dhc-6-300 'b' check basic inspection requirements - IDEAS-EC

dhc-6-300 'b' check basic inspection requirements - IDEAS-EC

dhc-6-300 'b' check basic inspection requirements - IDEAS-EC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

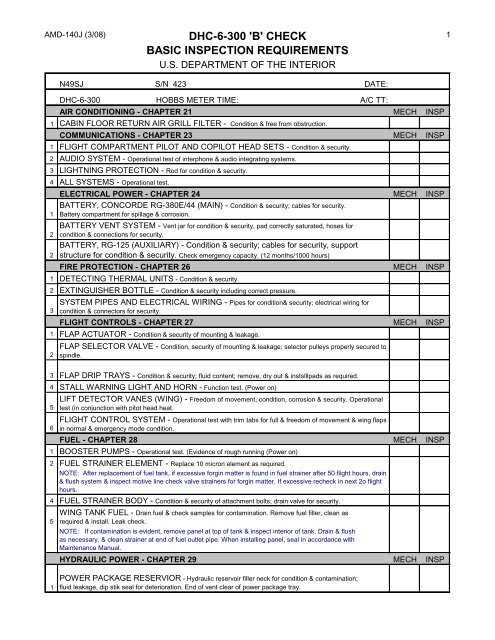

AMD-140J (3/08)<br />

DHC-6-<strong>300</strong> 'B' CH<strong>EC</strong>K<br />

BASIC INSP<strong>EC</strong>TION REQUIREMENTS<br />

U.S. DEPARTMENT OF THE INTERIOR<br />

1<br />

N49SJ S/N 423 DATE:<br />

DHC-6-<strong>300</strong> HOBBS METER TIME: A/C TT:<br />

AIR CONDITIONING - CHAPTER 21 M<strong>EC</strong>H INSP<br />

1 CABIN FLOOR RETURN AIR GRILL FILTER - Condition & free from obstruction.<br />

COMMUNICATIONS - CHAPTER 23 M<strong>EC</strong>H INSP<br />

1 FLIGHT COMPARTMENT PILOT AND COPILOT HEAD SETS - Condition & security.<br />

2 AUDIO SYSTEM - Operational test of interphone & audio integrating systems.<br />

3 LIGHTNING PROT<strong>EC</strong>TION - Rod for condition & security.<br />

4 ALL SYSTEMS - Operational test.<br />

EL<strong>EC</strong>TRICAL POWER - CHAPTER 24 M<strong>EC</strong>H INSP<br />

BATTERY, CONCORDE RG-380E/44 (MAIN) - Condition & security; cables for security.<br />

1 Battery compartment for spillage & corrosion.<br />

2<br />

2<br />

1<br />

2<br />

3<br />

1<br />

2<br />

BATTERY VENT SYSTEM - Vent jar for condition & security, pad correctly saturated, hoses for<br />

condition & connections for security.<br />

BATTERY, RG-125 (AUXILIARY) - Condition & security; cables for security, support<br />

structure for condition & security. Check emergency capacity. (12 months/1000 hours)<br />

FIRE PROT<strong>EC</strong>TION - CHAPTER 26 M<strong>EC</strong>H INSP<br />

DET<strong>EC</strong>TING THERMAL UNITS - Condition & security.<br />

EXTINGUISHER BOTTLE - Condition & security including correct pressure.<br />

SYSTEM PIPES AND EL<strong>EC</strong>TRICAL WIRING - Pipes for condition& security; electrical wiring for<br />

condition & connectors for security.<br />

FLIGHT CONTROLS - CHAPTER 27 M<strong>EC</strong>H INSP<br />

FLAP ACTUATOR - Condition & security of mounting & leakage.<br />

FLAP SEL<strong>EC</strong>TOR VALVE - Condition, security of mounting & leakage; selector pulleys properly secured to<br />

spindle.<br />

3<br />

4<br />

5<br />

6<br />

FUEL - CHAPTER 28 M<strong>EC</strong>H INSP<br />

1 BOOSTER PUMPS - Operational test. (Evidence of rough running (Power on)<br />

2<br />

4 FUEL STRAINER BODY - Condition & security of attachment bolts; drain valve for security.<br />

5<br />

FLAP DRIP TRAYS - Condition & security; fluid content; remove, dry out & instslllpads as required.<br />

STALL WARNING LIGHT AND HORN - Function test. (Power on)<br />

LIFT DET<strong>EC</strong>TOR VANES (WING) - Freedom of movement, condition, corrosion & security. Operational<br />

test (in conjunction with pitot head heat.<br />

FLIGHT CONTROL SYSTEM - Operational test with trim tabs for full & freedom of movement & wing flaps<br />

in normal & emergency mode condition.<br />

FUEL STRAINER ELEMENT - Replace 10 micron element as required.<br />

NOTE: After replacement of fuel tank, if excessive forgin matter is found in fuel strainer after 50 flight hours, drain<br />

& flush system & inspect motive line <strong>check</strong> valve strainers for forgin matter. If excessive re<strong>check</strong> in next 2o flight<br />

hours.<br />

WING TANK FUEL - Drain fuel & <strong>check</strong> samples for contamination. Remove fuel filler, clean as<br />

required & install. Leak <strong>check</strong>.<br />

NOTE: If contamination is evident, remove panel at top of tank & inspect interior of tank. Drain & flush<br />

as necessary, & clean strainer at end of fuel outlet pipe. When installing panel, seal in accordance with<br />

Maintenance Manual.<br />

HYDRAULIC POWER - CHAPTER 29 M<strong>EC</strong>H INSP<br />

1<br />

POWER PACKAGE RESERVIOR - Hydraulic reservoir filler neck for condition & contamination;<br />

fluid leakage, dip stik seal for deterioration. End of vent clear of power package tray.

AMD-140J (3/08)<br />

DHC-6-<strong>300</strong> 'B' CH<strong>EC</strong>K<br />

BASIC INSP<strong>EC</strong>TION REQUIREMENTS<br />

U.S. DEPARTMENT OF THE INTERIOR<br />

ICE AND RAIN PROT<strong>EC</strong>TION - CHAPTER 30 M<strong>EC</strong>H INSP<br />

PROPELLER DE-ICENG BLADE BOOTS - Boots for cuts, tears, burns, deterioration &<br />

2 proper adhesion.<br />

3 PROPELLER DE-ICENG BRUSH BLOCK ASSEMBLY - Condition & security.<br />

4<br />

LANDING GEAR - CHAPTER 32 M<strong>EC</strong>H INSP<br />

1 NOSE GEAR - Correct extension as given on data plate. Fork retaining nut secured properly.<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

NOTE: If indicator pins are flush with ends of adjustment nuts (brake pressure off), <strong>check</strong> that brake<br />

lining wear is within limits. Refer to Maintenance Manual.<br />

MAIN WHEEL BRAKE DISC GUIDE PAD (When installed) - Condition & security.<br />

MAIN WHEELS - Remove & clean as required; Inspect for abrasions, cracks, chipped rims; brake<br />

drive rings for condition & signs of wear, bearings, bush & seals for condition.Lubricate bearing. Install<br />

servicable wheel & tire.<br />

NAVIGATION - CHAPTER 34 M<strong>EC</strong>H INSP<br />

1 WEATHER RADAR SYSTEM - Operational test. (Power on)<br />

2 ALL SYSTEMS - Operational test. (Power on)<br />

1<br />

OXYGEN - CHAPTER 35 M<strong>EC</strong>H INSP<br />

2 PASSENGER OXYGEN - Proper operation; contamination (by smell).<br />

3<br />

PASSENGER OXYGEN INDICATOR AND CHARGING VALVE - Condition. Clean as<br />

required.<br />

4 PASSENGER OXYGEN OUTLETS- Clear of obstruction. Clean as required.<br />

1<br />

DOORS - CHAPTER 52 M<strong>EC</strong>H INSP<br />

CABIN ESCAPE HATCH DOORS - Proper operation; seals for condition & security.<br />

FUSELAGE - CHAPTER 53 M<strong>EC</strong>H INSP<br />

1 CABIN FLOOR PANELS - Condition, delamination, corrosion & security. Clean as required.<br />

NOTE: If floor panels are severely damaged, remove panels & inspect supporting structure for<br />

damage, buckling & cracks.<br />

2 CABIN FLOOR PANELS - Cargo tie-down ring locations & rings for condition & security.<br />

1<br />

2<br />

1<br />

PROPELLER DE-ICENG BACK SPIN PLATE AND SLIP RING - Condition & security.<br />

STEERING ACTUATOR - Condition & leakage; hydraulic pipes & input swivel lever for condition,<br />

connections for security & leakage.<br />

NOSE WHEEL ASSEMBLY - Remove & clean as required; Inspect for abrasions, cracks, chipped rims,<br />

bearings for condition, bushing for wear & seal for deteriortion. Install wheel assembly.<br />

STEERING ACTUATOR LINKAGE - Condition, corrosion & security; fouling of linkage on shock strut<br />

cylinder body.<br />

MAIN WHEEL BRAKE HOUSING - Cylinders & associated lines for condition, leakage & evidence of<br />

overheating.<br />

MAIN WHEEL BRAKE DISCS - Scoring & evidence of overheating.<br />

MAIN WHEEL BRAKE PUCK LIINGS - Wear within limits.<br />

CREW OXYGEN - Proper operation (normal & emergency); contamination (by smell).<br />

STABILIZERS - CHAPTER 55 M<strong>EC</strong>H INSP<br />

RUDDER TRIM AND GEAR TAB HINGE ARMS - Hinge arms for condition & security,<br />

connecting hinge arm bolts for safety & security.<br />

ELEVATOR TRIM AND INTERCONN<strong>EC</strong>T TAB HINGE ARMS - Hinge arms for<br />

condition & security, connecting hinge arm bolts for safety & security.<br />

WINGS - CHAPTER 57 M<strong>EC</strong>H M<strong>EC</strong>H INSP<br />

WING MAIN HINGE ARMS - Hinge arms, bonding wire & bearing for condition & security, &<br />

attachment bolts for safety & security.<br />

2 INBD TRAILING FLAP - Condition, skins for cracks & fasteners for security.<br />

NOTE: Refer to Servive Bulletin 6/345.<br />

WING FLAP, AILERON HINGE ARMS AND CONN<strong>EC</strong>TING LINK ATTACH BOLTS<br />

3 - Safety & security.<br />

2

AMD-140J (3/08)<br />

DHC-6-<strong>300</strong> 'B' CH<strong>EC</strong>K<br />

BASIC INSP<strong>EC</strong>TION REQUIREMENTS<br />

U.S. DEPARTMENT OF THE INTERIOR<br />

3<br />

PROPELLERS - CHAPTER 61 M<strong>EC</strong>H M<strong>EC</strong>H INSP<br />

1<br />

BLADES, SPINNER AND HUB PARTS - Condition, blades for nicks & cracks. Blend nicks out<br />

from leading edge.<br />

ENGINE - CHAPTER 72 M<strong>EC</strong>H M<strong>EC</strong>H INSP<br />

1 EXHAUST DUCTS - Condition, deflector vanes for cracks, erosion & security.<br />

STARTING - CHAPTER 80 M<strong>EC</strong>H M<strong>EC</strong>H INSP<br />

1 GLOW PLUGS - Remove for operational test. Clean as required. Install servicable unit.<br />

OPERATIONAL CH<strong>EC</strong>K AND POST INSP<strong>EC</strong>TION M<strong>EC</strong>H INSP<br />

1 ACCESS COVERS, FAIRINGS AND COWLINGS - Assure their proper reinstallation.<br />

2<br />

1<br />

ENGINE RUN-UP - Perform an operational <strong>check</strong> of the engine, engine instruments & other<br />

systems. Inspect the engine compartment following the operational <strong>check</strong> for leaks or abnormalities.<br />

Taxi <strong>check</strong> the operation of the brakes.<br />

SERVICE BULLETINS AND AIRWORTHINESS DIR<strong>EC</strong>TIVES M<strong>EC</strong>H INSP<br />

MANUFACTURE SERVICE BULLETINS - Check that all Bulletins complied with, at the<br />

governments request, are documented into the aircraft log books.<br />

2<br />

AIRWORTHINESS DIR<strong>EC</strong>TIVES - Check that all AD's have been complied with or determined<br />

to be not applicable and documented into the aircraft log books as such.<br />

3 LOG BOOK ENTRIES / FORM 337 / WEIGHT AND BALANCE - Ensure all maintenance record<br />

This <strong>inspection</strong> <strong>check</strong> list is derived from the <strong>requirements</strong> of the PSM 1-6-7 DHC-6 TWIN OTTER Inspection Requirements Manual,<br />

Revision 12,dated March 12, 2007, engine and component manufacturers Maintenance Manuals, Service Publications and STC<br />

instructions for continued airworthiness in compliance with FAR Part 91.409 (f)(3).