Focus on Best Practice and Customized Product ... - Tenaris

Focus on Best Practice and Customized Product ... - Tenaris

Focus on Best Practice and Customized Product ... - Tenaris

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

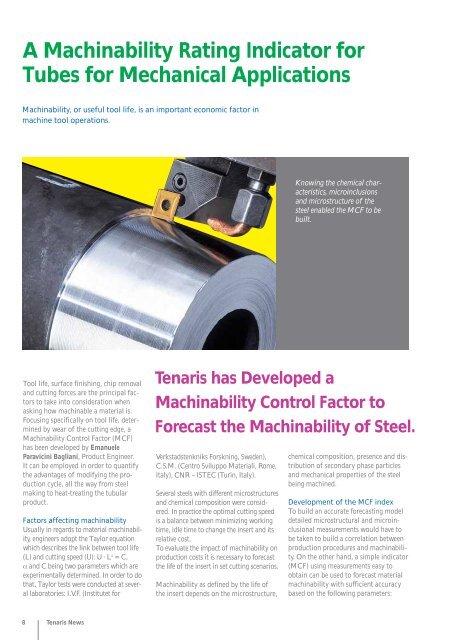

A Machinability Rating Indicator for<br />

Tubes for Mechanical Applicati<strong>on</strong>s<br />

Machinability, or useful tool life, is an important ec<strong>on</strong>omic factor in<br />

machine tool operati<strong>on</strong>s.<br />

Tool life, surface finishing, chip removal<br />

<strong>and</strong> cutting forces are the principal factors<br />

to take into c<strong>on</strong>siderati<strong>on</strong> when<br />

asking how machinable a material is.<br />

<str<strong>on</strong>g>Focus</str<strong>on</strong>g>ing specifically <strong>on</strong> tool life, determined<br />

by wear of the cutting edge, a<br />

Machinability C<strong>on</strong>trol Factor (MCF)<br />

has been developed by Emanuele<br />

Paravicini Bagliani, <strong>Product</strong> Engineer.<br />

It can be employed in order to quantify<br />

the advantages of modifying the producti<strong>on</strong><br />

cycle, all the way from steel<br />

making to heat-treating the tubular<br />

product.<br />

Factors affecting machinability<br />

Usually in regards to material machinability,<br />

engineers adopt the Taylor equati<strong>on</strong><br />

which describes the link between tool life<br />

(L) <strong>and</strong> cutting speed (U): U · L α = C,<br />

α <strong>and</strong> C being two parameters which are<br />

experimentally determined. In order to do<br />

that, Taylor tests were c<strong>on</strong>ducted at several<br />

laboratories: I.V.F. (Institutet for<br />

8 <strong>Tenaris</strong> News<br />

Verkstadstenkniks Forskning, Sweden),<br />

C.S.M. (Centro Sviluppo Materiali, Rome,<br />

Italy), CNR – ISTEC (Turin, Italy).<br />

Several steels with different microstructures<br />

<strong>and</strong> chemical compositi<strong>on</strong> were c<strong>on</strong>sidered.<br />

In practice the optimal cutting speed<br />

is a balance between minimizing working<br />

time, idle time to change the insert <strong>and</strong> its<br />

relative cost.<br />

To evaluate the impact of machinability <strong>on</strong><br />

producti<strong>on</strong> costs it is necessary to forecast<br />

the life of the insert in set cutting scenarios.<br />

Machinability as defined by the life of<br />

the insert depends <strong>on</strong> the microstructure,<br />

Knowing the chemical characteristics,<br />

microinclusi<strong>on</strong>s<br />

<strong>and</strong> microstructure of the<br />

steel enabled the MCF to be<br />

built.<br />

<strong>Tenaris</strong> has Developed a<br />

Machinability C<strong>on</strong>trol Factor to<br />

Forecast the Machinability of Steel.<br />

chemical compositi<strong>on</strong>, presence <strong>and</strong> distributi<strong>on</strong><br />

of sec<strong>on</strong>dary phase particles<br />

<strong>and</strong> mechanical properties of the steel<br />

being machined.<br />

Development of the MCF index<br />

To build an accurate forecasting model<br />

detailed microstructural <strong>and</strong> microinclusi<strong>on</strong>al<br />

measurements would have to<br />

be taken to build a correlati<strong>on</strong> between<br />

producti<strong>on</strong> procedures <strong>and</strong> machinability.<br />

On the other h<strong>and</strong>, a simple indicator<br />

(MCF) using measurements easy to<br />

obtain can be used to forecast material<br />

machinability with sufficient accuracy<br />

based <strong>on</strong> the following parameters: