Newpro Brochure - Liquidation - Maynards

Newpro Brochure - Liquidation - Maynards

Newpro Brochure - Liquidation - Maynards

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

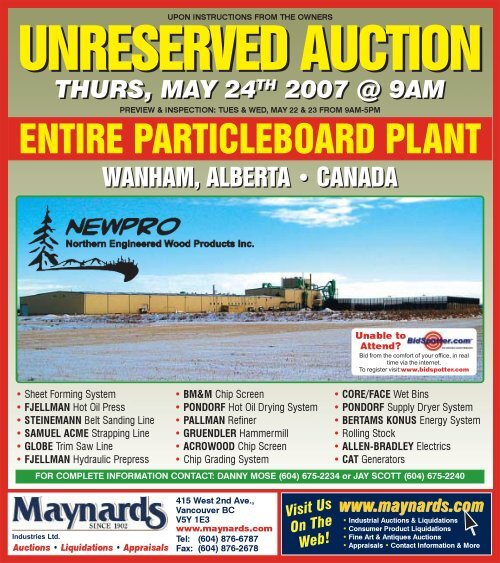

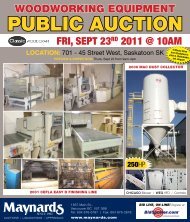

UPON INSTRUCTIONS FROM THE OWNERS<br />

UNRESERVED AUCTION<br />

THURS, MAY 24 TH 2007 @ 9AM<br />

PREVIEW & INSPECTION: TUES & WED, MAY 22 & 23 FROM 9AM-5PM<br />

ENTIRE PARTICLEBOARD PLANT<br />

WANHAM, ALBERTA • CANADA<br />

• Sheet Forming System<br />

• FJELLMAN Hot Oil Press<br />

• STEINEMANN Belt Sanding Line<br />

• SAMUEL ACME Strapping Line<br />

• GLOBE Trim Saw Line<br />

• FJELLMAN Hydraulic Prepress<br />

• BM&M Chip Screen<br />

• PONDORF Hot Oil Drying System<br />

• PALLMAN Refiner<br />

• GRUENDLER Hammermill<br />

• ACROWOOD Chip Screen<br />

• Chip Grading System<br />

Unable to<br />

Attend<br />

Bid from the comfort of your office, in real<br />

time via the internet.<br />

To register visit:www.bidspotter.com<br />

• CORE/FACE Wet Bins<br />

• PONDORF Supply Dryer System<br />

• BERTAMS KONUS Energy System<br />

• Rolling Stock<br />

• ALLEN-BRADLEY Electrics<br />

• CAT Generators<br />

FOR COMPLETE INFORMATION CONTACT: DANNY MOSE (604) 675-2234 or JAY SCOTT (604) 675-2240<br />

Industries Ltd.<br />

Auctions • <strong>Liquidation</strong>s • Appraisals<br />

415 West 2nd Ave.,<br />

Vancouver BC<br />

V5Y 1E3<br />

www.maynards.com<br />

Tel: (604) 876-6787<br />

Fax: (604) 876-2678<br />

Visit Us<br />

On The<br />

Web!<br />

www.maynards.com<br />

• Industrial Auctions & <strong>Liquidation</strong>s<br />

• Consumer Product <strong>Liquidation</strong>s<br />

• Fine Art & Antiques Auctions<br />

• Appraisals • Contact Information & More

5’x18’<br />

Hot Press Load Charger<br />

FJELLMAN 7-Opening Hot Oil Press<br />

INFEED BINS<br />

• (3) CHIT 12’ x 12’ Opening Infeed Sawdust Metering Bins, with (8) Auger Shaft Feeders<br />

each with (2) 20hp drives and Planet Gear Reducers, (1) 10’ x 40’ Cyclone and (1) 6’ x<br />

24’ Cyclone p/w Allied 40hp Blower and approx 400’ of Piping<br />

• CHIT 14’ x 20’ Opening Infeed Sawdust Metering Bin, with (2) 25hp drives with Planet<br />

Gear Reducers, Twin City Size 270 75hp blower with Type RTF-SW Tip Fan, Allied 7.5hp<br />

feeder, 8’ x 14’ Cyclone with 5hp Allied Blower, 12’ x 40’ Cyclone with 7.5hp Screw<br />

feeder, Roots type Blower, Allied Size 36N Blower and Allied Size 24 Blower<br />

HAMMERMILLS & BLOWERS<br />

• 1996 GRUNDLER Model 1040 s/n 500266 Fine<br />

Hammermill w/300hp Drive, with Allied Size 50 Blower<br />

• 1998 PALLMAN Model PSKM10.530 200 hp Refiner<br />

• (2) 2000 ALLIED Model RF60-60 hp Blowers<br />

• TWIN CITY Model RTF-SW Size 270-75 hp Blower<br />

• ALLIED Model RT300 125hp Air Density Blower<br />

System<br />

WITH<br />

EXHAUST<br />

Board Project Station Board Separator Caul Plate Return<br />

Bottom Surface Forming Bin<br />

Core Forming Bin

FJELLMAN Pre-Press<br />

Control Room<br />

SCREENS<br />

• BM&M Model 5044P11 8-Deck 5’ x 10’ fine chip screen,<br />

10hp drive, s/n 15393, 12,000 kg/hour Capacity, with<br />

55’ x 48” x 24” Bucket Elevator<br />

• ACROWOOD Model 824 s/n 59300 8’ x 24’ Diamond<br />

Roll Chip Screen w/15hp Drive and Dodge Reducer with<br />

ACROWOOD Model 6096 s/n 594-00 8’ x 24” Screw<br />

Feeder<br />

WET STORAGE BINS<br />

• (2) RAUTE WOOD 2000 cu/ft<br />

Metering Dosing Bins, w/10hp<br />

Drive, Dodge Gear Reducer, 30hp<br />

Levelling Screw, 30hp 12 Shaft<br />

Dolling Rollers, 12’ x 60’ Belt Type<br />

Walking Conveyor to Rollers and<br />

8’ x 24’ Cyclone<br />

DRYERS<br />

• 1998 PONDORF Model T212 2 Station Hot Oil<br />

Type Dryer, s/n 22400, w/Capacity of 12 Tons per<br />

hour/side, (2) 40hp Main Shaft Drive, Twin Top<br />

Loading Feeders and (2) Allied Size 50 Blowers<br />

• 2000 PONDORF Model ALD-01-001 Hot Oil Dryer,<br />

s/n 23200, w/14 Ton Capacity per hour, 65’ Flited<br />

Infeed Chain Conveyor w/Drive<br />

LITTLEFORD Blender LITTLEFORD Blender MILLTRONICS Accumass BW500<br />

Top Surface Forming Bin<br />

Core and Surface Dry Bins

(3) Metering Bins w/Blowers Sawdust Metering Bin w/Blower<br />

Dust Handling System Dust Storage Bins for KONUS MURPHY 150hp Bag House Resin Off-Loading System<br />

300<br />

HP<br />

GRUENDLER Hammermill<br />

ACROWOOD 824 Screen<br />

Mill Cyclones<br />

200<br />

HP<br />

ALLIED Blowers<br />

ALLIED Blowers<br />

PALLMAN Refiner

DUST FIRED KONUS SYSTEM<br />

KONUS HOT OIL ENERGY SYSTEM<br />

• BERTRAMS KONUS Model H19748000, 32 Million BTU Natural Gas/<br />

Dust fired 150 Bar Hot Oil Energy System w/Beth Electrostatic<br />

Precipitator, (2) Clyde Bergman PS-SL Soot Blowers, Krom Schroeder<br />

Primary Gas Burners, with Omega Controls<br />

• (2) ALLIED Model AAE-2520-N-M super Hot Natural Gas Fired Boilers<br />

• (2) ELTN Model XTV-60 90 Gallon Expansion Tanks<br />

• (4) OMER Systems EN125-400 Hot Oil Pumps with 100 hp Drives<br />

• ALLEN BRADLEY Centerline 2100 11 Section MCC w/40 Switches<br />

and (4) AB 1336 VFD Units to 75hp<br />

DRY STORAGE BINS<br />

• (2) RAUTE WOOD 2000 cu/ft Metering Dosing Bins, w/10hp Drive,<br />

Dodge Gear Reducer, 30 hp Levelling Screw, 30 hp 12 Shaft Dolling<br />

Rollers, 12’ x 60’ Belt Type Walking Conveyor to Rollers and 8’ x 24’<br />

Cyclone<br />

RESIN MIXING AND BLENDING<br />

• (4) 12’ x 40’ Steel 70,000 kg capacity Resin Storage Tanks<br />

• 12’ x 40’ Insulated 40,000 kg capacity Trial Tank w/Pumps<br />

• Complete Resin Metering and Dispensing System with Digital Flow<br />

Valves<br />

• (2) LITTLEFORD Model EK50 Core and Face Blenders w/75hp Drives,<br />

20F at 45 PSI, s/n 13527/13531<br />

• MILLTRONICS Accumass Model BW500 Weight Belt Calibrator<br />

SHEET FORMING LINE<br />

• DAPROMA SYSTEMS 60” Three phase continuous caul-plate forming<br />

line. Equipped with (3) Stronco auger type feeder conveyors, MSC<br />

Spectra ARAD continuous moisture analyzer, Toledo sheet scale system<br />

and rejecter<br />

• 1998 FJELLMAN 5’ x 18’ Hydraulic Prepress w/Adjustable 18’ Sheet<br />

Sizer, Infeed & Outfeed Belt Conveyors, Sheet Reject Station and<br />

Exhaust Blower<br />

• 1998 FJELLMAN Hot Oil Press w/7 Opening 5’ x 18’ Capacity Station,<br />

7 Sheet Cartridge Type Caul Plate Load and Unload System, p/w 2,000<br />

Gallon Twin 150 hp Hydraulic Power System w/(4) 75 hp Secondary<br />

Pumps, (4) Section Allen Bradley MCC and 3 Accumulator Towers<br />

• ULTRASONIC ARRAYS Model 5000 Blow Detector and Thickness<br />

Gage<br />

Fully Automated Caulplate Return System with Reject Sequencing<br />

• Complete Plant-Wide Control Room Equipped with ALLEN<br />

BRADLEY PLC-5 Integration System and WONDERWARE 7.1 Fully<br />

Graphical Interface Software, including ULTRASONIC ARRAYS<br />

Quality Control Monitors.<br />

COOLERS<br />

• GLOBE #135E0015 18” x 20” 70 Board Capacity Hydraulic Wicket<br />

Board Cooler w/15hp Hydraulic Unit<br />

• 6’ X 12’ 6 Arm Board Flipper w/Infeed and Outfeed Transfers<br />

FINISHING LINE AND SAW SYSTEMS<br />

• 1998 STEINEMAN Model 05US Nova 16OFS, s/n 304152, 6-Head 67”<br />

Wide Belt Sander w/Upgraded Allen Bradley Controls, 3 Line Chain<br />

18” Infeed Transfer Deck, 10 Sequenced Sheet Infeed System w/<br />

Optimized Return Line and (2) Burelback Model 206, s/n 582301-02<br />

Finishing Stacker<br />

• GLOBE MFG (2) 12” 30hp Trim Saw Edge Trimming System to Max 60”<br />

• GLOBE MFG 3 Saw 2 nd Pass 20hp Saw Sizing Table w/2 Multi Saws,<br />

Adjustable Center Saw, Roller Lugged Chain Feed Through s/n<br />

13H0019

Face and Core Wet Bins<br />

PANNDORF Core and Face Dryer<br />

PANNDORF Sawdust Dryer<br />

Resin Tank Farm<br />

KING Milling Machine Engine Lathe<br />

CAT IT28G Rubber Tire Loader w/Bucket<br />

GENIE Z60/34 Diesel Manlift<br />

CAT LPG Forklift<br />

SORTING LINE<br />

• 5 Bin Hydraulic Bin Sorting Line<br />

w/(5) Aerdon Hydraulic Scissor<br />

Lifts, Infeed, Chain H78 Outfeed &<br />

15hp Hydraulic Unit<br />

STRAPPING LINE<br />

• SAMUEL/ACME F7B5 Metal<br />

Strapping System w/Samuel<br />

Model G9G5 Strapping Head, Top<br />

and Bottom Squeeze, Cornering,<br />

turn Table Type Strapping Infeed,<br />

Infeed/Outfeed Rollcases with<br />

Bump Stops and ACME Bulk Strap<br />

Dispensing Unit<br />

ELECTRICAL<br />

• MAIN ROOM: 2000 CUTLER<br />

HAMMER 600 V Switch Gear Unit<br />

w/(2) 5000 amps 600 Volt Switch<br />

Gear Units<br />

• CUTLER HAMMER Series 2100<br />

3 section MCC w/11 Switches<br />

• CUTLER HAMMER AR03400ES<br />

400 Amp 347-600V 3PH Robotic<br />

Transfer Switch<br />

• CUTLER HAMMER Breaker<br />

Interface Module<br />

• CUTLER HAMMER 5000 Amp<br />

600V Switch Gear Unit<br />

• CUTLER HAMMER 5 Section<br />

MCC 19 Switches<br />

• ALLEN BRADLEY BUL2100 19<br />

Section 1200 amp Horizontal, 300<br />

amp Vertical MCC w/96 Switches<br />

• ALLEN BRADLEY BUL2100 19<br />

Section MCC w/51 Switches<br />

• ALLEN BRADLEY 13 Section<br />

MCC w/48 Switches, (2) Electrotier<br />

Model R7260-540K5910 F600V s/<br />

n 02-14418-1-523, Amp 30 PH 543<br />

24 KVAR at 600 V Rating Automatic<br />

Power Factor Corporation Unit<br />

• ALLEN BRADLEY 15 Section<br />

MCC w/46 Switches<br />

COMPRESSORS<br />

• SULLAIR LS205 125hp Rotary<br />

Screw Air Compressor<br />

• (2) ATLAS COPCO GA30FF 40hp<br />

90 CFM Air Compressors<br />

• DOMNICK HUNTER DTX0650,<br />

s/n 4584, Air Dryer w/Air Receiving<br />

Tank<br />

PLANT HVAC SYSTEM<br />

• 2000 ENGINEERED AIR HE751-<br />

0 40F Plant Air Make Up Unit<br />

• 2000 ENGINEERED AIR HE-221-<br />

0, 22000 CFM Capacity, Natural<br />

Gas Plant Air Make Up Unit<br />

• ENGINEERED AIR LM-8-67600<br />

CFM APG_3 575V 3 PH 7.5hp Air<br />

Make Up Unit<br />

• ENGINEERED AIR LM-4-C, s/n<br />

528350, 4734 CFM Air Make Up<br />

Unit<br />

• ENGINEERED AIR LM-6-C 6905<br />

CFM 7.5 hp Air Make Up Unit<br />

• ENGINEERED AIR HE751-0, 8<br />

Million BTU Direct Fired Furnace<br />

70000CFM, 75hp, 95% Efficient,<br />

575 Volt<br />

BACK-UP GENERATOR<br />

• CAT 3406-400 KVA 60 HZ 3 PH<br />

1800 RPM-600 Volt at 385 Amp<br />

Diesel Powered Generator w/159<br />

hours, 200 Gallon Double Wall<br />

Diesel Storage Tank, Auto Pulse<br />

Fire Protection System and 45’<br />

Steel Sea Can<br />

MAINTENANCE<br />

EQUIPMENT<br />

• 1998 KING Drill Press<br />

• CAROLINA CBP5500 Shop<br />

Press<br />

• LINCOLN V300Pro Welder<br />

• 2005 17”x67” Gap Bed Lathe<br />

• KING 942VS Vertical Milling<br />

Machine<br />

• Qty. of Hand Tools<br />

• Qty. of Spare Motors<br />

• HOMAG 6-Station Edge Bander<br />

• SELCO WTN200 Panel Saw<br />

• DELTA Unisaw<br />

• Lab Equipment<br />

• CAROLINA 712 Horiz. Bandsaw<br />

• Steel Rack w/Misc. Steel<br />

• EPPS 4300GH Pressure Washer<br />

• MILLER Dimension Welder<br />

• Bolt Bins & Contents<br />

BLOWERS & FEEDERS<br />

• TWIN CITY 75hp Blower<br />

• ALLIED 7.5hp Feeder<br />

• 8’ Dia. Cyclone w/5hp Blower<br />

• ALLIED Size 6N Blower<br />

• 12’ Cyclone w/Roots 7.5hp<br />

Blower<br />

• (2) CLYDE BERGMAN Soot<br />

Blowers<br />

• DIKA 4.5’ 20hp Board Breaker<br />

ROLLING STOCK<br />

• TRACKMOBILE 95TM, 10671 Hrs<br />

• CAT IT28G Rubber Tire Loader w/<br />

Bucket<br />

• CAT LPG Forklift<br />

• GENIE Z60/34 Diesel Manlift<br />

• 1999 CAT 938G Front End Loader

GLOBE 5’ 2-Saw Trim System Board Turner GLOBE Hydraulic Board Cooler<br />

6<br />

HEAD<br />

GLOBE 3-Saw Trim Station STEINEMANN Belt Sander ACME Strapping System<br />

ULTRASONIC Bond Measuring System 5 Stacker Line BURELBACH Twin Stackers<br />

ALLEN-BRADLEY MCC’s View of Electric Room View of Hydraulic Room<br />

DIKA Board Breaker<br />

SULLAIR 125hp Compressor CAT Backup Generator ATLAS-COPCO Air Compressors

AUCTION TIME:<br />

Thursday, May 24, 2007 at 9am<br />

PREVIEW & INSPECTION:<br />

Tuesday & Wednesday, May 22 & 23 from 9am-5pm<br />

SALE SITE:<br />

Wanham, Alberta, Canada<br />

DIRECTIONS:<br />

Located 89 km NE of Grande Prairie, on Hwy 49.<br />

Grande Prairie is located approximately 450 km NW<br />

from Edmonton.<br />

ACCOMMODATIONS (WANHAM):<br />

Widesky Inn, located on Hwy 49., 780-694-2484<br />

ACCOMMODATIONS (GRAND PRAIRIE):<br />

Best Western, 780-402-2378<br />

Holiday Inn, 780-402-6886<br />

Pomeroy Inn & Suites, 780-831-2999<br />

CONTACTS:<br />

Jay Scott 604-675-2240 / Dan Mose 604-675-2234<br />

BUYERS PREMIUMS:<br />

12% On-Site, 15% On-Line<br />

BETH Electrostatic Precipitator<br />

TERMS & CONDITIONS:<br />

PAYMENT: 25% NON-REFUNDABLE DEPOSIT ON AWARD OF BID, BALANCE WITHIN 48 HOURS. PAYMENT IS CASH, CASHIER’S CHEQUE,<br />

CERTIFIED CHEQUE, WIRE TRANSFER, COMPANY CHEQUE ONLY IF ACCOMPANIED BY A LETTER FROM YOUR BANK GUARANTEEING AMOUNT<br />

OF CHEQUE FOR DEPOSIT AND/OR PAYMENT IN FULL. NO PERSONAL CHEQUES. FULL PAYMENT MUST BE MADE BEFORE REMOVAL OF<br />

PURCHASE.<br />

REMOVAL: LAST DAY OF REMOVAL IS FRIDAY, JULY 27, 2007, AND AS FURTHER DEFINED IN THE SALE CATALOGUE. EVERYTHING IS SOLD<br />

“AS IS, WHERE IS.” ALL SALES FINAL. COST AND RESPONSIBILITY FOR REMOVAL OF PURCHASE REMAINS WITH THE PURCHASER. EVERY<br />

EFFORT WILL BE MADE TO FACILITATE REMOVAL. WHILE QUANTITIES AND DESCRIPTIONS ARE BELIEVED TO BE ACCURATE, THE AUCTIONEER,<br />

OWNERS OR COUNSEL MAKE NO WARRANTIES OR GUARANTEES EITHER EXPRESSED OR IMPLIED AS TO AUTHENTICITY, GENUINENESS OF,<br />

OR DEFECTS IN ANY LOT AND WILL NOT BE HELD RESPONSIBLE FOR ANY ADVERTISING DISCREPANCIES OR INACCURACIES. NO WARRANTIES<br />

WHATSOEVER ARE MADE AS TO CONDITION, MERCHANTIBILITY OR FITNESS FOR USE OF ANY ITEM. MAY WE SUGGEST YOU TAKE FULL<br />

ADVANTAGE OF THE PREVIEW AND INSPECTION PERIOD. SALE SUBJECT TO ADDITIONS AND DELETIONS<br />

Industries Ltd.<br />

Auctions • <strong>Liquidation</strong>s • Appraisals<br />

TRACKMOBILE 95TM<br />

415 West 2nd Ave.,<br />

Vancouver BC<br />

V5Y 1E3<br />

www.maynards.com<br />

Tel: (604) 876-6787<br />

Fax: (604) 876-2678<br />

CAE Two Deck Chip Screen<br />

Unable to Attend<br />

Bid from the comfort of your office, in real time<br />

via the internet.<br />

To register visit: www.bidspotter.com<br />

Idle Assets<br />

<strong>Maynards</strong> specializes in asset conversion of Industrial Equipment<br />

and Commercial Inventories<br />

We offer: Cash • Guarantees • Commission • Confidential Appraisals<br />

5 Offices To Serve You www.maynards.com