <strong>and</strong> can also<br />

deal directly with the AlgomaTubes mill<br />

when it comes to quality issues.<br />

Identifying fresh opportunities<br />

The Bay Street office is exploring openings<br />

for both strategic <strong>and</strong> n<strong>on</strong>-strategic<br />

seamless tube applicati<strong>on</strong>s in the<br />

Canadian market, involving other producti<strong>on</strong><br />

facilities within <strong>Tenaris</strong>.<br />

For example, whereas the billets for axle<br />

tubes may come from the <strong>Tenaris</strong>Siderca<br />

plant in Argentina (a 5,500 mile journey<br />

- hence the value of good forecasting),<br />

including tubular products coming out<br />

of the Arcore mill in Italy <strong>and</strong> the<br />

Romanian plant, <strong>Tenaris</strong>Silcotub, would<br />

mean a more diverse range, in terms of<br />

both size <strong>and</strong> the possibility to offer<br />

cold drawn <strong>and</strong> hot finished products.<br />

“We’re now focusing <strong>on</strong> products outside<br />

of axles, which would include ring<br />

gears, <strong>and</strong> also suitable applicati<strong>on</strong>s for<br />

tubes from Arcore or Silcotub, like spacer<br />

tubing for truck steering columns. –<br />

Nogalo c<strong>on</strong>cludes – We want to learn<br />

what seamless tube opportunities exist<br />

in the Canadian market, building <strong>on</strong><br />

what we have <strong>and</strong> trying to add to it.”<br />

<strong>Tenaris</strong> News 7

A Machinability Rating Indicator for<br />

Tubes for Mechanical Applicati<strong>on</strong>s<br />

Machinability, or useful tool life, is an important ec<strong>on</strong>omic factor in<br />

machine tool operati<strong>on</strong>s.<br />

Tool life, surface finishing, chip removal<br />

<strong>and</strong> cutting forces are the principal factors<br />

to take into c<strong>on</strong>siderati<strong>on</strong> when<br />

asking how machinable a material is.<br />

<str<strong>on</strong>g>Focus</str<strong>on</strong>g>ing specifically <strong>on</strong> tool life, determined<br />

by wear of the cutting edge, a<br />

Machinability C<strong>on</strong>trol Factor (MCF)<br />

has been developed by Emanuele<br />

Paravicini Bagliani, <strong>Product</strong> Engineer.<br />

It can be employed in order to quantify<br />

the advantages of modifying the producti<strong>on</strong><br />

cycle, all the way from steel<br />

making to heat-treating the tubular<br />

product.<br />

Factors affecting machinability<br />

Usually in regards to material machinability,<br />

engineers adopt the Taylor equati<strong>on</strong><br />

which describes the link between tool life<br />

(L) <strong>and</strong> cutting speed (U): U · L α = C,<br />

α <strong>and</strong> C being two parameters which are<br />

experimentally determined. In order to do<br />

that, Taylor tests were c<strong>on</strong>ducted at several<br />

laboratories: I.V.F. (Institutet for<br />

8 <strong>Tenaris</strong> News<br />

Verkstadstenkniks Forskning, Sweden),<br />

C.S.M. (Centro Sviluppo Materiali, Rome,<br />

Italy), CNR – ISTEC (Turin, Italy).<br />

Several steels with different microstructures<br />

<strong>and</strong> chemical compositi<strong>on</strong> were c<strong>on</strong>sidered.<br />

In practice the optimal cutting speed<br />

is a balance between minimizing working<br />

time, idle time to change the insert <strong>and</strong> its<br />

relative cost.<br />

To evaluate the impact of machinability <strong>on</strong><br />

producti<strong>on</strong> costs it is necessary to forecast<br />

the life of the insert in set cutting scenarios.<br />

Machinability as defined by the life of<br />

the insert depends <strong>on</strong> the microstructure,<br />

Knowing the chemical characteristics,<br />

microinclusi<strong>on</strong>s<br />

<strong>and</strong> microstructure of the<br />

steel enabled the MCF to be<br />

built.<br />

<strong>Tenaris</strong> has Developed a<br />

Machinability C<strong>on</strong>trol Factor to<br />

Forecast the Machinability of Steel.<br />

chemical compositi<strong>on</strong>, presence <strong>and</strong> distributi<strong>on</strong><br />

of sec<strong>on</strong>dary phase particles<br />

<strong>and</strong> mechanical properties of the steel<br />

being machined.<br />

Development of the MCF index<br />

To build an accurate forecasting model<br />

detailed microstructural <strong>and</strong> microinclusi<strong>on</strong>al<br />

measurements would have to<br />

be taken to build a correlati<strong>on</strong> between<br />

producti<strong>on</strong> procedures <strong>and</strong> machinability.<br />

On the other h<strong>and</strong>, a simple indicator<br />

(MCF) using measurements easy to<br />

obtain can be used to forecast material<br />

machinability with sufficient accuracy<br />

based <strong>on</strong> the following parameters:

RELATIONSHIP BETWEEN MCF AND U10<br />

U10 (m/min)<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

100<br />

FIGURE 1<br />

150 200 250 300 350<br />

MCF<br />

400 450 500 550<br />

.<br />

.<br />

.<br />

Hardness<br />

Carb<strong>on</strong> c<strong>on</strong>tent<br />

Sulfur c<strong>on</strong>tent<br />

Ca/Al ratio<br />

With these four parameters, it’s possible<br />

to evaluate the microstructure <strong>and</strong> the<br />

presence of carbides as well as the types<br />

of inclusi<strong>on</strong>s.<br />

Tests were carried out <strong>on</strong> seamless tubes<br />

for mechanical applicati<strong>on</strong>s in a range<br />

of dimensi<strong>on</strong>s in carb<strong>on</strong> <strong>and</strong> micro<br />

alloyed steel, completely killed <strong>and</strong> with<br />

a minimum guaranteed aluminum c<strong>on</strong>tent,<br />

tested ‘as rolled’, normalized <strong>and</strong><br />

quenched <strong>and</strong> tempered.<br />

In developing an index the cutting speed<br />

was set as corresp<strong>on</strong>ding to a cutting<br />

edge life of 10-minutes (U10). The c<strong>on</strong>diti<strong>on</strong>s<br />

adopted are summarized in the<br />

table below. The objectives of the tests<br />

carried out were to determine:<br />

The material parameters (C, α) that link<br />

tool life (L) with cutting speed (U), as<br />

described in the Taylor equati<strong>on</strong> menti<strong>on</strong>ed<br />

earlier.<br />

A machinability index, also said the cutting<br />

speed which corresp<strong>on</strong>ded to a tool<br />

life of 10 minutes (U10).<br />

Obtaining the chemical characteristics,<br />

microinclusi<strong>on</strong>s <strong>and</strong> microstructure of<br />

MAIN FEATURES<br />

Reference st<strong>and</strong>ard UNI ISO 3685:1981<br />

End of life criteria Maximum flank wear: VB=0.30 mm<br />

Maximum crater wear KT=0.18 mm<br />

Cutting operati<strong>on</strong> dry turning<br />

Cutting insert Coromant CNMG 120408-PM 4015<br />

Rake angle k=75°<br />

Cutting Depth 2.5 mm<br />

Feed 0.4 mm/rev<br />

100° corner, clearance angle: -6°<br />

the steel enabled the MCF to be built.<br />

The relati<strong>on</strong>ship between the MCF <strong>and</strong><br />

a cutting speed equal to a tool life of 10<br />

minutes (U10) is illustrated in figure 1.<br />

As it can be observed the MCF represents<br />

a good machinability index.<br />

C<strong>on</strong>clusi<strong>on</strong>s<br />

With simple, easy to obtain measurements<br />

it is possible to gain good tool life<br />

predicti<strong>on</strong> for the cutting c<strong>on</strong>diti<strong>on</strong>s used<br />

in the test <strong>and</strong> quantify the effects of the<br />

factors analyzed here. Carb<strong>on</strong> c<strong>on</strong>tent<br />

<strong>and</strong> hardness can hardly be used to c<strong>on</strong>trol<br />

machinability because they are generally<br />

fixed by customer specificati<strong>on</strong>s, but<br />

underst<strong>and</strong>ing their effects can be important<br />

when planning the producti<strong>on</strong> cycle<br />

for a comp<strong>on</strong>ent, adding for example a<br />

heat treatment to change the hardness.<br />

On the other h<strong>and</strong>, sulfur c<strong>on</strong>tent <strong>and</strong> the<br />

Ca/Al ratio can c<strong>on</strong>tribute to up to a 60-<br />

70 m/min improvement in the (U10) value<br />

for a comm<strong>on</strong> steel for mechanical applicati<strong>on</strong>s<br />

like 20MV6, which means<br />

improving the machinability index by as<br />

much as 10-15%.<br />

Based <strong>on</strong> experimental results c<strong>on</strong>ducted<br />

to answer the need for a product with<br />

superior characteristics in hydraulic cylinder,<br />

roller, bushing, c<strong>on</strong>nector <strong>and</strong> gear<br />

applicati<strong>on</strong>s, <strong>Tenaris</strong> has developed special<br />

seamless tubes with high machinability<br />

(HL) <strong>and</strong> close tolerances for mechanical<br />

applicati<strong>on</strong>s: TAM ® plus.<br />

<strong>Tenaris</strong> News 9

Taking Part in Turin 2006<br />

Winter Olympic Games<br />

<strong>Tenaris</strong> provided structural tubes to support the internal structure<br />

of the roof of the Turin “Oval”, <strong>on</strong>e of the competiti<strong>on</strong> facilities of<br />

the XX Winter Olympic Games hosted last February in Italy.<br />

<strong>Tenaris</strong> provided about 900 t<strong>on</strong>s of S355 J2H normalized<br />

carb<strong>on</strong> steel pipes in circular hollow secti<strong>on</strong>s to<br />

Costruzi<strong>on</strong>i Cimolai, the Italian company in charge of the<br />

c<strong>on</strong>structi<strong>on</strong> of the steel parts of the Turin “Oval” building,<br />

the indoor sports stadium that hosted the speed skating<br />

competiti<strong>on</strong>s during the last Winter Olympic Games.<br />

The building was designed by Hok Sport of L<strong>on</strong>d<strong>on</strong> <strong>and</strong><br />

the Zoppini Studio of Milan, two architectural studios<br />

specializing in sports buildings. The former followed the<br />

adaptati<strong>on</strong> of the Millennium Dome, Greenwich, L<strong>on</strong>d<strong>on</strong>,<br />

from civil building into a sports centre <strong>and</strong> the stadiums of<br />

Sydney <strong>and</strong> Wembley; the latter designed the Olympic<br />

swimming pool in Rijeka, Croatia, the Ryad stadium <strong>and</strong><br />

the Sciorba sports centre in Genoa.<br />

The “Oval” is composed of a main hall with a covered area<br />

of about 25,000 m 2 where the 400 m oval ice skating track<br />

is located; entrances with related services <strong>on</strong> the east side,<br />

service areas <strong>on</strong> the west side, <strong>and</strong> two large façades next<br />

to the south <strong>and</strong> north sides. The “Oval” can accommodate<br />

over 8,000 spectators <strong>and</strong>, after the Olympic event, it<br />

10 <strong>Tenaris</strong> News<br />

Even though the covered area of the stadium<br />

has a remarkable extensi<strong>on</strong> <strong>and</strong> is subject to<br />

high loads, the impact of the roof structure<br />

is extremely light.<br />

The same S355 J2H steel was employed in<br />

the tubes for the roof of the Olympic Stadium<br />

“Spyros Louis” which hosted the last 2004<br />

Olympic Games (photo <strong>on</strong> the right).<br />

became part of the largest exhibiti<strong>on</strong> structure in Turin<br />

located in the old Fiat factory of Lingotto.<br />

“Our pipes were used for the c<strong>on</strong>structi<strong>on</strong> of the structure<br />

with bow-string truss for the roof ”, explained Aless<strong>and</strong>ro<br />

Giacobbe, <strong>Tenaris</strong>Dalmine <strong>Product</strong> Manager for structural<br />

pipes, “The Oval project included a suspended roof structure<br />

with no intermediate supports to create a single open<br />

space: a massive yet light structure. In fact, even though<br />

the covered area of the stadium has a remarkable extensi<strong>on</strong><br />

(136x216 m) <strong>and</strong> is subject to high loads, the impact<br />

of the roof structure is extremely light”.<br />

“In accordance with the c<strong>on</strong>structi<strong>on</strong> company’s requests<br />

we customized our offer providing tubes in different<br />

lengths, ranging from 7,100 to 12,800 mm, <strong>and</strong> diameters,<br />

from 6 to 24 inches”, c<strong>on</strong>cluded Giacobbe, “from the time<br />

we received the order, we put it into producti<strong>on</strong> <strong>and</strong> delivered<br />

all the pipes in just two m<strong>on</strong>ths, allowing our client to<br />

comply with the tight c<strong>on</strong>structi<strong>on</strong> schedule given by the<br />

organizing committee of the Olympic Games.”

Photo courtesy of Costruzi<strong>on</strong>i Cimolai

www.tenaris.com<br />

ARGENTINA<br />

Buenos Aires<br />

Adrian Fila<br />

afila@tenaris.com<br />

(54) 3489 435332 tel<br />

(54) 3489 435366 fax<br />

BOLIVIA<br />

Santa Cruz de la Sierra<br />

Richard Mariaca<br />

rmariaca@tenaris.com<br />

(591) 3 312 0603 tel<br />

(591) 3 312 0602 fax<br />

BRAZIL<br />

Sao Paulo<br />

Germano Fehr<br />

gfehr@c<strong>on</strong>fab.com.br<br />

(55) 12 244 9400 tel<br />

(55) 12 244 9003 fax<br />

CANADA<br />

Tor<strong>on</strong>to<br />

George Nogalo<br />

gnogalo@tenaris.com<br />

(416) 216 4617 tel<br />

(416) 214 2043 fax<br />

CASPIAN SEA<br />

Aktau<br />

Derek Smith<br />

dsmith@tenaris.com<br />

(994) 12 921411 tel<br />

(994) 12 971023 fax<br />

CHINA<br />

Beijing<br />

David Crooks<br />

dcrooks@tenaris.com<br />

(86) 10 6437 6744 tel<br />

(86) 10 6437 6746 fax<br />

COLOMBIA<br />

Bogotá<br />

Gast<strong>on</strong> Mengelle<br />

gmengelle@tenaris.com<br />

(57) 1 636 2920 tel<br />

(57) 1 623 4780 fax<br />

ECUADOR<br />

Quito<br />

Marcelo G<strong>on</strong>zalez P<strong>on</strong>dal<br />

mg<strong>on</strong>zalezp<strong>on</strong>dal@tenaris.com<br />

(593) 2 298 6240 tel<br />

(593) 2 298 6250 fax<br />

FRANCE<br />

Paris<br />

Gregoire Flipo<br />

gflipo@tenaris.com<br />

(33) 1 4757 1212 tel<br />

(33) 1 4757 1081 fax<br />

GERMANY<br />

München<br />

Marc Rennings<br />

mrennings@tenaris.com<br />

(49) 0 89 5908 2111 tel<br />

(39) 035 378 097 fax<br />

ITALY<br />

Dalmine<br />

Caterina Epis<br />

ceois@tenaris.com<br />

(39) 035 560 3505 tel<br />

(39) 035 560 2454 fax<br />

JAPAN<br />

Kawasaki<br />

Marcelo Ramos<br />

mramos@tenaris.com<br />

(81) 44 328 3400 tel<br />

(81) 44 328 3456 fax<br />

KOREA<br />

Seoul<br />

Le<strong>and</strong>ro Ramos<br />

lramos@tenaris.com<br />

(82) 2 798 3385 tel<br />

(82) 2 798 3392 fax<br />

MEXICO<br />

Veracruz<br />

Ricardo Baez<br />

rbaez@tenaris.com<br />

(52) 229 989 1911 tel<br />

(52) 229 989 404 fax<br />

NETHERLANDS<br />

Rotterdam<br />

Frans Reijkersz<br />

freijkersz@dalmine.it<br />

(31) 651 359 914 tel<br />

(39) 035 378 095 fax<br />

NIGERIA<br />

Port Harcourt<br />

Jorge Mayer<br />

jmayer@tenaris.com<br />

(234) 84 610299 tel<br />

(234) 84 611859 fax<br />

NORWAY<br />

Stavanger<br />

Arnt Oxaas<br />

aoxaas@tenaris.com<br />

(47) 51 44 3440 tel<br />

(47) 51 44 3441 fax<br />

ROMANIA<br />

Zalau<br />

Laurentiu Paval<br />

laurentiu.paval@silcotub.ro<br />

(40) 745 107 093 tel<br />

(40) 260 610 743 fax<br />

RUSSIA<br />

Moscow<br />

Alex K<strong>on</strong>drashov<br />

ak<strong>on</strong>drashov@tenaris.com<br />

(7) 095 502 1630 tel<br />

(7) 095 937 6781 fax<br />

SINGAPORE<br />

Singapore<br />

Sia So<strong>on</strong> Tee<br />

stsia@tenaris.com<br />

(65) 6395 9000 tel<br />

(65) 6 222 4090 fax<br />

UAE<br />

Dubai<br />

Ricardo Capria<br />

rcapria@tenaris.com<br />

(971) 4 2725 394 tel<br />

(971) 4 2725 392 fax<br />

UK<br />

Coseley<br />

Carlo Alberto De Stefanis<br />

cdestefanis@tenaris.com<br />

(44) 1902 665288<br />

(44) 1902 665263<br />

USA<br />

Houst<strong>on</strong><br />

Fabio Gomez<br />

fgomez@tenaris.com<br />

(1) 713 767 4484 tel<br />

(1) 713 336 7610 fax<br />

VENEZUELA<br />

Caracas<br />

Jorge Samitier<br />

jsamitier@tenaris.com<br />

(58) 212 902 3969 tel<br />

(58) 212 902 3937 fax