Download pdf - BLM GROUP

Download pdf - BLM GROUP

Download pdf - BLM GROUP

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The key to UNIVER’s production: combining quality, price and delivery<br />

successfully, to compete with Chinese products.<br />

A winning bet.<br />

INSPIRED FOR TUBE Stampings<br />

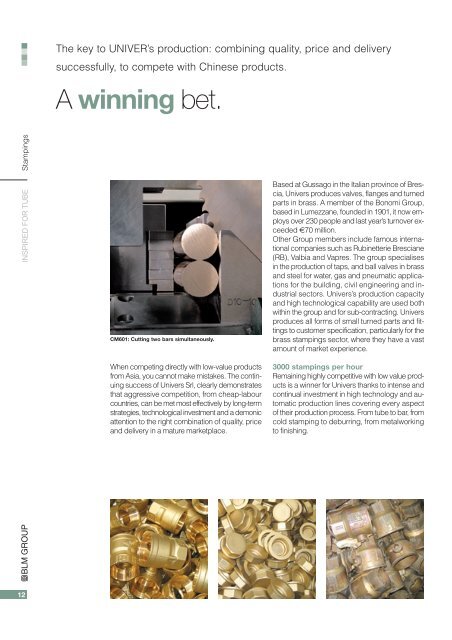

CM601: Cutting two bars simultaneously.<br />

Based at Gussago in the Italian province of Brescia,<br />

Univers produces valves, flanges and turned<br />

parts in brass. A member of the Bonomi Group,<br />

based in Lumezzane, founded in 1901, it now employs<br />

over 230 people and last year’s turnover exceeded<br />

€70 million.<br />

Other Group members include famous international<br />

companies such as Rubinetterie Bresciane<br />

(RB), Valbia and Vapres. The group specialises<br />

in the production of taps, and ball valves in brass<br />

and steel for water, gas and pneumatic applications<br />

for the building, civil engineering and industrial<br />

sectors. Univers’s production capacity<br />

and high technological capability are used both<br />

within the group and for sub-contracting. Univers<br />

produces all forms of small turned parts and fittings<br />

to customer specification, particularly for the<br />

brass stampings sector, where they have a vast<br />

amount of market experience.<br />

When competing directly with low-value products<br />

from Asia, you cannot make mistakes. The continuing<br />

success of Univers Srl, clearly demonstrates<br />

that aggressive competition, from cheap-labour<br />

countries, can be met most effectively by long-term<br />

strategies, technological investment and a demonic<br />

attention to the right combination of quality, price<br />

and delivery in a mature marketplace.<br />

3000 stampings per hour<br />

Remaining highly competitive with low value products<br />

is a winner for Univers thanks to intense and<br />

continual investment in high technology and automatic<br />

production lines covering every aspect<br />

of their production process. From tube to bar, from<br />

cold stamping to deburring, from metalworking<br />

to finishing.<br />

12