Responding to waste minimisation and management ... - Wrap

Responding to waste minimisation and management ... - Wrap

Responding to waste minimisation and management ... - Wrap

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

22 <strong>Responding</strong> <strong>to</strong> <strong>waste</strong> <strong>minimisation</strong> <strong>and</strong> <strong>management</strong> requirements <strong>Responding</strong> <strong>to</strong> <strong>waste</strong> <strong>minimisation</strong> <strong>and</strong> <strong>management</strong> requirements 23<br />

The preferred approach <strong>to</strong> pre-demolition<br />

advocated in WRAP’s regeneration guidance<br />

would be <strong>to</strong> commission a pre-demolition<br />

audit as part of the design stage.<br />

This would provide:<br />

data on the potential range <strong>and</strong> quantities<br />

of recovered materials available for the<br />

new build, allowing the designer <strong>to</strong> modify<br />

the new build design <strong>to</strong> maximise the<br />

amount of on site recovered materials; <strong>and</strong><br />

data for inclusion in the tender<br />

documents, removing the need for<br />

multiple ‘pricing audits’ <strong>to</strong> be undertaken<br />

by the contrac<strong>to</strong>rs bidding for the work<br />

<strong>and</strong> maximising the likelihood of<br />

innovative proposals for the demolition<br />

which improve the quantity of<br />

recovered materials.<br />

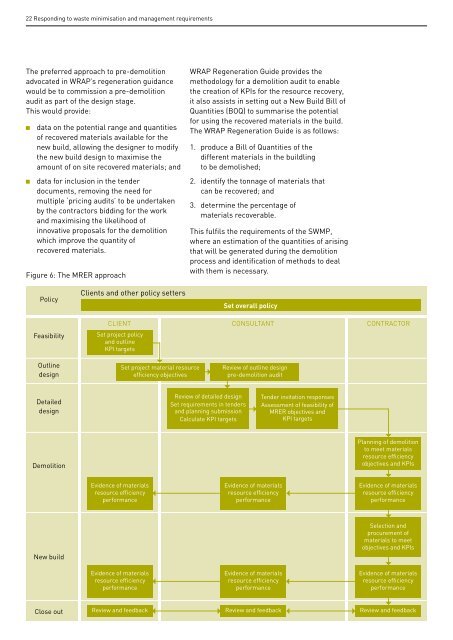

Figure 6: The MRER approach<br />

Policy<br />

Feasibility<br />

Clients <strong>and</strong> other policy setters<br />

WRAP Regeneration Guide provides the<br />

methodology for a demolition audit <strong>to</strong> enable<br />

the creation of KPIs for the resource recovery,<br />

it also assists in setting out a New Build Bill of<br />

Quantities (BOQ) <strong>to</strong> summarise the potential<br />

for using the recovered materials in the build.<br />

The WRAP Regeneration Guide is as follows:<br />

1. produce a Bill of Quantities of the<br />

different materials in the buildling<br />

<strong>to</strong> be demolished;<br />

2. identify the <strong>to</strong>nnage of materials that<br />

can be recovered; <strong>and</strong><br />

3. determine the percentage of<br />

materials recoverable.<br />

This fulfils the requirements of the SWMP,<br />

where an estimation of the quantities of arising<br />

that will be generated during the demolition<br />

process <strong>and</strong> identification of methods <strong>to</strong> deal<br />

with them is necessary.<br />

Set overall policy<br />

client consultant contrac<strong>to</strong>r<br />

Set project policy<br />

<strong>and</strong> outline<br />

KPI targets<br />

Construction companies must ask four<br />

questions at the strip-out stage <strong>and</strong> the table<br />

below identifies the department(s) which<br />

should be responsible for acting upon these<br />

questions <strong>and</strong> the related actions.<br />

Provisions must be made <strong>to</strong> find uses for<br />

resources recovered from the strip-out,<br />

particularly those which can be reused.<br />

A good start is <strong>to</strong> contact local resource<br />

recovery charities <strong>and</strong> publicise excess<br />

material <strong>and</strong> equipment on <strong>waste</strong> exchange<br />

data-bases, 5 particularly when they cannot be<br />

reused on site or on other company projects.<br />

These websites provide information on<br />

companies or organisations that could use<br />

the equipment either in the locality or<br />

further afield.<br />

2.3 Key Performance Indica<strong>to</strong>rs<br />

There are two Key Performance Indica<strong>to</strong>rs<br />

(KPIs) which should be used <strong>to</strong> drive forward<br />

the recovery <strong>and</strong> reuse of demolition <strong>and</strong><br />

construction <strong>waste</strong> material on a project.<br />

These include:<br />

the Demolition Recovery Index (DRI)<br />

– describes the efficiency of material<br />

recovery from demolition calculated as the<br />

quantity of materials recovered from the<br />

demolition process, divided by the <strong>to</strong>tal<br />

quantity of materials generated by it.<br />

the Retained Material (RM) KPI<br />

– a measure of the extent of reuse of<br />

demolition materials on site, calculated<br />

as the quantity of recovered materials<br />

generated from the demolition phase<br />

that are used in the new build, divided by<br />

the <strong>to</strong>tal quantity of recovered materials<br />

created from the demolition.<br />

THINGS TO CONSIDER<br />

Ensure comprehensive underst<strong>and</strong>ing of the principles of<br />

WRAP’s Efficient Use of Materials in Regeneration.<br />

Contrac<strong>to</strong>r should bring the <strong>waste</strong> <strong>management</strong> <strong>and</strong><br />

demolition contrac<strong>to</strong>r on-board immediately.<br />

Design team should be made aware of the data from the<br />

demolition/new build audits <strong>to</strong> incorporate demolition<br />

material in<strong>to</strong> new build design.<br />

Ensure procurement team is aware of demolition materials<br />

available <strong>and</strong> responds accordingly.<br />

Outline<br />

design<br />

Detailed<br />

design<br />

Demolition<br />

New build<br />

Evidence of materials<br />

resource efficiency<br />

performance<br />

Set project material resource<br />

efficiency objectives<br />

Review of detailed design<br />

Set requirements in tenders<br />

<strong>and</strong> planning submission<br />

Calculate KPI targets<br />

Review of outline design<br />

pre-demolition audit<br />

Evidence of materials<br />

resource efficiency<br />

performance<br />

Tender invitation responses<br />

Assessment of feasibility of<br />

MRER objectives <strong>and</strong><br />

KPI targets<br />

Planning of demolition<br />

<strong>to</strong> meet materials<br />

resource efficiency<br />

objectives <strong>and</strong> KPIs<br />

Evidence of materials<br />

resource efficiency<br />

performance<br />

Selection <strong>and</strong><br />

procurement of<br />

materials <strong>to</strong> meet<br />

objectives <strong>and</strong> KPIs<br />

Question<br />

1. Can the materials be<br />

recycled or reused within<br />

the new build<br />

2. Can materials be<br />

reused elsewhere within<br />

the company<br />

Who should be involved<br />

Design team Procurement team Site team<br />

The design team should<br />

follow the ICE Demolition<br />

Pro<strong>to</strong>col <strong>and</strong> WRAP’s<br />

Efficient Use of Materials<br />

in Regeneration guide. 6<br />

Table 3: Structuring the materials recovery process<br />

The procurement team<br />

should be responsible for<br />

finding out where these<br />

materials might be needed<br />

in the company <strong>and</strong> whether<br />

it would be economically<br />

viable <strong>to</strong> deliver them <strong>to</strong> the<br />

specified site.<br />

The site team should utilise<br />

the expertise <strong>and</strong> knowledge<br />

of the <strong>waste</strong> <strong>management</strong><br />

contrac<strong>to</strong>r.<br />

Close out<br />

Evidence of materials<br />

resource efficiency<br />

performance<br />

Evidence of materials<br />

resource efficiency<br />

performance<br />

Evidence of materials<br />

resource efficiency<br />

performance<br />

Review <strong>and</strong> feedback Review <strong>and</strong> feedback Review <strong>and</strong> feedback<br />

5. See Table 7: Materials Exchange Websites<br />

6. WRAP’s Efficient Use of Materials in Regeneration guide is a step-by-step guide linking the Demolition Pro<strong>to</strong>col through <strong>to</strong> the<br />

initiation of a SWMP