Contractor: SGS Contact Info: PO - IDEAS-EC

Contractor: SGS Contact Info: PO - IDEAS-EC

Contractor: SGS Contact Info: PO - IDEAS-EC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

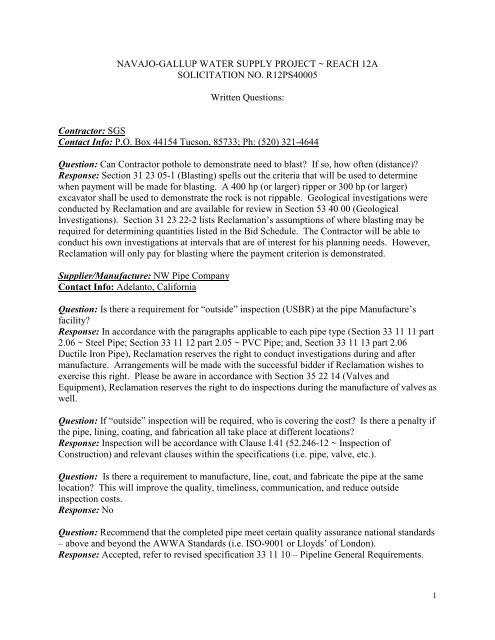

NAVAJO-GALLUP WATER SUPPLY PROJ<strong>EC</strong>T ~ REACH 12A<br />

SOLICITATION NO. R12PS40005<br />

Written Questions:<br />

<strong>Contractor</strong>: <strong>SGS</strong><br />

<strong>Contact</strong> <strong>Info</strong>: P.O. Box 44154 Tucson, 85733; Ph: (520) 321-4644<br />

Question: Can <strong>Contractor</strong> pothole to demonstrate need to blast If so, how often (distance)<br />

Response: Section 31 23 05-1 (Blasting) spells out the criteria that will be used to determine<br />

when payment will be made for blasting. A 400 hp (or larger) ripper or 300 hp (or larger)<br />

excavator shall be used to demonstrate the rock is not rippable. Geological investigations were<br />

conducted by Reclamation and are available for review in Section 53 40 00 (Geological<br />

Investigations). Section 31 23 22-2 lists Reclamation’s assumptions of where blasting may be<br />

required for determining quantities listed in the Bid Schedule. The <strong>Contractor</strong> will be able to<br />

conduct his own investigations at intervals that are of interest for his planning needs. However,<br />

Reclamation will only pay for blasting where the payment criterion is demonstrated.<br />

Supplier/Manufacture: NW Pipe Company<br />

<strong>Contact</strong> <strong>Info</strong>: Adelanto, California<br />

Question: Is there a requirement for “outside” inspection (USBR) at the pipe Manufacture’s<br />

facility<br />

Response: In accordance with the paragraphs applicable to each pipe type (Section 33 11 11 part<br />

2.06 ~ Steel Pipe; Section 33 11 12 part 2.05 ~ PVC Pipe; and, Section 33 11 13 part 2.06<br />

Ductile Iron Pipe), Reclamation reserves the right to conduct investigations during and after<br />

manufacture. Arrangements will be made with the successful bidder if Reclamation wishes to<br />

exercise this right. Please be aware in accordance with Section 35 22 14 (Valves and<br />

Equipment), Reclamation reserves the right to do inspections during the manufacture of valves as<br />

well.<br />

Question: If “outside” inspection will be required, who is covering the cost Is there a penalty if<br />

the pipe, lining, coating, and fabrication all take place at different locations<br />

Response: Inspection will be accordance with Clause I.41 (52.246-12 ~ Inspection of<br />

Construction) and relevant clauses within the specifications (i.e. pipe, valve, etc.).<br />

Question: Is there a requirement to manufacture, line, coat, and fabricate the pipe at the same<br />

location This will improve the quality, timeliness, communication, and reduce outside<br />

inspection costs.<br />

Response: No<br />

Question: Recommend that the completed pipe meet certain quality assurance national standards<br />

– above and beyond the AWWA Standards (i.e. ISO-9001 or Lloyds’ of London).<br />

Response: Accepted, refer to revised specification 33 11 10 – Pipeline General Requirements.<br />

1

Question: Is this a federally funded project<br />

Response: Yes, Navajo-Gallup Water Supply Project is a federally funded project.<br />

Question: If it is a federally funded project, does the Buy American Act Apply<br />

Response: Yes, please see amended solicitation clauses.<br />

Question: What is the anticipated award date for the contract to the <strong>Contractor</strong><br />

Response: Award is expected late March to mid-April.<br />

Question: Is the Bureau able to pre-pay for finished pipe at the Manufacturers plant<br />

Response: See updated section B of the solicitation for more information.<br />

<strong>Contractor</strong>: Garney Construction.<br />

<strong>Contact</strong> <strong>Info</strong>: 7911 Shaffer Parkway, Littleton, CO 80127; (720) 420-4881.<br />

Question: Can the bid date be pushed back<br />

Response: No.<br />

<strong>Contractor</strong>: Elstrom Construction<br />

<strong>Contact</strong> <strong>Info</strong>: none provided.<br />

Question: Can the pipe be sectioned off during testing<br />

Response: Yes, please see amended specification paragraphs.<br />

Question: Construction water<br />

Response: Section 01 51 00 (Temporary Utilities), lists potential sources for construction water.<br />

Offeror’s will need to contact entities listed to get pricing and location information.<br />

Question: Where do we list NM Gross Receipts Tax and Terro Tax<br />

Response: Include in bid prices. No separate line item will be provided for taxes.<br />

Question: Email address of the Point of <strong>Contact</strong><br />

Response: Point of <strong>Contact</strong> is George Kuechmann; gkuechmann@usbr.gov; (505) 462-3624.<br />

Question: Clarify Pipe Materials<br />

Response: Sections 33 11 10, 33 11 11, 33 11 12, and 33 11 13 discuss the requirements for the<br />

allowable pipe materials. Allowable pipe materials are Steel, PVC (at appropriate pressure<br />

range), and Ductile Iron Pipe. Bidders shall select the type of pipe to be used during the<br />

preparation of their bid. It is anticipated that the overall price for the installation of the pipe<br />

taking the cost of materials, excavation costs, embedment and backfill costs, etc will be a prime<br />

consideration in this decision. Other factors determined by the bidder may also be a<br />

consideration in the decision on the type of pipe to be used.<br />

Question: Can the submittal time frame be reduced from 40 to 10 days Is there any way to<br />

change the submittal review<br />

Response: Section 01 33 00 (Submittals) reserves 40 days for Government review of each<br />

2

submittal or re-submittal. Offeror’s should assume that Government review will require this full<br />

duration.<br />

Question: Will the Government consider procurement of the concrete to keep pricing equal<br />

Response: In accordance with Section 03 30 00 (Cast-In-Place Concrete) the <strong>Contractor</strong> will be<br />

required to procure the concrete.<br />

Question: Air Quality/Dust Control<br />

Response: Section 01 57 20 (Environmental Controls) covers the requirements for Dust and Air<br />

Quality Controls. Section 31 02 10 (Water for Dust Abatement) provides payment for the water<br />

used for dust control. See also Specification Section 31 02 20 (Dust Palliative).<br />

<strong>Contractor</strong>: Saguaro Geo Services.<br />

<strong>Contact</strong> <strong>Info</strong>: P.O. Box 44154 Tucson, 85733; (520) 321-4644.<br />

Question: If water is not present in drill holes and vibration/fly rock considerations are<br />

controlled is there any likelihood that ANFO can be permitted/allowed for blasting<br />

Response: In accordance with Section 31 23 05, ANFO is not allowed unless otherwise<br />

approved by the Contracting Officers Representative. Determination on use of ANFO will not<br />

be made until actual conditions are evaluated.<br />

<strong>Contractor</strong>: Yenter Companies, Inc.<br />

<strong>Contact</strong> <strong>Info</strong>: 20300 W. Hwy 72, Arvada, CO 80007; (303) 279-4458.<br />

Question: Will explosive magazines be allow to be stored on the easement (ROW), or will they<br />

be stored off-site<br />

Response: In accordance with Section 31 23 05 (Blasting), Explosives shall be stored off-site.<br />

Question: Will the blasting be required only after the rock is completely exposed and tested for<br />

rippability Or, can the contractor be allowed to pot-hole along the easement for rock to<br />

eliminate the need for open trench blasting<br />

Response: Section 31 23 05, 1.01 (Blasting) spells out the criteria that will be used to determine<br />

when payment will be made for blasting. A 400 hp (or larger) ripper or 300 hp (or larger)<br />

excavator shall be used to demonstrate the rock is not rippable. Geological investigations were<br />

conducted by Reclamation and are available for review in Section 53 40 00 (Geological<br />

Investigations). Section 31 23 22-2 lists Reclamation’s assumptions of where blasting may be<br />

required for determining quantities listed in the Bid Schedule. The <strong>Contractor</strong> will be able to<br />

conduct his own investigations at intervals that are of interest for his planning needs. However,<br />

Reclamation will only pay for blasting where the payment criterion is demonstrated.<br />

Question: How close are the Navajo Nation Water Department wells to the pipeline easement<br />

Where are they<br />

Response: Section 01 51 00 (Temporary Utilities), lists potential sources for construction water.<br />

Offeror’s shall need to contact entities listed to get pricing and location information.<br />

Question: Any blasting permits required by the Navajo Nation<br />

3

Response: In accordance with Specification Section 31 23 05 (Blasting), Part 1.07, <strong>Contractor</strong><br />

Requirements, Paragraph B; <strong>Contractor</strong> is responsible to meet all federal, state, local, and tribal<br />

regulations. Also see Part 3.01, General, A.; The <strong>Contractor</strong> needs to obtain approval of<br />

submitted Blasting Plan and all required permits. And, FAR 52.236-07, Permits and<br />

Responsibilities.<br />

<strong>Contractor</strong>: A&A Drilling and Blasting.<br />

<strong>Contact</strong> <strong>Info</strong>: 20315 W. Beloat Rd., Buckeye, Az; (623) 386-1212.<br />

Question: Are the blasting numbers for cubic yard or linear foot<br />

Response: Section 31 23 05 (Blasting) provides for payment by the cubic yard.<br />

<strong>Contractor</strong>: Aimone-Martin Assoc. LLC (Blasting and Vibration control).<br />

<strong>Contact</strong> <strong>Info</strong>: 1005 Bullock Ave, Socorro, NM 87801; (505) 970-9949.<br />

Response: Questions submitted referred to previously submitted questions and review of<br />

attached documentation. Response to questions are addressed below.<br />

<strong>Contractor</strong>: North Wind<br />

<strong>Contact</strong> <strong>Info</strong>: 1425 Higham Street, Idaho Falls, ID 83402; Phone: (208) 557-0862<br />

Question: Section B – Supplies or Services and Prices, Item B.1(e) denoted that New Mexico<br />

Gross Receipts Tax and Navajo Nation Gross Receipts Tax are to be included as a separate line<br />

item in the offer. The schedule of values CLIN 1 through 54 does not address these costs. Where<br />

shall the bidder itemize these taxes in their offer<br />

Response: Item B.1(e) has been edited by amendment. Taxes shall be included in bid prices.<br />

No separate line item will be provided for taxes. In accordance with Section B.1(e), contractors<br />

are responsible “to ensure all applicable New Mexico and Navajo Nation gross receipts tax are<br />

included in their Proposals”.<br />

Question: Based on the bid break-down this appears to be a unit price contract. Who and how<br />

are the actual quantities measured for payment<br />

Response: The Bid Schedule lists the applicable Sections for each pay item. Paragraph 1.01<br />

(Measurement and Payment) in each Section lists how each line in the Bid Schedule shall be<br />

measure and payment applied. See also FAR 52.232-05 (Payments under Fixed-Price<br />

Construction Contracts), FAR 52.236-16 (Quantity Surveys), and Section 01 71 20, Part 3.02<br />

(Quantity Surveys).<br />

Question: Section L.12, Page 70 of 84, denotes Offeror past performance and experience during<br />

the past 3 years, and the Evaluation Criteria, page 81 of 84, denotes past performance during the<br />

last 5 years. Which is it We are leaning toward 5 years.<br />

Response: The past performance requirements have been clarified in the amended documents.<br />

4

<strong>Contractor</strong>: NOV Ameron.<br />

<strong>Contact</strong> <strong>Info</strong>: 2325 South 7 th Street, Phoenix, AZ 85034; Phone (602) 252-7111.<br />

Question: Section 33 11 11, 2.01 D. 1. – Butt weld joints are called out on drawings for the steep<br />

areas. Is a backer bar required for the butt weld joints<br />

Response: Yes, refer to revised specification 33 11 11 – Steel Line Pipe<br />

Question: Section 33 11 11, 3.03 A. 3. – Field coating of joints references Section 09 96 02. Is<br />

this Section 09 96 20<br />

Response: Yes the Section number is 09 96 20 – Coatings.<br />

Question: Section 09 96 20 – Field coating of joints is not addressed in this section. Are heat<br />

shrink sleeves required<br />

Response: Yes, refer to revised specification 09 96 20 – Coatings.<br />

<strong>Contractor</strong>: Aimone-Martin Assoc. LLC (Blasting and Vibration control).<br />

<strong>Contact</strong> <strong>Info</strong>: 1005 Bullock Ave, Socorro, NM 87801; (505) 970-9949.<br />

Question: Request the Bureau of Reclamation consider the wording of three items for the<br />

purpose of clarification and providing consistency with blasting industry protocols and<br />

guidelines. These are as follows:<br />

Section 3.21 Monitoring, B. 2. on page 31 23 05 – 26; “…seismographs shall not be placed<br />

inside of a structure … shall be placed on secured to sound bedrock or … soil, or mass concrete<br />

foundation.”<br />

Section 3.21 Monitoring, C. 1. B. on page 31 23 05 – 26; “…to determine background levels on<br />

structures within 1,500 feet”<br />

It appears the baseline monitoring is required to be performed on structures while blast vibration<br />

monitoring required that geophones are not to be placed in structures (and by default construed<br />

as on structures). Industry standards used to comply with safe blasting vibration criteria<br />

recommended by the US Bureau of Mines in 1980 (Siskind D. E., et al., 1980 Structure<br />

Response and Damage Produced by Ground Vibrations from Surface Mine blasting, RI 8507, US<br />

Bureau of Mines) specify all geophone measurements shall be in the ground adjacent to<br />

structures. If this is not possible, geophone attachment to structure foundations may be used. To<br />

be consistent with industry practices, baseline monitoring should be performed in the ground<br />

next to structures.<br />

Recommend wording in Section 3.21 Monitoring, C. 1. B. be changed to specify that baseline<br />

vibration measurements be made in the ground adjacent to structures within 1500 feet.<br />

Response: Refer to revised specification 32 23 05 – Blasting.<br />

5

Question: Table 31 23 05-1, page 32 23 05-28 standard for allowable peak particle velocity<br />

(PPV)<br />

Vibration limits for structures by structure type include 2.0 in/s for interior drywall and 4.0 in/s<br />

for interior plaster on lath walls of older homes. We believe the 4.0 in/s limit for aged structures<br />

with interior plaster that is more fragile than drywall is in error. This limit should be lower than<br />

that specified for structured with modern drywall. US Bureau of Mines, RI 8507 provides<br />

recommendations and guidelines for safe blasting next to structure with these types of interior<br />

wall surfaces. These standards are widely used in the US blasting industry for vibration and air<br />

over pressure monitoring.<br />

Recommend the values in Table 31 23 05-1 be changed to values that are consistent with current<br />

industry criteria for the protection of structure interior wall surfaces.<br />

Response: Refer to revised Specification.<br />

Question: Section 3.21 Monitoring, b. 1. A. on page 31 23 05-25; “Provide up to… with<br />

specifications that show event sampling rates of 15,000 samples per second or higher, available<br />

from PMT … or VCE …”<br />

A sampling rate of 15,000 samples per second for blast vibration measurements is far in excess<br />

of industry standards for velocity sensors used with blasting-type seismographs. This sample<br />

rate is more appropriate for accelerometers used in extremely high-frequency environments.<br />

The International Society of Explosives Engineers (ISEE, http://www.isee.org) sponsors the<br />

Blast Vibration and Seismograph Section through which members set performance standards for<br />

seismograph use<br />

(http://www.isee.org/index.phpoption=com_content&view=article&id=224:vibrationsection&catid=51:sections&Itemid=158).<br />

The Field Practice Guidelines for Blasting Seismographs, 2009 Edition, is available from the<br />

above site and attached herein for your review. The guidelines set forth operating and use<br />

specifications recommended by world-wide industry leaders and researchers. On page 2,<br />

recommendations for sample rate states it should be set “at least 1000 samples per second”.<br />

Blasting seismographs manufactured by White Seismology and Instantel (two of the most widely<br />

used blasting seismographs around the world) do not currently offer sample rates greater than<br />

2048 and 4096, respectively, for normal blasting with velocity geophones. This is because higher<br />

rates are not needed for ground vibration frequencies from blasting that range between 4 Hz (for<br />

softer rocks) to 350 Hz (for close-in monitoring in harder rock). Based on our experience<br />

blasting in the Gallup area, we anticipate ground motion frequencies to range from 10 to 30 Hz<br />

depending on measurement distance from the blast site. Thus, sample rates above 2048 for<br />

blasting applications are not required based on the Nyquist sampling criterion.<br />

6

PMT (http://www.pmtvib.com) builds measurement systems for elevator and escalator vibration<br />

analysis (EVA-625 model). The company website does not provide evidence that blasting-type<br />

seismographs complying with ISEE standards are available or manufactured by PMT.<br />

VCE (http://www.vceinc.com) is a consulting firm that specializes in seismic monitoring,<br />

forensics investigations, and video productions. They are fine company with excellent engineers.<br />

To my knowledge, they do not manufacture blasting-type seismograms.<br />

Recommend the reference to specific companies in this section be replaced by wording that<br />

requires blasting-type seismographs to be used for the project and their use complies with the<br />

ISEE Field Practice Guidelines for Blasting Seismographs, 2009 Edition, as well as the<br />

Performance Specification for Blasting Seismographs (attached).<br />

Response: Section 31 23 05 – Blasting doesn’t specify how many samples per second must be<br />

obtained, only that the equipment must be capable of taking 15,000 samples or higher.<br />

The Government has used instruments capable of taking 15,000 samples on other projects.<br />

Specific manufacturers’ have been removed.<br />

Question: Is there a need to establish permission to place seismographs on/at homes/structures<br />

Response: The contractor shall be responsible for obtaining written permission to enter/place<br />

equipment on property outside of the construction ROW shown on the drawings. Refer to<br />

revised Section 31 23 05- Blasting.<br />

<strong>Contractor</strong>: LifeLast.<br />

<strong>Contact</strong> <strong>Info</strong>: 1301 NE 144 th Street, Suite 125, Vancouver, WA 98685; Phone: (360) 254-0563.<br />

Question: Specification 09 96 20-16, Tabulation No. 01 (099CT_31.DOC): Archive 4-mil<br />

surface profile, minimum.<br />

There is not a need to require 4-mil minimum.<br />

Recommend amending to read, “Achieve 3-mil surface profile, minimum”<br />

Response: Reclamation requires a 4 mil surface profile.<br />

Question: Specification 09 96 20-16, Tabulation No. 01 (099CT_31.DOC): Material option:<br />

Areas 1-inch square or less, use of polyethylene melt stick is permitted.<br />

The Coating Repair Patch is commonly used in the field for small repairs on pipeline and<br />

delivers strong corrosion protection properties and is user friendly during application in a variety<br />

of installation environments.<br />

Recommend amending to read, “Areas 1-inch square or less, use of polyethylene melt stick or<br />

Coating Repair Patch (CRP) is permitted”.<br />

7

Response: Refer to revised Specification 09 96 20 – Coatings.<br />

Question: Specification 09 96 20-40, Category BE-5A: The approved products are Madison<br />

Chemical’s Corropipe II Omni and ITW Futura Coating’s Protec II.<br />

LifeLast, Inc. DuraShield 210 meets the composition and physical characteristics with the<br />

exception of the 1:1 ratio requirement. LifeLast DuraShield polyurethanes have been used very<br />

successfully on many miles of welded steel pipe ranging in diameter from 4” to 184” for over<br />

eight years. Included in our case histories is The Bureau of Reclamation’s Deer Flats Dams<br />

Project for raw water transmission through 7,900 lineal feet of 42” diameter welded steel pipe.<br />

This, combined with the fact that the physical properties of the LifeLast DuraShield 210 are well<br />

above both the AWWA C222 Standard and the specifications of this project, supports that the<br />

mix ratio of the material is not predictive of the success of a coating or lining in the welded steel<br />

pipe market. In addition, the epoxies used as linings and coatings in the welded steel pipe market<br />

for the past 15+ years have varying mix ratios – from 2:1 to 4:1 – further representing that mix<br />

ratio has little relevance to the successful performance of a coating or lining on steel pipe.<br />

Additionally, LifeLast’s DuraShield 210 and 310 have passed Metropolitan Water District of<br />

Southern California’s minimum requirements for immersion use.<br />

Recommend amending Category BE-5A to add LifeLast DuraSheild 210 as follows: DuraShield<br />

210; as manufactured by: LifeLast, Inc., 1301 NE 144th Street, Suite 125, Vancouver, WA<br />

98685, www.LifeLast.com Under Physical Characteristics, please remove the mix ratio<br />

requirement.<br />

Response: Refer to revised Section 09 96 20 – Coatings.<br />

<strong>Contractor</strong>: Ferguson Waterworks, Albuquerque<br />

<strong>Contact</strong> <strong>Info</strong>: 801 Candelaria NE, Albuquerque, NM 87107; Phone: (505) 449-4900<br />

Question: Request clarification of the Pipe Type that is preferred. The specification gives three<br />

choices, C900, C905, and Ductile Iron pipe. Which one is what is to be quoted on this project<br />

Response: Sections 33 11 10, 33 11 11, 33 11 12, and 33 11 13 discuss the requirements for the<br />

allowable pipe materials. Allowable pipe materials are Steel, PVC (at appropriate pressure<br />

range), and Ductile Iron Pipe (except on steep slopes). Bidders shall select the type of pipe to be<br />

used during the preparation of their bid. It is anticipated that the overall price for the installation<br />

of the pipe taking the cost of materials, excavation costs, embedment and backfill costs, etc will<br />

be a prime consideration in this decision. Other factors determined by the bidder may also be a<br />

consideration in the decision on the type of pipe to be used.<br />

8

<strong>Contractor</strong>: Northwest Pipe Company.<br />

<strong>Contact</strong> <strong>Info</strong>: 555 Broadway, Blvd NE, Suite 100, Albuquerque, NM 87102; Phone: (505) 462-<br />

3624.<br />

Question: Spec 33 11 11 – 1.04.A: To insure experience and quality of manufacture please make<br />

new requirement “B” that states, “Pipe Manufacturer / Fabricator:<br />

1. Experienced in fabricating pipe of similar diameters, lengths, and wall thickness required<br />

for the Work.<br />

2. Steel Pipe Fabricators Association (SPFA), Lloyd’s Registry Certification, or ISO 9000<br />

Certification.<br />

3. Demonstrate current production capability for volume of work required for this Project.<br />

4. Experience shall include successful fabrication to AWWA C200 standards of at least<br />

30,000 linear feet of 42-inch diameter or larger pipe, with wall thickness of 1/4 inches or<br />

greater, within past 5-year period within the United States of America.<br />

5. Experience shall be applicable to fabrication plant facilities and personnel, not company<br />

or corporation that currently owns fabrication facility or employs personnel.<br />

6. Steel pipe, fittings, specials, coating, and linings shall be the product of and applied by<br />

one manufacturer.<br />

Response: Refer to revised Section 33 11 11 – Steel Line Pipe.<br />

Question: Spec 33 11 11 – 2.01.C.1: Please add the following sentence to end of section, “Steel<br />

shall be ordered in accordance with tolerances in accordance with AWWA C200-05 section<br />

4.7.3.”<br />

Response: Section 2.01 A.2 indicates line pipe shall be fabricated in in accordance AWWA C<br />

200.<br />

Question: Spec 33 11 11 – 2.01.C [Table]: Please replace table with the following table:<br />

Pipe<br />

Symbol<br />

Minimum Steel<br />

Wall<br />

Thickness, (Inches)<br />

42B100 0.175<br />

42C125 0.175<br />

42C225 0.175<br />

42D225 0.175<br />

42B250 0.175<br />

42C250 0.175<br />

42C275 0.175<br />

42B300 0.175<br />

42C300 0.175<br />

42D300 0.175<br />

42E300 0.175<br />

42B325 0.175<br />

42C325 0.175<br />

9

42B350 0.175<br />

42C350 0.175<br />

42D350 0.178<br />

42B375 0.178<br />

42C375 0.178<br />

42B400 0.190<br />

42C400 0.190<br />

42D400 0.190<br />

42B425 0.202<br />

42B450 0.214<br />

42B475 0.226<br />

42C475 0.226<br />

42B500 0.237<br />

42C500 0.237<br />

These wall thicknesses are calculated in accordance with AWWA C200-05, page xii<br />

and AWWA Manual M11, Steel Water Pipe: A Guide for Design & Installation,<br />

Chapter 4, Eq 4-1 with a steel grade of 40,000 psi. Wall thicknesses are governed<br />

by internal pressure. Earth loadings are addressed by allowable deflections and soil<br />

types in other parts of the specifications and should not limit minimum wall<br />

thicknesses. Installation contractor is bound by performance standards to limit pipe<br />

deflection.<br />

Response: Refer to revised Specifications table 33 11 11A. – Minimum Steel Wall Thickness for<br />

Symbol Pipe. The table now uses standard pipe wall thicknesses listed in AWWA M-11.<br />

Question: Spec 33 11 11 – 2.01.D.2: Request revise sentence to state, “Weld lap weld<br />

joints inside or outside, or both as required for pressure restraint.”<br />

Response: When the contractor chooses to use welded joints instead of gasketed joints, the joint<br />

shall be double lap welded.<br />

Question: Spec 33 11 11 – 2.05.A.1: Recommend modifying the hydrotest value to state,<br />

“…which stresses steel to 0.75 times the specified minimum yield point of the steel used, in<br />

accordance with AWWA C200-05, Section 5.2.1.” Current stress requirement of 23,000 lb/in²<br />

equates to 57.5% of yield and not the 75% required by AWWA C200-05.<br />

Current specification requires (15) minute hydro test hold time. This requirement<br />

far exceeds what is required by AWWA C200. Current AWWA requirements, shown on page 24<br />

of AWWA C200-05 Standard, states, “5.2.1.1 Other requirements. The [shop] test pressure<br />

shall be held for sufficient time to observe the weld seams.” Standard practice to achieve this<br />

visual leak inspection is (30) seconds or less depending on operator experience and pipe<br />

diameter. In the case of 42-inch diameter pipe, 30-seconds is ample time for in-plant hydrostatic<br />

testing. Hold times in excess of (30) seconds will not add value to the pipe system, but will<br />

absolutely add additional costs to manufacture. As a comparison, the ductile iron pipe standard<br />

AWWA C151, requires hydro test pressure held for (5) seconds. PVC has even lower<br />

requirements for hydro testing.<br />

10

Response: Refer to revised 33 11 11-Pipeline General Requirements, section 2.05. The current<br />

version of the specifications refer to AWWA C200, instead of the 15 minute hold time.<br />

Question: Spec 33 11 11 – 2.05.A.1.a: Request revision of this statement to read, “Test sections<br />

prior to forming of lap weld bell and spigot joints and o-ring gasketed bells and spigots.” Testing<br />

of cylinders with shapes already formed could distort joint shape and dimensions. This is<br />

consistent with current industry practices.<br />

Response: Refer to revised 33 11 11- Pipeline General Requirements paragraph 2.05.<br />

Question: Spec 33 11 11 – 2.05.A.2: Recommend adding new section “e” that states, “In lieu of<br />

hydrostatic pressure test for fittings made from untested hydrostatic tested cylinders, do one of<br />

the following.”:<br />

1. Spot radiographically examine pipe in accordance with ASME BPVC Sec VIII, Div. 1,<br />

Par. UW 52. Ultrasonically examine welds that cannot readily be radiographed.<br />

a. Fillet Welds: 100 percent examine using magnetic particle inspection method in<br />

accordance with ASME BPVC S<strong>EC</strong> VIII, Division 1.<br />

b. Groove Welds: 100 percent ultrasonically examine those that cannot be readily<br />

radiographically spot examined in accordance with ASME BPVC S<strong>EC</strong> VIII,<br />

Division 1.<br />

c. Air test collars and wrappers in accordance with AWWA C206.<br />

Response: Reclamation requires the welds and steel plate to be tested with a hydrostatic pressure<br />

test.<br />

Question: 33 11 11 – 3.01.E.2: Request revise sentence to state, “Air test double lap welds in<br />

accordance with AWWA C206.”<br />

Response: Refer to revised specification 33 11 11 – Steel Line Pipe, paragraph 3.01.<br />

Question: 33 11 11 – 3.05.A.1: Request revise value to state, “3 percent of nominal pipe<br />

diameter.” This is consistent with AWWA Manual M11, Steel Water Pipe: A Guide for Design<br />

& Installation, Chapter 6, Pg. 61.<br />

Response: Reclamation requires 2% deflection criteria during installation and initial loading to<br />

ensure that the AWWA deflections are not exceeded over time.<br />

Question: Spec 09 96 20 – 3.10: Tabulation No. 01 – Option 3 Polyurethane: Request revised<br />

surface preparation profile to 3-mil minimum.<br />

Response: Reclamation requires a 4 mil surface profile.<br />

Question: Spec 09 96 20 – 3.10: Tabulation No. 02 : Request deletion of surface preparation<br />

method “C” and revise to state, “Surface preparation in accordance with AWWA C205-07,<br />

Section 4.3.” Cement mortar lined pipe should not be blasting prior to application.<br />

Response: Refer to revised Section 09 96 20 – Coatings.<br />

Question: Spec 09 96 20 – 3.11: Coating Category BE-5A: Request revised sentence to state,<br />

“mix ration as required by polyurethane manufacturer.”<br />

Response: Refer to revised Section 09 96 20 – Coatings.<br />

11

Question: Section B – Bid Schedule: Recommend combining bid items 18 through 43 into a<br />

single bid item. This will simplify the proposal for manufacturers and interested bidders.<br />

Response: The current bid schedule facilitates field changes in quantities of specific class of<br />

pipe.<br />

Question: Additional <strong>Info</strong>rmation: Are there any Buy American Act requirements on materials<br />

Response: Yes, please see amended solicitation clauses.<br />

12