You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

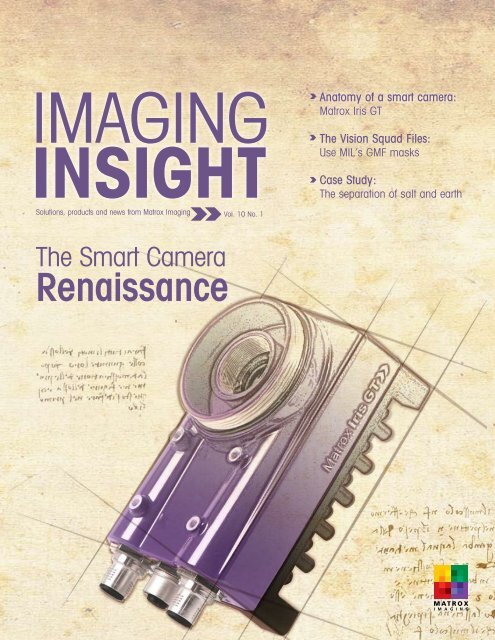

IMAGING<br />

INSIGHT Case<br />

Solutions, products and news from <strong>Matrox</strong> Imaging<br />

The Smart Camera<br />

Renaissance<br />

Vol. 10 No. 1<br />

Anatomy of a smart camera:<br />

<strong>Matrox</strong> Iris GT<br />

The Vision Squad Files:<br />

Use MIL’s GMF masks<br />

Study :<br />

The separation of salt and earth

Contents<br />

IMAGING INSIGHT Vol. 10 No. 1<br />

VP’s Commentary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03<br />

Vice President of Sales & Marketing François Bertrand focuses on the<br />

light at the end of the economic tunnel<br />

Featured Product: <strong>Matrox</strong> Iris GT . . . . . . . . . . . . . . . . . . . 04<br />

Experience the smart camera renaissance<br />

Product News: <strong>Matrox</strong> Supersight . . . . . . . . . . . . . . . . . . 06<br />

Meet the biggest brother in the <strong>Matrox</strong> 4Sight family<br />

Case Study: Salt Sorter by Winn Hardin . . . . . . . . . . . 07<br />

Linescan camera-based machine-vision system images<br />

falling salt and enables contaminant removal<br />

Case Study: Novartis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10<br />

Automated microscopy system uses MIL to detect chromosomal<br />

abnormalities in cells<br />

The Vision Squad Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

How to effectively use MIL GMF masks<br />

Trade Show Calendar<br />

Visit <strong>Matrox</strong> Imaging on the road!<br />

For tickets or more info, contact Joanna Puccio: jpuccio@matrox .com .<br />

IFSEC<br />

Birmingham, UK<br />

May 11-14, 2009<br />

2009 International<br />

Robots, Vision &<br />

Motion Control Show<br />

and Conference<br />

Chicago, USA<br />

June 9-11, 2009<br />

04<br />

06<br />

07<br />

10

IMAGING<br />

INSIGHT<br />

Publisher: <strong>Matrox</strong> Imaging<br />

Editor: Sarah Sookman<br />

Art Director: Roland Joly<br />

Marketing Communications:<br />

Catherine Overbury, Manager<br />

Reproduction in whole or in part, without the<br />

prior written permission of <strong>Matrox</strong> Imaging,<br />

is prohibited . For more information on<br />

articles published in this issue, or to share your<br />

comments, please contact the editor:<br />

Tel: 1-514-685-7230 ext. 2753<br />

Fax: 1-514-822-6273<br />

Email: imagingmr@matrox.com<br />

Want to subs cribe?<br />

Go to:<br />

matrox .com/imaging/news_events/newsletter/<br />

Corporate headquarters:<br />

Canada and U .S .A .<br />

<strong>Matrox</strong> Electronic Systems Ltd .<br />

1055 St . Regis Blvd .<br />

Dorval, QC H9P 2T4<br />

Canada<br />

Tel: +1 (514) 685-2630<br />

Fax: +1 (514) 822-6273<br />

Offices:<br />

Europe, Middle East & Africa<br />

<strong>Matrox</strong> VITE Limited<br />

Chaplin House<br />

Widewater Place<br />

Moorhall Road<br />

Harefield<br />

Middlesex<br />

United Kingdom, UB9 6NS<br />

Tel: +44 (0) 1895 827300<br />

Fax: +44 (0) 1895 827301<br />

Germany<br />

<strong>Matrox</strong> Electronic Systems GmbH<br />

Inselkammerstr . 8<br />

D-82008 Unterhaching<br />

Germany<br />

Tel: +49 (0) 89 / 62170 0<br />

Fax: +49 (0) 89 / 614 97 43<br />

From the<br />

VP’s Desk<br />

The winter’s tale<br />

During a recent visit, a customer commented to us: “in our market, this is a very long<br />

winter” . Unfortunately, for a certain segment of our customer base, this is a reality; the<br />

economy is in a state of hibernation, and it’s on the news every day .<br />

In a recession, there are tough choices to make . <strong>Matrox</strong> Imaging’s strategy is to protect<br />

its existing customer base and engage in targeted marketing and product initiatives to<br />

prepare for the upturn, when it does come .<br />

That brings us to our <strong>Matrox</strong> Iris GT smart camera and Design Assistant software . This<br />

product bundle helps us to expand our customer base, to reach out to customers beyond<br />

the traditional OEM developer .<br />

<strong>Matrox</strong> Iris GT is built for automation experts who need to integrate vision . On the<br />

outside, the <strong>Matrox</strong> Iris GT has a rugged, dust proof, washable casing with IP67 rating,<br />

and lockable and waterproof M12 connectors, and even a VGA output . We’ve made it<br />

easy for the camera to communicate with automation devices though Ethernet/IP and<br />

Modbus® over TCP/IP . On the inside, we’ve got the Intel® Atom . The intelligence lies in<br />

the Design Assistant interactive camera configuration environment . The flow chart-based<br />

interface is intuitive and makes vision accessible to anyone who wants to solve a machine<br />

vision problem without complex programming tools . Design Assistant’s functionality is<br />

based on our field-proven <strong>Matrox</strong> Imaging Library (MIL) . What’s more, we are offering the<br />

<strong>Matrox</strong> Iris GT and Design Assistant bundle at a very attractive price point .<br />

Ironically, economic downtime often allows companies to redefine themselves and look<br />

at simpler and/or speedier ways to achieve their business goals . These times can become<br />

good opportunities to experiment; we believe the <strong>Matrox</strong> Iris GT makes experimentation<br />

a sound investment .<br />

Let’s get ready for spring!<br />

Commentary<br />

François Bertrand<br />

Vice President, Sales & Marketing<br />

IMAGING INSIGHT Vol. 10 No. 1<br />

03

04<br />

Featured Product: <strong>Matrox</strong> Iris GT<br />

Anatomy of a<br />

smart camera<br />

<strong>Matrox</strong> Iris GT<br />

Experience the smart camera renaissance with <strong>Matrox</strong> Iris GT . Our 2nd generation smart<br />

camera is more efficient, 20% smaller, and three times faster than its predecessor!<br />

Eye<br />

• Two sensor options (more in development)<br />

• 640 x 480 @ 100fps 1/3” monochrome CCD<br />

• 1280 x 960 @ 20fps 1/3” monochrome CCD<br />

• Direct intensity and strobe control of third-party<br />

LED light sources1 Language<br />

• Video output for image and operator interface<br />

• 10/100/1000 Ethernet port<br />

2,3<br />

• USB 2 .0 port<br />

• RS-232 serial port<br />

®<br />

• Support for Ethernet/IP and Modbus over TCP/IP<br />

communications to directly interact with automation<br />

devices (PLCs, robots, etc .)<br />

• Trigger input and conventional Strobe output<br />

2<br />

• Discrete I/Os including rotary encoder support<br />

IMAGING INSIGHT Vol. 10 No. 1

Featured Product: <strong>Matrox</strong> Iris GT<br />

Intelligence<br />

<strong>Matrox</strong> Design Assistant interactive development software<br />

• An interface where machine vision applications are created<br />

by constructing a flowchart instead of writing traditional<br />

program code<br />

• Image processing and analysis functions are based on the<br />

algorithms from the <strong>Matrox</strong> Imaging Library<br />

• Create flowchart steps to calibrate, enhance and transform<br />

images, locate objects, extract and measure features, read<br />

character strings, and decode and verify identification marks<br />

• Design a graphical operator interface for the application<br />

Power source<br />

® • Powerful embedded Intel Atom architecture processor<br />

•<br />

45 nm Ultra Low Power (ULP) CPU at 1 .6GHz<br />

Shell<br />

• Rugged, dust-proof, immersion-resistant casing with<br />

IP67 rating<br />

• Lockable and waterproof M12 connectors<br />

1 Support for select Advanced Illumination models .<br />

2 Support available through a future software update .<br />

3 USB port intended for keyboard/mouse/touch-screen only .<br />

IMAGING INSIGHT Vol. 10 No. 1<br />

05

06<br />

Product News: <strong>Matrox</strong> Supersight<br />

Set your sights on high-performance computing<br />

It’s big . It’s powerful . It can process billions of pixels per second .<br />

There’s a new high-performance computing (HPC) platform on the<br />

horizon . We’re so excited about it, we unveiled this new blue box at<br />

Vision 2008 in Stuttgart before its official release . 2009 promises to<br />

be the year of the <strong>Matrox</strong> Supersight, and Imaging Insight had a chat<br />

with Product Manager Dwayne Crawford about it .<br />

Imaging Insight: What exactly is the <strong>Matrox</strong> Supersight?<br />

Dwayne Crawford: <strong>Matrox</strong> Supersight is a high-performance computing<br />

platform for OEMs . We like to think of it as the big brother to the 4Sight<br />

family that we have been shipping for over 10 years now . What’s<br />

different about the <strong>Matrox</strong> Supersight is that it combines CPU, GPU<br />

and FPGA technologies into one or many computing clusters .<br />

II: So it’s an industrial computer . How does it differ from a highperformance<br />

PC?<br />

DC: The <strong>Matrox</strong> Supersight creates massive parallelism, enables<br />

large pipelines and removes I/O bottlenecks with PCIe x16 (Gen 2)<br />

interconnects between the processing nodes . By mapping the<br />

interconnects through an advanced PCIe switched fabric, nodes can<br />

be grouped into compute clusters that seamlessly share data without<br />

burdening other nodes within the system . The <strong>Matrox</strong> Supersight<br />

offers unprecedented processing performance in part because it’s so<br />

configurable . As CPU, GPU and FPGA technologies evolve, how the<br />

application is balanced between them will change . With the <strong>Matrox</strong><br />

Supersight and MIL the developer can easily “re-cluster” the compute<br />

elements to ensure the application is optimally balanced between<br />

these technologies .<br />

II: What were the reasons for the <strong>Matrox</strong> Supersight’s development?<br />

DC: We constantly see high-performance imaging applications that are<br />

subject to hardware limitations . I/O limitations such as bottlenecks<br />

within blade servers and external cable connects between 1U pizza<br />

boxes pose a major challenge to creating effective parallelism .<br />

Furthermore, in order to support acceleration hardware such as FPGAs<br />

<strong>Matrox</strong> Supersight<br />

IMAGING INSIGHT Vol. 10 No. 1<br />

and GPUs, physical slots with sufficient bandwidth, power and cooling<br />

are required – and they are not always available in blade and pizza<br />

box environments . It’s possible to accelerate image processing to its<br />

maximum with the judicious application of multiple GPUs, CPUs and<br />

FPGAs all working together . The Supersight hosts all these devices yet<br />

circumvents the I/O, space, power and cooling limitations of current<br />

processing platforms .<br />

II: What are the other benefits of the Supersight?<br />

DC: Consumer PCs are built and sold for the short term, typically<br />

around 12 to 14 months . OEMs make significant investments in<br />

development and need products that are available for the long term .<br />

<strong>Matrox</strong> provides 5 to 7 years of availability for its products; we help<br />

OEMs get the maximum return on their investment and avoid costly<br />

and constant re-validation of new platforms . Furthermore, companies<br />

in the medical and pharmaceutical industries face strict governmental<br />

regulation to ensure public safety . Unforeseen changes can freeze<br />

production, and in a worst case scenario, even result in product<br />

recalls . Because change is unavoidable, all <strong>Matrox</strong> Imaging hardware<br />

products, not just the <strong>Matrox</strong> Supersight, benefit from our managed<br />

life cycle programs . We can manage products for long-term fit, form<br />

and function . We can also offer the option of strict revision control<br />

that includes prior change notification, risk analysis and acceptance<br />

sign-off .<br />

II: Will the <strong>Matrox</strong> Imaging Library (MIL) support the Supersight<br />

platform?<br />

DC: Absolutely . Naturally our hardware and software are optimized<br />

for each other – that’s another benefit . OEMs who work with a single<br />

supplier spend far more time adding value to their product – they<br />

focus on developing their application without the struggles of software<br />

and hardware compatibility issues . <strong>Matrox</strong> validates both hardware<br />

and software changes to prevent unexpected incompatibility in the<br />

field .

Salt Sorter<br />

By Winn Hardin<br />

Dataschalt’s DataSort system can find and remove stones from a cascade of falling salt<br />

crystals in real time using a single 2000-pixel linescan camera.<br />

Case Study: dataschalt<br />

Linescan camera-based machine-vision system images<br />

falling salt and enables contaminant removal<br />

IMAGING INSIGHT Vol. 10 No. 1<br />

07

08<br />

Case Study: dataschalt<br />

RHEWUM has built screening machines and vibrating feeders since<br />

the 1950s . To keep its customers ahead of the productivity curve,<br />

RHEWUM decided it needed to incorporate an automated sorting<br />

system to its screening systems—in particular, using machine vision<br />

to sort rocks and other contaminants from salt as it falls from a chute<br />

to a collection bin .<br />

Hitting a stationary target is relatively easy; however, directing an<br />

air jet to hit a falling stone as it cascades along with a sheet of salt<br />

crystals from a chute to a bin is not an easy task . RHEWUM turned to<br />

industrial electronics and food sorting specialist dataschalt Group to<br />

build a system capable of detecting falling contaminants in real time<br />

and interfacing with RHEWUM’s OEM screening equipment to blow the<br />

contaminants out of the product stream .<br />

Dataschalt accomplished the task by integrating machine-vision<br />

components from <strong>Matrox</strong> Imaging and Basler Vision Technologies into<br />

a system capable of sorting salt crystals in real time at a rate of up to<br />

120 tons per hour .<br />

Speeding the sort<br />

Until recently, microprocessors and other computational elements<br />

were not powerful enough to sort contaminants from hundreds of salt<br />

crystals falling through space . To use air to blow falling contaminants<br />

from cascading salt crystals, the vision system needed to be able to<br />

classify each crystal based on size, shape, and location, and then<br />

provide a bank of air jets with the specific location of the contaminant<br />

as it is falling from feeder chute to collection chute . A PMC I/O card<br />

inside the PC host then triggers the appropriate air jets, which blow<br />

the contaminant into a defect bin .<br />

“Because we are sorting products when they are falling we need to<br />

reduce the time between object scan and object rejection,” explains<br />

Kai Schwarz, automation engineer at dataschalt . “This is necessary<br />

because the behavior of a single falling object within the product<br />

stream is actually nondeterministic, but if the time between scan<br />

and shot is small we can assume that the object has moved linearly<br />

and will be able to hit it with the air blast . The air blast will always hit<br />

IMAGING INSIGHT Vol. 10 No. 1<br />

‘good’ product as well but this is accepted . This would be easier with<br />

a conveyor belt but you wouldn’t be able to sort the same amount of<br />

product . So we were looking for a very fast real-time [image-processing]<br />

platform with the capability to process blobs .”<br />

Schwarz says that a sorting machine already existed that processes<br />

pixel by pixel completely in hardware with a processing time faster<br />

than 4 ms, but this platform was not able to process blobs and<br />

therefore had limitations . Dataschalt evaluated the Tsunami embedded<br />

computing board from SBS Technologies (now GE Fanuc), but the<br />

Odyssey Xpro+ platform from <strong>Matrox</strong> had the advantage that it comes<br />

with the <strong>Matrox</strong> Imaging Library (MIL), which solved nearly all of the<br />

image algorithm problems and enabled dataschalt to concentrate on<br />

the process itself .<br />

“The Odyssey provides the possibility to program the PowerPC on the<br />

card itself,” adds Schwarz . “So we had a really fast processor with<br />

real-time capabilities that gets the image information directly [from<br />

the camera] via the [board’s] internal bus .” The board had a limited<br />

number of I/O channels to control the valve battery and so <strong>Matrox</strong><br />

developed a solution by using their carrier board and a third-party PCM<br />

I/O with 64 I/O channels . Schwarz says, “These channels were enough<br />

for our valve control hardware—our DataSort Sorting Application (DSA),<br />

which consist of a transmitter unit, a receiver unit, and an optical fiber<br />

connection . The valve triggers are now written from the Xpro+ via the<br />

PCI-X bus to the PMC-IO-Card and we have no bandwidth problem .”<br />

Crystal-clear sorts<br />

During the salt sorting application, crystals are poured into a feeder<br />

bin and a vibrating conveyor channel separates the salt into a thin<br />

layer of crystals 2 m wide . The crystals then accelerate down a chute<br />

and freefall across a short gap before landing on a collecting chute,<br />

which funnels the good product into a collection bin .<br />

To correct for changes in illumination across the 2-m chute, the system uses a<br />

calibration bar at the beginning of each shift. The data is stored and used by the MIL<br />

software to correct images prior to thresholding and blob analysis.

Mounted on either side of the salt crystals are banks of white LED<br />

lights to illuminate the crystals as they fall . On one side of the<br />

crystal cascade is a bank of air valves that can be turned on and off<br />

independently by the PC based on information from the MIL software<br />

running on the Xpro+ image-processing board .<br />

To begin the sort, the operator sets a calibration bar within the Basler<br />

Vision L103KM-2K Camera Link linescan camera . This allows the MIL<br />

software to correct for changes in illumination across the 2-m-wide<br />

chute . dataschalt chose the L103 because of its relatively high pixel<br />

resolution and fast acquisition speeds . The clock runs at 18 .7 kHz,<br />

compared to 9 kHz for the L101 camera, which is important when trying<br />

to image falling product in real time and with high spatial resolution<br />

from a linescan camera . The camera clock and frame data passed to the<br />

MIL software also act as the synchronization signal for triggering the air<br />

jets to blow out contaminants from the salt crystal stream .<br />

As salt crystals begin to fall in front of the camera, each line along<br />

with its time stamp is passed to the MIL software . The Xpro+ board<br />

features an ASIC to accelerate certain image-processing algorithm<br />

convolutions running on the nearby G4 Power-PC processor; a FPGA<br />

handles filtering, normalization, and similar repetitive tasks based on<br />

the specific inspection routine .<br />

The board collects line images in local buffer memory, checking<br />

each pixel for intensity variations that indicate the pixel is either a<br />

background pixel, salt pixel, or—if darker— indicative of a stone or<br />

contaminant . Once contaminant-level pixels are identified, the MIL<br />

software runs a blob analysis to determine whether the contaminant<br />

is large enough to warrant rejection by the air jets .<br />

“The stones are darker than the salt,” explains dataschalt’s Schwarz .<br />

“Often they are included within the salt pieces . So we examine a<br />

blob and count the amount of dark or ‘bad’ classified pixels . The user<br />

defines beforehand the percentage of bad pixels that are allowed per<br />

piece .” The salt pieces are sometimes large (approximately 10 × 10<br />

cm), so often it is not enough to shoot only the bad pixels [from an<br />

Case Study: dataschalt<br />

embedded stone] but it is essential to recognize the complete piece<br />

and turn on enough valves to reject it . Furthermore, it is possible to<br />

sort the pieces by size .<br />

Once the MIL software determines that a contaminant has exceeded<br />

the allowable size, the horizontal location information and time<br />

stamps for the defect are passed across the compact PCI bus inside<br />

the host PC, through the carrier board to the Acromag PMC464 I/O<br />

board . Using its 64 I/O channels, the PMC card then sends that<br />

location information to the dataschalt DSA electronic control system,<br />

which fires specific valves in the bank of 255 air jets that stretch across<br />

the sort stream . The jets blow the defective crystal or contaminant out<br />

of the stream and into a defect bin .<br />

Adding color to the mix<br />

While the salt-sorting application only required monochrome images<br />

to differentiate white salt crystals from darker stones, many foodprocessing<br />

applications require more data to pick good product from<br />

bad . For these applications, dataschalt uses the same processing<br />

hardware with a color camera . To accommodate the additional<br />

data while maintaining high-speed processing, Schwarz says he<br />

uses principle component analysis (PCA) techniques to remove one<br />

dimension in the RGB color space that holds the least amount of data,<br />

essentially compressing the 3-D color space into 2-D .<br />

The throughput of the DataSort depends on particle size, the material’s<br />

bulk density, and the width of the machine . Currently, the sorting<br />

capacity can be up to 120 t/h at a machine width of 1200 mm .<br />

“We are very happy with the fast-working, high-tech solution we have<br />

received from dataschalt,” says Sigurd Schuetz, managing director<br />

of RHEWUM . “It enables us to provide a reliable and cost-efficient<br />

sorting technology to our customers, who greatly benefit from this<br />

combination of dataschalt and RHEWUM technological knowledge .”<br />

This article originally appeared in the January 2009 issue of Vision<br />

Systems Design . Used with permission .<br />

The MIL software compiles a complete image of a falling stone from individual<br />

line images and then uses the location across the linear array, plus the time<br />

stamps from each line associated with the stone, to provide location information<br />

to the dataschalt DSA system, which controls the bank of 255 air jets.<br />

IMAGING INSIGHT Vol. 10 No. 1<br />

09

10<br />

Case Study: Novartis<br />

It’s in<br />

the genes<br />

Automated microscopy system uses MIL to detect<br />

chromosomal abnormalities in cells<br />

The comet assay quantifies the DNA damage in a cell. The DNA particles migrating in an<br />

electric field are stained with propidium-iodide. The comet assay locates suitable nuclei<br />

and analyzes these “comet tails” using parameters such as tail length, intensity, tail<br />

moment etc. The number and brightness of particles directly correlates to the level of DNA<br />

damage.<br />

IMAGING INSIGHT Vol. 10 No. 1

The drug discovery process not only develops new drugs that cure,<br />

control, or prevent disease . This process must also include rigorous<br />

testing for severe side effects . This is particularly true for drugs that<br />

are intended for long-term or even lifetime use, such as anti-rejection<br />

drugs for transplant patients .<br />

Long before human trials can proceed, drugs must be tested for their<br />

efficacy and safety . The Preclinical Safety unit at Novartis (Basel,<br />

Switzerland) has the responsibility of determining adverse side effects<br />

of all new molecular entities (drugs) in vitro (i .e ., in cultured cells)<br />

and in vivo (animal testing) . Besides other toxicological studies, the<br />

researchers perform genetic toxicology assays (tests) to assess the<br />

genotoxic potential of new drug candidates . Drug effects on mammalian<br />

cells are studied, using chromosomal abnormalities (besides other<br />

cellular and nuclear endpoints) to assess the compound’s potential<br />

hazards . When such abnormalities occur, it means that the drug in<br />

question has interacted with the cell’s genome . Dr . Wilfried Frieauff,<br />

Laboratory Manager of the Preclinical Safety unit says that when a<br />

statistically and biologically significant increase in these events are<br />

observed, there’s a potential for the drug candidate to induce cancer .<br />

Frieauff manages the labs, and he is responsible for the image analysis<br />

platform – its development, system maintenance, and support . The<br />

Preclinical Safety unit runs hundreds of tests annually on literally<br />

millions of cells . Given the numbers, it’s no surprise that the analysis<br />

process is one that benefits from automation .<br />

At the end of the 1980s, Frieauff’s lab began to use Leitz MIAS image<br />

analyzers for that purpose . But by the late 1990s, Dr . Frieauff realized<br />

that the systems were seriously outdated . “It was a stand-alone system<br />

that could not be part of a network . Replacement parts were no longer<br />

available,” he explains . These early image analysis systems had a<br />

maximum capacity of processing only 16 slides in a row . “Sometimes we<br />

would load the slides on Friday, and the system would finish and sit idling<br />

until Monday morning .” More importantly, Frieauff expected the future<br />

would bring more image analysis development projects and he “realized<br />

that it was time to totally re-engineer and modernize our image analysis .”<br />

Case Study: Novartis<br />

After extensive research of the market, Frieauff selected several<br />

components that would comprise the new ROBIAS, the Robotic Image<br />

Analysis System . ROBIAS is built from an electronically-driven Leica DM<br />

RXA/2 microscope mounted with a SONY DXC-390 color CCD camera<br />

that is connected to host PC with a <strong>Matrox</strong> Meteor-II/Multi-Channel<br />

frame grabber . An optional robotic slide feeder can automatically<br />

place up to 130 slides on the microscope’s stage for processing, which<br />

is performed by using custom-developed image analysis algorithms<br />

based on the <strong>Matrox</strong> Imaging Library .<br />

Automated microscopy<br />

Due to the subjective nature of manual microscopy and the increasing<br />

need for accurate, standardized results, image processing techniques<br />

have been used in microscopy for some time . Indeed, medical<br />

diagnostic and pharmaceutical applications need precise results<br />

– lives are at stake – and automated microscopy offers complete<br />

objectivity (thanks to image processing algorithms) and relieves the<br />

human eye of difficult and fatiguing tasks .<br />

The ROBIAS system performs specific cytogenetics assays (cell-genetic<br />

tests) that examine both in vitro and in vivo samples:<br />

• micronucleus test (MNT) in vivo (regulatory test to be conducted for<br />

drug registration)<br />

• comet assay in vivo<br />

• metaphase finding for chromosome aberration analysis (regulatory<br />

test to be conducted for drug registration )<br />

• MNT in vitro (for early genotoxicity screening)<br />

• comet assay in vitro (for early genotoxicity screening)<br />

• MNT in primary human lymphocytes (currently under development)<br />

By studying the cells’ DNA, the researchers can add evidence to a drug’s<br />

relative safety, or identify potential hazards . For the micronucleus<br />

test or the chromosome aberration analysis, the researchers look<br />

for chromosomal abnormalities which become visible when the cell<br />

passes through mitosis .<br />

The Robotic Image Analysis System (ROBIAS) is built from a electricpowered<br />

microscope and an optional robotic slide feeder .<br />

IMAGING INSIGHT Vol. 10 No. 1<br />

11

12<br />

Case Study: Novartis<br />

Metaphase is the stage of mitosis where the chromosomes migrate to the center of the cell<br />

before it divides. This metaphase test is the basis for chromosome aberration analysis. This<br />

image shows the “collection” of chromosomes of a dividing cell.<br />

As an example, a micronucleus reflects a genotoxic insult because<br />

it originates from a chromosome strand break due to the compound<br />

interaction with the nuclear material . Direct DNA lesions are assessed<br />

using the comet assay where DNA particles migrating in an electric field,<br />

are stained with a fluorescent dye and can be measured to assess the<br />

overall DNA damage following the compound administration .<br />

Summarizing genetic toxicology’s mission - if the drug does not damage<br />

a cell’s DNA, an important hurdle is passed for being a good candidate<br />

for later Phase 1 clinical trials .<br />

M is for morphology<br />

MIL markedly supports the researchers to extract the vital information<br />

they seek . After “discovering” MIL in 1999, Frieauff found that it was<br />

“the most flexible and ready-to-use tool library which fully supported<br />

mathematical morphology functions, as well as advanced blob analysis,<br />

both very important for biological image analysis .” These functions<br />

comprise the “core” of Frieauff’s software . With more than 20 years of<br />

experience in image analysis development, Frieauff had already built<br />

some powerful software tools based on low-level imaging functions .<br />

MIL’s functional interface simplified the overall software development .<br />

“For my applications,” he explains, “automated segmentation of<br />

biological structures, that is, cells containing nuclei or other cellular<br />

patterns, is crucial . Thus, I developed automated segmentation<br />

functions for various specific applications in industrial toxicology .”<br />

The “various specific applications” of which Frieauff speaks is one of<br />

the unique features of ROBIAS . “You may find diverse systems covering<br />

individual solutions,” he says, “but not one system covering all these<br />

tox[ological] assays on one platform . That was the main idea behind<br />

ROBIAS .”<br />

Currently, five ROBIAS units are deployed in Novartis locations, plus<br />

an additional two systems without the robotic slide feeder . These days<br />

IMAGING INSIGHT Vol. 10 No. 1<br />

In this micronucleus test, two cells show micronuclei, evidence that the drug compound<br />

interacted with the cell’s genetic material.<br />

Frieauff manages the laboratory’s toxicology assays and oversees all<br />

aspects of ROBIAS . Always in the midst of new application development,<br />

he is currently investigating sophisticated details of the MIL’s Edge<br />

Finder module . He is also working through the process of patenting<br />

ROBIAS . His determination has certainly paid off . In fact, in 2007<br />

Frieauff received the Novartis VIVA Leading Scientist award . “I was<br />

extremely proud,” recalls Frieauff, “the award reflects the importance<br />

of the ROBIAS system and the development of fully automatic image<br />

analysis applications for various units within Novartis Pharma research<br />

and development .”<br />

References:<br />

Sookman, Sarah . “In Living Color Microscopy tool uses MIL to automate<br />

color-based cell analysis” Imaging Insight 5 .3 (2003): 4-5 .

The The The<br />

VISION VISION<br />

SQUAD SQUAD<br />

Using MIL<br />

The Vision Squad Files: MIL GMF masks<br />

Geometric Model<br />

Finder masks<br />

Pattern recognition is used to locate an object in an image. For that reason, it is one of the most widely used<br />

operations in the machine vision industry. While the normalized grayscale correlation (NGC) technique uses a pixelby-pixel<br />

comparison, the MIL Geometric Model Finder (GMF) uses a technique based on the geometric features of an<br />

object. GMF is not only more flexible, but also more tolerant of lighting variations, model occlusion and variations<br />

in scale and angle. One way to get even better results with GMF is to apply masks to the search model. This Vision<br />

Squad article describes how to use the various masking capabilities of GMF so that the tool can be used to its full<br />

potential.<br />

IMAGING INSIGHT Vol. 10 No. 1<br />

13

14<br />

The Vision Squad Files: MIL GMF masks<br />

Determining model and target coverage<br />

The model coverage quantifies the model’s edges found in the<br />

occurrence or target. Model coverage of 100% means a perfect<br />

match, where every edge element in the model image has found<br />

a corresponding edge element in the target. Missing or occluded<br />

edges in the target decrease the model coverage. In Figure 1, 80% of<br />

the model’s edges are found in the first occurrence and 50% in the<br />

second.<br />

Model edge map<br />

Model edge map<br />

Edge map + Mask<br />

Model coverage<br />

el weight Positive Negative<br />

et contribution<br />

Target coverage<br />

Model coverage<br />

Flat region mask<br />

Model coverage<br />

Target coverage<br />

The flat region mask (M_FLAT_REGIONS) Edge map + Mask is used to Model Final mask edge coverage the mapmodel<br />

edges only. Note Target 100% that A the corresponding Target target 100% B edges that fall in the masked<br />

Target coverage<br />

100%<br />

80%<br />

area still contribute to the target coverage when using a flat region mask.<br />

Model coverage 100%<br />

Model Target A<br />

Target B<br />

In Target A, both the model and target coverage score 100% since all edges of the model are found in the target and vice-versa. In Target B the<br />

< 100% b<br />

model coverage is 100% because the remaining edges in the final model are found in the target; however, the target coverage decreases to 80%<br />

because of the extra edges (Figure 4).<br />

Model coverage<br />

Enhanced 100% model 100%<br />

Target A<br />

Target coverage<br />

100%<br />

100%<br />

Model Target A<br />

Target B<br />

Ta<br />

Enhanced model<br />

IMAGING INSIGHT Vol. 10 No. 1<br />

Target edge map<br />

Missing edges Occluded edges<br />

Model edge map<br />

80% 50%<br />

Figure 1. Figure 2.<br />

Target edge map<br />

Model coverage 80% Edge 50% map + Mask<br />

Missing edges Extra edges<br />

Model<br />

Final<br />

edge<br />

edge<br />

map<br />

map<br />

100% 60%<br />

Model coverage<br />

Target coverage<br />

Model coverage Target coverage<br />

Target coverage<br />

Model coverage<br />

100%<br />

100%<br />

Target edge map Target coverage<br />

Missing edges<br />

Target A<br />

Extra edges<br />

Target B<br />

Model coverage<br />

100%<br />

Target coverage<br />

100%<br />

100% 100%<br />

60%<br />

100%<br />

100%<br />

The target coverage quantifies the percentage of the target occurrence’s<br />

Model edge map<br />

Missing edges Occluded edges<br />

edges present in the model. This means that edges that are found in<br />

the occurrence but not in the model are considered extra edges.<br />

Therefore, they reduce the target coverage. In Figure 2 (below) the<br />

target coverage is 100% in the first occurrence because all of the<br />

target edges correspond to edge elements in the model. In the second<br />

occurrence, the Model target coverage<br />

80% is lower because only 60% 50% of the<br />

target edge elements correspond to the model’s edge elements.<br />

Model edge map<br />

100%<br />

100%<br />

100%<br />

80%<br />

Target coverage<br />

Model coverage<br />

Model coverage<br />

< 100% but still very high<br />

Missing edges Extra edges<br />

100% 60%<br />

Final edge map<br />

Model Target coverage B<br />

Target coverage<br />

Target edge map<br />

Target edge map<br />

Masks<br />

Masks are applied to models for two reasons: either to remove any irrelevant, inconsistent or featureless areas of the model, or to modify the<br />

Target edge map<br />

Positive Negative None<br />

relative contribution of model Model edges edge mapto<br />

the model coverage. Missing edgesThe GMF module Extra provides edges three types of masks that have different effects on model<br />

Model coverage<br />

100%<br />

coverage: don’t care, flat region and weighted.<br />

Target coverage<br />

100%<br />

Don’t care mask Model coverage<br />

Model edge map<br />

Missing edges<br />

Target<br />

Occluded<br />

coverage Edge edges map + Mask<br />

Final edge map<br />

Target A<br />

The don’t care mask (M_DONT_CARES) masks any irrelevant regions in the model and the corresponding region in the target. Masked edges in the model<br />

Edge map + Mask<br />

Final edge mapTarget<br />

coverage 100% Target A<br />

60% Target B<br />

do not contribute to the model coverage, and any edges in the target’s corresponding region will not contribute to the target coverage (Figure 3).<br />

Figure 3.<br />

Edge map + Mask<br />

Model coverage<br />

Target edge map<br />

Missing edges Occluded edges<br />

Final edge 80% map<br />

50% Target A<br />

Target coverage<br />

Model Target A<br />

In Target A, both the model and target Model coverage coveragescore<br />

100% since all edges of the model are Target found coverage in the target and vice-versa. In Target B, the<br />

model coverage is 100% because Edge map + all Mask edges of the model Final edge are map found in the target; the target Target Acoverage<br />

is also 100% Target because B the two circles fall within<br />

the corresponding region masked by the don’t care mask.<br />

Figure 4.<br />

Edge map + Mask<br />

Model coverage<br />

Model coverage<br />

Enhanced model<br />

Final edge map<br />

Target edge map<br />

Target A<br />

Target coverage<br />

Target coverage<br />

Target coverage<br />

Model coverage<br />

100%<br />

100%<br />

Target coverage<br />

100%<br />

Target A Target B<br />

Model coverage<br />

80%<br />

100%

ative<br />

ative None<br />

ative<br />

ative None<br />

Model edge map<br />

Additional tips:<br />

Model edge map<br />

Model edge map<br />

Model coverage<br />

Target edge map<br />

Missing edges Occluded edges<br />

80% 50%<br />

Missing edges<br />

Target edge map<br />

Target edge map Extra edges<br />

The Vision Squad Files: MIL GMF masks<br />

Use the following guidelines to maximize the effect of don’t care and flat region masks on both model and target coverage:<br />

• Use don’t care masks to remove edges that lie “outside” the model geometry (sometimes associated with background noise). This will<br />

prevent these model edges and any irrelevant edges found in the corresponding target region from lowering the model and/or target<br />

Model coverage 100% 60%<br />

scores .<br />

Model coverage 80% 50%<br />

• Use flat region masks to remove edges that lie “inside” the model geometry. Such edges may be associated with extra geometry, for<br />

Model coverage<br />

Target coverage<br />

example, that could indicate an error in the manufacturing process; therefore these edges must be reflected by the target coverage .<br />

Edge map + Mask<br />

Final edge map<br />

Target A<br />

Target B<br />

• If masked regions overlap, don’t care regions Target edge map take precedence over flat regions.<br />

Model edge map<br />

Missing edges Extra edges<br />

• Masks usually speed up the matching process because they reduce the number of edges to process during a matching operation.<br />

Edge map + Mask<br />

Model coverage<br />

Model coverage<br />

Model coverage<br />

Model coverage<br />

Target coverage<br />

Final edge map<br />

100%<br />

100%<br />

Target A<br />

Target coverage<br />

Weighted mask Edge map + Mask<br />

Final edge map<br />

Target A<br />

Target B<br />

One very useful application of the weighted mask (M_WEIGHT_REGIONS) is when a model contains a major repetitive pattern . Models based on<br />

repetitive patterns can generate unstable results in real images . For example, false positives are possible simply because the occurrence might<br />

Model coverage<br />

100%<br />

100%<br />

Target coverage<br />

100%<br />

80%<br />

have a “better” coverage than the desired match due to some missing or extra or occluded edges, or have coverage above the certainty threshold<br />

Model coverage<br />

100%<br />

100%<br />

set by the user . A target can get ‘better Target model coverage coverage’ because 100% the omission of 100% a few elements of the repetitive pattern does not significantly<br />

lower the model coverage (Figure 5) .<br />

Edge map + Mask<br />

Model coverage<br />

Final edge map<br />

Model Target A<br />

Figure 5.<br />

Model coverage 100%<br />

< 100% but still very high<br />

Model Target A<br />

Target B<br />

The model coverage for Enhanced Target B model in Figure 5 is still high Target enough A to be considered a match Target B because the extra geometries offset the desired match<br />

without significantly reducing the model edge elements found in the target .<br />

A weighted mask adjusts an edge element’s importance when the model coverage is calculated . Target edges that match model edges with<br />

negative weights will be ignored when the target coverage is calculated . To reduce ambiguity in repetitive patterns, first add “virtual” copies of the<br />

pattern . Then, mask the copies with negative weights (Figure 6) .<br />

Model coverage 100%<br />

< 100% but still very high<br />

Figure 6.<br />

Model coverage<br />

Enhanced model<br />

Missing edges Occluded edges<br />

100% 60%<br />

Model coverage<br />

Target coverage<br />

Model coverage<br />

Target A<br />

100%<br />

100%<br />

Target coverage<br />

Target coverage<br />

The enhanced model has eight “pins” that have a negative mask (red lines) . When the model assesses Target B in Figure 6, Edge the map negative<br />

+ Mask<br />

weights significantly lower the model coverage of the misaligned/offset candidate, enough to reject this occurrence as a match (depending on<br />

the acceptance/certainty thresholds set by the user) . Therefore, even though the model is offset in Target B, the negative weights ensure the<br />

occurrence does not count as a match; only the desired match (Target A) will receive a high model score .<br />

100%<br />

100%<br />

Target B<br />

Target B<br />

100%<br />

80%<br />

Target B<br />

100%

©<strong>Matrox</strong> Imaging<br />

Printed in Canada $IE-5458-B