THURS, DEC. 3RD @ 10AM EST - Maynards Industries

THURS, DEC. 3RD @ 10AM EST - Maynards Industries

THURS, DEC. 3RD @ 10AM EST - Maynards Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

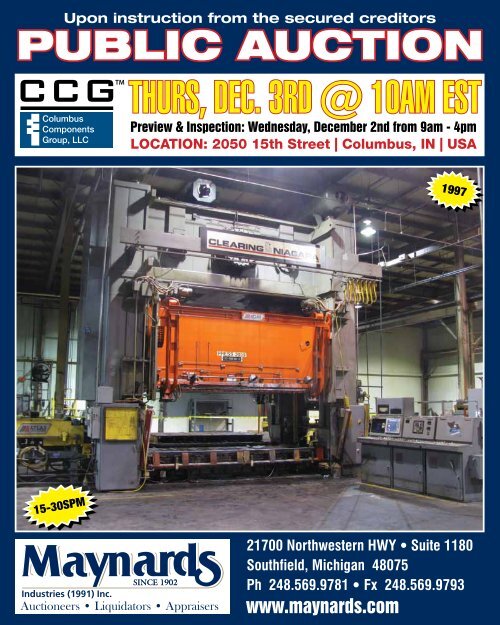

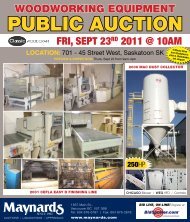

Upon instruction from the secured creditors<br />

PUBLIC AUCTION<br />

Columbus<br />

Components<br />

Group, LLC<br />

TM<br />

<strong>THURS</strong>, <strong>DEC</strong>. <strong>3RD</strong> @ <strong>10AM</strong> <strong>EST</strong><br />

Preview & Inspection: Wednesday, December 2nd from 9am - 4pm<br />

LOCATION: 2050 15th Street | Columbus, IN | USA<br />

1997<br />

15-30SPM<br />

21700 Northwestern HWY • Suite 1180<br />

Southfield, Michigan 48075<br />

Ph 248.569.9781 • Fx 248.569.9793<br />

<strong>Industries</strong> AUCTIONEERS (1991) • Inc. LIQUIDATORS • APPRAISERS<br />

VISIT WWW.MAYNARDS.COM FOR MORE INFORMATION<br />

Auctioneers • Liquidators • Appraisers<br />

www.maynards.com<br />

1

TRANSFER PRESS LINE • SERVO COIL FEED LINES<br />

1997<br />

COE Servo Feedline<br />

15-30SPM<br />

Clearing Niagara LE2-1000-180-72 Straight Side Press<br />

Perfecto Servo Feedline<br />

3 AVAILABLE<br />

20-45SPM<br />

Verson S4-600-144-84T Straight Side Press<br />

Niagara BP2-500-144-60 Straight Side Press<br />

TRANSFER PRESS LINE<br />

• 1997 CLEARING NIAGARA LE2-1000-180-72 Ton Straight Side Link Drive Two-Point Press, Stroke 24”, Strokes per Minute 15-30 Variable, Full Tonnage at .5” Above Bottom Stroke, Bed 72” x<br />

180”, Shut Height 54”, Motorized Adjustment 16”, T-slotted Bolster Plate, Windows 78” Wide, Wintriss Smart Pac, Bolster Clamp/Unclamp Control, Die Lift, S/N P-54393; Coe Servo Feed LIne:<br />

Reel Mdl CPR-PO-20042, S/N 15087-4, Capacity 20,000 Lb, Width 42”, ID 19.5” - 24.5”, Hydraulic Expansion, OD 72”, Coil Car; Coe Mdl CPPS-PO-350-42 Straightener, Capacity 42” x .140”<br />

Thickness, 7-Straightening Rolls, Entry & Exit Pinch Rolls - Pneumatic Lift, Debender, Powered Hold Down Arm, Peeler; Coe Mdl CPDTT-4214 Threading Table; Coe Model CPRF-542 Servo Feed,<br />

Cabinet Power Height Adjustment<br />

• ATLAS 120,000# Capacity Die Train, 92” x 418”, 30 FPM, S/N G316.13; 60,000# Die Train, 84” x 180”, 15-30 FPM, S/N G316.03;<br />

SERVO COIL FEED LINES<br />

• PERFECTO 20,000# x 42” W x .078” Servo Feed Line: Reel Model RS20-42, ID 19.5” - 24.5”, Hydraulic Expansion, OD 60”, Hydraulic Expansion, Adjustable Base, Travelling Coil Car, S/N R6-89156;<br />

Straightener Model #28-42-7, Hold Down Roll, Peeler, Entry & Exit Pinch Rolls, S/N S4-89157; Threading Table; Servo Feed Model 500-42, Power Height Adjustment, Roll Diameter 5”, S/N EE-89157<br />

• COE 20,000# x 30” Wide Servo Feed Line: Reel Model CPR-PO-20030, ID 19” - 24”, Hydraulic Expansion, OD 60”, Travelling Coil Car, S/N 12031-4; Straightener Width 30”, Hold Down Arm, Peeler,<br />

Entry & Exit Pinch Rolls - Pneumatic Lift; Threading Table Model CPTT-3015; Servo Feed, Cabinet Power Height Adjustment<br />

• PERFECTO/COE 20,000# x 36” Servo Feed Line: Perfecto Reel Model RS-20-36B, ID 19.5” - 24.5”, Hydraulic Expansion; OD 60”, Coil Car; Coe Straightener Model CPPS-PO-350-36, Entry<br />

2 AUCTIONS • LIQUIDATIONS • APPRAISALS

SERVO COIL FEED LINES • STRAIGHT SIDE PRESSES<br />

Minster & Niagara OBI Press<br />

Niagara E-200-S Gap Press<br />

9 AVAILABLE<br />

Magnum Hydraulic Press<br />

0-120SPM<br />

Niagara 150-250 Ton Straight Side Presses<br />

& Exit Pinch Rolls, Hold Down, Peeler, S/N 8762-1;<br />

Threading Table; Coe Servo Feed Model CPRF-536,<br />

Roll Diam. 5”, Indramat Feed Console, S/N 1094143<br />

• COE 6,000# x 24” Servo Feed Line; Double End Reel<br />

Model CPR-DE-PO-6024, Width 24”, OD 60”, Hold<br />

Down Arm, S/N 12620-3; Coe Straightener Model<br />

CPPS-PO-300-24, 7 Straightening Rolls, Entry & Exit<br />

Pinch Rolls, S/N 12620-2<br />

• COE CPRFSM-224 24” Servo Feed, 24” W, Roll<br />

Diameter 2”, Servo Master Control, S/N 228191<br />

• COE 20,000# Model CPR-PO-20030 Reel, Width<br />

30”, Hydraulic Expansion, OD 60”, Motorized Hold<br />

Down Arm, Peeler, S/N 8414-3; Coe Model CPPS-<br />

PO-350-30 Straightener, Width 30”, 7-Straightening<br />

Rolls - 3.5” Dia, Debender, Entry & Exit Pinch Rolls<br />

- Pneumatic Lift, S/N 8414-3; Coe CPTT-3018<br />

Threading Table<br />

• COE CPR-20060 20,000# Reel, Width 60”, ID 19”-<br />

25”, Hydraulic Expansion, OD 60”, Hold Down<br />

Arm, Pneumatic Brake, Travelling Coil Car Model<br />

CPTCC-20060, Rotating Coil Head, S/N 20701<br />

• PERFECTO 13,500# Double End Reel, Model RD10-<br />

24B, Width 24”, ID 19.5” - 24.5”, Power Expansion,<br />

OD 72”, S/N RD-76789; Perfecto Model 38-26-5<br />

Straightener, Capacity 26” x .188” - .250”, Hold Down,<br />

Peeler, Entry & Exit Pinch Rolls - Pneumatic Lift, S/N S5-<br />

76781<br />

• ROWE 7530-DSJ/DE 7,500# Motorized Double End Reel,<br />

Width 30”, ID 16” - 20”, OD 60”, S/N 26308<br />

• PERFECTO RD6-24B 6,000# Double End Reel, Width 24”,<br />

ID 17.5” - 22.5”, OD 60”, Hold Down Arms, Pneumatic<br />

Brake, S/N RC-94031<br />

• COE CPR-6018 6,000# Motorized Reel, Width 18”, ID 16”<br />

- 20”, OD 60”<br />

• (2) NORWALK CR5052 5,000 Lb Pallet Uncoilers,<br />

Diameter 52”, S/N 520621 & 522993<br />

• COE CPPS-PO-300-42 Straightener, Width 42”, 7-<br />

Straightening Rolls 3” Dia, Entry & Exit Pinch Rolls -<br />

Pneumatic Lift, Power Adjustment, S/N 18108-1<br />

• COE CPPS-PO225-12 Straightener, 12” W, S/N 2081-3,<br />

7-Straightening Rolls<br />

• ROWE C-30 Straightener, Capacity 30” x .020”-.105”, Entry &<br />

Exit Pinch Rolls, S/N 11703, 7-Straightening Rolls<br />

• ROWE Straightener, Width 18”, 7-Straightening Rolls,<br />

Entry & Exit Pinch Rolls<br />

• 300 Lb Littell Reel & 6” Rapid Air Mdl. FSC-6A Pneumatic<br />

Shear, S/N 85560<br />

Minster E2-200-60-54 Straight Side Press<br />

2 AVAILABLE<br />

VISIT WWW.MAYNARDS.COM FOR MORE INFORMATION<br />

3

STRAIGHT SIDE PRESSES • OPEN BACK INCLINABLE & GAP FRAME PRESSES<br />

1999<br />

8 AVAILABLE<br />

Acrotech Shear<br />

View of Eagle I/O Tube End Sizers<br />

STRAIGHT SIDE PRESSES<br />

• VERSON S4-600-144-84T 600 Ton Straight Side 4-Point Press, Stroke 14”, Strokes per Minute 16 & 24, Bed 60” x 144”, Shut<br />

Height 34”, Motorized Adjustment 12”, T-slotted Bolster Plate 9.5”, Windows 60” Wide, Light Curtains, GE AF-300ES Drive Control,<br />

Air Cushions, Light Curtains, S/N 21751; Coe 60” Servo Feed, Model CPRF-760, Width 60”, Roll Diameter 7”, S/N 12280-1A-B<br />

Panelview Control; Coe Threading Table<br />

• NIAGARA BP2-600-84-42 600 Ton Straight Side Double Crank Press, Stroke 12”, Strokes per Minute 20-60 Variable, Bed 42” x<br />

84”, Shut Height 36”, Motorized Adjustment 16”, T-slotted Bolster Plate 54” x 84” x 7”, Windows 31” Wide, Recirculating Lube,<br />

Shadow V Light Curtains, S/N 48215, Servo Feed 30” Wide<br />

Neff Hydraulic Press<br />

• (3) NIAGARA BP2-500-144-60 500 Ton Straight Side Double Crank Presses, Stroke 14”, Strokes per Minute 20-45, Bed 60” x 144”,<br />

Shut Height 36”, Motorized Adjustment 12”, Bolster Plate 6.5” & 5” Thick, Windows 39” Wide, Link LCD Terminal, Sytech Die Clamps, Pro Cam 1500<br />

PLS, Smart Pac, Light Curtains, S/N 50600, 50601 & 50602<br />

• BLISS S4-500-96-72 500 Ton Straight Side 4-Point Press, Stroke 18”, Strokes per Minute 20, Bed 72” x 96”, Shut Height 50”, Motorized Adjustment<br />

10”, T-slotted Bolster Plate 9”, Sytech Die Clamp System, Smart Pac, S/N C-132-03<br />

• NIAGARA PN-260-84-48 260 Ton Straight Side Double Crank Press, Stroke 6”, T-slotted Bolster Plate 3.5”<br />

• NIAGARA SC2-250-96-54 250 Ton Straight Side Double Crank Press, Stroke 16”, Strokes per Minute 18, Bed 54” x 96”, Shut Height 36”, Motorized<br />

Adjustment 11”, T-slotted Bolster Plate 4.75”, Windows 23” Wide, Smart Pac, S/N 45798; Coe Servo Feed, 24” W, ServoMax Control<br />

• FEDERAL S2-250-72-42 250 Ton Straight Side Double Crank Press, Stroke 6”, Strokes per Minute 60-120 Variable, Bed 42” x 72”, Die Height 14”,<br />

T-slotted Bolster Plate 48” x 72” x 6” thick, Windows 20” Wide, Smart Pac, S/N S2-224; Rowe Model PM-FAC-053-215 Servo Feed, Capacity 15”<br />

Wide x .135”, S/N 28874 Servo Feed, Capacity 15” Wide x .135”, S/N 28874<br />

• NIAGARA S2-250-72-42 250 Ton Straight Side Double Crank Press, Stroke 12”, T-slotted Bolster 48” x 72” x 5.75”, Riser in Uprights 10”, Smart<br />

Pac, Shadow V Light Curtains, Windows 19” Wide; Coe Model CPRF324 Servo Feed, 24” W, Roll Diameter 3”, S/N 10376-1<br />

• MINSTER E2-200-60-48 200 Ton Hevistamper Straight Side Double Crank Press, Stroke 6”, Strokes per Minute 0-120 Variable, Bed 48” x 60”, Shut<br />

Height 21”, Motorized Adjustment 6”, T-Slotted Bolster Plate 4” Thick, Windows 27” Wide, Recirculating Lube, Light Curtains, Smart Pac, S/N 20172;<br />

Coe Model CPRF-324 Servo Feed, 24” W, S/N 12620-1<br />

• MINSTER E2-200-60-54 200 Ton Hevistamper Straight Side Double Crank Press, T-slotted Bolster 3.5”, Windows 24”<br />

• (4) NIAGARA SC2-150-84-48 150 Ton Straight Side Double Crank Press, Stroke 10”, Strokes per Minute 28, Bed 48” x 84”, Shut Height 24.5”,<br />

Addison Mckee Tube End Sizer<br />

Motorized Adjustment 9”, T-slotted Bolster Plate 3.75”, S/N 43510, 43890, 45803 & 46136<br />

• (3) NIAGARA PN-150-84-48 150 Ton Straight Side Double Crank Presses, Stroke 6”, Strokes per Minute 33, Bed 48” x 84”, Shut Height 27”, Motorized Adjustment 5”, T-Slotted Bolster Plate 3.75”, Serial<br />

#40098, 40100 & 42199<br />

OPEN BACK INCLINABLE & GAP FRAME PRESSES<br />

• NIAGARA E-200-S 220 Ton OBS Gap Frame Press, Stroke 10”, Strokes per Minute 20-40 variable, Bed 34” x 58”, Slide 28” x 36”, Shut Height 31”, Motorized Adjustment 6”, Die Clamp System, Link<br />

SS-501 Control, S/N P-53768<br />

• WARCO G-200-I 200 Ton OBI Press, Stroke 12”, Strokes per Minute 36, Bed 34” x 52”, Shut Height 22”, Adjustment 5”, Bolster Plate 4” Thick, S/N 672892-10<br />

• WARCO 150 150 Ton OBI Press, Stroke 8”, Single Back Geared, Bed 33” x 50”, Shut Height 31”, Slide Adjustment 4.5”, Bolster Plate 3.75”, Link SS-501 Control, s/N 5275<br />

• NIAGARA E-110 110 Ton OBI Press, Stroke 6” Strokes per Minute 40, Bed 27” x 42”, Slide 21”x 28”, Shut Height 18.25”, Adjustment 5”, AC Vector Saftronics GP10 Drive Control, S/N 43508<br />

• VERSON 7.5 105 Ton OBI Press, Stroke 8”, Strokes per Minute 105, Bed 30” x 39”, Shut Height 18”, Adjustment 4”, T-Slotted Bolster, S/N 6894 & 6895<br />

• NIAGARA M-75 75 Ton OBI Press, Stroke 4”, Strokes per Minute 42, Bed 24” x 36”, Flanged Ram 18” x 24”, Shut Height 20.5”, Slide Adjustment 3.375”, Bolster Plate 3”, Link Control, S/N 42205<br />

• (2) NIAGARA ABE-75 75 Ton Adjustable Bed Gap Frame Presses, Stroke 8”, Strokes per Minute 65, Bed 24” x 36”, Shut Height 6” - 18”, Adjustment 4”, Link SS-501 Controls, S/N 52336 & 52333<br />

• FEDERAL F6 70 Ton OBI Press, Strokes per Minute 45, Bed 25.5” x 33”, Die Height 19.5”, Adjustment 3”, S/N 6-703<br />

• FEDERAL 60AB 60 Ton Adjustable Bed Gap Frame Press, Stroke 8”, Strokes per Minute 90, Bed 21” x 32”, Shut Height 13” - 24”, Adjustment 2.5”, S/N 60AB683<br />

•(3) FEDERAL 60 Ton Adj. Bed Gap Frame Presses, Stroke 6”, Strokes per Minute 90, Bed 21” x 32”, Die Space 7.5”-18.5” & 15”- 26”, Adjustment 2.5”, S/N 60AB690; 60-145, Wintriss WPC Control<br />

4 AUCTIONS • LIQUIDATIONS • APPRAISALS

TUBE END FORMING & SIZING • ROBOTIC WELDING CELL & ROBOTIC INSERTION CELL<br />

View of Milling Machines<br />

•(2) NIAGARA M-60 60 Ton OBI Presses, Stroke 4”, Strokes<br />

per Min. 45, Bed 21” x 32”, Shut Height 19.25”, Adjustment<br />

3”, Auto Lube, Rapid Air 6” Feeder, Wintriss Smart Pac/<br />

Console Control, S/N 42222<br />

• MINSTER 4 32 Ton OBI Press, Stroke 3”, Strokes per Min.<br />

175, Bed 16” x 24”, Shut Height 12”, Slide Adjustment 2.25”,<br />

Bolster Plate, Auto Lube, Honeywell WPC Control, S/N 22999<br />

HYDRAULIC & PNEUMATIC PRESSES<br />

• WILLIAMS & WHITE SH-1000-96-60 Straight Side<br />

Downacting Hydraulic Press, Bed 60” x 96”, Bolster Plate<br />

10”, A-B Control<br />

• WILLIAMS & WHITE SH-750-96-60 Straight Side Downacting<br />

Hydraulic Press, Bed 60” x 96”, Bolster Plate 7.5”, S/N C-4347<br />

• HFM-60B 60 Ton Gap Frame Hydraulic Press, Stroke 12”,<br />

Daylight 20”, Bed 25” x 28”, Light Curtains, S/N 96119<br />

• HANNIFIN 4C28P 28 Ton 4-Post Hydraulic Press, Stroke 6”,<br />

Daylight 20”, Between Posts 15” x 25”, 25 HP Motor & Pump,<br />

S/N 50941-1<br />

• DENISON 25 Ton Gap Frame Hydraulic Press, Bed 19 1/2” x<br />

30”, Daylight 19”, 25 HP Motor & Pump<br />

• 1999 NEFF 18.9 Ton Hydraulic Press, Stroke 10” Max, Bed<br />

20” x 23”, Platen 10” x 28.5”, Daylight Max 20”, ATC Shuttle<br />

Feed Cell, Allen Bradley Panelview 550, S/N 11106<br />

• HAEGER HP6-C-4 6 Ton Insertion Press, Feed Bowl & Batch<br />

Counter, Throat 17.5”, S/N 2512<br />

• BTM P-20-Bx4.5” / P-400 20 Ton Pneumatic Toggle Press,<br />

Stroke 4.5”, Throat 10”, Bed 12” x 14.5”<br />

TUBE END FORMING & SIZING<br />

• MCKEE FM-70 DIGI II Tube End Sizer, S.O. 79990, Capacity<br />

2.75” OD, A-B Panelview 550<br />

• MANCH<strong>EST</strong>ER M.82-H-3 Tube End Former, Programmable<br />

Three Position Rotary Tool Holder, Tube OD 3” Capacity, 20 HP<br />

Hydraulic Unit, S/N 1299-2040<br />

• ARISTO (2) Rebuilt Tube End Sizer, 2 5 HP & 30 HP Hydraulic<br />

Unit, S/N 9-98, 10-98, 1298A<br />

• (8) EAGLE I/O Tube End Sizers, Capacity 2.75” OD, 10 HP<br />

Hydraulic Unit, S/N 2778, 2616, 2228, 2003, 1611, 1469,<br />

731138B<br />

• EAGLE I/O Tube End Sizer, Capacity 2.75” OD, 10 HP Hydraulic<br />

Unit, Rebuilt by Aristo - S/N 0899<br />

• HAWTHORN Vertical Tube Sizer, 4-Post Hydraulic Press<br />

• EAGLE C Tube End Former, Capacity 2 3/4” OD, 10 HP<br />

Hydraulic Unit, S/N 2565<br />

DoAll Vertical Bandsaw<br />

Standard Modern Engine Lathe<br />

• EAGLE SVCS Tube Spinner, 40 HP Hydraulic Unit, Quartech<br />

Datamate 8330 Control, S/N 91-670<br />

• Tube Flarer, 3 HP Hydraulic Unit<br />

• Tube End Sizing Dies<br />

• CONTINENTAL MACHINE CO Rotary Tube Cutter, Feed Table<br />

• 1999 COLLINS (2) E-Z Cutter Tube Cutters, S/N 4217 & 4268<br />

• EAGLE LXS-FLO Muffler Shell Maker, S/N 92-685/686 & Lock<br />

Seamer; 15 HP & (2) 10 HP Hydraulic Units<br />

• CLIFTY ENGINEERING Baffle Ram Tube Stuffer<br />

Trinco Shot Blast Cabinet<br />

• ACROTECH 1824 Roll Bending Machine, Capacity 18 Gauge,<br />

Width 24”, Upper Roll Diameter 3.5”, Lower Roll Diameter 6”,<br />

1 HP, S/N 0701-110-210<br />

INSPECTION<br />

• 1998 ZEISS SCAN MAX Inspection System, Plate Range 14”<br />

x 14”, Probes, S/N 632001-9901<br />

• MTS SINTECH Q Test 1 Tensile Tester, S/N QT1/794/046<br />

• MTS SINTECH Q Test 6 Tensile Tester<br />

• TINIUS OLSEN 5000 Pull Tester, Single Phase, S/N154845<br />

• GAGE MASTER SERIES 80 Optical Comparator, Diameter<br />

20”, 2-Axis DRO, S/N 347288b<br />

Blanchard Rotary Surface Grinder<br />

• STARRETT Crystal Pink Granite Plate, 48” x 72” x 10” Thick<br />

• CHALLENGE MACHINERY CO Steel Layout Plate, 48” x 20” x<br />

6” Thick<br />

• LECO M-400-H1 Hardness Tester, Code No 810-118A, S/N<br />

170828<br />

• WILSON 4JSBB Hardness Tester, No 4JS 368<br />

• ROCKWELL 3JR Hardness Tester, No 10314<br />

ROBOTIC WELDING CELL & ROBOTIC<br />

INSERTION CELL<br />

Wysong 1210 Shear<br />

• RPT-ROBOTIC PRODUCTION TECHNOLOGY AUTO-WELD II (2)<br />

ABB Model IRB 1400 M98 Robots, S/N 14-10605 & 14-10606,<br />

A-B Panelview 550 Control, (2) Nozzle Reamers; Dual Sided<br />

Rotary Turntable-37” x 108”, (2) Miller Auto Invision Welders<br />

• 1999 HIRATA AR-M350-4-200 4-Axis Robot Arm, HNC-134A<br />

Controller, S/N 16217 w/Model ED15100 Feed Bowl<br />

WELDERS<br />

• PRECISION AVA-2 150 KVA Spot Welder, Throat 18.5”, View of Surface Grinders<br />

VISIT WWW.MAYNARDS.COM FOR MORE INFORMATION<br />

5

WELDERS • AUTOMATIC TUBE SEAM WELDING CELLS & ASSEMBLY CELLS<br />

Haeger Spot Welder<br />

View of Miller Welders<br />

ABB IRB1400 Robotic Welding Cell<br />

Robotron Series 3050 Control, Allen Bradley Panelview 550,<br />

S/N 860177-3<br />

• B<strong>EST</strong> 92-102 150 KVA Spot Welding Cell, Robotron Series<br />

115 Control<br />

• PRECISION Special 150 KVA Spot Welder, S/N 370171-5<br />

• McCREERY MPP-150-12 150 KVA Spot Welder, Throat 18.5”,<br />

S/N 21472<br />

• TELEDYNE SS-1 100 KVA Spot Welder, Throat 22”, Robotron<br />

Series 50 Control, S/N 88015-1<br />

• GENERAL WELDERS 100 KVA Spot Welder, Throat 26”,<br />

Robotron Series 3050 Control, S/N 1639-2<br />

• BANNER 1FG-85-A12 85 KVA Spot Welder, Throat 18”,<br />

Technitron T34145 Control, A-B Panelview 550, S/N<br />

7471<br />

• TREE CITY Press Type Welder, S/N T-2067-1<br />

• MILLER INVISION 456D DC Inverter Arc Welder<br />

• MILLER MAXTRON 450 Welder w/Series 60 Wire<br />

Feed<br />

• MILLER DELTAWELD 452, 451 & 450 (8) Welders, Series<br />

60/24 Volt Wire Feed & Super S-32 Wire Feeds<br />

• 2008 MILLER AXCESS 300 (2) Welders, ROI Control, Welding<br />

Fixture, A-B Panelview 300, S/N LH030016U & LH130107U<br />

• MILLER 330 ARC (4) Welders<br />

• MILLER SYNCROWAVE 250 Welder<br />

• MILLER DELTAWELD 450 Welder<br />

• THERMCO 8510CA2X1100 Argon & CO2 Mixer, S/N 24023<br />

AUTOMATIC TUBE SEAM WELDING CELLS<br />

• 2000 LORS Auto Seam Welder, Semtorq Weld Head, Job<br />

4010137-1, Allen Bradley Panelview 550 Control<br />

• SEMTORQ Welder, Robotron Series 3050 Control<br />

• Linear Tube Transfer, 40 HP Hydraulic Unit, Allen Bradley<br />

Panelview 600<br />

• SEMTORQ Bracket Welder, (2) Welding Guns, Technitron<br />

Series T3400 Control, Allen Bradley Panelview 550<br />

• SEMTORQ Frame Frame Welder, (2) Welding Guns, Allen<br />

Inspection Equipment<br />

Bradley Panelview 550<br />

• SEMTORQ Transfer Welder, Three Station Transfer & Weld<br />

Cell, Robotron Control<br />

• WELTRONIC TECHNITRON CORP (WTC) Welding Cell, (4)<br />

Guns, Robotron Series 400 Control, A-B Panelview 550<br />

• ACRO Welding Cell, A-B Panelview 550 Control, Bowl Feed,<br />

Roman Welder, WTC Series 400 Control, Schreiber Chiller<br />

• ACRO Welding Cell, (2) Guns, Medar Medweld 3000 S Control,<br />

Roman 24 Volt Model RGR 24/4-1099 Welders<br />

• ACRO Welding Cell, (4) Guns, Robotron Series 400 Control,<br />

A-B Panelview 550<br />

• GWI ENGINEERING Tube Cap Welding Cell, (2) Miyachi Model<br />

MM-12B Weld Checkers, Entron EN1000 Control<br />

• ROUCHE Welding Cell, (2) Miller XMT 304 CC/CV DC<br />

Inverter Arc Welders w/60M Wire Feed, Autolink Option, A-B<br />

Panelview 600<br />

AUTOMATIC TUBE ASSEMBLY CELLS<br />

• 36” Diameter Rotary Table,<br />

8-Station Table, Penta Drive DC Motor<br />

(3) Air-Hydraulic Presses,<br />

• 2003 GRIFFIN AUTOMATION 4650 Rotary Staking Cell,<br />

Performance Bowl Feeder, (3) Kraft Paket Presses, Allen<br />

Bradley Panelview 550<br />

TOOL ROOM<br />

• BLANCHARD Rotary Surface Grinder, Rotary Chuck 42”<br />

Diameter, Neutrifier, S/N 12582<br />

Zeiss ScanMax<br />

Inspection Machine<br />

1998<br />

• OKAMOTO ACC-124N Hydraulic Surface Grinder, Chuck 12”<br />

Miller Welders<br />

x 24”, Incremental Auto Down Feed, S/N 7218<br />

• CHEVALIER FSG-1224AD Automatic Surface Grinder, Chuck 12” x<br />

24”, No E1805006<br />

• CHEVALIER FSG-618M (2) Manual Surface Grinders, Chuck 6” x<br />

18”, 2 HP, No A3853009 & A3847037<br />

• BOYAR SCHULTZ H618 Hydraulic Surface Grinder, Chuck 6” x 18”,<br />

Challenger, S/N C-2696<br />

• POWERMATIC 3I Grinder, Belt 6” Disc 12” Diam. S/N 9731225<br />

• STANDARD MODERN 1960 Engine Lathe, Swing 19”, Centers 60”<br />

Hole through Spindle 3”, RPM 115-1600; Tail Stock, Cross Slide,<br />

10” 3-Jaw Chuck, S/N 8925<br />

• HARRISON M250 Engine Lathe, Swing 10”, Centers 30”, Hole<br />

through Spindle 1.375”, 3-Jaw Chuck, S/N 250347 324<br />

• SUPERMAX Engine Lathe, Swing 14”, Centers 40”, S/N LB1428<br />

• ENCO 111-1445 Engine Lathe, Swing 14”, Centers 45”, Tail Stock,<br />

Cross Slide, 3-Jaw Chuck<br />

• SCHAUER VA3BO Speed Lathe, S/N 40708M<br />

• SCHAUER TYPE LA2B Speed Lathe, S/N 41126M<br />

• BRIDGEPORT SERIES I (3) Vertical Mills, Table 9” x 42”, Acu-Rite<br />

2-Axis DRO, Power Feed Table, Quill Travel 5”, S/N BR242683,<br />

BR23073 & BR12 60082<br />

• CHEVALIER FM3FKH Vertical Mill, Table 10” x 50”, Quill Travel 5”,<br />

S/N HM872323<br />

• DOALL 16-3 Vertical Band Saw, Throat 16”, Table 24” x 30”,<br />

Welder, S/N 124-59249<br />

• DOALL ZS-3620 Vertical Band Saw, Throat 36”, Table 30” x 36”<br />

• POWERMATIC Vertical Band Saw, Throat 19”, S/N 22455<br />

• AMERICAN Radial Arm Drill, Column Diameter 9”, Travel 3’<br />

• DIACRO 2 Punch, Throat 12”, S/N 2648<br />

6 AUCTIONS • LIQUIDATIONS • APPRAISALS

TOOL ROOM • FABRICATING & FINISHING EQUIPMENT • CRANES • ROLLING STOCK<br />

• KO LEE BA960 Grinder, S/N 16034-EJ<br />

• KALAMAZOO 6” Belt Grinder, 3 HP;<br />

• KALAMAZOO Cut-Off Saw<br />

• Drill Presses: Fosdick, Johansson<br />

• BALDOR Belt Grinder, Width 2”, 1.5 HP<br />

• BALDOR Pedestal Grinder<br />

• BOYAR SCHULTZ NO 2 Profiler, S/N 6-1110-DS<br />

FABRICATING EQUIPMENT<br />

• WYSONG 1210 Power Squaring Shear, Capacity 10’ x<br />

12 Gauge, Front Stock Supports, 5 HP, Rear Operated<br />

Manual Back Gauge 24”<br />

• NIAGARA 160GD Power Squaring Shear, Capacity 54” x<br />

16 Gauge, Rear Operated Manual Back Gauge 18”<br />

• TENNSMITH T5215 Foot Shear, Capacity 52” x 16<br />

Gauge, S/N 17518<br />

• 1995 NATIONAL U6 7212 Finger Brake, Capacity 72” x<br />

12 Gauge, S/N 297-995<br />

FINISHING EQUIPMENT<br />

• ALMCO OR3 Vibratory Finisher, Capacity 2.5 Cubic Ft,<br />

S/N 08901-4<br />

• SWECO/ROTO FINISH FM-24LR Vibratory Finisher, Bowl<br />

Diameter 68”, 10 HP, S/N FM-1285-6<br />

• EMPIRE PF-3648 Blast Cabinet, Chamber 36”x48”,<br />

S/N 8595, Empire Dust Collector Mdl DCCM-80-A,<br />

S/N C-20873<br />

• TRINCO Blast Cabinet<br />

CRANES<br />

• P&H 15 Ton Bridge Crane, Span 45’, Double Girder,<br />

6-Way Pendant, Variable Speed, TM Equipment<br />

Bridge S/N 68626; P&H Hoist<br />

• ROBBINS & MYERS 15 Ton Bridge Crane, Span<br />

25’, Rail 50’ Length<br />

• ACECO 15 Ton Bridge Crane, Span 45’, Double<br />

Girder, 6-Way Pendant, DuoBox Hoist<br />

• DEARBORN 10 Ton Bridge Crane, 6-Way<br />

Pendant, Rail 275’ Length<br />

• HURRICANE 10 Ton Bridge Crane, Span 35’,<br />

Yale Hoist Underhung, Single Girder, 6-Way<br />

Pendant<br />

• WHITING 10 Ton Bridge Crane, Span 35’, Dual<br />

Girder, Top Rigind, 6-Way Pendant, S/N 11464<br />

• P&H 5 Ton Bridge Crane, Span 35’ Dual Girder,<br />

6-Way Pendant, S/N CH-26322 & Bridge S/N<br />

CH-26322B<br />

• ABELL HOWE 4 Ton Jib Crane, P&H Hevi Lift<br />

Hoist, 4-Way Pendant, S/N MC73B<br />

• CM CADY 15 Ton C-Hook, Width 72”<br />

• CALDWELL 10 Ton C-Hook, Width 30”, S/N 87809<br />

• ELT Inc SCC-20-48-30-24 10 Ton C-Hook, Throat<br />

48”, S/N ELT2051-SCC<br />

• YALE 2 Ton Hoist; CM 3 Ton, 2 Ton & 1 Ton<br />

Electric & Manual Hoists<br />

• Crane Scale; Lifting Tongs<br />

ROLLING STOCK<br />

• AUTO LIFT L5-300-30 30,000 Lb. Fork Lift, LPG, Side Shift, Max Lift 127”, Forks<br />

60”, S/N B-1324<br />

• CATERPILLAR M80 8,000lb ForkLift, Electric, Side<br />

Shift, Max Lift 156”, Forks 48”, S/N 73S00476<br />

• HYSTER 5,250 Lb. Fork Lift, Electric, Max Lift 118”, S/N B1G8VO47064<br />

• CATERPILLAR M40 (2) 4,000 Lb. Fork Lifts, Electric, Max Lift 156”, Forks 60” &<br />

48”, S/N 23N1904 & 23N1905<br />

• YALE K66C-040G367-071 4,000 Lb. Fork Lift, Electric, Max Lift 180”, S/N P-245970<br />

• PRIME MOVER RR34B 4,000 Lb. Stand-Up Lift,<br />

RR340224782<br />

View of Qty. of Collapsable Tubs<br />

Side Shift, Electric, S/N<br />

• YALE MRW030LC24TE088 3,000 Lb. Fork Lift, Electric, Side Shift, Max Lift 197”,<br />

S/N B821N01957V & B821N01859U<br />

• MULTITON 2,204 Lb. Lift, Electric<br />

• GMC Pickup Truck<br />

• JLG Manlift<br />

For more information, please visit us<br />

online at www.maynards.com<br />

Large Quantity of Dump Hoppers<br />

30,000# CAP<br />

Car Hoist<br />

Die Racks<br />

View of Scrap Conveyors<br />

Autolift Forktruck<br />

P&H 5 Ton Overhead Crane<br />

View of Forktrucks<br />

GMC Pickup Truck<br />

Atlast Copco Air Compressor<br />

Marathon Vert. Bailer View of Flammable Cabinets Abell-Howe Job Crane Whitting 10 Ton Crane JLG Manlift<br />

VISIT WWW.MAYNARDS.COM FOR MORE INFORMATION<br />

7

Upon instruction from secured creditors<br />

PUBLIC AUCTION<br />

TM<br />

<strong>Maynards</strong> <strong>Industries</strong><br />

250 H Street<br />

PMB 207<br />

Blaine WA 98230<br />

Columbus<br />

Components<br />

Group, LLC<br />

<strong>THURS</strong>, <strong>DEC</strong>. <strong>3RD</strong> @ <strong>10AM</strong> <strong>EST</strong><br />

2050 15th Street<br />

Columbus, INDIANA<br />

Preview & Inspection: Wed, Dec. 2nd from 9am - 4pm or by appointment.<br />

1997<br />

3 AVAILABLE<br />

COE Servo Feedline<br />

Online bidding<br />

available. For more<br />

information, visit<br />

www.maynards.com.<br />

14th Street<br />

Central Avenue<br />

2050 15th St.<br />

15th Street<br />

14th Street<br />

20-45SPM<br />

CLEARING NIAGARA LE2-1000-180-72<br />

Straight Side Press<br />

Niagara BP2-500-144-60<br />

Straight Side Press<br />

<strong>Industries</strong> (1991) Inc.<br />

AUCTIONEERS • LIQUIDATORS • APPRAISERS<br />

TERMS & CONDITIONS: Payment: 25% NON-REFUNDABLE deposit on award of bid, balance within 48 hours. payment<br />

is cash, cashier’s CHECK, certified CHECK, wire transfer, company chECK only if accompanied by a letter from your<br />

bank guaranteeing amount of CHECK for deposit and/or payment in full. no personal CHECKS. full payment must<br />

be made before removal of purchase.<br />

REMOVAL: LAST DAY OF REMOVAL IS FRIDAY, December 18, 2009. and as further defined in the sale catalogue.<br />

everything is sold “as is, where is.” all sales final. cost and responsibility for removal of purchase remains with<br />

the purchaser. every effort will be maDe to facilitate removal. while quantities and descriptions are believed to<br />

be accurate, the auctioneer, owners or counsel make no warranties or guarantees either expressed or implied<br />

as to authenticity, genuineness of, or defects in any lot and will not be held responsible for any advertising<br />

discrepancies or inaccuracies. no warranties whatsoever are made as to condition, merchantibility or fitness<br />

for use of any item. may we suggest you take full advantage of the preview and inspection period. sale subject<br />

to additions AND deletions and prior sales. Please check availability of equipment.<br />

21700 Northwestern HWY • Suite 1180<br />

Southfield, Michigan 48075<br />

Ph 248.569.9781 • Fx 248.569.9793<br />

8 AUCTIONS • LIQUIDATIONS • APPRAISALS<br />

www.maynards.com<br />

BUYERS PREMIUMS: 13.5% ON-SITE, 16.5% ON-LINE