The Scrader concept - Dredgepoint

The Scrader concept - Dredgepoint

The Scrader concept - Dredgepoint

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

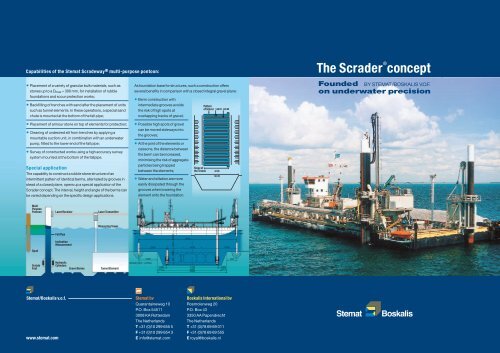

Capabilities of the Stemat Scradeway ® multi-purpose pontoon:<br />

®<br />

<strong>The</strong> <strong>Scrader</strong> <strong>concept</strong><br />

• Placement of a variety of granular bulk materials, such as<br />

stones up to a D max ≈ 300 mm, for installation of rubble<br />

foundations and scour protection works;<br />

• Backfilling of trenches with sand after the placement of units<br />

such as tunnel elements. In these operations, a special sand<br />

chute is mounted at the bottom of the fall pipe;<br />

As foundation base for structures, such a construction offers<br />

several benefits in comparison with a closed integral gravel plane:<br />

• Berm construction with<br />

intermediate grooves avoids<br />

the risk of high spots at<br />

overlapping tracks of gravel;<br />

Pattern<br />

of Gravel<br />

1.65 m 1.00 m<br />

Founded BY STEMAT/BOSKALIS V.O.F.<br />

on underwater precision<br />

• Placement of armour stone on top of elements for protection;<br />

• Cleaning of undesired silt from trenches by applying a<br />

mountable suction unit, in combination with an underwater<br />

pump, fitted to the lower end of the fall pipe;<br />

• Survey of constructed works using a high accuracy survey<br />

system mounted at the bottom of the fallpipe.<br />

Special application<br />

<strong>The</strong> capability to construct a rubble stone structure of an<br />

intermittent pattern of identical berms, alternated by grooves in<br />

stead of a closed plane, opens up a special application of the<br />

<strong>Scrader</strong> <strong>concept</strong>. <strong>The</strong> interval, height and angle of the berms can<br />

be varied depending on the specific design applications.<br />

• Possible high spots of gravel<br />

can be moved sideways into<br />

the grooves;<br />

• At the joint of the elements or<br />

caissons, the distance between<br />

the berm can be increased,<br />

minimising the risk of aggregate<br />

particles being trapped<br />

between the elements;<br />

• Water and siltation are more<br />

easily dissipated through the<br />

grooves when lowering the<br />

element onto the foundation.<br />

Slope of<br />

the Trench<br />

42 m<br />

56 m<br />

Multi<br />

Purpose<br />

Pontoon<br />

Laser Receiver<br />

Laser Transmitter<br />

Measuring Tower<br />

Spud<br />

Fall Pipe<br />

Inclination<br />

Measurement<br />

Scrade<br />

Foot<br />

Hydraulic<br />

Cylinders<br />

Gravel Berms<br />

Tunnel Element<br />

Stemat/Boskalis v.o.f.<br />

www.stemat.com<br />

Stemat bv<br />

Quarantaineweg 10<br />

P.O. Box 54511<br />

3008 KA Rotterdam<br />

<strong>The</strong> Netherlands<br />

T +31 (0)10 299 655 5<br />

F + 31 (0)10 299 654 3<br />

E info@stemat.com<br />

Boskalis International bv<br />

Rosmolenweg 20<br />

P.O. Box 43<br />

3350 AA Papendrecht<br />

<strong>The</strong> Netherlands<br />

T +31 (0)78 69 69 011<br />

F +31 (0)78 69 69 555<br />

E royal@boskalis.nl<br />

Stemat<br />

Boskalis

Granular bulk material is fed into the fall pipe by a conveyor belt.<br />

<strong>The</strong> <strong>Scrader</strong> <strong>concept</strong> proved<br />

extremely valuable in the<br />

construction of the second<br />

Benelux tunnel across the<br />

port entrance of Rotterdam,<br />

for which the foundation<br />

accuracy requirements were<br />

very stringent.<br />

immersed tunnels, and can be used with a wide variety<br />

of granular bulk materials. It has been successfully<br />

employed in major projects.<br />

With its telescopic fall pipe, the Stemat Scradeway can<br />

operate in water depths of up to 28 metres, laying gravel<br />

foundations with a tolerance of only 25 mm.<br />

Scrading allows for incredible accuracy. In a water depth<br />

of up to 28 metres, the tolerance in laying a gravel<br />

foundation can be less than 25 mm (!). <strong>The</strong> screadhead is<br />

fitted with five multi-transducer echosounders for<br />

continuous survey of the newly 'scraded' layer.<br />

Combining their know-how and equipment in a joint venture, Stemat and Boskalis have set a new<br />

world standard in seabed treatment for underwater construction: the <strong>Scrader</strong> ® <strong>concept</strong>.<br />

Using the specially developed multi-purpose pontoon Stemat Scradeway, the company is capable of<br />

constructing gravel beds with extremely high accuracy in waters up to 28 metres deep.<br />

®<br />

<strong>The</strong> <strong>Scrader</strong> <strong>concept</strong>:<br />

Founded on underwater precision<br />

<strong>The</strong> precision performance of the <strong>Scrader</strong> method allows<br />

for ballasting and placing tunnel elements right onto a final<br />

foundation of gravel, saving time and minimising<br />

construction risks. Besides tunnel projects, the technique<br />

can also be used for other underwater construction works,<br />

such as foundations for bridges, caissons, windmills and<br />

offshore outfalls.<br />

A common technique for building underwater foundations<br />

is known as 'grading', a two step operation of depositing<br />

and subsequent levelling of a gravel bed. Scrading<br />

combines these two operations: the Stemat Scradeway is<br />

equipped with a telescopic fall pipe to deposit and level<br />

the material at the same time. <strong>The</strong> fall pipe is positioned at<br />

the side of the multi-purpose pontoon and can be moved<br />

47 metres, horizontally across the trench. A conveyor belt<br />

on the pontoon feeds the fall pipe with scrade material.<br />

As the fall pipe moves across the trench, it is kept at the<br />

required level by means of a laserguided hydraulic<br />

'screadhead' and remains in constant contact with the<br />

gravel berm. With the vertical flow of the material confined<br />

within the fall pipe, segregation is virtually eliminated, while<br />

substantially less gravel is used.<br />

<strong>The</strong> <strong>Scrader</strong> method is ideal for construction of underwater<br />

foundations for projects such as caisson walls and<br />

Construction of gravel bed foundation for breakwater in<br />

Cartagena, Spain<br />

Reference list executed projects:<br />

Gravel bed for Øresund tunnel<br />

Copenhagen, Denmark<br />

Gravel bed for second Benelux tunnel<br />

Rotterdam, <strong>The</strong> Netherlands<br />

<strong>The</strong> Scrading process is fully<br />

automated. <strong>The</strong> system<br />

operator observes the<br />

process on a computer<br />

monitor, displaying the<br />

underwater actions as well<br />

as the positioning<br />

information.<br />

Bachfilling powercable trench with slacks<br />

Westerschelde, <strong>The</strong> Netherlands<br />

Renewal of roof cover of Elbe tunnel<br />

Hamburg, Germany<br />

Gravel bed for caisson quay wall<br />

Cartagena, Spain