Glassbond Sauereisen Electric Resistor Cement No

Glassbond Sauereisen Electric Resistor Cement No

Glassbond Sauereisen Electric Resistor Cement No

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Glaassssbond Saaueerreei isseen Eleeccttrri<br />

icc Reessi issttorr Ceemeentt <strong>No</strong>. .78//3<br />

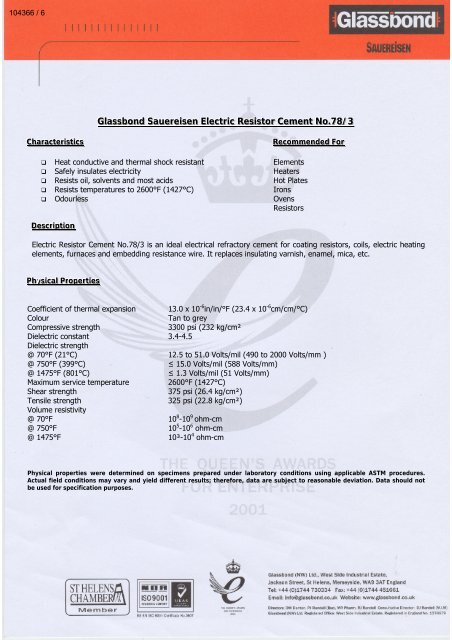

CChhaarraacctteerri iisstti iiccss<br />

RReeccoommeennddeedd FFoorr<br />

Heat conductive and thermal shock resistant Elements<br />

Safely insulates electricity Heaters<br />

Resists oil, solvents and most acids Hot Plates<br />

Resists temperatures to 2600°F (1427°C) Irons<br />

Odourless Ovens<br />

<strong>Resistor</strong>s<br />

DDeessccrri iipptti iioonn<br />

<strong>Electric</strong> <strong>Resistor</strong> <strong>Cement</strong> <strong>No</strong>.78/3 is an ideal electrical refractory cement for coating resistors, coils, electric heating<br />

elements, furnaces and embedding resistance wire. It replaces insulating varnish, enamel, mica, etc.<br />

PPhhyssi y iiccaal ll PPrrooppeerrtti iieess<br />

Coefficient of thermal expansion 13.0 x 10 -6 in/in/°F (23.4 x 10 -6 cm/cm/°C)<br />

Colour<br />

Tan to grey<br />

Compressive strength<br />

3300 psi (232 kg/cm²<br />

Dielectric constant 3.4-4.5<br />

Dielectric strength<br />

@ 70°F (21°C) 12.5 to 51.0 Volts/mil (490 to 2000 Volts/mm )<br />

@ 750°F (399°C)<br />

≤ 15.0 Volts/mil (588 Volts/mm)<br />

@ 1475°F (801°C)<br />

≤ 1.3 Volts/mil (51 Volts/mm)<br />

Maximum service temperature<br />

2600°F (1427°C)<br />

Shear strength<br />

375 psi (26.4 kg/cm²)<br />

Tensile strength<br />

325 psi (22.8 kg/cm²)<br />

Volume resistivity<br />

@ 70°F<br />

10 8 -10 9 ohm-cm<br />

@ 750°F<br />

10 5 -10 6 ohm-cm<br />

@ 1475°F<br />

10³-10 4 ohm-cm<br />

Physical properties were determined on specimens prepared under laboratory conditions using applicable ASTM procedures.<br />

Actual field conditions may vary and yield different results; therefore, data are subject to reasonable deviation. Data should not<br />

be used for specification purposes.

Application/Instructions<br />

<strong>No</strong>78/3 should be thoroughly remixed before using. Weigh approximately 33 parts powder and 10 parts water. Place<br />

powder in a clean mixing container. Add water to the powder at one time while mixing- do not add water gradually.<br />

Continue mixing until a smooth, uniform consistency is obtained. Mixing may be done with a slow-speed mixer or by<br />

hand with a spatula. Minimum amount of water should be used as excess water reduces mechanical strength,<br />

increases shrinkage and delays set time. Failure of cement to adhere indicates setting has begun- discard cement. Do<br />

not attempt to re-temper by adding more water.<br />

<strong>No</strong>.78/3 may be applied by brushing, dipping or spraying. <strong>No</strong>.78/3 is suitable for use on production lines with<br />

mechanical dispensers or applicators because it will not harden in the equipment during normal operation. <strong>No</strong>.78/3<br />

should be thoroughly remixed to a smooth, uniform consistency prior to use. Surfaces to receive <strong>No</strong>.78/3 should be<br />

clean and free of grease and dirt. Porous substrates should be dampened slightly with Thinning liquids <strong>No</strong>s.14 or 15<br />

prior to the application of <strong>No</strong>.78/3. <strong>No</strong>.78/3 should be used in thin applications; apply several coats where a heavy<br />

layer is desired. In multiple coat applications, each coat must be thoroughly dry prior to applying additional coats. If<br />

necessary, Thinning Liquid <strong>No</strong>s. 14 or 15 should be used where the <strong>No</strong>.78/3 cement is required in a thinner<br />

consistency. Minimum amounts of liquid should be used as excess liquid reduces mechanical strength, increases<br />

shrinkage and delays set time. <strong>No</strong>.78/3 should not be applied in a thickness greater than ¼ ".<br />

SSeetttti iinngg//CCuurri iinngg<br />

<strong>No</strong>.78/3 cures by air drying at room temperature. Drying time depends on the consistency and thickness of the<br />

application. <strong>No</strong>rmally 18-24 hours drying at ambient temperature is sufficient. When the cement has minimal<br />

exposure to air, or if it is desired to accelerate the cure, low temperature oven drying at 82°C can be used. Avoid<br />

steaming while drying. If the cement will be exposed to elevated temperatures, contact <strong>Glassbond</strong> for appropriate<br />

drying schedule recommendation.<br />

If high humidity resistance is required and it is impractical to fire cement, moisture-resistant lacquer or silicone<br />

coating should be applied to the exposed surfaces.<br />

PPaacckkaaggi iinngg<br />

This material is supplied in various types and sizes of containers. See price list for details.<br />

SShheel llf f LLi iif fee<br />

<strong>No</strong>.78/3 powder has a shelf life of twelve (12) months when stored in unopened, tightly sealed containers in a dry<br />

location at 21°C. If there is any doubt as to the quality of the material, contact <strong>Glassbond</strong>.<br />

CCaauutti iioonn<br />

Consult the Material Safety Data Sheets and container label Caution Statements for any hazards in handling this<br />

material.<br />

Waarrrraannttyy<br />

We warrant that our goods will conform to the description contained in the order and that we have good title to all<br />

goods sold. WE GIVE NO WARRANTY, WHETHER OF MERCHANTABILITY, FITNESS FOR PURPOSE OR OTHERWISE,<br />

EXPRESS OR IMPLIED, OTHER THAN AS EXPRESSLY SET FORTH HEREIN. Users shall determine the suitability of the<br />

product for intended application before using.<br />

Manufactured under licence from <strong>Sauereisen</strong> Pittsburgh PA.

11 PPrroodduucct t Iddeennt I tificcaat<br />

tioonn:<br />

:<br />

PRODUCTT HEALLTTH AND SAFFETTY A DATTA SHEETT<br />

Glaassssbboonndd SSaauueerreei isseenn PP7788/ /33 Issssuuee I <strong>No</strong>o 44, , Issssuuee I Daat tee 2244. .0088. .22000066<br />

SShheeeet t 11 oof f 44<br />

PPrroodduucct t Naamee: : <strong>Glassbond</strong> <strong>Sauereisen</strong> <strong>Electric</strong> Heater <strong>Resistor</strong> <strong>Cement</strong> P78/3<br />

PPaacckkaaggi inngg: : Plastic containers<br />

Deessccrri ippt ti iionn: o : Coating/embedding for resistors, coils and heating elements.<br />

Cool loouurr aanndd aappppeeaarraannccee: : White powder<br />

SSuuppppl lieerr'<br />

''ss nnaamee aanndd aaddddrressss: e : <strong>Glassbond</strong> (NW) Limited<br />

Westside Industrial Estate<br />

Jackson Street<br />

St Helens<br />

Merseyside WA9 3AT<br />

UK<br />

TTeel l <strong>No</strong>o: : +44 (1744) 730334<br />

FFaaxx <strong>No</strong>o: : +44 (1744) 451661<br />

Maannuuf faacct tuurreerr' ''ss nnaamee aannd d aaddddrreessss: : <strong>Glassbond</strong> (NW) Limited<br />

Westside Industrial Estate<br />

Jackson Street<br />

St Helens<br />

Merseyside WA9 3AT<br />

UK<br />

22 Coomppoossi itioonn/<br />

/Innf<br />

foorrmaat tioonn oonn Innggreeddi I r ieenntss t<br />

CAS <strong>No</strong> Components Range Risk Classification<br />

14808-60-7 Silica Flour 40 R20, R48/20 Xn<br />

1344-09-8 Sodium Silicate 10 R37/38 Xi

33 Heeaal lthh Haazzaarrddss Daat taa<br />

PRODUCTT HEALLTTH AND SAFFETTY A DATTA SHEETT<br />

Glaassssbboonndd SSaauueerreei isseenn PP7788/ /33 Issssuuee I <strong>No</strong>o 44, , Issssuuee I Daat tee 2244. .0088. .22000066<br />

SShheeeet t 22 oof f 44<br />

The dust arising from this product is mainly fibrogenic potential. It could be harmful if swallowed or<br />

ingested and is irritating to skin, eyes and respiratory system. Refer to Section 8 for Occupational<br />

Exposure Limits.<br />

44 FFi irrsst t Aidd i Meeaassuurreess<br />

SKIN CONTACT:<br />

EYE CONTACT:<br />

INHALATION:<br />

INGESTION:<br />

Wash thoroughly with soap and water. Remove contaminated clothing. Seek<br />

medical advice if irritation persists.<br />

Irrigate with copious quantities of water for at least 15 minutes. Seek medical<br />

advice.<br />

Remove to fresh air at once. In the event of respiratory difficulties apply standard<br />

first aid techniques and seek medical advice.<br />

DO NOT induce vomiting. Give large quantities of water. Seek medical attention.<br />

55 FFi irreef figghht<br />

tinngg i Meeaassuurress e (aanndd ( EExxppl loossi ioonn Haazzaarrddss) )<br />

<strong>No</strong>t flammable.<br />

66 Acccci iddeent ntaal<br />

l Reel leeaassee/ /SSppi illaaggee Meeaassuurreess<br />

Sweep or vacuum up wearing all the recommended protective equipment.<br />

77 Haannddl linngg aanndd SStoorraaggee t Reeccoommeennddaat tioonnss<br />

Store in a cool dry place in original packaging away from food stuffs.<br />

88 PPeerrssoonnaal l PPrroot teecct tioonn aanndd EExxppoossuurree Coonnt trrool lss<br />

Maat teerri iaal l<br />

OEELL<br />

Haanndd PPrroot teecct tioonn:<br />

: Tear resistant industrial gloves Crystalline Silica 0.4mg/m 3 MEL<br />

8hr TWA<br />

Reesppi s irraat toorryy: : If conditions generate dust, Total Inhalable 10mg/m 3 OES 8hr<br />

wear an approved respirator Dust TWA<br />

appropriate for those emission<br />

levels.<br />

EEyyee PPrroot teecct tioonn:<br />

: Safety spectacles with side shields.<br />

An eyewash station should be available.<br />

Personal:<br />

Overalls and safety footwear.

PRODUCTT HEALLTTH AND SAFFETTY A DATTA SHEETT<br />

Glaassssbboonndd SSaauueerreei isseenn PP7788/ /33 Issssuuee I <strong>No</strong>o 44, , Issssuuee I Daat tee 2244. .0088. .22000066<br />

SShheeeet t 33 oof f 44<br />

99 PPhhysi<br />

iccaal l aanndd Chheemi iccaal l PPrrooppeerrt ti iieess/ /SSaaf feet tyy SSppeecci ificcaat<br />

tioonnss<br />

Colour and Appearance: White Powder<br />

Changes in State: Stable<br />

Density: 1.10 g/cm 3 (20°C)<br />

Compacted Bulk Density: 1.60 g/cm 3 (20°C)<br />

Vapour pressure: N/A<br />

Viscosity:<br />

N/A<br />

Solubility in Water: Less then 15% (20°C)<br />

pH value: Slightly Alkaline (20°C)<br />

Stability:<br />

Stable<br />

Flash Point:<br />

<strong>No</strong>n-flammable<br />

Ignition Temperature: N/A<br />

Explosion Limits: N/A<br />

1100 SSt taabbi ilityy aanndd Reeaacct tivvi<br />

ityy<br />

Haasaarrddoouuss s PPrroodduucct tss oof f TThheerrmaal l Deeccoomppoossi itioonn<br />

Hazardous Reactions<br />

<strong>No</strong>ne<br />

Aqueous solutions may react with<br />

aluminium, zinc and tin evolving<br />

hydrogen gas.<br />

1111 TTooxxi iccool looggi iccaal l Innf I foorrmaat tioonn<br />

EYES:<br />

SKIN:<br />

INGESTION:<br />

INHALATION:<br />

Irritation. May cause serious damage to eyes.<br />

Irritation. Ulceration may occur from prolonged or repeated contact. Pain and<br />

redness at site of contact.<br />

Nausea, vomiting and diarrhoea. Seek medical attention.<br />

Irritation of the nose, throat and lungs. The dust arising from this product is<br />

mainly fobrogenic potential and should be controlled to the Crystalline Silica<br />

OEL. (See Section 8).<br />

1122 EEccool looggi iccaal l Innf I foorrmaat tioonn<br />

This product does not constitute a risk to the environment.<br />

1133 Dissppoossaal<br />

l Coonnssi iddeerraat tioonnss<br />

In accordance with local authority regulations.

1144 TTrraannssppoorrt t Innf I foorrmaat tioonn<br />

PRODUCTT HEALLTTH AND SAFFETTY A DATTA SHEETT<br />

Glaassssbboonndd SSaauueerreei isseenn PP7788/ /33 Issssuuee I <strong>No</strong>o 44, , Issssuuee I Daat tee 2244. .0088. .22000066<br />

SShheeeet t 44 oof f 44<br />

ADR/RID/IMDG/ICAO – Description<br />

<strong>No</strong>t classified for conveyance purposes.<br />

<strong>No</strong>t classified as dangerous goods under the UN Transport Recommendations.<br />

1155 Reeguul g laat tooryy r Innf I foorrmaat tioonn<br />

Supply classification - HARMFUL<br />

Risk Phrases: . R20 Harmful by inhalation.<br />

R48/20 Harmful – danger of serious damage to health<br />

by prolonged exposure through inhalation.<br />

Safety Phrases: S22 Do not breathe dust.<br />

1166 Othheerr Innf I foorrmaat tioonn<br />

S37<br />

S26<br />

Wear suitable gloves.<br />

In case of contact with eyes, rinse immediately<br />

with plenty of water and seek medical advice.<br />

This data sheet has been compiled in accordance with the Chemicals (Hazard Information and Packaging<br />

for Supply). Regulations 1994.