Drum mowers - ACI Distributors

Drum mowers - ACI Distributors

Drum mowers - ACI Distributors

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

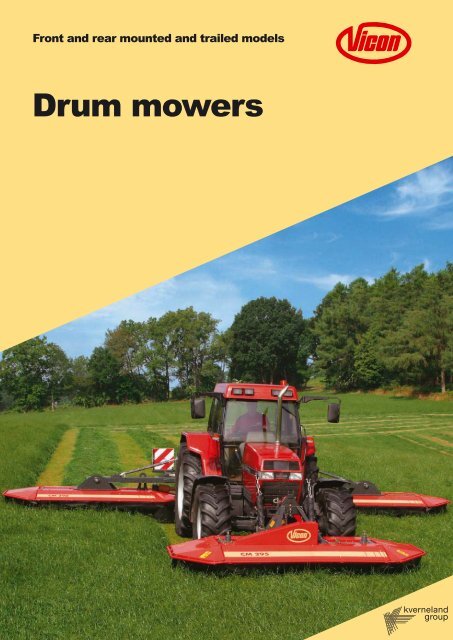

Front and rear mounted and trailed models<br />

<strong>Drum</strong> <strong>mowers</strong>

CM 168-188-218<br />

Reliable mowing quality<br />

in all crop conditions<br />

Vicon drum <strong>mowers</strong> are reliable,<br />

safely and easy-to-operate highquality<br />

machines that produce perfect<br />

results under all conditions.<br />

It all revolves around the drum<br />

For a better and faster crop throughput, each<br />

mower drum has two flat sides on which strips<br />

with replaceable transport plates are fitted.<br />

These plates pull the crop between the drums<br />

and directly transport it to the rear.<br />

This patented invention keeps the crop away<br />

from the drums, thus considerably reducing<br />

wear and the risk of wrapping in long crops.<br />

Freely rotating saucers<br />

The saucers can rotate during mowing. So<br />

the machine can closely follow the ground<br />

contours. That prevents swath damage in all<br />

conditions.<br />

Exchangeable transport plates

Standard compensation springs<br />

Adapter for tractors with wide tyres<br />

<strong>Drum</strong>s with flat sides<br />

Round drums don’t transport. Vicon uses<br />

drums with two flat sides for optimum crop<br />

transport. The drum and drum skirt consist of<br />

two separate parts. That greatly facilitates<br />

maintenance and repairs.<br />

Compensation springs<br />

The front mounted as well as the rear mounted<br />

<strong>mowers</strong> are equipped with compensation<br />

springs to keep the ground pressure as low<br />

as possible.<br />

Exchanging blades quickly<br />

Adjustable overload protection<br />

Great performers in the compact<br />

class<br />

The Vicon CM 168, CM 188 and CM 218<br />

offer advanced engineering also in the<br />

compact class with working widths of 1.65 to<br />

2.10 metres. The right choice for small and<br />

middle-sized farms that have deliberately<br />

chosen not to work with a mower-conditioner.<br />

A long service life, easy to operate and reliable<br />

performance. That’s what characterises every<br />

Vicon drum mower.<br />

Easy hitching<br />

The CM 168, CM 188 and CM 218 are hitched<br />

easily to every tractor with Cat. I or II linkage<br />

pins. A special adapter is available for tractors<br />

with wide tyres.<br />

Complete equipment<br />

The standard fitted compensation springs<br />

reduce the ground pressure of the saucers<br />

and protects the swath. Moreover, the mower<br />

follows the tractor more closely on slopes.<br />

Hydraulic folding cylinder available as an option (CM 168-CM 188)

CM 268-298-338<br />

Mounted <strong>mowers</strong><br />

ready for action<br />

The Vicon CM 268, CM 298 and<br />

CM 338 are proof that drum <strong>mowers</strong><br />

certainly don’t have to be heavier<br />

than disc <strong>mowers</strong> with a comparable<br />

mowing width. The CM 268, CM 298<br />

and CM 338 only weigh 645, 745 kg<br />

and 810 kg respectively. Already<br />

more than 12.000 CM 268 units have<br />

been sold all over the world. The<br />

unique combination of two large outer<br />

drums and two small inner drums<br />

results in the fastest possible crop<br />

transport. In addition, the CM 268<br />

requires relatively little tractor<br />

power so it can also be used behind<br />

light tractors without front lift.<br />

The CM 298 sets the new standard in the field<br />

of capacity, service life and mowing quality.<br />

With a mowing width of 2.95 m and the<br />

characteristic double swath, the CM 298 is<br />

the ideal team mate for baler or forage wagon.<br />

The two large outer drums and two small<br />

inner drums result in an easy crop transfer<br />

and minimum tractor power requirements.<br />

With a mowing width of 3.30 m and four large<br />

equal size drums the CM 338 offers high<br />

capacity at minimum power requirements.<br />

A new head stock and sub frame enables<br />

working with bigger tractors and combinations<br />

with every kind of front mounted <strong>mowers</strong>.<br />

The patented quick blade exchange system<br />

has been adopted from the CMP series.<br />

Perfect weight distribution<br />

The large compensation springs effectively<br />

transfer a substantial part of the mower weight<br />

to the tractor. In combination with the freely<br />

rotating saucers that prevents swath damage.<br />

Transport<br />

You don’t have to leave the tractor seat to<br />

simply swing the CM 268, CM 298 and<br />

CM 338 drum <strong>mowers</strong> to transport position<br />

straight behind the tractor. A hydraulic cylinder<br />

is optionally available to fold up the machine<br />

next to or behind the tractor. The weight<br />

remains as closely as possible to the tractor<br />

so the tractor manoeuvrability is hardly or not<br />

affected.

CM 338<br />

3 transport positions: to the rear lengthwise, folded up, or folded up to the side<br />

From transport to working<br />

position<br />

The drums are gear driven in a maintenance<br />

free enclosed grease bath.<br />

Compensation springs<br />

A reliable safety breakaway prevents<br />

damage to the mowing frame<br />

when hit by foreign objects<br />

Reliable drive system<br />

Power from the tractor to the drums is<br />

transmitted by a pto drive shaft with an<br />

integrated overrun clutch. The well proven<br />

V-belt drive protects the driveline and drums<br />

in case of foreign objects blocking the mower.<br />

A shear bolt in the horizontal drive shaft<br />

provides additional protection to the outer<br />

drums.<br />

Large outer drums and<br />

small inner drums offer great<br />

advantages: perfectly following<br />

the ground, neat swaths and a<br />

high throughput capacity

CM 190-230-270F(P)-295F(P)<br />

Continuously variable<br />

cutting height adjustment<br />

Vicon offers four models with<br />

continuously variable cutting height<br />

adjustment; two front <strong>mowers</strong><br />

CM 270F(P) and CM 295F(P) and two<br />

mounted <strong>mowers</strong> CM 190 and CM 230.<br />

The cutting height is adjusted with<br />

a spindle at the top of the mower;<br />

within easy reach and continuously<br />

variable. So you no longer have to<br />

crawl under the mower and you can<br />

check at a glance whether the<br />

cutting height on the left and on the<br />

right are set the same.<br />

Cutting height adjustment<br />

CM 190 and CM 230 quickly ready<br />

for operation<br />

You can put both <strong>mowers</strong> from transport to<br />

working position and back without leaving<br />

the tractor. On the CM 230 that is done<br />

hydraulically. In order not to take too much<br />

load off the tractor front axle, a hydraulic folding<br />

cylinder is available that folds up the mower<br />

to the rear or to the right of the tractor.<br />

Also available with conditioner<br />

The CM 190 and 230 can be supplied or<br />

retrofitted with a drum conditioner. With a<br />

special mounting plate and cleverly designed<br />

fasteners, the conditioner can be mounted<br />

and dismounted without special tools; flexible<br />

and time-saving.<br />

combination of large and small drums<br />

ensures maximum crop discharge and a<br />

double swath that is easily picked up by<br />

tedders or loading wagons. With the large<br />

swath wheels you determine the width: narrow<br />

swaths (90 cm) for daily indoor feeding or<br />

wide for forage harvesting.<br />

Optimum ground adaptation<br />

With their simple, rigid frame both <strong>mowers</strong><br />

are an efficient and cost-effective solution for<br />

every forage specialist. The flexible top link<br />

‘Flextop’ or the telescopic top link ‘Frontflex’<br />

ensure unique ground adaptation in the driving<br />

direction. Transverse ground adaptation is<br />

ensured by the front lift linkage arms. For<br />

tractor front lifts without pendulum device, a<br />

version with pendulum frame is available.<br />

This frame is designed to push the mower<br />

from fixed hinge points rather than vertical<br />

slotted holes. That allows the mower to move<br />

across the driving direction, also at high ground<br />

pressure. The result is a clear cut and an<br />

undamaged sward.<br />

Tested safety drive<br />

The V-belts with automatic tensioner ensure<br />

a regular and reliable drive. A shearbolt in the<br />

main drive shaft protects the drive against<br />

overload.<br />

Top quality front <strong>mowers</strong><br />

With the two large outer drums and two<br />

small inner drums the CM 270F(P) and CM<br />

295F(P) set the standard in their class. The

Pendelflex frame<br />

Front mower combined with TK 300; cutting, conditioning and spreading full width<br />

Flextop<br />

Optimum swath shape<br />

Mowing at the front, conditioning<br />

at the rear<br />

If you use your front mower to cut fresh feed<br />

every day, but still want to condition the crop,<br />

you can opt for the TK 300. This trailed finger<br />

conditioner conditions the crop and spreads<br />

it full width in one pass without driving over<br />

the crop.<br />

CM 270F mower frame

CMP 2601-2901<br />

Professional drum<br />

mower conditioners<br />

Simple design, reliable, economical<br />

and affordable. That’s what we call a<br />

mower conditioner without ceremony.<br />

Those were the main requirements<br />

for the development of the new<br />

Vicon drum mower conditioners:<br />

the CMP 2601 and CMP 2901. With<br />

their working widths of 260 and<br />

290 cm respectively, both these<br />

mounted drum mower conditioners<br />

are geared to the needs of the<br />

professional user, farmers and<br />

contractors alike.<br />

Rugged suspension frame<br />

The suspension frame is made of one heavy<br />

tube section. The two hitching points allow<br />

lateral adjustment over 12.5 cm. That makes<br />

the CMP mower conditioners suitable for use<br />

with all common tractors.<br />

Pure ease of operation<br />

The new Vicon CMP mower conditioners are<br />

operated fully hydraulically. You use a hydraulic<br />

lever to put the mower into transport, working<br />

or head-land position. In headland position<br />

the mower frame can be lifted fully.<br />

Particularly the outer edge, that sags too far<br />

on many large three-points <strong>mowers</strong>, is lifted<br />

high off the ground. Very important when<br />

working in dense crop. Of course that also<br />

facilitates cleaning or exchanging the blades.<br />

Cutting height adjustment

Ground pressure compensation<br />

prevents swath damage<br />

Two sturdy compensation springs reduce the<br />

pressure of the mower frame on the ground.<br />

You can quickly adjust the setting to the soil<br />

conditions. Together with the freely rotating<br />

saucers this prevents sward damage.<br />

Standard conditioner<br />

Both <strong>mowers</strong> have an integrated conditioner<br />

with extra large conditioning rotor and wearresistant<br />

stiff synthetic fingers. The throughput<br />

capacity is high, even in dense crop the<br />

conditioner requires relatively little power. As<br />

standard the <strong>mowers</strong> come with continuously<br />

adjustable spreader elements that allow you<br />

to deposit the swath at any desired width.<br />

Moreover, you can adjust the conditioning<br />

intensity to any type and quantity of crop.<br />

To enable you to work without conditioner in<br />

certain cases, for instance for feeding in the<br />

barn, it can be mounted and dismounted very<br />

quickly. For this purpose a set of support<br />

wheels for the conditioner and a protective<br />

cover are optionally available.<br />

Always a regular swath<br />

The mower frames of the CMP 2601 and<br />

2901 have two large outer drums and two<br />

smaller inner drums. They effortlessly transport<br />

the crop over the full width to the conditioner.<br />

In the CMP 2901 the drum directly next to<br />

the tractor wheel has an extra large diameter.<br />

Also when cutting with more overlap, the crop<br />

quantity to the conditioner on the left and on<br />

the right remains the same and in all events<br />

an even swath is produced.<br />

Quick exchange of blades<br />

The quick exchange system allows you to<br />

exchange blades with one hand. With a special<br />

blade wrench you push the blade holder down<br />

over the dead centre position and you have<br />

both hands free to exchange the blades.<br />

Combination of a front mower, a CMP 2901<br />

and a TK 300D. A mowing width of<br />

5.50 metres and full width spreading<br />

without driving over the crop<br />

Quick exchange of blades

CMP 3001A<br />

Reliable cost effective<br />

mowing<br />

CMP 3001A during road transport<br />

The Vicon CMP 3001A is a trailed<br />

drum mower with a cutting width of<br />

300 cm and an integrated conditioner.<br />

It is a compact no-frills machine for<br />

cost conscious farmers. Wheels,<br />

cutting head and conditioner are one<br />

unit. Together with a large conditioner<br />

this makes the CMP 3001A suitable<br />

for use with low horse power tractors.<br />

Linkage<br />

The most economic version of the CMP 3001A<br />

can simply and quickly be attached to the fixed<br />

lower hitch of the tractor. The 180 degrees<br />

(wide angle of the main pto drive shaft enables<br />

sharp turns to the left and to the right.<br />

The full swivel hitch version (with Pivot Star)<br />

is hitched up to the draught links of the 3-point<br />

hydraulics. With the Pivot Star (also available<br />

as an option) the main pto drive shaft remains<br />

in alignment with the tractor allowing full<br />

freedom to turn without damaging the pto drive<br />

shaft. It also minimises variation in pto shaft<br />

lenghts.<br />

Transport and working position<br />

The double acting hydraulic steering cylinder<br />

moves the machine from transport (in line<br />

behind the tractor) into working position. It also<br />

provides an on-the-move means of adjusting<br />

the draw bar position for varying field conditions<br />

and working on slopes or mowing around<br />

obstacles. The stroke of the single acting<br />

cylinders on the wheel brackets is long enough<br />

to allow for sufficient ground clearance for<br />

transport and on headlands.<br />

Ground pressure compensation<br />

The CMP 3001A’s ground pressure<br />

compensation is very sophisticated. The<br />

ground pressure is compensated by means<br />

of two sets of torsion bars. The torsion bars<br />

are connected via a triangular lever which<br />

again is connected with the draw bar by a<br />

rod. So ground pressure is controlled by the<br />

draw bar. Consequently independent of the<br />

position of the mower the ground pressure is<br />

always equal over the full cutting width. This<br />

means excellent adaptation to ground contours,<br />

no swath damage and minimum saucer wear.

Wheels<br />

Wide Multi-Ring Profil tyres are standard.<br />

These tyres keep the mower always in a<br />

stable position beside the tractor also when<br />

mowing on slopes and in hilly conditions.<br />

Hydraulic control cylinder<br />

Large conditioner<br />

The standard conditioner handles heavy crops<br />

very easily. Adjustable spreading elements and<br />

adjustable guiding vanes on the spreading flap<br />

enable spreading over the full cutting width. The<br />

conditioning effect can also simply be adjusted.<br />

Drive<br />

Power from the tractor to the drums is<br />

transmitted by a pto drive shaft with an<br />

integrated overrun and slip clutch, a heavy<br />

double cv-joint, and an extra strong hexagon<br />

shaft running inside a completely welded<br />

gear casing. The conditioner is driven via a<br />

maintenance free duplex chain. The cutting<br />

head has 2 large outer and 2 smaller inner<br />

drums. Cutting height is adjusted via spacers<br />

or optionally via a stepwise height adjustment<br />

in steps of 0, 10, 20 or 30 mm. The quick blade<br />

change system permits changing with one<br />

hand. The special lever is designed in such<br />

a a way that the blade holder is immobilised,<br />

so the operator has both hands free to replace<br />

the blades.<br />

Wide conditioning rotor with nylon fingers<br />

Pivot Star swivel hitch<br />

A strong hexagon shaft drives the mowing<br />

drums

CM 908<br />

Top performance<br />

for medium size farms<br />

CM 908 in transport<br />

Another high-performance mower<br />

comes from the inventor of the drum<br />

mower technology. Completing the<br />

existing mower combination for<br />

large agricultural enterprises and<br />

contractors, this new version has<br />

been designed with the medium size<br />

farm in mind.<br />

Really a remarkable development<br />

from 0.8 m cutting width in 1963 to<br />

Vicon’s top performance <strong>mowers</strong><br />

reaching up to 9 m working width.<br />

Proven mower technology<br />

The two rear units of this mower combination<br />

are the tried and proven design of the CM 298.<br />

With the legendary drum design of more than<br />

15.000 front and rear mounted Vicon <strong>mowers</strong><br />

so far sold, the CM 908 ensures top cutting<br />

quality and ideally textured swaths at minimum<br />

power requirement.<br />

Any combination<br />

Variable by steps on a perforated strip, the<br />

working width of the rear mowing units can be<br />

adjusted to match front <strong>mowers</strong> of different<br />

cutting width (possible setting options are<br />

7.9 m, 8.2 m and 8.5 m).<br />

As an option comes a special mounting frame<br />

permitting the front mowing unit to be attached<br />

to the rear end of the CM 908 which then is<br />

used as an entirely rear-mounted combination.<br />

Best weight transfer<br />

With one unit coupled to the front power lift<br />

and two units attached to the tractor rear end,<br />

this mower combination ensures an excellent<br />

weight transfer for best manoeuvrability in<br />

sloping terrain. With a weight of 1800 kg the<br />

CM 908 is ideally suited for use on mediumsize<br />

and large farms operating tractors from<br />

120 to 150 HP.<br />

CM 908 in triple version

CMP 9001(TK) - CMP 3001FZ-TK<br />

9 m mower combinations<br />

Mower combination<br />

CMP 9001TK<br />

Mower combination CMP 9001<br />

The CMP 9001TK mower combination<br />

offers the highest feasible mowing<br />

capacity. It is a combination of two<br />

<strong>mowers</strong>, to the left and to the right<br />

of the tractor, each with a working<br />

width of 3 metres. The machine is<br />

simply hitched to the tractor power<br />

lift. In combination with a front mower<br />

that results in a mowing width of no<br />

less than 8.40 metres.<br />

CMP 3001FZ-TK<br />

The Vicon CM 3001FZ-TK front mower has<br />

all the technical features for high-capacity<br />

forage harvesting. The drag suspension, the<br />

wide conditioning rotor and the spreader hood<br />

are all standard.<br />

Even weight distribution<br />

The clever combination of a front mower and<br />

two <strong>mowers</strong> behind the tractor results in an<br />

optimum weight distribution of the CMP 9001.<br />

The weight does not rest only on the rear axle,<br />

but on both tractor axles. In addition to reduced<br />

track formation, it also offers comfortable<br />

road transport.<br />

CMP 3001FZ-TK<br />

Slope mowing<br />

Slope mowing is a job for experts. If the tractor<br />

starts to drift, the mowing pattern no longer<br />

links up with the previous pass resulting in<br />

stripes. Vicon has a fitting solution. For the<br />

CMP 9001 a hydraulic side shift is optionally<br />

available allowing you to shift the complete<br />

mower combination 20 cm to the left or to the<br />

right. That way you compensate any tractor<br />

drift and you can make sure the mowing<br />

pattern links up neatly.<br />

With or without conditioner<br />

You can choose between two versions:<br />

the CMP 9001 without conditioner or the<br />

CMP 9001TK with conditioner.<br />

Free Float Suspension System

Technical specifications<br />

CM 190<br />

CM 168<br />

CM 295F<br />

Mower CM 168 CM 188 CM 190 CM 218 CM 230 CM 268 CM 270F CM 298<br />

Working width (cm) 165 185 185 210 230 265 265 295<br />

Transport width (cm) 140 150 150 160 165 180 260 200<br />

Transport height approx. (cm) - - - - - - - -<br />

Weight (kg) 380 420 475 580 630 645 570 745<br />

Number of drums 2 2 2 2 2 4 4 4<br />

Number of blades per drum 6 6 6 8 8 10 10 12<br />

Cutting height adjustment (mm)<br />

- continuous - - 30 - 30 - 30 -<br />

- with spacer rings 12 24 - 24 - 24 - 24<br />

- incremental - - - - - - - -<br />

PTO speed (rpm) 540 540 540 540 540 540 1000 540<br />

Required PTP power (kW/hp) 20/27 25/35 25/30 30/40 33/45 40/55 37/50 47/65<br />

- two-wheel drive from - - - - - - -<br />

- four-wheel drive from - - - - - - -<br />

Linkage cat. I+II cat. I+II cat. I+II cat II cat. II cat. II cat. II cat. II<br />

+ Accord<br />

quick hitch<br />

Tyres<br />

Required number of hydraulic connections - - - - 2 - - -<br />

Swath wheels (1x) o (1x) o (1x) o (1x) o (1x) o (2x) o (2x)●(2x)o (2x) o<br />

Hydraulic transport cylinder o* o* o* o* o* o* - o*<br />

Depth limiter chain o o o o o o - o<br />

540/740/1000 rpm set ●/-/- ●/-/- ●/-/- ●/-/o ●/-/o ●/-/o o/o/● ●/-/o<br />

Set spacer rings per saucer (4x3) o (1x8)●(2x8)o - (1x8)●(2x8)o - (1x8)●(2x8)o - (1x8)●(2x8)o<br />

Continuous cutting height adjustment - -- - - - - - -<br />

Warning signs and lighting set - - - - - - - -<br />

Adapter for wider tractors o o - o - - - -<br />

Flextop - - - - - - o -<br />

Frontflex - - - - - - o -<br />

Conditioner - - o o o - - -<br />

Weight (kg) - - 105 115 120 - - -<br />

Set parking wheels and protective cloth<br />

for removing the conditioner - - - - - - - -<br />

Mounting frame TK 300D - - - - - - - -<br />

Tandem axle (tyres) - - - - - - - -<br />

● = standard o = option - = not available<br />

* with cylinder (1 s.a. valve required)<br />

** in combination with front mower<br />

*** incl. factory fitted conditioner<br />

CM 600<br />

CMP 9001A

CM 298<br />

CMP 2901<br />

CM 338<br />

CMP 3001FZ<br />

CM 295F CM 338 CM 908 CMP 2601 CMP 2901 CMP 3001FZ CMP3001A CMP 9001 TK 300<br />

295 330 790/820/850** 260 290 300 300 840** 300<br />

290 200 300 195 195 300 300 300 250<br />

- - 400 370 400 - - 400 475<br />

645 810 1800 970*** 1015*** 1200*** 1200*** 3000***<br />

4 4 8 4 4 4 4 8<br />

12 12 24 8 9 10 10 20<br />

30 - - - - - - -<br />

- 24 24 24 24 24 24 24<br />

- - 30 30 30 30 30 30<br />

1000 540 1000 540 1000 1000 1000 1000 1000<br />

44/60 - 74/100 - - 55/75 40/55 118/160 18/25<br />

- 59/80 - 59/80 66/90 - - -<br />

- 52/70 - 52/70 59/80 - - -<br />

cat. II cat. II cat. II cat. II cat. II Accord lower hitch cat. II+III cat. I+II<br />

+ Accord quick hitch or cat. II<br />

quick hitch<br />

(Pivot Star)<br />

11.50/80- 16x6.50-<br />

15.3MR<br />

8 4PR<br />

- - 3 1 1 - 2 1 -<br />

(2x)●(2x)o (2x)o - (2x) o (2x) o - - - -<br />

- o* - ● ● - - - -<br />

- o - o o - - - -<br />

o/o/● ●/-/o -/-/● ●/-/o o/-/● -/-/● o/-/● -/-/● -<br />

- (1x8)●(2x8)o (1x8)●(2x8)o (1x8)●(2x8)o (1x8)●(2x8)o (1x8)●(2x8)o (1x8)●(2x8)o (1x8)●(2x8)o -<br />

- - - o o o o o -<br />

- - o o o - o o -<br />

- - - - - - - - -<br />

o - - - - - - - -<br />

o - - - - - - - -<br />

- - - o*** o*** o*** o*** o*** -<br />

- - - 180 195 200 200 400 -<br />

- - - o o - - - -<br />

- - - o o - - - -<br />

- - - - - - - - o***<br />

(15x6.00-<br />

6 6PR)<br />

CM 908<br />

CMP3001A<br />

This documentation is not binding. Availability of models, specifications and optional equipment may differ from country to country. Please consult<br />

your local dealer. Specifications and design are subject to change without notice. Printed in Holland. © Kverneland Group<br />

Vital parts<br />

The Kverneland Group regards the sale of each machine as the start of a long-term and<br />

valuable relationship. To support the relationship, we provide the vital high quality spare parts<br />

and an efficient spare parts service.<br />

Our parts are designed to ensure reliability, safety and an optimal performance of the machines.<br />

The quality lies in the innovative construction work and in the production processes at our<br />

production sites. The spare parts are available in close proximity to you; at our dealership in<br />

your area as well as at our distribution centres. We maintain high availability of spare parts to<br />

ensure minimum operational disruption at your end.<br />

You can depend on the Kverneland Group to offer a premium service. It’s vital for us!

Kverneland Group is the largest<br />

specialised producer and<br />

distributor of farming implements<br />

in the world. The Group is a<br />

family of strong brands enabling<br />

us to provide both the farmer<br />

and dealer with a unique and<br />

complete range of high quality<br />

products for soil preparation,<br />

grass harvesting, seeding,<br />

spreading, spraying, potato<br />

cultivation and grape harvesting.<br />

www.kvernelandgroup.com<br />

A full range of<br />

forage harvesting<br />

equipment<br />

Vicon offers you a full range of<br />

forage harvesting equipment:<br />

drum and disc <strong>mowers</strong> and mower<br />

conditioners, tedders, rakes,<br />

fixed and variable chamber round<br />

balers, big square balers, bale<br />

wrappers, fertiliser spreaders<br />

and maize choppers.<br />

All Vicon machines are protected by a<br />

Duracoat powder paint coating.<br />

The result is a sealed extremely hard<br />

wearing and attractive finish.<br />

Kverneland Group UK Ltd<br />

Walkers Lane, Lea Green, St. Helens<br />

Merseyside WA9 4 AF<br />

Tel 01744 853 200, Fax 01744 853 400<br />

Kverneland Group Ireland Ltd<br />

Hebron Industrial Estate<br />

Kilkenny<br />

Tel 056 51597, Fax 056 62207<br />

F 1301-GB