15,000 PRODUCTS IN STOCK - Ptreview

15,000 PRODUCTS IN STOCK - Ptreview

15,000 PRODUCTS IN STOCK - Ptreview

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

&<br />

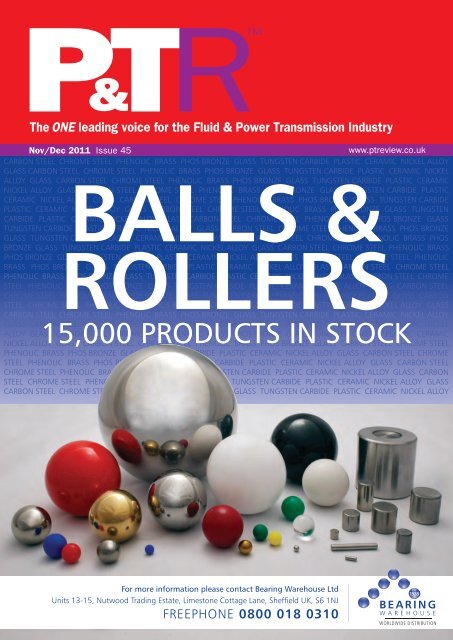

The ONE leading voice for the Fluid & Power Transmission Industry<br />

Nov/Dec 2011 Issue 45<br />

www.ptreview.co.uk<br />

CARBON STEEL CHROME STEEL PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY<br />

GLASS CARBON STEEL CHROME STEEL PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL<br />

ALLOY GLASS CARBON<br />

BALLS<br />

STEEL CHROME STEEL PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN<br />

&<br />

CARBIDE PLASTIC CERAMIC<br />

NICKEL ALLOY GLASS CARBON STEEL CHROME STEEL PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC<br />

CERAMIC NICKEL ALLOY GLASS CARBON STEEL CHROME STEEL PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE<br />

PLASTIC CERAMIC NICKEL ALLOY GLASS CARBON STEEL CHROME STEEL PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN<br />

CARBIDE PLASTIC CERAMIC NICKEL ALLOY GLASS CARBON STEEL CHROME STEEL PHENOLIC BRASS PHOS BRONZE GLASS<br />

TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY GLASS CARBON STEEL CHROME STEEL PHENOLIC BRASS PHOS BRONZE<br />

GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY GLASS CARBON STEEL CHROME STEEL PHENOLIC BRASS PHOS<br />

BRONZE GLASS<br />

ROLLERS<br />

TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY GLASS CARBON STEEL CHROME STEEL PHENOLIC BRASS<br />

PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY GLASS CARBON STEEL CHROME STEEL PHENOLIC<br />

BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY GLASS CARBON STEEL CHROME STEEL<br />

PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY GLASS CARBON STEEL CHROME<br />

STEEL PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY GLASS CARBON STEEL<br />

CHROME STEEL PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY GLASS CARBON<br />

STEEL CHROME STEEL PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY GLASS<br />

CARBON STEEL CHROME STEEL PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY<br />

GLASS CARBON<br />

<strong>15</strong>,<strong>000</strong><br />

STEEL CHROME STEEL<br />

<strong>PRODUCTS</strong><br />

PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN<br />

<strong>IN</strong><br />

CARBIDE<br />

<strong>STOCK</strong><br />

PLASTIC CERAMIC NICKEL<br />

ALLOY GLASS CARBON STEEL CHROME STEEL PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC<br />

NICKEL ALLOY GLASS CARBON STEEL CHROME STEEL PHENOLIC BRASS PHOS BRONZE GLASS CARBON STEEL CHROME STEEL<br />

PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY GLASS CARBON STEEL CHROME<br />

STEEL PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY GLASS CARBON STEEL<br />

CHROME STEEL PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY GLASS CARBON<br />

STEEL CHROME STEEL PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY GLASS<br />

CARBON STEEL CHROME STEEL PHENOLIC BRASS PHOS BRONZE GLASS TUNGSTEN CARBIDE PLASTIC CERAMIC NICKEL ALLOY<br />

For more information please contact Bearing Warehouse Ltd<br />

Units 13-<strong>15</strong>, Nutwood Trading Estate, Limestone Cottage Lane, Sheffield UK, S6 1NJ<br />

FREEPHONE 0800 018 0310<br />

EST<br />

1988<br />

B E A R I N G<br />

W A R E H O U S E<br />

WORLDWIDE DISTRIBUTION

Wishing you all a<br />

Happy Christmas<br />

and a prosperous<br />

New Year<br />

Transmission Developments Co. (GB) Ltd<br />

Dawkins Road, Hamworthy, Poole, Dorset, BH<strong>15</strong> 4HF<br />

Tel: +44 (0)1202 675555 Fax: +44 (0)1202 677466 Email: sales@transdev.co.uk<br />

www.transdev.co.uk

Nov/Dec 2011 P&TR 3<br />

This month from the editor<br />

Dear Readers/Advertisers,<br />

Getting 2011 all wrapped up for Christmas<br />

With the festive season just around the corner and 2012 not far behind, I’ve been<br />

reflecting on what a year it’s been for the Power Transmission Review team.<br />

Not only have we successfully launched our new, comprehensive and fully interactive<br />

website but we’ve received incredible feedback on it from the industry, too. So if you<br />

haven’t visited yet, please do take a look at www.ptreview.co.uk.<br />

You’ll see our website gives you all the industry latest, from features, profiles and<br />

products to events and recruitment. Plus you can sign up for our FREE newsletter and<br />

have it delivered directly to your inbox.<br />

New Year, new magazine<br />

Incredibly, PTR has been going from strength to strength for over seven years. Since our<br />

launch in early 2004 we’ve become the leading publication in the UK power transmission<br />

distributor industry.<br />

But 2012 promises to be our most exciting year since 2004. Why Because we’re<br />

planning to amalgamate PTR with its popular sister publication dedicated to the fluid and<br />

hydraulic power industry, FPR.<br />

We believe our new ‘integrated’ magazine will be ‘The ONE leading voice for the Fluid,<br />

Power & Transmission Industry.’ And we hope upon reading it you will think so as well.<br />

Together, our new website and our new magazine offer you unbeatable news, information<br />

and, of course, opportunities to promote a business, its products and services - whether<br />

you’re an advertiser, advertising agency or PR consultancy.<br />

On that positive note, we do welcome your feedback, comments, views and news so<br />

please feel free to e-mail me, The Editor - tony@internalaffairs.co.uk or call me on<br />

01202 3<strong>000</strong>33.<br />

News<br />

Transmission Developments<br />

signs a UK distribution<br />

agreement. p8<br />

Renold’s highly wear resistant<br />

chain, Synergy, is still the<br />

longest lasting solution. p14<br />

Products<br />

Bearing isolator and grounding<br />

ring combination provides<br />

electrical protection for motor<br />

bearings. p18<br />

The overrunning alternator<br />

pulley. p20<br />

p22<br />

p14<br />

I would like to take this opportunity to wish you all a very merry Christmas and a happy,<br />

peaceful and successful New Year.<br />

Tony Letts<br />

Managing Editor<br />

A detailed resource brochure<br />

entitled ‘Linear Actuators for<br />

On/Off Highway Vehicles’<br />

available from Heason<br />

Technology. p22<br />

The ‘mia’ electric car,<br />

incorporates a Leroy-Somer<br />

motor. p26<br />

Compact precision stage range<br />

benefits from advanced bearing<br />

and ballscrew technologies.<br />

p28<br />

All articles are checked for accuracy. However,<br />

PTR cannot legally accept any responsibility<br />

for any misrepresentation that may occur on<br />

factual feature, or errors that may occur by<br />

misprint. Whilst every effort is made to ensure<br />

the accuracy and authenticity of advertisements<br />

appearing. PTR does not accept any<br />

responsibility for claims made by advertisers. PTR<br />

cannot be held responsible for advertisements<br />

reproduced from poor quality artwork.<br />

All rights reserved. No part of this publication<br />

may be reproduced or transmitted in any form or<br />

by any means, electronic or mechanical including<br />

photocopying, recording or any<br />

information storage or retrieval system without<br />

the express prior written consent<br />

of the publisher.<br />

Additional copies may be requested at a<br />

nominal charge.<br />

22 Leydene Avenue, Bournemouth,<br />

Dorset BH8 9JG United Kingdom.<br />

Tel: +44 (0) 1202 3<strong>000</strong>33<br />

Fax:+44(0) 1202 399998<br />

E-mail: tony@internalaffairs.co.uk<br />

www.internalaffairs.co.uk<br />

Latest generation Motion<br />

Coordinator controllers aimed<br />

at 2-servo/3-stepper and<br />

4-servo/5-stepper applications.<br />

p28<br />

Schmidt thoroughbreds join the<br />

stable. p29

4 P&TR Nov/Dec 2011<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

P&TR News<br />

Control Techniques appoint new<br />

Regional Director for UK and Ireland<br />

Shaun Prinsloo has been appointed<br />

to the key management position of<br />

Regional Director, UK and Ireland,<br />

managing the Control Techniques<br />

Drive Centres in both countries.<br />

Shaun has relocated to the UK<br />

from South Africa and started in his<br />

new role on 1st October, reporting<br />

directly to Phil Sewell, Executive Vice<br />

President, Sales and Marketing.<br />

Hillhead 2012<br />

Stand spaces filling up quickly!<br />

WITH almost nine months to<br />

go, 91% of the stand space at<br />

Hillhead 2012 has already been<br />

allocated to exhibitors, including<br />

major players such as Volvo,<br />

Sandvik, Metso, Terex Group,<br />

Finning/Caterpillar, Liebherr and<br />

Bell Equipment.<br />

Event director Jack Berridge<br />

said demand for space over the<br />

summer had been very buoyant<br />

and the site plan had filled up<br />

very quickly. “At the present time<br />

the exhibitor list stands at 248<br />

companies who have confirmed<br />

their requirements, while a<br />

number of other stands have been<br />

reserved pending sign-off,” he<br />

commented.<br />

In the 2012 Olympic year, the<br />

show dates have been brought<br />

forward by one week to 19–21<br />

June. Details of remaining stand<br />

space availability can be obtained<br />

from Penny Lewin, operations<br />

manager, on tel: +44 (0)1<strong>15</strong> 945<br />

3890; or by email: penny.lewin@<br />

qmj.co.uk<br />

Born in South Africa, Shaun<br />

completed his electrical engineering<br />

degree at Durban University before<br />

moving into sales of electrical<br />

equipment and components. He has<br />

some <strong>15</strong> years experience in the<br />

drives industry having worked as<br />

a Sales Director, a Sales Manager<br />

and, most recently, as a Business<br />

Development Manager responsible<br />

for developing the reseller and end<br />

user business.<br />

His experience encompasses<br />

the steel, mining, water and<br />

HVAC/R industries and includes<br />

OEM projects, servo systems and<br />

upgrades of drive systems.<br />

Shaun’s brief is to significantly grow<br />

Control Techniques’ market share<br />

in the UK and Ireland, developing<br />

relationships with OEM companies<br />

and end users alike.<br />

For reader enquiries, please<br />

mention PTR:<br />

Control Techniques,<br />

Unit 79 Mochdre Industrial Estate,<br />

Newtown, SY16 4LE,<br />

Tel: +44 (0) 1686 612<strong>000</strong>,<br />

Fax: +44 (0) 1686 612999<br />

Email: controltechniques@emerson.com<br />

www.controltechniques.com

Pennine Pneumatic Services<br />

celebrates 20th anniversary<br />

Pennine Pneumatic Services,<br />

an Atlas Copco Compressors’<br />

Premier Distributor in West<br />

Yorkshire, is celebrating its<br />

20th year in the compressed air<br />

business. Founders and joint<br />

directors, Gary Whitaker and<br />

Leighton Harris, attribute the<br />

company’s commercial success<br />

to its ability to offer cost effective<br />

and energy efficient solutions,<br />

setting a clear strategy with<br />

market leading suppliers to<br />

ensure long term support for<br />

businesses in the region.<br />

Pennine Pneumatic Services<br />

(PPS) has been an authorised<br />

Atlas Copco Compressors<br />

distributor for 20 years. From<br />

its Halifax site, the company<br />

offers complete compressed<br />

air solutions specialising in the<br />

design, supply, installation and<br />

after sales service of industrial<br />

and automotive compressed<br />

air systems. It provides a<br />

full range of ancillary and air<br />

related products, in-line filters,<br />

compressed air dryers, oil<br />

condensate removal systems<br />

and pipe work installations. PPS<br />

also has a dedicated energy audit<br />

department to carry out full site<br />

air audits and leak surveys using<br />

the latest Atlas Copco iiTrak<br />

loggers to provide a reliable and<br />

cost-effective energy efficient<br />

compressed air package.<br />

In fact, the two directors believe<br />

the ever-increasing cost of<br />

electrical energy has had a<br />

profound influence on the way<br />

compressed air business is<br />

conducted today. As Leighton<br />

Harris comments: “These days<br />

it is reasonable to expect any<br />

professional organisation to<br />

offer the most cost effective<br />

and energy efficient solution. In<br />

partnership with Atlas Copco,<br />

Pennine applied this policy many<br />

years ago and it is this approach<br />

which we believe has set us apart<br />

from our competitors, leading to<br />

the success we enjoy today”.<br />

For reader enquiries, please<br />

mention PTR:<br />

Atlas Copco Ltd,<br />

Swallowdale Lane,<br />

Hemel Hempstead,<br />

Herts,<br />

HP2 7EA<br />

Tel: +44 (0) 1442 261201<br />

Fax: +44 (0) 1442 234791<br />

www.atlascopo.co.uk<br />

PIX awarded coveted<br />

DNV-MED certification<br />

PIX hydraulic hose & end-fittings<br />

have been awarded the prestigious<br />

DNV (Det Norske Veritas) MED<br />

(Marine Equipment Directive) Type<br />

Approval. This recognition is in<br />

addition to the DNV certification<br />

that was previously conferred upon<br />

the company in 2008.<br />

The MED Type Approval is an<br />

unbiased third-party certification<br />

attesting to a product’s adherence<br />

to specific standards or<br />

specifications, and verification of<br />

an appropriate production quality<br />

system. This approval is strongly<br />

recommended for products used<br />

in high performance industries,<br />

in particular, marine, mining and<br />

offshore, endorsing their quality<br />

and safety.<br />

Following receipt of the<br />

certification, Operations Director<br />

for UK based PIX Hydraulics,<br />

Karan Sethi said: “In this day<br />

and age of ever increasing quality<br />

expectations from our customers,<br />

the DNV MED will serve as our<br />

competitive edge. As a company,<br />

we have made a conscious<br />

effort to be at the forefront<br />

of continuous improvement in<br />

our manufacturing standards,<br />

quality, and processes; and this<br />

approval confirms that we are<br />

heading in the right direction.<br />

This is a fantastic feat and we<br />

are absolutely thrilled to join an<br />

elite league of DNV MED approved<br />

manufacturers.”<br />

For reader enquiries, please<br />

mention PTR:<br />

PIX Hydraulics (Europe) Ltd,<br />

Unit 24 Farthing Road,<br />

Industrial Estate,<br />

Sproughton,<br />

Ipswich,<br />

Suffolk IP1 5AP,<br />

Tel: +44 (0) 1473 744612<br />

Fax: +44 (0) 1473 744613<br />

Email: mdeal@pixeuro.com<br />

www.pixhydraulics.com<br />

Nov/Dec 2011 P&TR 5<br />

ContiTech at MDA India: Innovations<br />

for machine and plant engineering<br />

Technology company ContiTech presents solutions for drive<br />

technology and air actuators • Environmentally-friendly<br />

belts for industrial applications • Production sites in India<br />

Environmentally-friendly drive belts<br />

and air actuators that are resistant<br />

to harsh environmental conditions<br />

are the highlights presented<br />

by ContiTech (hall 1 DL, booth<br />

422) at MDA India in Banga-lore.<br />

From December 6 to 9, 2011,<br />

the technology company from<br />

Hanover, Germany, displayed its<br />

rubber and plastic products at the<br />

leading trade fair in India for drive<br />

technology and automation. India is<br />

one of ContiTech’s most important<br />

markets, and is also equally<br />

interesting as a production location<br />

and sales market. The company<br />

has increased its commitment in<br />

the market over the past several<br />

years and will continue to expand its<br />

presence there significantly.<br />

Drive belts for<br />

environmental protection<br />

With the BlueConcept family of drive<br />

belts, ContiTech has taken on a<br />

trail-blazing role in environ-mentallyfriendly<br />

and health-friendly industrial<br />

applications. At MDA India, the<br />

company is showing the CONTI-V®<br />

PIONEER wrapped V-belt, which is<br />

composed mainly of renewable raw<br />

materials, and, although it is made<br />

without carbon black, it is electrically<br />

conductive. In addition, the carbon<br />

black and allergen-free timing belt,<br />

CONTI® SYNCHROBELT PIONEER,<br />

will be on display. It is the ideal<br />

solution for drive applications that<br />

people come into contact with.<br />

From its complete range of drive<br />

belts for machine and plant<br />

engineering, ContiTech is also<br />

pre-senting its high-performance<br />

timing belts and flat belts made of<br />

polyurethane, rubber timing belts<br />

as well as wrapped V-belts and raw<br />

edge heavy-duty V-belts.<br />

Air actuators with an<br />

impressively long-life design<br />

Also on display are air actuators<br />

for pneumatic tasks in machine,<br />

apparatus and plant engineer-ing.<br />

Air actuators are used in many<br />

industries when a lot of force has<br />

to be produced with pneumat-ics,<br />

but little space is left for installation<br />

and especially difficult environmental<br />

conditions are preva-lent.The<br />

long-life design of ContiTech air<br />

actuators is a convincing factor in<br />

applications involving heavy deposits<br />

and contamination – such as in the<br />

With their long-life design, air actuators<br />

from ContiTech for pneumatic tasks<br />

in machine, apparatus and plant<br />

engineering are convincing products.<br />

With the CONTI-V® PIONEER, ContiTech<br />

is presenting the world’s first eco-friendly<br />

wrapped V-belt. It is composed largely of<br />

renewable raw materials.<br />

The environmentally-friendly timing<br />

belt, CONTI® SYNCHROBELT<br />

PIONEER from ContiTech, is ideal for<br />

applications that people come into<br />

contact with.<br />

wood processing or textile machine<br />

industries, in offshore usage, saw<br />

mill machines or the food industry.<br />

Since air actuators function without<br />

me-chanically operated parts like<br />

pistons, piston rods and friction<br />

seals, they are not subject to<br />

wear and require no maintenance.<br />

This gives them an edge over<br />

conventional cylinders.They are also<br />

more environmentally-friendly as they<br />

do not require oil.<br />

Involvement in India<br />

ContiTech has had a presence in<br />

India for many years, operating two<br />

production plants and em-ploying<br />

around 900 people there. At the New<br />

Delhi location ContiTech produces<br />

high-quality drive belts, and it is from<br />

here that Indian customers get their<br />

supplies. Air spring systems are<br />

also manufactured in New Delhi for<br />

the Indian market, and especially<br />

for the state-run Indian Railways.<br />

Near Kolkata, ContiTech produces<br />

conveyor belts for mining and<br />

other industrial uses. In addition,<br />

ContiTech supplies the Indian<br />

subcontinent with hoses.<br />

For reader enquiries, please<br />

mention PTR:<br />

Mario Töpfer,<br />

ContiTech AG,<br />

VahrenwalderStrasse 9,<br />

D-30165 Hanover, Germany<br />

Tel: +49 511 938-1304<br />

Fax: +49 511 938-1305<br />

Email: mario.toepfer@contitech.de<br />

www.contitech.de

6 P&TR Nov/Dec 2011<br />

P&TR News<br />

Driven linear actuator<br />

system for bottle spraying<br />

The Liverpool-based company<br />

Dibro has one of the largest<br />

facilities in the UK for decorating<br />

glass bottles. It applies decorative<br />

painted finishes, acid-etched<br />

effects and lacquers to a variety of<br />

glass containers and has recently<br />

installed a new printing facility for<br />

the ceramic and precious metal<br />

printing of glass containers. The<br />

company is a specialist in its field<br />

but by its own admission no expert<br />

in linear motion. So when it came<br />

to automating a glass treatment<br />

process on the new plant to increase<br />

productivity it chose HepcoMotion®<br />

to recommend the most appropriate<br />

system for linear actuation.<br />

Alert on HSE cost recovery proposals<br />

New proposals by the Health<br />

& Safety Executive (HSE) are<br />

likely, if they are implemented<br />

in their present form, to have<br />

serious financial implications for<br />

employers that are found to be in<br />

breach of health and safety laws,<br />

warns Paul Laidler, Managing<br />

Director of Laidler Associates,<br />

a division of TÜV SÜD Product<br />

Service.<br />

In essence, the HSE is seeking to<br />

recover, from offending employers,<br />

the costs it incurs while<br />

investigating a material breach of<br />

health and safety law, and also<br />

any additional costs in providing<br />

support to the employer as an aid<br />

to ensuring that the situation is<br />

successfully remedied.<br />

The arrangements have already<br />

been agreed in principle with the<br />

Government, and the proposals<br />

were available for public<br />

consultation until 14th October.<br />

If, as seems likely, the proposals<br />

are adopted, the new system of<br />

charging could start as soon as<br />

April 2012, and it is estimated<br />

that the HSE will charge for its<br />

The process Dibro was seeking<br />

to automate involves spraying<br />

the bottles with a slip coating<br />

after printing as they emerge on a<br />

conveyor from the firing lehr. This is a<br />

kiln with a temperature gradient from<br />

end to end for annealing glass, a<br />

method of slowly cooling the product<br />

to prevent thermal shock. The linear<br />

system was required to transport a<br />

spray nozzle mechanism across the<br />

full width of the conveyor, coating a<br />

line of bottles on each pass.<br />

For this purpose HepcoMotion®<br />

suggested a complete system based<br />

on a hybrid version of its Profile<br />

Driven Unit, the PDU2; a bespoke<br />

inspectors’ time at a rate of £133<br />

per hour.<br />

“The costs will certainly mount<br />

up very quickly,” said Paul<br />

Laidler, “so it’s important that<br />

employers are fully aware of<br />

these new proposals. However,<br />

they should also bear in mind<br />

that the charges will only apply<br />

to companies that break health<br />

and safety laws, so those that<br />

are careful about meeting their<br />

responsibilities and staying within<br />

the law will not be affected in any<br />

way.”<br />

The new proposals are, however,<br />

a wake-up call to businesses to<br />

review their health and safety<br />

practices and procedures to<br />

ensure that nothing has been<br />

overlooked. In particular,<br />

machinery users are advised<br />

to check that their PUWER<br />

assessments are up to date and<br />

comprehensive in their coverage.<br />

Should these checks throw up<br />

any concerns, businesses are<br />

encouraged to seek expert advice<br />

of the type provided by Laidler<br />

Associates rather than taking the<br />

solution from its standard range of<br />

products. “We knew we needed a<br />

linear system that would provide<br />

consistent speed of the traverse unit<br />

to ensure an even spray coating and<br />

also the accurate positioning of the<br />

spray head so only the sides of the<br />

bottles are coated,” explained Tom<br />

Dickinson, Managing Director and<br />

son of one of the Dickinson brothers<br />

that founded the company in 1933.<br />

Many HepcoMotion® customers<br />

know precisely what they want to<br />

achieve through automation within<br />

a given budget but they do not have<br />

the linear motion expertise to specify<br />

the required system with confidence.<br />

Tom Dickinson continued: “We were<br />

certainly attracted by the quality<br />

of the HepcoMotion® product but<br />

more importantly for us it was<br />

the technical understanding the<br />

company brought to the table.<br />

HepcoMotion® just made it so easy<br />

for us.”<br />

The PDU2 at the heart of the<br />

Dibro system is a belt-driven linear<br />

actuator and ideal for this high<br />

performance application because<br />

it is compact and, thanks to its<br />

Herculane® wheels, runs virtually<br />

friction-free on the inside of the<br />

profile. This provides extremely<br />

stable support for the carriage plate<br />

that carries the spray nozzle; felt<br />

wipers sweep away any debris in its<br />

path.<br />

The overall system comprises a<br />

rigid but lightweight aluminium<br />

slotted profile into which fits the<br />

toothed belt drive and carriage,<br />

an arrangement that effectively<br />

encloses the unit and makes it ideal<br />

for operating in the damp conditions<br />

on the Dibro bottle production<br />

risk that HSE inspectors may be<br />

the first to discover a problem.<br />

“The cost of professional advice<br />

from a consultant with a proven<br />

track record is modest,” said Paul<br />

Laidler, “and will certainly be less<br />

than the fines and the new HSE<br />

cost recovery charges that are<br />

likely to be imposed if health and<br />

safety laws have been broken,<br />

even inadvertently. Therefore<br />

where there is any doubt at<br />

all about health and safety<br />

compliance, professional advice is<br />

a very sound investment.”<br />

line. This quality is enhanced<br />

by stainless fixings, available<br />

as a standard choice within the<br />

HepcoMotion® product programme.<br />

HepcoMotion® specified and<br />

delivered the turnkey driven system<br />

complete with extra long beam to<br />

accord with the width of the lehr<br />

and AC motor to drive the PDU2.<br />

“We also wanted to fit ancillary<br />

sensors for positioning and control<br />

of the drive unit to vary speed<br />

using an inverter,” Tom Dickinson<br />

explained. “And the HepcoMotion®<br />

system gave us the facility to do<br />

that easily.”<br />

The system cycle is dictated by<br />

the belt speed of the lehr which<br />

in turn is dependent on the size<br />

of the bottles being printed.<br />

Typically the traverse unit operates<br />

every minute, travelling at around<br />

200mm/sec. The lehr is 2m wide<br />

so it typically takes the system 10<br />

seconds to coat <strong>15</strong> one-litre spirit<br />

bottles or 50 perfume bottles.<br />

The new printing facility is now<br />

up and running bringing new<br />

business to this family firm. Tom<br />

Dickinson concludes: “Currently<br />

the lehr is operating 24 hours a<br />

day and I’m pleased to confirm the<br />

HepcoMotion® system is working<br />

very well.”<br />

For reader enquiries, please<br />

mention PTR:<br />

HepcoMotion,<br />

Lower Moor Business Park,<br />

Tiverton Way, Tiverton,<br />

Devon EX16 6TG<br />

Tel: +44 (0) 1884 243400<br />

Fax: +44 (0) 1884 243399<br />

Email: hepco@hepcomotion.com<br />

www.HepcoMotion.com<br />

News in brief<br />

EPTDA Annual Convention<br />

for 2012 will be held in<br />

Lisbon, Portugal on 26-28<br />

September.<br />

Learning to walk faster<br />

with high performance<br />

modelling<br />

Discover how MapleSim physical<br />

modelling software is helping to<br />

perfect the process of humanoid<br />

walking in robots at MMU.<br />

MapleSim’s accuracy and kinematics<br />

capabilities help construct complex<br />

simulations and build models faster,<br />

plus complete experiments with<br />

better data.<br />

Huco Sliding Disc<br />

Couplings<br />

Providing generous radial<br />

compensation and easy<br />

maintenance, the Huco Oldham<br />

sliding disc, backlash-free couplings<br />

are available in a wide choice of<br />

materials and configurations to suit<br />

your application.

Exclusive system of premium engineered sprockets<br />

and belts has Goodyear’s patented H.O.T. (Helical<br />

Offset Tooth) design. Eagle NRG merges belt and<br />

sprocket into the quietest, smoothest and one of the<br />

most compact drive packages available.<br />

WHITEHAWK<br />

The premium choice for greater horsepower<br />

capacity and high-performance, all in a universaltooth<br />

profile belt.<br />

®<br />

A revolutionary new drive system that can easily<br />

and seamlessly replace old-fashioned chain drives.<br />

Falcon HTC® can replace the problematic chain<br />

drive with a clean and quiet rubber compound belt<br />

that delivers exceptional performance under higher<br />

torque and low speed.<br />

UK & IRELAND<br />

SOLE MASTER<br />

DISTRIBUTOR<br />

Call today to discuss your requirements<br />

Tel: 01709 789 999<br />

Fax: 01709 789 988<br />

E-mail: sales@acorn-ind.co.uk<br />

www.acorn-ind.co.uk

8 P&TR Nov/Dec 2011<br />

P&TR News<br />

Transdev adds Esband <br />

and Werner GRAF<br />

endless flat belts<br />

Transmission Developments has signed a UK distribution<br />

agreement with the endless flat belt specialist Max<br />

Schlatterer GmbH, bringing the premier Esband and Werner<br />

GRAF brands to its comprehensive range of belting products.<br />

These drive and conveyor belts are<br />

manufactured using a genuinely<br />

endless woven technique in a<br />

wide range of carcass materials<br />

and finished with special coatings<br />

that are matched to the friction<br />

coefficient, durability, speed and<br />

accuracy requirements for high<br />

precision/high performance power<br />

transmission and conveying.<br />

The range is characterised with<br />

application advantages such as<br />

low and uniform elongation, long<br />

operational life, excellent flexibility<br />

for small bending radii, high tear<br />

resistance plus extremely consistent<br />

tensile strength.. The truly endless<br />

belt design also allows the ability<br />

in manufacture to precisely control<br />

the belt thickness over its entire<br />

length, avoiding the step problem<br />

found in jointed alternatives; and<br />

with no splice or seam they are also<br />

extremely quiet in operation with no<br />

step-induced noise spike or vibration.<br />

British engineering innovators<br />

scoop prestigious manus awards<br />

At a recent awards ceremony igus UK, a leading manufacturer of high-performance polymer<br />

bearings, presented its coveted manus awards to two British engineering companies, Trailerteq and<br />

MBP Concepts. The manus competition is a plastic bearing design innovation contest held every<br />

two years and winners are selected by an independent panel of academics and industry specialists.<br />

Winning the manus award for ‘Most<br />

Eye Catching Design’ was MBP<br />

Concepts with its Tyligo product. The<br />

Tyligo trailer, designed and developed<br />

in Britain, uses the iglidur sleeve<br />

bearing from igus for the critical<br />

function of folding and opening the<br />

trailer by sliding the front bracket on<br />

the main stainless steel beam.<br />

Key requirements for the trailer were<br />

that the bearing should combine high<br />

load bearing capacity with long life,<br />

small size and minimal maintenance<br />

requirements. It was decided that<br />

the iglidur sleeve bearing would<br />

Esband drive and conveyor belts<br />

address the needs of specialists<br />

application areas and are custom<br />

manufactured with traction elements,<br />

coatings and finishes to optimise<br />

machine performance. They are<br />

widely used in packaging machinery<br />

for form-fill-seal and flow wrapping<br />

or precision infeed and outfeed<br />

conveying with design characteristics<br />

tuned for any combination of dry or<br />

wet grip, high or low speed, hygiene,<br />

and durability. They particularly<br />

suit food and beverage production<br />

machinery and weighing equipment<br />

and are available with perforations<br />

for vacuum processes, and<br />

processes requiring knife shaped<br />

edges and tight flexing radii. Esband<br />

belts are also critical process<br />

enabling components for paper<br />

handling machinery such as printing<br />

press, copiers, scanners, ticketing,<br />

ATMs, postal sorting machines and<br />

many more.<br />

best meet these requirements, as<br />

it has characteristics that are far<br />

superior to those of conventional<br />

metal bearings. The ability to carry<br />

a much greater load for the same<br />

physical size of bearing is thanks<br />

to the material’s high compressive<br />

strength and superior elasticity<br />

properties.<br />

The second winner on the day was<br />

Trailerteq, who won the manus<br />

‘Plastic Bearing Innovation’ award.<br />

Trailerteq is a British manufacturing<br />

company, based in Lancashire, and<br />

it used igus’ range of iglidur polymer<br />

The GRAF range is available<br />

in a number of standard build<br />

configurations covering both stable<br />

length or elastic belt properties<br />

to suit applications where perfect<br />

running is critical. HEVALOID®<br />

standard belts are available for<br />

crowned pulley diameters from 4<br />

mm to 40 mm and have a high<br />

and uniform tensile strength with<br />

polyester endless woven tensile<br />

members and synthetic rubber<br />

coatings (Chloroprene) which are<br />

antistatic and highly resistant to<br />

abrasion. CRELAST® elastic fold<br />

and conveyor belts are used for low<br />

power transmission and exacting<br />

conveyor use and are particularly<br />

suited to paper handing. They are<br />

supplied with chloroprene, nitrile,<br />

EP and silicon coatings. Solutus®flat<br />

belts consist of endlessly<br />

wound polyester yarns with leather<br />

or fleece plies. They are used<br />

for very oily or wet processes as<br />

well as feeding and accumulating<br />

processes for folding/gluing<br />

machinery. A version is available<br />

bearings in its compact Rapid<br />

Deployment Transport (RDT) trailer.<br />

The igus bearing was used after it<br />

was discovered that a phosphorbronze<br />

bearing used in the main<br />

arm, linking the body of the RDT with<br />

the towing vehicles, was prone to<br />

premature failure.<br />

The iglidur polymer bearings range<br />

have extremely high compressive<br />

strength coupled with high elasticity,<br />

which means that, size for size,<br />

they have a much higher load<br />

carrying capacity than conventional<br />

metal bearings. In addition, the<br />

bearings require no lubrication or<br />

other maintenance, and they are<br />

highly resistant to the effects of dirt<br />

ingress or other contamination.<br />

“We selected these two worthy<br />

winners for the igus UK manus<br />

awards, as they both used plastic<br />

bearings to perform a key function<br />

while transforming the performance<br />

with steel cords for specialist<br />

newspaper print friction drives.<br />

Across both Esband and Werrner<br />

GRAF product lines, special<br />

processing and finishing is available<br />

to include ground surfaces, multiple<br />

layers, perforations for vacuum or air<br />

blowing processes, and machined or<br />

bonded features for flights. Transdev<br />

provides a complete design and<br />

application engineering service<br />

which also covers manufacturing for<br />

specialist crown pulleys for use with<br />

the endless flat belt range.<br />

For reader enquiries, please<br />

mention PTR:<br />

Ian Osborne<br />

Transmission Developments Co<br />

(G.B.) Ltd,<br />

Dawkins Road, Poole,<br />

Dorset BH<strong>15</strong> 4HF<br />

Tel +44 1202 675555<br />

Fax +44 1202 677466<br />

Email: iano@transdev.co.uk<br />

www.transdev.co.uk<br />

L-R: Ian Dunn of Trailerteq, Matthew<br />

Aldridge of igus UK and Matthieu<br />

Philippault of MBP Concepts at the<br />

awards presentation<br />

of their product and helping reduce<br />

costs. We are always pleased to<br />

see plastic bearings being used in<br />

unusual applications, and for solving<br />

engineering problems that would<br />

be difficult to address in any other<br />

way. We congratulate both Trailerteq<br />

and MBP Concepts on their superb<br />

designs and we are confident that<br />

both their products will have a wide<br />

market appeal”, said Matthew<br />

Aldridge, director of igus UK.<br />

For reader enquiries, please<br />

mention PTR:<br />

Matthew Aldridge,<br />

igus UK Ltd,<br />

51A Caswell Road, Brackmills,<br />

Northampton NN4 7PW<br />

Tel +44 (0)1604 677240<br />

Fax +44 (0)1604 677245<br />

sales@igus.co.uk<br />

www.igus.co.uk

Brammer fundraisers<br />

for Make-A-Wish<br />

Foundation ® UK<br />

Nicola Sivori (left), Charity<br />

Committee Chairperson at<br />

Brammer UK, part of Europe’s<br />

leading distributor of maintenance,<br />

repair and overhaul (MRO)<br />

products and services, presents<br />

a cheque for £20,<strong>000</strong> to Karen<br />

England (right), Director of<br />

Fundraising at Make-A-Wish<br />

Foundation® UK.<br />

The presentation, which took place<br />

at Brammer’s highly successful<br />

Manufacturing Forum held at the<br />

Museum of Science and Industry in<br />

Manchester, brings the total raised<br />

by Brammer for the charity to more<br />

than £120,<strong>000</strong> since early 2007.<br />

Make-A-Wish Foundation® UK<br />

grants magical wishes to children<br />

and young people fighting lifethreatening<br />

illnesses, and has<br />

granted more than 7,<strong>000</strong> wishes<br />

since the charity was established<br />

in 1986.<br />

Fundraising efforts undertaken by<br />

Brammer staff nationwide this year<br />

have included a 686 mile cycle<br />

tour around 16 Brammer locations<br />

in Scotland and Northern Ireland,<br />

climbing Snowdon and the BUPA<br />

Great North Run.<br />

Nicola Sivori commented:<br />

“The money raised this year<br />

demonstrates our commitment<br />

to Make-A-Wish, which is a very<br />

deserving cause and one that<br />

Brammer is only too happy to<br />

support. The difference that a<br />

charity like Make-A-Wish can make<br />

to children with life-threatening<br />

illnesses is remarkable, and we<br />

are proud to have continued our<br />

association with the charity since<br />

2007.”<br />

… well done Guys at Brammer,<br />

wonderful news, Ed.<br />

Nov/Dec 2011 P&TR 9<br />

EPTDA’s 2011 Convention in<br />

Budapest closes on a high note<br />

The European Power Transmission<br />

Distributors Association (EPTDA),<br />

the leading European organisation<br />

for the mechanical Power<br />

Transmission and Motion Control<br />

(PT/MC) industry, reports recordbreaking<br />

attendance at its 2011<br />

Annual Convention in Budapest.<br />

With more than 350 participants<br />

featuring 32 companies joining for<br />

the first time, over 700 individual<br />

meetings between Distributors &<br />

Manufacturers at the signature MD-<br />

IDEX sessions, EPTDA re-establishes<br />

its position as the leading<br />

association in Europe for PT/MC<br />

decision makers.<br />

Signalling its commitment to<br />

personal training and development,<br />

at the Budapest 2011 Annual<br />

Convention, EPTDA also launched<br />

its much-awaited EPTDA Academy<br />

in collaboration with Nyenrode<br />

University of The Netherlands. The<br />

EPTDA Academy will host its first<br />

Executive Training programme in<br />

June 2012 focusing on Strategy –<br />

new business models for growth<br />

and creating the future in the<br />

power transmission and motion<br />

control industry; Leadership – in<br />

transforming the organisation<br />

towards the future; and Innovation –<br />

as a source for strategy execution.<br />

The 2011 Annual Convention<br />

brought to stage some of the most<br />

sought-after and influential public<br />

speakers of our times including<br />

Mrs Connie Podesta on Standout<br />

Leadership - How To Achieve<br />

Success By Influencing Others To<br />

Be Successful; Mr Alan Beaulieu,<br />

Principal ITR, Institute of Trend<br />

Research, and EPTDA Economic<br />

Forecaster on Global Prosperity<br />

– Maximising Profits; and Mr Ben<br />

Legg, Former COO of Google and<br />

COO of European Directories on The<br />

internet – what is next.<br />

From “Next Generation Event”<br />

to “Distributor Forum” delegates<br />

interacted and engaged on a formal<br />

and informal level to address the<br />

future of the industry and areas of<br />

mutual growth and mutual issues.<br />

In 2012, EPTDA Annual Convention<br />

will be held in Lisbon, Portugal<br />

on 26-28 September. For more<br />

on EPTDA 2011 Convention<br />

highlights, please refer to www.<br />

eptdaconvention.org.<br />

Intelligent Solutions In Power Transmission<br />

An increasing range of quality industrial disc brakes<br />

• Excellent technical support<br />

• 3D Solid models available<br />

• Most models X-Stock<br />

• 40 years experience<br />

HPW 101 R<br />

Hydraulically actuated -<br />

pneumatically released<br />

Up to 21,<strong>000</strong> Nm<br />

DVH 40 FPM/T<br />

Spring actuated -<br />

pneumatically released<br />

Heavy Duty<br />

Up to 29,<strong>000</strong> Nm<br />

R<strong>IN</strong>GSPANN (U.K.) Ltd.<br />

Telephone: 01234 342511<br />

Telefax: 01234 217322<br />

info@ringspann.co.uk<br />

www.ringspann.com<br />

DV 20 MS<br />

Manually actuated -<br />

manually released<br />

Industrial Disc Brakes • Torque Limiters • Couplings • Shaft-Hub-Connections • Freewheels • Force Limiters • Irreversible Locks

12 P&TR Nov/Dec 2011<br />

P&TR News<br />

See Inside Manufacturing<br />

open day at Schaeffler UK<br />

gives pupils a taste of a<br />

career in manufacturing<br />

More than 60 pupils from local secondary schools took part<br />

in a See Inside Manufacturing open day event at Schaeffler<br />

UK’s automotive engine component manufacturing plant in<br />

Llanelli, South Wales.<br />

More than 60 pupils from local<br />

secondary schools took part in a<br />

See Inside Manufacturing open day<br />

event at Schaeffler UK’s automotive<br />

engine component manufacturing<br />

plant in Llanelli, South Wales.<br />

The event was part of the<br />

UK Government’s See Inside<br />

Manufacturing Initiative, a<br />

nationwide ‘open days’ programme<br />

to help improve the image of UK<br />

manufacturing to young people,<br />

with the objective of attracting<br />

the brightest and best talent into<br />

a career in manufacturing and<br />

engineering. The event at Schaeffler<br />

UK was arranged in conjunction with<br />

the local college, Coleg Sir Gar, and<br />

was facilitated by Schaeffler’s own<br />

apprentices and toolmakers.<br />

The open day, which took place on<br />

21st November 2011, was divided<br />

into a morning and afternoon<br />

session in order to accommodate<br />

more children. In the morning<br />

session, 30 Year 9 pupils (aged<br />

13-14) attended from three local<br />

secondary schools: Amman Valley,<br />

St John Lloyds and Bryngwyn. In the<br />

afternoon, 32 Year 9 pupils visited<br />

the plant from three other schools:<br />

Queen Elizabeth High School,<br />

Coedcae and Glan y Mor.<br />

On arriving at the plant, pupils<br />

and teachers were welcomed by<br />

presentations from Plant Director<br />

Roger Evans MBE and from<br />

Schaeffler UK’s Training Manager<br />

Donna Williams-Bevan. The pupils<br />

and teachers were then given<br />

a guided tour of the factory by<br />

Schaeffler apprentices and toolroom<br />

staff. This gave pupils an opportunity<br />

to see what it would be like to work in<br />

a real manufacturing environment.<br />

Pupils were then split into teams in<br />

order to compete in an Engineering<br />

Challenge. Led by Schaeffler UK’s<br />

toolroom technician Gareth Gravell,<br />

this challenge involved pupils having<br />

to correctly read an engineering<br />

drawing before devising a suitable<br />

method for assembling an idler hub<br />

bearing. The winner was the team<br />

that correctly assembled their idler<br />

hub in the fastest time.<br />

The Engineering Challenge was<br />

followed by a Schaeffler quiz, which<br />

tested the pupils’ ability to recall<br />

information provided in the Schaeffler<br />

presentations. Before departing the<br />

plant, lunch with senior managers<br />

and apprentices gave pupils the<br />

opportunity to ask any further<br />

questions in an open, informal<br />

environment.<br />

Also in attendance on the day<br />

were Alex Robinson, Automotive<br />

Components Section Manager at<br />

The Society of Motor Manufacturers<br />

& Traders (SMMT) and Paul Bullock,<br />

Industry Liaison Manager at the<br />

Welsh Automotive Forum.<br />

As Alex Robinson commented:<br />

“The SMMT, in accordance with<br />

the Automotive Council, has aimed<br />

to build on local activities already<br />

undertaken by individual companies<br />

to coordinate a nationwide See<br />

Inside Manufacturing programme for<br />

young people considering their future<br />

career options. I believe Schaeffler’s<br />

event is a credit to the initiative<br />

and has undoubtedly left a positive<br />

impression on many of the school<br />

children who visited.”<br />

“It is especially pleasing to see<br />

the automotive sector taking a<br />

lead on this activity in 2011, with<br />

government keen to extend the<br />

initiative across other manufacturing<br />

sectors in 2012. Schaeffler’s event<br />

will hopefully serve as a tool to spark<br />

off an interest amongst local school<br />

children in engineering and dispel the<br />

outdated attitudes towards a career<br />

in the profession.”<br />

Paul Bullock of the Welsh Automotive<br />

Forum agreed: “If the UK is to<br />

plug the current skills gap in UK<br />

manufacturing and engineering, it is<br />

critical that we attract more young<br />

people, both boys and girls, into<br />

a career in manufacturing. It was<br />

therefore particularly pleasing to see<br />

as many girls attending the Schaeffler<br />

open day as there were boys.<br />

Interestingly, three of the four winning<br />

teams on the Engineering Challenges<br />

comprised all-girl members.”<br />

Roger Evans MBE, Plant Director<br />

at Schaeffler UK commented: “The<br />

open day has been a tremendous<br />

success for everyone involved and<br />

we look forward to holding similar<br />

events in the future. Giving school<br />

children the opportunity to visit a real<br />

manufacturing plant, to ask questions<br />

of apprentices working there and to<br />

see what it’s really like working with<br />

the latest modern machinery in a<br />

dynamic, fast-moving manufacturing<br />

environment is essential if we are<br />

to attract more young people into a<br />

future career in this industry.”<br />

For reader enquiries, please<br />

mention PTR:<br />

Schaeffler (UK) Ltd,<br />

Forge Lane, Minworth,<br />

Sutton Coldfield,<br />

West Midlands,<br />

B76 1AP<br />

Tel: 0121 313 5870<br />

Fax: 0121 351 7686<br />

Email: info.uk@schaeffler.com<br />

www.schaeffler.co.uk<br />

Atlas Copco Compressors appoints Paul Clark<br />

as Industrial Air Business Line Manager<br />

Atlas Copco Compressors has<br />

announced the appointment of Paul<br />

Clark as Business Line Manager<br />

of its Industrial Air division in<br />

Great Britain. Commenting on his<br />

new position in the company, Paul<br />

Clark said: “It is a challenging<br />

role. I see my task as ensuring<br />

that the company continues to be<br />

represented by professional, trained,<br />

motivated and experienced people,<br />

backed by world-leading products.”<br />

Paul started his engineering career<br />

as a qualified toolmaker first in the<br />

UK, and then in the USA, before<br />

returning back to the UK to take<br />

up a sales role for a compressed<br />

air distributor. He then took up<br />

the position of Sales Manager<br />

for a dryer manufacturer before<br />

his appointment to Managing<br />

Director of air dryer and filtration<br />

specialist, Hankison UK. Following<br />

the company’s acquisition by<br />

SPX, Paul Clark was employed as<br />

Sales Director for its air treatment<br />

division with responsibility for<br />

establishing business line goals<br />

and strategy. After this, Paul joined<br />

Atlas Copco Compressors within<br />

Business Development, before being<br />

promoted to Business Line Manager.<br />

In his new role Paul and his team<br />

will be focused on the sales and<br />

marketing of cost-effective, energyefficient<br />

industrial air compressors,<br />

quality air accessories and nitrogen<br />

generators, including solutions<br />

that not only embrace improved<br />

productivity but offer the tangible<br />

benefits of energy recovery, remote<br />

monitoring, and real-time control<br />

and management. They will also<br />

continue to increase Atlas Copco<br />

Compressors’ representation across<br />

GB through direct and distributor<br />

sales and continue the long term<br />

support and stability which the<br />

company has maintained for its<br />

customers over the years.<br />

Outside of work, Paul, who comes<br />

from Baldock, Hertfordshire, runs a<br />

junior football team in his home town<br />

and plays golf as often as he can.<br />

For reader enquiries, please<br />

mention PTR:<br />

Atlas Copco Compressors Ltd<br />

Swallowdale Lane,<br />

Hemel Hempstead,<br />

Herts, HP2 7EA<br />

Tel: +44 (0) 1442 261201<br />

Fax: +44 (0) 1442 234791<br />

Email: gba.info@uk.atlascopco.com<br />

www.atlascopco.co.uk

Diageo receives award for<br />

Business process improvement<br />

Leading premium drinks manufacturer<br />

Diageo has received an award at<br />

the 2011 Brammer Manufacturing<br />

Forum and Awards for cost-savings<br />

achieved within the management of<br />

its maintenance spares supply chain<br />

working in partnership with Brammer.<br />

The business process improvement<br />

award was given to Diageo by<br />

Brammer, the UK’s leading distributor<br />

of industrial maintenance, repair<br />

and overhaul (MRO) products, at<br />

Manchester’s Museum of Science<br />

and Industry. The Brammer Awards,<br />

now in their fifth year, celebrated the<br />

very best in product and business<br />

process innovation within the UK<br />

manufacturing industry.<br />

The business process improvement<br />

award highlights how production<br />

operations can be made to run<br />

more efficiently and profitably<br />

through better management of<br />

the maintenance spares supply<br />

chain.. Brammer has worked with<br />

Diageo over the past 12 months<br />

to improve its maintenance spares<br />

procurement and management. This<br />

was achieved through reducing total<br />

acquisition costs over 37 UK sites<br />

by improving the purchase to pay<br />

process (removing 8,<strong>000</strong> invoices),<br />

and through vendor consolidation,<br />

re-routing 243 suppliers and<br />

consolidating 114,<strong>000</strong> parts.<br />

Tony McCartney of Diageo (right)<br />

receives the business process<br />

improvement award from Brammer plc<br />

Chief Executive Ian Fraser (centre)<br />

and Brammer UK Managing Director<br />

Ian Ritchie<br />

Ian Ritchie, Managing Director<br />

of Brammer UK, said: “We have<br />

worked closely with Diageo over<br />

the last year to evaluate how the<br />

company can increase efficiency<br />

and reduce costs by improving the<br />

management of their maintenance<br />

spares supply chain, which were<br />

then put into action. The results<br />

simply speak for themselves and we<br />

would like to congratulate Diageo<br />

once again for winning the business<br />

process improvement award, which<br />

demonstrates that optimised<br />

changes to managing a businesses<br />

spares supply chain really can make<br />

a huge difference.”<br />

The business process improvement<br />

award was presented to Tony<br />

McCartney, Supplier Performance<br />

Manager at Diageo.<br />

Nov/Dec 2011 P&TR 13<br />

R. A. Rodriguez expands<br />

its sales team<br />

The precision engineering<br />

component specialist R.A. Rodriguez<br />

is growing and there are a number<br />

of reasons for this good news. The<br />

company’s appointment as the<br />

European master distributor for<br />

KHK is partly responsible. So too<br />

is its increasing export sales for<br />

KAYDON® thin section bearings<br />

and the development of the R.A.<br />

Rodriguez automation business.<br />

Indeed, such has been the demand<br />

for the latter that Southern Area<br />

Sales Manager, Andrew Mason has<br />

now changed roles to focus on this<br />

burgeoning market.<br />

As a result, R.A. Rodriguez is<br />

pleased to confirm the appointment<br />

of Darren Reynolds to fill the<br />

vacated southern sales position.<br />

Darren is now responsible for<br />

selling the company’s entire product<br />

range across England and Wales,<br />

an area bordered by Staffordshire,<br />

Lincolnshire and Leicestershire<br />

in the north. He is based at<br />

the company’s sales office in<br />

Letchworth.<br />

Darren brings with him a background<br />

in engineering sales and technical<br />

support as well as <strong>15</strong> years<br />

purchasing experience in the bearing<br />

industry; this included the R.A.<br />

Rodriguez brand. “Having worked<br />

with R.A. Rodriguez as a distributor, I<br />

know the strength of the engineering<br />

support the company provides and<br />

quality of the products it markets.<br />

I’m looking forward to being part<br />

of this family-owned company that<br />

gives applications support such high<br />

priority.”<br />

For reader enquiries, please<br />

mention PTR:<br />

R.A. Rodriguez,<br />

28 Campus Five,<br />

Letchworth Business Park,<br />

Letchworth, Herts. SG6 2JF<br />

Tel: 01462 670044<br />

Fax: 01462 670880<br />

Email: info@raruk.com<br />

www.rarodriguez.co.uk<br />

News in brief<br />

Vibration testing made<br />

easy with the Fluke 810<br />

Equipped with the new and unique<br />

Fluke 810 Vibration Tester-the<br />

maintenance professional can<br />

quickly and reliably determine<br />

the cause and severity of most<br />

machine vibration and receive<br />

recommendations for repair.

14 P&TR Nov/Dec 2011<br />

P&TR News<br />

Wear resistant chain<br />

is still the longest<br />

lasting solution<br />

Renold’s highly wear resistant chain, Synergy, is still<br />

the longest lasting solution available to engineers for<br />

applications where maintenance reduction is desirable, or<br />

where short wear life is a problem. According to Renold,<br />

laboratory tests show that Synergy lasts up to six times<br />

longer than other major brands of standard chain.<br />

PIX Hydraulics launch new<br />

Bastion Hose – Safety fortified!<br />

PIX Hydraulics (Europe) Ltd. have<br />

launched a brand new range of<br />

hydraulic hoses dubbed ‘BASTION’.<br />

As part of their constant endeavour<br />

for product improvement and desire<br />

to provide innovative solutions, PIX<br />

have designed BASTION for use<br />

in severe hydraulic applications in<br />

challenging conditions.<br />

BASTION has been specially<br />

designed to outperform standard<br />

hose when used in heavy duty<br />

hydraulic systems and applications<br />

where components are subject to<br />

high abrasion exposure and extreme<br />

environmental conditions such as<br />

temperature, UV and ozone.<br />

Furthermore, BASTION is also MSHA<br />

certified due to its flame resistant<br />

and antistatic properties. With a<br />

wide range of fluid compatibility,<br />

applications for the new hose<br />

include marine and offshore,<br />

underground and open pit mining<br />

and quarrying.<br />

Commenting on the launch of the<br />

BASTION hose range, Operations<br />

Director for UK based PIX Hydraulics<br />

(Europe) Ltd, Karan Sethi said: “As<br />

the applications and the working<br />

environment for hydraulic hoses gets<br />

more complex, our BASTION range<br />

will allow customers to effectively<br />

use the hose in the most adverse<br />

conditions. This product has been<br />

engineered in a way that allows it<br />

to exhibit its superior performance<br />

qualities whilst withstanding the<br />

harsh environments prevalent in<br />

mines, etc.”<br />

The PIX BASTION series hose range<br />

includes: 1SN, 2SN, 1SC and 2SC<br />

standard braided hose, and 4SP,<br />

4SH, R12, R13 and R<strong>15</strong> standard<br />

multi-spiral hose.<br />

For reader enquiries, please<br />

mention PTR:<br />

Matt Deal,<br />

PIX Hydraulics (Europe) Ltd,<br />

Unit 24 Farthing Rd<br />

Industrial Estate,<br />

Sproughton, Ipswich,<br />

Suffolk. IP1 5AP<br />

Tel: 01473 744612<br />

Email: mdeal@pixeuro.com<br />

www.pixhydraulics.com<br />

Synergy was recently enhanced<br />

with a specially developed<br />

lubricant that reduced initial<br />

wear by up to 50 percent. The<br />

chain is ready to install right<br />

out of the box. It should then<br />

be lubricated as normal while in<br />

operation.<br />

Synergy has helped maintenance<br />

engineers reduce servicing on<br />

new products in a wide range of<br />

sectors from wool processing<br />

to breeze block production and<br />

even equipment for the film<br />

industry. It has also helped<br />

maintenance engineers cut down<br />

time and increase productivity,<br />

delivering significantly longer<br />

wear life than previous chains.<br />

According to David Turner,<br />

Renold Chain’s marketing<br />

communications manager,<br />

“Synergy is the only true<br />

high-performance chain on<br />

the market. Engineers and<br />

maintenance professionals<br />

around the world have come to<br />

rely on the wear resistance and<br />

exceptional working life of this<br />

remarkable chain technology.”<br />

Synergy is available in British<br />

Standard sizes ranging from<br />

06B to 24B in Simplex, duplex<br />

and triplex construction. It is<br />

also available in ANSI standard<br />

sizes ranging from 35 to 160 in<br />

simplex, duplex and triplex.<br />

For reader enquiries, please<br />

mention PTR:<br />

Chris Bradley,<br />

The Marketing Practice,<br />

792 Wilmslow Road,<br />

Didsbury,<br />

Manchester,<br />

M20 6UG<br />

Tel: 0161 442 3700,<br />

Email: themarketingpractice@<br />

yahoo.co.uk<br />

NKE joins Research<br />

Association Power Transmission<br />

Engineering FVA<br />

In July 2011 bearing manufacturer<br />

NKE Austria GmbH became a<br />

member of Frankfurt-based research<br />

association Forschungsvereinigung<br />

Antriebstechnik e.V. (FVA).<br />

In joining the network, which<br />

focuses on research all around<br />

power transmission, NKE aims<br />

to participate in the member<br />

organisations’ joint research<br />

activities and to gain additional<br />

research capacity for developing new<br />

products and technologies.<br />

FVA – part of the German<br />

Engineering Federation VDMA – is a<br />

network of mainly German research<br />

institutions and manufacturing<br />

companies. Its objective is joint<br />

research and training in the fields<br />

of electrical, mechanical and<br />

mechatronic drive engineering.<br />

An important criterion for NKE’s<br />

admission to the network, for<br />

which it was audited by FVA, was<br />

the bearing manufacturer’s value<br />

creation in Austria. Supplementing<br />

its own research capabilities, FVA<br />

membership will allow NKE to<br />

participate in research ventures with<br />

leading research establishments<br />

and companies and to benefit<br />

from their outcomes. The research<br />

project aims, which are defined by<br />

working committees made up of FVA<br />

members, are to advance technical<br />

expertise and product quality and to<br />

cut production costs.<br />

“All of our key customers and<br />

industry trend-setters are<br />

represented in FVA. This enables<br />

us to develop a good sense<br />

of direction for future product<br />

developments”, explains Gunnar<br />

Simm, Head of Engineering at<br />

NKE. “To obtain valuable stimuli<br />

for the continued expansion of our<br />

production facilities in Steyr, we will<br />

be able to draw on the extensive<br />

know-how available within FVA.”<br />

For reader enquiries, please<br />

mention PTR:<br />

NKE AUSTRIA GmbH,<br />

Janet Mo, Marketing,<br />

Im Stadtgut C4,<br />

A-4407 Steyr, Austria<br />

Tel: +43 7252 86667 345<br />

Fax: +43 7252 86667 59<br />

E-mail: j.mo@nke.at<br />

www.nke.at

Stema wins major contract<br />

for tyre plant upgrade<br />

Collaboration between Italian engineering company Stema<br />

Service Srl and Control Techniques Italy has resulted in<br />

a substantial contract with one of Italy’s leading tyre<br />

manufacturing groups.<br />

The project, with Unidrive SP<br />

AC drives used throughout, has<br />

produced energy savings, increased<br />

production and resulted in a<br />

reduction in maintenance costs.<br />

Stema Service Srl is an engineering<br />

company providing automation<br />

and process control solutions<br />

for companies in the plastics,<br />

rubber, iron and steel, marine and<br />

galvanic water treatment sectors.<br />

Stema Service routinely works with<br />

automation systems to improve<br />

production throughput, efficiency<br />

and reliability. Recently, with<br />

increased success in international<br />

markets, the company has<br />

standardised on suppliers in key<br />

areas, including PLC platforms and<br />

drives, with Control Techniques<br />

selected as its technological<br />

partner because of the technical<br />

excellence of its product and<br />

application experience and the<br />

worldwide support from the network<br />

of Drive and Applications Centres.<br />

At the tyre manufacturing company,<br />

a variety of applications, including<br />

rubber mixers and calendar lines,<br />

still used DC technologies and<br />

solutions. Following extensive<br />

study, it was determined that a<br />

switch to AC throughout could offer<br />

real benefits in terms of energy<br />

savings, reduced maintenance and<br />

downtime and better throughput<br />

and quality. With the maintenance<br />

needs of the DC motors eliminated,<br />

the company turned its attention<br />

to a review of the control system<br />

leading to a new approach utilising<br />

new PLCs and the introduction of a<br />

digital communication bus system<br />

based on ethernet.<br />

The company has a mixture of<br />

induction and synchronous motors<br />

and has been able to standardise<br />

on Unidrive SP AC drives from<br />

Control Techniques for all of these.<br />

Mixers rated at up to 400kW utilise<br />

Unidrive SPM modular drives,<br />

which, by virtue of their modular<br />

configuration – AC/DC modules,<br />

plus power modules – deliver<br />

greater flexibility for the architecture<br />

of the system, as well as minimising<br />

back-up spares. On the calendar<br />

line, where motor powers vary<br />

from just a few kilowatts up to<br />

90kW, Unidrive SP drives are used<br />

throughout in open loop, closed loop<br />

and brushless servo configurations,<br />

depending on the motors employed.<br />

All drives were fitted with Ethernet<br />

plug-in modules to give a single<br />

Ethernet fieldbus.<br />

Some drives feature SM-Applications<br />

modules, bringing a high level of<br />

motion control functionality down<br />

to the drive level, with the major<br />

benefits of less wiring, less chance<br />

of interference and enhanced<br />

process reliability and performance.<br />

Control Techniques’ Unidrive<br />

SP ‘solutions platform’ AC<br />

variable speed drive range spans<br />

0.75kW right up to 1.9MW and<br />

is configurable into five operating<br />

modes – open and closed loop,<br />

vector, servo and regenerating<br />

mode. A wide range of plug-in option<br />

modules provide extra processing<br />

power and functionality including<br />

extra I/O and field bus connectivity<br />

to most industry standard networks<br />

and compatibility with most position<br />

feedback protocols.<br />

The customer is delighted with the<br />

results of this extensive project, with<br />

the result that other commissions<br />

have followed and Stema Service<br />

has become the point of reference<br />

for other turnkey projects.<br />

For reader enquiries, please<br />

mention PTR:<br />

Joseph Walker,<br />

Control Techniques Ltd,<br />

Ty Rheoli,<br />

Unit 79 Mochdre Industrial Estate,<br />

Newtown, Powys SY16 4LE<br />

Tel: 01686 612900.<br />

Fax: 01686 612999.<br />

Email: joseph.walker@emerson.com<br />

www.Emerson.com<br />

Nov/Dec 2011 P&TR <strong>15</strong><br />

Precise engineering<br />

Feedback<br />

perfectly<br />

packaged<br />

An incremental encoder<br />

sandwiched between the<br />

motor and gearbox to deliver<br />

feedback across the range<br />

Call or visit our web-site<br />

to nd out about this<br />

revolutionery concept<br />

produced with engineers<br />

in mind.

MECHANICAL POWER<br />

TRANSMISSION<br />

<strong>PRODUCTS</strong><br />

Top Performing products at breakthrough prices!<br />

• Increased efficiency • Long service life<br />

• Wide product range • Quality assured<br />

• One of the largest stock holdings in Europe<br />

Wishes all our customers<br />

a Merry Christmas<br />

and a prosperous 2012<br />

+44 (0) 1233 663340<br />

+44 (0) 1233 664440<br />

sales@medwaypt.co.uk<br />

www.medwaypt.co.uk

ROD ENDS, SPHERICAL<br />

BEAR<strong>IN</strong>GS & L<strong>IN</strong>KAGE<br />

COMPONENTS<br />

DEEP GROOVE, SELF LUBE<br />

ROD END & PLA<strong>IN</strong><br />

BEAR<strong>IN</strong>GS<br />

Pillow<br />

Blocks<br />

Flanged<br />

Popular<br />

Metric<br />

Miniature<br />

Rod End<br />

Plain<br />

Top Performing products at breakthrough prices!<br />

Top Performing products at breakthrough prices!<br />

• Increased efficiency<br />

• Wide product range<br />

• Engineering design service<br />

• UK manufactured<br />

• Patented designs<br />

• ELV & RoHS compliant<br />

• Increased efficiency • Long Service Life<br />

• Wide product range • Quality Assured<br />

• One of the largest stock holdings in Europe<br />

+44 (0) 1233 663340<br />

+44 (0) 1233 664440<br />

sales@medwaylinkages.co.uk<br />

www.medwaylinkages.co.uk<br />

+44 (0) 1233 663340<br />

+44 (0) 1233 664440<br />

sales@medwaybearings.co.uk<br />

www.medwaybearings.co.uk

18 P&TR Nov/Dec 2011<br />

P&TR Products<br />

Bearing isolator<br />

and grounding ring<br />

combination<br />

The new Garlock SGi Shaft<br />

Grounding Bearing Isolator<br />

protects motor bearings from<br />

electrical damage as well as from<br />

lubricant loss and contamination.<br />

Maintenance-free, the Garlock SGi<br />

bearing isolator combines the proven<br />

technologies of Garlock’s GUARDIAN<br />

non-sparking bronze labyrinth seal<br />

together with an AEGIS shaft<br />

grounding ring in a single unit.<br />

It is ideally suited for motors<br />

controlled by variable frequency<br />

drives (VFDs) running pumps,<br />

fans, high-speed spindles, and<br />

other equipment in severe-duty<br />

applications such as mining and<br />

the processing of pulp/paper, food,<br />

pharmaceuticals, chemicals, and<br />

water/wastewater.<br />

Commonly used to save energy,<br />

VFD’s induce motor-shaft currents<br />

that can damage bearings,<br />

completely wiping out any energy<br />

cost savings.<br />

Standard bearing seals only keep<br />

out contamination and prevent<br />

leaks, but the Garlock SGi diverts<br />

harmful currents safely to ground,<br />

bypassing the bearings entirely and<br />

extending motor life. The patented<br />

AEGIS FiberLock Channel built<br />

into the Garlock SGi permanently<br />

secures circumferential rows of<br />

conductive micro fibres, preventing<br />

their dislocation and the resulting<br />

accidental contamination of the<br />

bearing.<br />

The micro fibres themselves,<br />