L8 Ceramics NOTES.pdf

L8 Ceramics NOTES.pdf

L8 Ceramics NOTES.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

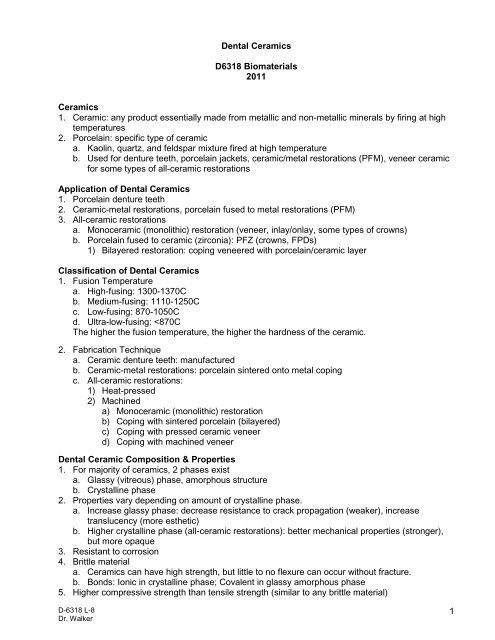

Dental <strong>Ceramics</strong><br />

D6318 Biomaterials<br />

2011<br />

<strong>Ceramics</strong><br />

1. Ceramic: any product essentially made from metallic and non-metallic minerals by firing at high<br />

temperatures<br />

2. Porcelain: specific type of ceramic<br />

a. Kaolin, quartz, and feldspar mixture fired at high temperature<br />

b. Used for denture teeth, porcelain jackets, ceramic/metal restorations (PFM), veneer ceramic<br />

for some types of all-ceramic restorations<br />

Application of Dental <strong>Ceramics</strong><br />

1. Porcelain denture teeth<br />

2. Ceramic-metal restorations, porcelain fused to metal restorations (PFM)<br />

3. All-ceramic restorations<br />

a. Monoceramic (monolithic) restoration (veneer, inlay/onlay, some types of crowns)<br />

b. Porcelain fused to ceramic (zirconia): PFZ (crowns, FPDs)<br />

1) Bilayered restoration: coping veneered with porcelain/ceramic layer<br />

Classification of Dental <strong>Ceramics</strong><br />

1. Fusion Temperature<br />

a. High-fusing: 1300-1370C<br />

b. Medium-fusing: 1110-1250C<br />

c. Low-fusing: 870-1050C<br />

d. Ultra-low-fusing:

Ceramic denture teeth<br />

1. Disadvantages:<br />

a. Higher fracture rate<br />

b. No bond to PMMA denture resin base: Mechanical retention (pegs or holes in teeth)<br />

c. More difficult to adjust<br />

d. Abrade tooth structure and other non-ceramic restorations<br />

2. Advantages<br />

a. Minimal denture tooth wear with max/mand complete denture, as opposed to polymer<br />

denture teeth.<br />

Vertical dimension changes are related to what factors<br />

Historical background ceramic restorations<br />

1. 1900’s, porcelain jackets; Low strength, limited to anterior teeth<br />

2. 1960’s, porcelain fused to metal restorations<br />

a. Higher strength due to metal framework<br />

b. Better match of coefficient of thermal expansion between alloy & ceramic<br />

3. Late 1990’s all-ceramic restorations<br />

a. Glass ceramics (monoceramic-no coping/framework)<br />

b. Porcelain fused to alumina (ceramic coping/framework)<br />

c. Porcelain fused to zirconia (ceramic coping/framework)<br />

<strong>Ceramics</strong> for ceramo-metal restorations (PFM)<br />

1. Low and ultra-low fusing ceramics<br />

a. Melting temperature of the alloy must not be exceeded during ceramic firing process<br />

b. Coefficient of thermal expansion (CTE) of alloy slightly greater than ceramic<br />

c. Ultra-low fusing ceramics are less abrasive than low fusing.<br />

1) Important consideration when ceramic restorations are used in anterior mandible and will<br />

occlude with maxillary natural dentition.<br />

2) In contrast, less of a problem with anterior maxillary restorations, because can have<br />

lingual metal occluding with anterior mandibular natural dentition.<br />

d. UMKC ceramic: Ceramco 3, Low-fusing.<br />

2. Feldspathic dental porcelain<br />

a. Composition: Feldspar 75-85%; Kaolin ~5%; Silica 15%; Metallic Oxides ≤ 3%<br />

b. Powder contains glass components and crystals (leucite)<br />

1) Metallic oxides (pigments/opaquers) added to powder<br />

c. Sintering (Firing)<br />

1) Used in crown/FPD fabrication process; porcelain sintered onto the metal framework<br />

2) Powder particles sintered together to form a continuous mass<br />

a) Glassy matrix with leucite crystals = Porcelain<br />

3) Although porcelain is a glass matrix with crystals, it is not a true “Glass Ceramic”<br />

a) Glass ceramic: during heating process, some glass is converted into crystal.<br />

3. Microstructure feldspathic porcelain<br />

a. Glassy matrix surrounding leucite crystals (10-20% crystalline)<br />

4. Ceramic adhesion to metal<br />

a. Chemical bonding of ceramic metallic oxides with oxides of alloy structure<br />

b. Micro-mechanical interlock<br />

c. Macro-mechanical interlock<br />

D6318 L-8 2

All-ceramic restorations<br />

1. All-ceramic materials<br />

a. Glass ceramics<br />

1) Start with glass to form restoration and crystalline phase forms during processing (heatpressing).<br />

a) Final material has higher crystalline percentage than dental porcelain.<br />

2) Can be monoceramic/monolithic restoration: no separate framework, no porcelain<br />

veneering step<br />

3) Some too opaque and must be veneered with porcelain<br />

b. Glass-infiltrated ceramics<br />

1) Molten glass is infused into porous, crystalline ceramic<br />

2) Higher crystallinity than glass ceramic<br />

3) Serve as a framework that is veneered with porcelain<br />

c. Glass-free, Polycrystalline ceramics<br />

1) 100% crystalline material<br />

2) Framework material that must be veneered with porcelain<br />

2. All-ceramic processing techniques<br />

a. Heat-pressed: Glass ceramics<br />

b. Machined (CAD/CAM):<br />

1) Glass ceramics, Glass-infiltrated ceramics, Polycrystalline (glass-free) ceramics<br />

Current All-Ceramic Systems<br />

1. Heat-pressed all-ceramic restoration<br />

a. Lost-wax technique, injection molding of ceramic<br />

b. Glass ceramics used<br />

1) Leucite-based ceramic<br />

a) 35-55% crystalline (higher crystalline % than feldspathic porcelain,10-20%)<br />

b) Options:<br />

(1) Used alone—monolithic (must be stained)<br />

(2) Veneered with CTE compatible ceramic<br />

c) Examples: Empress (Ivoclar); OPC (Pentron), Cerinate (DenMat)<br />

d) Flexural strength: ~110-140 MPa<br />

e) Applications: Anterior crowns, onlays, inlays, veneers (Single units)<br />

Lumineers (Cerinate, www.cerinate.com)<br />

1. Veneering system which can be fabricated so thin that tooth reduction may not be necessary.<br />

2. 0.3-0.7 mm thick veneers, returned to the dental office etched and ready for bonding to uncut,<br />

etched tooth structure<br />

3. Cerinate porcelain composition is a closely guarded trade secret.<br />

a. Apparently, contains a high proportion of leucite crystalline inclusions<br />

b. Crystals contact each other and form a nearly contiguous internal skeleton to support and<br />

strengthen the surrounding glass matrix<br />

c. Microstructural examination showed leucite crystals clusters (1.5 microns) in Empress.<br />

Cerinate porcelain exhibited a uniform distribution of fine leucite crystals (1 micron).<br />

(Cattell et al 1997)<br />

4. Flexural strength (MPa): Cerinate 110; Empress 135; Feldspathic porcelain 75<br />

2) Lithium disilicate-based ceramic<br />

a) ~60-70% crystalline: stronger, more opaque than leucite-based heat-pressed<br />

b) Examples: IPS e.max (Ivoclar); OPC 3G (Pentron)<br />

c) Options:<br />

(1) Monolithic restoration<br />

(2) Ceramic core with CTE compatible porcelain<br />

d) Flexural strength: 350 MPa<br />

e) Applications: Crowns and FPDs<br />

D6318 L-8 3

2. Machined all-ceramic restoration<br />

a. Computer-aided manufacturing (CAM) (most dental applications use machining process)<br />

Typically linked to computer-aided design (CAD), restoration design<br />

b. Depending on the material and application, can be machined as a monolithic restoration or<br />

as a coping/framework that is veneered with a CTE compatible porcelain<br />

c. In-office CAD/CAM systems, such as CEREC, machined single-unit monolithic/monoceramic<br />

restorations (not crown coping or FPD framework).<br />

d. Only specific materials are appropriate for copings/frameworks with added porcelain layer<br />

(bilayered restorations).<br />

1) Zirconia is commonly used today as framework material, but must be machined with an<br />

in-lab CAM system (not in-office)<br />

2) *Y-TZP = Yttria stabilized-tetragonal zirconia polycrystals<br />

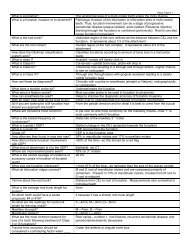

3. All-ceramic materials flexural strength comparisons<br />

Product Material Application Flexural Strength (MPa)<br />

Coping/Framework:<br />

Zirconia (Y-TZP)*<br />

for crowns,<br />

950<br />

(Polycrystalline, Glass-free)<br />

anterior/posterior FPDs<br />

Lava, Cercon,<br />

Procera AllZirkon<br />

e.maxZirCAD<br />

Procera AllCeram<br />

inCoris Al (Cerec)<br />

inCeram Zirconia<br />

e.Max CAD<br />

Empress<br />

Vita Mark II<br />

Alumina<br />

(Polycrystalline, Glass-free)<br />

Alumina/Zirconia<br />

(Glass-infilitrated)<br />

Lithium disilicate<br />

Leucite-based<br />

(Glass ceramic)<br />

Feldspar-based<br />

(Glass ceramic)<br />

Coping/Framework:<br />

for crowns, anterior FPDs<br />

Coping/Framework:<br />

for crowns, post FPDs<br />

Coping/Framework:<br />

for crowns, ant FPDs<br />

OR Crowns, onlays<br />

Restorations: Crowns,<br />

veneers, onlays, inlays<br />

Restorations: Crowns,<br />

veneers, onlays, inlays<br />

650<br />

600<br />

350<br />

150<br />

100<br />

4. Zirconia properties<br />

a. Zirconia = Zirconium dioxide (ZrO 2 ) Key Properties<br />

1) High density, High wear resistance, High fracture toughness, High hardness<br />

b. Ceramic strength differences related to differences in crystallinity. Higher crystallinity, higher<br />

strength. Crystals inhibit crack/fracture propagation. However, with increased strength, also<br />

increased opacity and typically requires a porcelain veneer.<br />

c. Polycrystalline materials exhibit the highest strength. Takes more energy for the<br />

crack/fracture to go around the crystals.<br />

1) Although both alumina and zirconia are polycrystalline higher strength ceramics, zirconia<br />

exhibits the highest fracture resistance, which is related to load-induced phase<br />

transformation. Cracks that might form during loading are closed due to a load-induced<br />

change in the crystalline structure, i.e. smaller crystals become larger with loading and<br />

close the crack. (Rose 1987)<br />

D6318 L-8 4

5. All-ceramic, zirconia-based restoration (PFZ) considerations<br />

a. CAD software: coping/framework is automatically designed to be 0.5 mm thick.<br />

1) However, in situations where excess tooth structure has been lost, a 0.5 mm thick<br />

coping/framework results in thick, unsupported veneer porcelain that is susceptible to<br />

fracture.<br />

2) Most systems have been modified to allow override for coping/framework design.<br />

b. Very thin coping<br />

c. Internal adjustments<br />

6. All-ceramic restoration overview<br />

a. Monoceramic/monolithic restoration (does not include high-strength core/framework)<br />

1) VitaMark II (machined feldspar glass ceramic)<br />

2) Empress (pressed or machined (CAD) leucite glass ceramic)<br />

3) e.max (Press or CAD) lithium disilicate ceramic)<br />

b. Ceramic core veneered with compatible porcelain/ceramic veneer<br />

1) Empress (see above, can also be used as single material)<br />

2) e.max (lithium disilicate glass ceramic)<br />

3) InCeram (machined Glass-infilitrated ceramics)<br />

4) AllCeram (machined Polycrystalline alumina)<br />

5) Lava; Cercon; AllZirkon, e.maxZirCAD (machined polycrystalline zirconia)<br />

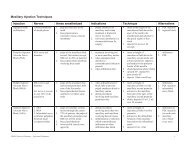

Clinical Performance of Ceramo-metal and All-Ceramic Restorations<br />

1. Ceramo-metal crowns and FPD (PFM)<br />

a. High strength; less translucent due to metal coping<br />

b. FPD survival: 96% at 5 yrs, 87% at 10 yrs; 85% at 15 yrs (Walton et al 2002)<br />

c. Failure modes: Tooth fracture, 38%; Perio breakdown, 27%; retention loss, 13%;<br />

caries, 11%. Small percentage, loss of veneer porcelain.<br />

d. When less than optimal occlusal clearance, can modify coping/framework to have partial<br />

metal occlusion.<br />

2. All-ceramic restorations<br />

a. More esthetic<br />

b. Improved strength with newer systems (PFZ)<br />

c. No long-term (>10 yrs) survival studies:<br />

d. Crowns<br />

1) Greatest survival with incisors<br />

2) Decreases progressively to a maximum failure level (fracture) with 2nd molars<br />

3) ProCera AllCeram crowns (6-year study, 60 anterior, 46 posterior crowns):<br />

a) Survival: anterior, 96%; posterior, 91%, does not include fractured posterior crowns<br />

repaired with composite and not replaced (Walter et al 2006)<br />

4) Empress: 95% survival 5-10 years (Update on All-Ceramic Products, JADA supplement Sept 2008)<br />

e. All-ceramic FPD less successful than all-ceramic crowns<br />

1) Empress 2 (e. Max), 30-50% fracture within 2 years (Marquardt & Strub 2006; Taskonak & Sertgoz 2005)<br />

2) InCeram Alumina, 88-90% survival, 3-5 years (vonSteyern et al 2001; Olsson et al 2003)<br />

3) InCeram Zirconia (35%ZrO/65%AlO), 95% survival, 3 yrs (Suarez et al 2004)<br />

4) Lava (PFZ), 100% frame work survival, 3-6 yrs (Dental Advisor 2009-Blackboard)<br />

5) Catastrophic failure mode: fracture at connector<br />

a) Critical factors: material strength and connector size<br />

6) Other failures, porcelain/veneer chipping<br />

D6318 L-8 5

f. All-ceramic FPD failures<br />

1) Posterior FPD require higher strength material<br />

a) Occlusal forces: Anterior 150-300 N vs Posterior 400-800 N<br />

b) Most potential for posterior FPD success: using machined polycrystalline zirconia<br />

framework veneered with compatible ceramic (PFZ)<br />

2) Connector size (height) very critical (height > width)<br />

a) Measure space available from interproximal papilla to incisal edge or marginal ridge<br />

b) Anterior: need 5 mm; Posterior: need 4-5 mm depending on material used<br />

Material<br />

e.Max CAD<br />

InCeram alumina<br />

InCeram zirconia<br />

Procera AllCeram<br />

Application<br />

c) Is there adequate space for the connector Important clinical decision in treatment<br />

planning.<br />

(1) How do you measure the space<br />

(2) Which dimension is more critical<br />

3. Considerations: Zirconia-based restorations<br />

a. Veneer porcelain chipping is a problem with PFZ restorations.<br />

1) Initially used porcelain for PFMs; coefficient of thermal expansion mismatch resulted in<br />

porcelain fracture<br />

2) Porcelain reformulated, specific for ZrO-based restorations (PFZ)<br />

3) Veneer fracture related to CAD software issues<br />

a) Coping/framework automatically designed 0.5 mm thick.<br />

b) Problem if thick unsupported porcelain<br />

c) System override to design as needed<br />

b. Porcelain veneer options for PFZ restorations<br />

1) Powdered, sintered veneer on CAD/CAM ZrO framework<br />

(same porcelain process as PFM)<br />

2) Pressed ceramic veneer on ZrO framework<br />

a) e.max ZirCAD (ZrO): CAD/CAM frame<br />

b) e.max ZirPress: ceramic veneer pressed onto the ZrO frame<br />

3) CAD-on veneer<br />

a) e.max ZirCAD (ZrO): CAD/CAM framework<br />

b) e.max CAD (lithium disilicate): CAD/CAM (machined) ceramic veneer<br />

c) Glass sintering ‘cement’ is used to fuse the framework and the veneer together<br />

c. Despite updates, chipping continues to be a problem with PFZ.<br />

d. PFZ adequate occlusal clearance required<br />

1) Occlusion on ZrO framework not recommended. Why<br />

Connector Dimensions<br />

Occlusal x Buccal<br />

Total area (mm 2 )<br />

(mm)<br />

3-unit Anterior FPD 4-5 x 3-4 12-20<br />

3-unit Posterior FPD<br />

(not adequate esthetics for anterior)<br />

3-unit Anterior FPD<br />

(Maximum 11-mm edentulous space)<br />

4-5 x 3-4 12-20<br />

3 x 3 9<br />

Lava, Cercon<br />

3-unit<br />

3 x 3<br />

9<br />

Procera AllZirkon,<br />

4-unit (2 pontics)<br />

4 x 3 (min)<br />

12 (min)<br />

e.max ZirCAD Anterior or Posterior FPD<br />

Ceramo-metal FPD connectors: Occl/Bucc dimensions, 2.5X2.5 mm=6.25mm 2 (Raigrodski 2004; Ivoclar 2009)<br />

2) With PFM, framework can be in occlusion, if limited occlusal clearance.<br />

e. Full-contour zirconia restorations now available<br />

1) No porcelain veneer (eliminate porcelain chipping problem)<br />

2) ZrO high hardness, concern for wear of opposing dentition<br />

3) Applications: ZrO opposing ZrO restorations; Bruxers (BruxZir Brand)<br />

D6318 L-8 6

All-ceramic crown/abutment preparation (See 3M ESPE LAVA Handout Bb)<br />

1. Anterior: Incisal reduction: 1.5-2.0 mm; Labial/Lingual reduction: 1.0-1.5mm; Chamfer/shoulder<br />

margin: 1.0 mm<br />

2. Posterior: Occlusal reduction: 1.5-2.0 mm; Axial reduction: 1.0-1.5 mm; Chamfer/shoulder<br />

margin: 1.0 mm<br />

All-ceramic restoration cementation procedures<br />

1. Glass and glass-infiltrated ceramics (Ex: VitaMark II, Empress, e.max, InCeram)<br />

a. After restoration fit adjustments, clean internal surface, etch with hydrofluoric acid (HF),<br />

rinse, and place silanating agent<br />

1) Why use HF with these materials What’s etched<br />

b. Conventional resin cement (shades) with dentin bond agent (DBA) (not an adhesive RC)<br />

1) These are typically dual-cure, light-cure initially and any deeper areas will cure over time.<br />

2) Due to restoration translucency, cements with shade options are beneficial especially for<br />

crowns in the anterior/esthestic zone. (High bond strength not a requirement, so<br />

adhesive RCs, which are not as esthetic, not required)<br />

3) Example cement options:<br />

a) Calibra/NT Prime & Bond (Dentsply)<br />

b) Variolink II/Syntac (Ivoclar)<br />

c) RelyX ARC/Single Bond (3M ESPE)<br />

4) RMGI problems with causing fracture of glass/glass infiltrated ceramic restorations<br />

c. Excess cement cleaned, then light cure<br />

d. With lower strength materials, occlusal adjustments after cementation<br />

1) Increased strength from bonding to tooth<br />

2. Polycrystalline Alumina or Zirconia coping/framework restorations (most are PFZ)<br />

(AllCeram, Lava, Cercon, AllZirkon, e.maxZirCAD)<br />

a. After restoration fit adjustments<br />

1) Clean internal surface with phosphoric acid (remove saliva proteins), rinse and dry<br />

2) Dehydrate with isopropyl alcohol, air dry<br />

3) These restorations are NOT etched with HF and silane is NOT used. Why not<br />

b. Cement Options:<br />

1) GI (Ketac), RMGI (RelyX)<br />

2) Adhesive resin cement/ no DBA (Panavia, RelyX Unicem)<br />

a) Adhesive RC will bond to AlO or ZrO.<br />

b) RMGI not cause fracture of high strength polycrystalline coping/framework<br />

Clinical Studies<br />

1. 640 Lava restorations (Dental Advisor 2009-Bb)<br />

a. 42% molars<br />

b. 39% premolars<br />

c. 12% anterior<br />

d. 6% bridges<br />

e. 1% implants<br />

Most cemented with RelyX Unicem cement<br />

2. 100 posterior FPDs (3- or 4-unit), 4-yr study a<br />

(Roediger et al. 2010)<br />

3. 15 posterior FPDs (3- or 4-unit), 51 individual units,<br />

4-yr study b<br />

(Schmitt et al. 2010)<br />

D6318 L-8 7

Reference materials:<br />

Craig’s Restorative Dental Materials, 12 th ed, 2006, Ch 18 <strong>Ceramics</strong><br />

Blackboard Resources:<br />

Lava All-Ceramic System Clinical Preparation, 3M ESPE<br />

Dental Advisor 2009, 3M ESPE Lava Crowns and Bridges 6-year Clinical Performance<br />

Objectives and Study Questions:<br />

1. Know dental ceramic applications.<br />

2. Understand the basic dental ceramic composition and properties.<br />

a. For example,<br />

1) What are the phases present in most ceramics<br />

2) How does the percentage of each phase affect the ceramic properties<br />

3. Be familiar with ceramo-metal porcelains that are less abrasive and situations when those<br />

materials are more appropriate.<br />

4. Understand the differences in crystallinity, strength, and translucency between feldspathic<br />

porcelain, glass ceramics, glass-infiltrated ceramics, and polycrystalline ceramics.<br />

5. Understand the importance of the coefficient of thermal expansion (CTE) for porcelain-fused to<br />

metal (PFM) restorations and porcelain-fused to zirconia restorations (PFZ).<br />

6. Have a basic understanding of the different fabrication techniques for all-ceramic restorations.<br />

7. Compare flexural strength of materials used for PFM and various types of all-ceramic<br />

restorations.<br />

8. Be able to identify which current all-ceramic materials appear to be most appropriate for various<br />

applications.<br />

a. Understand the difference between a monoceramic/monolithic restoration (no porcelain<br />

veneer) and an all-ceramic restoration with a ceramic framework that must be veneered with<br />

porcelain.<br />

b. What materials are appropriate for Single crowns vs FPD applications<br />

c. Which material appears to be most appropriate for posterior FPD use<br />

d. What are common complications associated with all-ceramic restorations<br />

1) Understand why despite using high strength zirconia as a coping or framework for allceramic<br />

crowns or FPDs, the CAD-CAM restorations can be susceptible to veneer<br />

ceramic fracture.<br />

9. Discuss advantages and disadvantages of ceramo-metal versus all-ceramic FPDs.<br />

a. What are differences related to occlusal clearance between preparation and opposing<br />

dentition and restoration occlusion for PFM and PFZ<br />

b. Zirconia restorations with no porcelain veneer are now available. What potential problem<br />

could occur when these restorations oppose natural dentition or other non-zirconia<br />

materials Why For what applications could these restorations be considered<br />

c. Besides using high strength material, what is the most critical fabrication factor for allceramic<br />

FPD success How does this differ from a ceramo-metal FPD How is this factor<br />

evaluated<br />

10. Be familiar with cements and procedures for the different types of all-ceramic materials.<br />

a. Which materials should be etched with hydrofluoric acid (HF) and silanated<br />

1) Understand what component can be etched.<br />

b. Which materials are not HF etched and why not<br />

D6318 L-8 8