BETA® - MPS Electronic

BETA® - MPS Electronic

BETA® - MPS Electronic

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

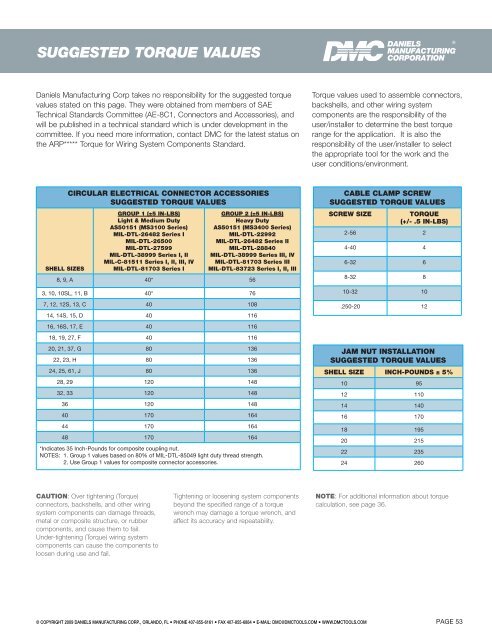

Suggested torque values<br />

Daniels Manufacturing Corp takes no responsibility for the suggested torque<br />

values stated on this page. They were obtained from members of SAE<br />

Technical Standards Committee (AE-8C1, Connectors and Accessories), and<br />

will be published in a technical standard which is under development in the<br />

committee. If you need more information, contact DMC for the latest status on<br />

the ARP***** Torque for Wiring System Components Standard.<br />

Torque values used to assemble connectors,<br />

backshells, and other wiring system<br />

components are the responsibility of the<br />

user/installer to determine the best torque<br />

range for the application. It is also the<br />

responsibility of the user/installer to select<br />

the appropriate tool for the work and the<br />

user conditions/environment.<br />

Shell Sizes<br />

CIRCULAR ELECTRICAL CONNECTOR ACCESSORIES<br />

suggested TORQUE VALUES<br />

Group 1 (±5 in-lbs)<br />

Light & Medium Duty<br />

AS50151 (MS3100 Series)<br />

MIL-DTL-26482 Series I<br />

MIL-DTL-26500<br />

MIL-DTL-27599<br />

MIL-DTL-38999 Series I, II<br />

MIL-C-81511 Series I, II, III, IV<br />

MIL-DTL-81703 Series I<br />

Group 2 (±5 in-lbs)<br />

Heavy Duty<br />

AS50151 (MS3400 Series)<br />

MIL-DTL-22992<br />

MIL-DTL-26482 Series II<br />

MIL-DTL-28840<br />

MIL-DTL-38999 Series III, IV<br />

MIL-DTL-81703 Series III<br />

MIL-DTL-83723 Series I, II, III<br />

8, 9, A 40* 56<br />

3, 10, 10SL, 11, B 40* 76<br />

7, 12, 12S, 13, C 40 108<br />

14, 14S, 15, D 40 116<br />

16, 16S, 17, E 40 116<br />

18, 19, 27, F 40 116<br />

20, 21, 37, G 80 136<br />

22, 23, H 80 136<br />

24, 25, 61, J 80 136<br />

28, 29 120 148<br />

32, 33 120 148<br />

36 120 148<br />

40 170 164<br />

44 170 164<br />

48 170 164<br />

*Indicates 35 Inch-Pounds for composite coupling nut.<br />

Notes: 1. Group 1 values based on 80% of MIL-DTL-85049 light duty thread strength.<br />

2. Use Group 1 values for composite connector accessories.<br />

CABLE CLAMP SCREW<br />

suggested TORQUE VALUES<br />

Screw Size<br />

Torque<br />

(+/- .5 In-lbs)<br />

2-56 2<br />

4-40 4<br />

6-32 6<br />

8-32 8<br />

10-32 10<br />

.250-20 12<br />

JAM NUT INSTALLATION<br />

suggested TORQUE VALUES<br />

SHELL SIZE INCH-POUNDS ± 5%<br />

10 95<br />

12 110<br />

14 140<br />

16 170<br />

18 195<br />

20 215<br />

22 235<br />

24 260<br />

CAUTION: Over tightening (Torque)<br />

connectors, backshells, and other wiring<br />

system components can damage threads,<br />

metal or composite structure, or rubber<br />

components, and cause them to fail.<br />

Under-tightening (Torque) wiring system<br />

components can cause the components to<br />

loosen during use and fail.<br />

Tightening or loosening system components<br />

beyond the specified range of a torque<br />

wrench may damage a torque wrench, and<br />

affect its accuracy and repeatability.<br />

NOTE: For additional information about torque<br />

calculation, see page 36.<br />

© Copyright 2009 Daniels Manufacturing Corp., Orlando, FL • Phone 407-855-6161 • Fax 407-855-6884 • E-Mail: dmc@dmctools.com • www.dmctools.com PAGE 53