Palm Based Oleochemicals - Cosmetics - American Palm Oil Council

Palm Based Oleochemicals - Cosmetics - American Palm Oil Council

Palm Based Oleochemicals - Cosmetics - American Palm Oil Council

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

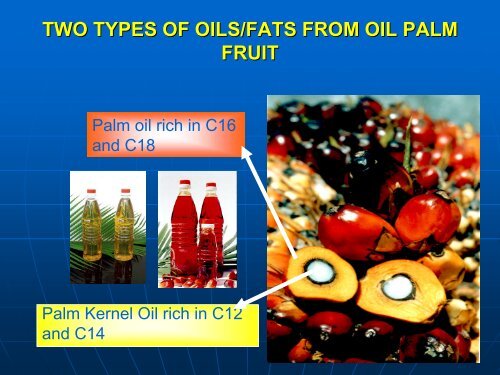

TWO TYPES OF OILS/FATS FROM OIL PALM<br />

FRUIT<br />

<strong>Palm</strong> oil rich in C16<br />

and C18<br />

<strong>Palm</strong> Kernel <strong>Oil</strong> rich in C12<br />

and C14<br />

1

NONFOOD USES<br />

<strong>Palm</strong> oil<br />

Fractionated into<br />

palm olein and<br />

stearin<br />

<strong>Palm</strong> olein – food<br />

<strong>Palm</strong> stearin –<br />

nonfood /<br />

oleochemicals<br />

<strong>Palm</strong> Kernel <strong>Oil</strong><br />

Fractionated into<br />

palm kernel olein and<br />

kernel stearin<br />

<strong>Palm</strong> kernel stearin –<br />

food<br />

<strong>Palm</strong> kernel olein –<br />

nonfood /<br />

oleochemicals<br />

2

COMPOSITION OF<br />

PO = TALLOW & PKO = CNO<br />

R, R’, R , R’’ R<br />

PO<br />

Tallow<br />

CNO<br />

PKO<br />

C6 0.2<br />

0.3<br />

C8 8.0<br />

4.4<br />

C10 7.0<br />

3.7<br />

C12 C14 C16 C18 C18:1 C18:2 0.23<br />

1.09<br />

44.02<br />

4.54<br />

39.15<br />

10.12<br />

2.5 26.6 21.8 42.8 2.3 48.2<br />

18.0<br />

8.5<br />

2.3<br />

5.7<br />

2.1<br />

48.3<br />

15.6<br />

7.8<br />

2.0<br />

15.1<br />

2.7<br />

C18:3<br />

0.37<br />

4

CHANGING THE SCENARIO<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Availability of lauric<br />

oils<br />

Predictability in<br />

supply<br />

Good Government<br />

incentives<br />

Good infrastructure<br />

Political stability<br />

FAC Tallow = PO<br />

FAC CNO = PKO<br />

The development of<br />

oleochemicals industry<br />

in Malaysia (&<br />

Indonesia)<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

1975 1980 1985 1990 1995 2000 2005<br />

<strong>Palm</strong> <strong>Oil</strong> PK <strong>Oil</strong><br />

5

Percent Utilization of <strong>Palm</strong> Products in<br />

Malaysian Oleochemical Industry<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

1990 1998 1999 2000 2001 2002 2003 2004 2005<br />

PO 2 3.1 3.4 4.5 4.6 4.6 4.6 4.7 4.9<br />

PKO 13.3 51.7 47.6 59.3 50 59.2 58.5 63.6 60.7<br />

Total P 3.4 9 8.5 10.5 10 10.6 10.5 10.9 11.3<br />

6

MALAYSIAN OLEOCHEMICALS: CAPACITY,<br />

PRODUCTION AND EXPORTS (in‘000 tonnes).<br />

2000<br />

1500<br />

1000<br />

500<br />

0<br />

1998 1999 2000 2001 2002 2003 2004 2005<br />

#Co: 15 14 16 17 16 17<br />

Capacity <strong>Oil</strong> used Export<br />

7

TYPES OF BASIC OLEOCHEMICALS<br />

EXPORTED FROM MALAYSIA (in tonnes)<br />

800000<br />

700000<br />

600000<br />

500000<br />

400000<br />

300000<br />

200000<br />

100000<br />

0<br />

1998 1999 2000 2001 2002 2003 2004 2005<br />

Acids Alcohol Methyl Ester Glycerol<br />

8

METHYL ESTER FROM PKO<br />

PKO<br />

MES<br />

Crude Methyl<br />

Ester<br />

High temp. & High pressure<br />

Hydrogenation<br />

sulfation<br />

Distilled Methyl<br />

Ester<br />

Fatty Alcohol<br />

ethoxylation<br />

PKO rich in C12 & C14<br />

- desired chain length for<br />

surfactants<br />

Fatty Alcohol<br />

Sulfates<br />

Fatty Alcohol<br />

Ethoxylates<br />

Fatty Alcohol<br />

Ether Sulfates<br />

9

LOTION WITH VITAMIN E<br />

Isopropyl Myristate<br />

Octyl Stearate<br />

Stearic Acid<br />

MCT<br />

Water<br />

Glycerin<br />

Preservatives<br />

Rheological additives<br />

Vitamin E<br />

Triethanol Amine<br />

11

CREAM<br />

Isopropyl palmitate<br />

Octyl palmitate<br />

Stearic acid<br />

MCT<br />

Cetyl alcohol<br />

Glycerol<br />

Preservative<br />

Rheological additives<br />

Neutraliser<br />

12

COLLABORATION WITH HR<br />

MARKETING SDN. BHD.<br />

Skincare with goat’s milk<br />

13

PRODUCTS WITH ROSELLE<br />

14

PRODUCTS WITH PALM VITAMIN E<br />

15

COLOR COSMETICS<br />

• LIPSTICKS<br />

• DEODORANT STICK<br />

• COMPACT POWDER<br />

• LIQUID FOUNDATION<br />

LIPGLOSS<br />

MASCARA<br />

LOOSE POWDER<br />

16

EFFICACY TESTING<br />

• Efficacy tests (in-<br />

vivo and in-vitro)<br />

are carried out to<br />

get data.<br />

• Data is used to<br />

substantiate claims<br />

made on a<br />

particular product.<br />

• In developed<br />

countries – claim<br />

substantiation is<br />

necessary.<br />

17

SAFETY AND EFFICACY<br />

EVALUATION OF SOAPS<br />

Figure 4. Results of Chromamater Readings<br />

Figure 7. Results of Skin Hydration<br />

V ariation of a*<br />

value<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

0.0<br />

-0.5<br />

Soap A COM2 C<br />

Variation of Hydration<br />

0.0<br />

-2.0<br />

-4.0<br />

-6.0<br />

-8.0<br />

-10.0<br />

-12.0<br />

-14.0<br />

-* -*<br />

Soap A COM2 C<br />

-*<br />

Product<br />

Product<br />

Soap A COM2 C<br />

Soap A COM2 C<br />

Irritation test<br />

Skin Hydration test<br />

18

ROSELLE MOISTURIZING CREAM<br />

35-38% 38% increase in skin moisture<br />

after application (Rosnah(<br />

Rosnah, , 2002)<br />

Figure 2 : Increase in moisture treated with<br />

cream vs untreated<br />

% Increase<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

-5<br />

0 30 60 90 120 180<br />

Control<br />

DC2<br />

DC3<br />

Time (minutes)<br />

19

WHITENING EFFICACY<br />

Variation in L<br />

value<br />

Study 49/01 : Effect on skin<br />

lightness between treated and<br />

untreated<br />

1.5<br />

1.0<br />

0.5<br />

0.0<br />

-0.5<br />

T0 T4 T6<br />

SLC<br />

Time (weeks)<br />

Untreated<br />

V ariation in m e lanin<br />

index<br />

Study49/01 : Effect on skin melanin<br />

between treated and untreated<br />

0.0<br />

-2.0<br />

-4.0<br />

-6.0<br />

T0 T4 T6<br />

Time (weeks)<br />

SLC<br />

Untreated<br />

No. of Volunteers = 20 Product type = cream<br />

Skin types = Group 3 (14), 4 (6)<br />

Result = significant (p

<strong>Palm</strong>-based anti acne cream<br />

• In vitro tests of using the essential oil at 50mg/ml showed that the<br />

compounds could significantly reduce Propionibacterium acnes and<br />

Staphylococcus aureus, which are the main microflora of acne lesion.<br />

120<br />

% Bacterial Count<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Control<br />

6.25<br />

12.5<br />

25<br />

50<br />

100<br />

P. acne<br />

S. aureus<br />

Dose (mg/ml)<br />

In vitro anti-microbial test of essential oil against<br />

Propionibacterium acnes and Staphylococcus aureus<br />

21

<strong>Palm</strong>-based anti acne cream<br />

Direct sebum measurement indicated a 9% reduction after 6 weeks<br />

application of the anti-acne cream.<br />

Sebum (mg.cm-2)<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

-20<br />

Sebum<br />

(mg/cm2)<br />

% Sebum<br />

Reduction<br />

T0 (Control)<br />

T1 (Week 1)<br />

T4 (Week 4)<br />

T6 (Week 6)<br />

In vivo study on the effect of anti-acne cream on sebum production<br />

against time<br />

22

PALM DIHYDROXYSTEARIC ACIDS<br />

(PALM DHSA)<br />

OH<br />

CH3 -(CH<br />

2 ) 7 CH-CH-(CH<br />

2 ) 7 -COOH<br />

OH<br />

MW 316<br />

24

PRODUCTION OF DHSA<br />

HCO 3 H or CH 3 CO 3 H)<br />

COOH<br />

H +<br />

OH<br />

O<br />

OH<br />

H 2 O<br />

COOH<br />

COOH<br />

9,10-dihydroxystearic acid<br />

25

In Vitro test for Skin Corrosion<br />

Not Not determine determined<br />

In Vitro test for Skin Irritation<br />

In Vitro Dermal irritection Assay<br />

Human irritancy Equivalent (HIE)<br />

1.4<br />

1.2<br />

1<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0<br />

R10 R11-A R11-1 R13<br />

50uL<br />

75uL<br />

100uL<br />

125uL<br />

Non-Irritant<br />

Moderate Irritant<br />

DHSA Samples<br />

26

3 PROCESSES TO PRODUCE<br />

SOAP/SOAP NOODLES<br />

RCH 2 COO-CH<br />

CH 2<br />

RCH 2 COO-CH<br />

CH<br />

RCH 2 COO-CH<br />

CH 2<br />

RCH 2 COOH<br />

RCH 2 COOCH 3<br />

NaOH<br />

NaOH<br />

NaOH<br />

3 RCH 2 COO - Na +<br />

+ CH 2 OHCHOHCH 2 OH<br />

RCH 2 COO - Na +<br />

RCH 2 COO - Na +<br />

+ CH 3 OH<br />

Soap noodles<br />

USP glycerin<br />

Soap noodles<br />

Soap noodles<br />

29

DIFFERENCES BETWEEN THE<br />

VARIOUS SOAP NOODLES<br />

Saponification of<br />

oils/fats<br />

FAC depend on the<br />

types and ratio of<br />

various oils/fats<br />

used<br />

Neutralization of<br />

fatty acids<br />

FAC can be varied<br />

by selecting the<br />

fatty acids to<br />

neutralize<br />

Saponification of<br />

fatty methyl ester<br />

FAC can be varied by<br />

selecting the fatty<br />

methyl ester to<br />

saponify<br />

Color – darker<br />

Color – good<br />

Color – Very good<br />

Elaborate process<br />

Simplified process<br />

Process is simple but<br />

CH 3 OH can pose<br />

problem to some.<br />

<br />

30

PALM-BASED SOAP NOODLES<br />

FROM MALAYSIA<br />

PO 80, 75, 70, 60<br />

PKO 20, 25, 30, 40<br />

H 2 O 9-12.5%<br />

TFM 79-83%<br />

FFA 1.3 - 7.0%<br />

GLY 0.4 - 0.6%<br />

Sesq. Present<br />

31

PALM-BASED TRANSPARENT SOAP FOR<br />

SKIN CARE & DECORATIVE<br />

• Developed by<br />

neutralization of fatty<br />

acids and in<br />

combination with<br />

polyol (i.e. glycerine)<br />

as an agent to impart<br />

transparency to the<br />

soap.<br />

32

PALM-BASED TRANSPARENT SOAP VS<br />

COMMERCIAL TRANSPARENT SOAPS<br />

Sample<br />

pH<br />

(1% solution)<br />

Penetration<br />

depth (mm)<br />

Transparenc<br />

y value<br />

<strong>Palm</strong>-based<br />

transparent soap<br />

for skin care<br />

9.84 1.09 0.90<br />

Commercial 1 10.17 0.18 0.77<br />

Commercial 2 10.46 1.09 0.88<br />

Commercial 3 10.28 3.09 0.86<br />

33

SUMMARY<br />

o<br />

o<br />

o<br />

o<br />

<strong>Palm</strong> oil is an important oil in the<br />

oils/fats market<br />

Very versatile – many potential<br />

applications<br />

Some applications compete with<br />

petro-based products<br />

Oleochemical products can<br />

compete in terms of performance<br />

and cost<br />

34