Responding to waste minimisation and management ... - Wrap

Responding to waste minimisation and management ... - Wrap

Responding to waste minimisation and management ... - Wrap

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

48 <strong>Responding</strong> <strong>to</strong> <strong>waste</strong> <strong>minimisation</strong> <strong>and</strong> <strong>management</strong> requirements <strong>Responding</strong> <strong>to</strong> <strong>waste</strong> <strong>minimisation</strong> <strong>and</strong> <strong>management</strong> requirements 49<br />

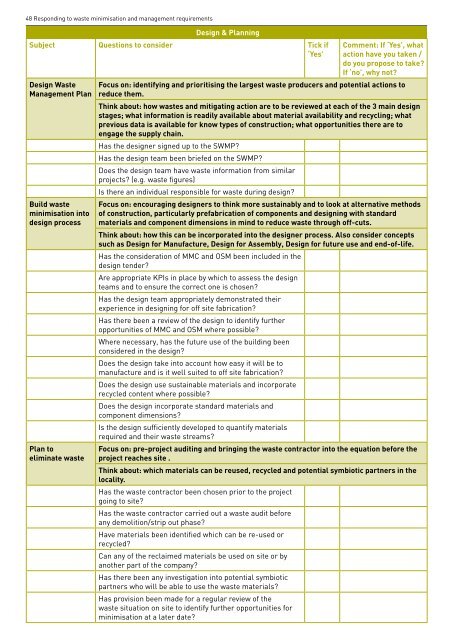

Design & Planning<br />

Subject Questions <strong>to</strong> consider Tick if<br />

‘Yes’<br />

Design Waste<br />

Management Plan<br />

Build <strong>waste</strong><br />

<strong>minimisation</strong> in<strong>to</strong><br />

design process<br />

Plan <strong>to</strong><br />

eliminate <strong>waste</strong><br />

Comment: If ‘Yes’, what<br />

action have you taken /<br />

do you propose <strong>to</strong> take<br />

If ‘no’, why not<br />

Focus on: identifying <strong>and</strong> prioritising the largest <strong>waste</strong> producers <strong>and</strong> potential actions <strong>to</strong><br />

reduce them.<br />

Think about: how <strong>waste</strong>s <strong>and</strong> mitigating action are <strong>to</strong> be reviewed at each of the 3 main design<br />

stages; what information is readily available about material availability <strong>and</strong> recycling; what<br />

previous data is available for know types of construction; what opportunities there are <strong>to</strong><br />

engage the supply chain.<br />

Has the designer signed up <strong>to</strong> the SWMP<br />

Has the design team been briefed on the SWMP<br />

Does the design team have <strong>waste</strong> information from similar<br />

projects (e.g. <strong>waste</strong> figures)<br />

Is there an individual responsible for <strong>waste</strong> during design<br />

Focus on: encouraging designers <strong>to</strong> think more sustainably <strong>and</strong> <strong>to</strong> look at alternative methods<br />

of construction, particularly prefabrication of components <strong>and</strong> designing with st<strong>and</strong>ard<br />

materials <strong>and</strong> component dimensions in mind <strong>to</strong> reduce <strong>waste</strong> through off-cuts.<br />

Think about: how this can be incorporated in<strong>to</strong> the designer process. Also consider concepts<br />

such as Design for Manufacture, Design for Assembly, Design for future use <strong>and</strong> end-of-life.<br />

Has the consideration of MMC <strong>and</strong> OSM been included in the<br />

design tender<br />

Are appropriate KPIs in place by which <strong>to</strong> assess the design<br />

teams <strong>and</strong> <strong>to</strong> ensure the correct one is chosen<br />

Has the design team appropriately demonstrated their<br />

experience in designing for off site fabrication<br />

Has there been a review of the design <strong>to</strong> identify further<br />

opportunities of MMC <strong>and</strong> OSM where possible<br />

Where necessary, has the future use of the building been<br />

considered in the design<br />

Does the design take in<strong>to</strong> account how easy it will be <strong>to</strong><br />

manufacture <strong>and</strong> is it well suited <strong>to</strong> off site fabrication<br />

Does the design use sustainable materials <strong>and</strong> incorporate<br />

recycled content where possible<br />

Does the design incorporate st<strong>and</strong>ard materials <strong>and</strong><br />

component dimensions<br />

Is the design sufficiently developed <strong>to</strong> quantify materials<br />

required <strong>and</strong> their <strong>waste</strong> streams<br />

Focus on: pre-project auditing <strong>and</strong> bringing the <strong>waste</strong> contrac<strong>to</strong>r in<strong>to</strong> the equation before the<br />

project reaches site .<br />

Think about: which materials can be reused, recycled <strong>and</strong> potential symbiotic partners in the<br />

locality.<br />

Has the <strong>waste</strong> contrac<strong>to</strong>r been chosen prior <strong>to</strong> the project<br />

going <strong>to</strong> site<br />

Has the <strong>waste</strong> contrac<strong>to</strong>r carried out a <strong>waste</strong> audit before<br />

any demolition/strip out phase<br />

Have materials been identified which can be re-used or<br />

recycled<br />

Can any of the reclaimed materials be used on site or by<br />

another part of the company<br />

Has there been any investigation in<strong>to</strong> potential symbiotic<br />

partners who will be able <strong>to</strong> use the <strong>waste</strong> materials<br />

Has provision been made for a regular review of the<br />

<strong>waste</strong> situation on site <strong>to</strong> identify further opportunities for<br />

<strong>minimisation</strong> at a later date<br />

Procurement<br />

Subject Questions <strong>to</strong> consider Tick if<br />

‘Yes’<br />

General<br />

Procurement<br />

Policy<br />

Materials<br />

supply only<br />

Sub-contrac<strong>to</strong>r<br />

procurement<br />

Comment: If ‘Yes’, what<br />

action have you taken /<br />

do you propose <strong>to</strong> take<br />

If ‘no’, why not<br />

Focus on: setting out company procurement policy that integrates <strong>waste</strong> as a key area. Also<br />

setting up supplier frameworks based on relevant criteria <strong>and</strong> KPIs.<br />

Think about: relevant KPIs <strong>and</strong> criteria that might be incorporated in<strong>to</strong> procurement of both<br />

materials <strong>and</strong> works packages.<br />

Do you have a procurement policy which integrates<br />

<strong>waste</strong> <strong>minimisation</strong> <strong>and</strong> sets out the corporate stance on<br />

issues like packaging <strong>and</strong> KPIs that must be met by subcontrac<strong>to</strong>rs<br />

<strong>and</strong> suppliers before they can be hired<br />

Focus on: underst<strong>and</strong>ing alternative product availability for major <strong>waste</strong> producing materials,<br />

including realistic <strong>waste</strong> allowances <strong>and</strong> <strong>waste</strong> recyclability.<br />

Think about: dimensional flexibility; sizes made <strong>to</strong> fit; fac<strong>to</strong>ry finished components; recycled<br />

content; h<strong>and</strong>ling, protection <strong>and</strong> packaging.<br />

Have KPIs been set for the recycled content of the works<br />

Is the recycled content of the material known<br />

Are materials available in dimensions which will minimise<br />

site <strong>waste</strong> through off-cuts/surplus<br />

Can <strong>waste</strong> streams be re-used or recycled<br />

Is packaging needed<br />

If packaging is required, is it re-usable<br />

Are materials available in dimensions which will minimise<br />

site <strong>waste</strong> through off-cuts/surplus<br />

Can <strong>waste</strong> arising from materials through off-cuts/surplus<br />

be recycled<br />

Can excess materials be reduced <strong>and</strong> eliminated in future<br />

through improved Quantity Surveying<br />

Is there a feedback mechanism <strong>to</strong> inform the procurement<br />

department of actual volumes of materials used <strong>to</strong> ensure<br />

<strong>waste</strong> is minimised next time<br />

Focus on procuring subcontrac<strong>to</strong>rs who will use materials efficiently <strong>and</strong> effectively; who<br />

will adhere <strong>to</strong> the SWMP <strong>and</strong> are prepared <strong>to</strong> obtain <strong>and</strong> work with specified materials where<br />

major <strong>waste</strong> streams are anticipated, <strong>and</strong> will offer realistic <strong>waste</strong> allowances.<br />

Think about: how <strong>to</strong> communicate <strong>waste</strong> <strong>management</strong> requirements <strong>and</strong> how <strong>to</strong> involve the<br />

sub-contrac<strong>to</strong>rs constructively.<br />

Have relevant KPIs <strong>and</strong> criteria been set <strong>to</strong> select the most<br />

appropriate sub-contrac<strong>to</strong>rs<br />

Have the sub-contrac<strong>to</strong>rs, in particular the <strong>waste</strong><br />

contrac<strong>to</strong>rs, been involved in the SWMP<br />

Are incentives for good performance in place <strong>to</strong> encourage<br />

sub-contrac<strong>to</strong>rs <strong>to</strong> pay heed <strong>to</strong> minimising <strong>waste</strong><br />

Are there opportunities for on site forums <strong>to</strong> air good ideas<br />

<strong>and</strong> facilitate feedback<br />

Will the <strong>waste</strong> contrac<strong>to</strong>r be providing regular<br />

<strong>waste</strong> reports<br />

Has any mix of nationalities within the team been<br />

considered <strong>and</strong> catered for in terms of getting the <strong>waste</strong><br />

<strong>management</strong> method across