View Brochure (PDF) - Maynards Industries

View Brochure (PDF) - Maynards Industries

View Brochure (PDF) - Maynards Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

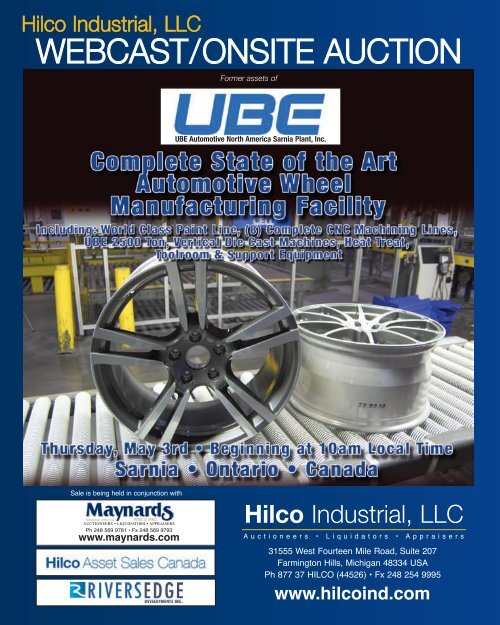

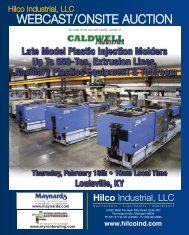

Hilco Industrial, LLC<br />

WebCast/OnsIte auCtIOn<br />

Former assets of<br />

UBE Automotive North America Sarnia Plant, Inc.<br />

Sale is being held in conjunction with<br />

Auctioneers • LiquidAtors • ApprAisers<br />

Ph 248 569 9781 • Fx 248 569 9793<br />

www.maynards.com<br />

Hilco Industrial, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

31555 West Fourteen Mile Road, Suite 207<br />

Farmington Hills, Michigan 48334 USA<br />

Ph 877 37 HILCO (44526) • Fx 248 254 9995<br />

www.hilcoind.com

HILCO WebCast/OnsIte auCtIOn<br />

Former assets of<br />

UBE Automotive North America Sarnia Plant, Inc.<br />

auCtIOn Date<br />

tHursDay, May 3 rD<br />

begInnIng at 10aM LOCaL tIMe<br />

PrevIeW Date<br />

WeDnesDay, May 2 nD<br />

9aM tO 4PM LOCaL & MOrnIng OF saLe<br />

For earlier inspection, please contact ken planet<br />

at 248.254.9999 x33 or email kplanet@hilcoind.com<br />

auCtIOn & PrevIeW LOCatIOn<br />

21 ube DrIve<br />

sarnIa • OntarIO • CanaDa<br />

sarnIa, OntarIO HOteLs:<br />

HOWarD JOHnsOn ..............519-541-9400<br />

QuaLIty Inn ..........................519-344-1157<br />

COMFOrt Inn........................519-383-6767<br />

DIreCtIOns<br />

traveL HWy 402 tO exIt #9 FOr aIrPOrt rD. traveL nOrtH On aIrPOrt rD FOr<br />

¼ MILe anD turn LeFt OntO ube Dr (beFOre sarnIa aIrPOrt).<br />

PLant Is aPPrOx 60 MILes FrOM LOnDOn, On; 80 MILes FrOM DetrOIt<br />

MetrOPOLItan aIrPOrt (DtW) anD 93 MILes FrOM WInDsOr InternatIOnaL<br />

aIrPOrt (yQg).<br />

PassPOrt Is reQuIreD FOr bOrDer CrOssIngs betWeen CanaDa anD unIteD<br />

states. PLease aLLOW aDDItIOnaL tIMe FOr DeLays at bOrDer CrOssIngs.<br />

FurtHer InFOrMatIOn<br />

• aLL On-sIte, HILCO WebCast anD bIDsPOtter bIDDers are reQuIreD tO<br />

subMIt vIa WIre transFer a QuaLIFyIng DePOsIt OF 25% OF tHeIr tOtaL<br />

exPeCteD PurCHases.<br />

• an 18% buyer's PreMIuM WILL be CHargeD FOr aLL bIDsPOtter saLes. a 15%<br />

buyer's PreMIuM WILL be CHargeD FOr aLL HILCO WebCast saLes anD<br />

On-sIte saLes. auCtIOn WILL be COnDuCteD In engLIsH, aCCePtIng<br />

CanaDIan CurrenCy OnLy.<br />

• REMOVAL DEADLINE IS MAy 25 WITH HOURS OF REMOVAL BETWEEN 8AM TO 4PM<br />

MONDAy THRU FRIDAy. BUyERS WITH ITEMS LEFT ON SITE AFTER DEADLINE ARE<br />

SUBjEcT TO FINES OF $500 PER DAy.<br />

• FOr FurtHer InFOrMatIOn On MaCHInery & eQuIPMent, PLease COntaCt<br />

Ken PLanet at 248.254.9999 x33 Or eMaIL KPLanet@HILCOInD.COM<br />

• FOr PayMents PLease COntaCt FranCa guIDa at 416.252.1955 Or eMaIL<br />

FguIDa@HILCOCanaDa.COM<br />

• FOr CustOMer servICe, PLease COntaCt sanDI neeLy at 248.254.9999 x16 Or<br />

eMaIL sneeLy@HILCOInD.COM<br />

Major Assets Available Immediately for Pre-Sale<br />

This Auction Will Be Conducted Onsite & Online at<br />

HILCAST TM<br />

www.hilcoind.com and<br />

(8) AUTOMATED ALUMINUM WHEEL MACHINING LINES<br />

LINES MAy BE OffErED IN BULk AND AS INDIvIDUAL MACHINES<br />

8 – FKI LOGISTEX AUTOMATION DEPILER SYSTEMS including: Reforme Arm, Basket Lift, Turning<br />

Unit, Pusher; Gantry Delivery System w/Three Gantry Servo Controlled Arms, Pick & Place Holders<br />

– GREAT Mfg Controllers, Gantry Rail Length Approx. 105'<br />

8 – OKUMA LAW-FL 2-AXIS CNC WHEEL LATHES, S/Ns 0325, 0328, 0329, 0330, 0331, 0332, 0333,<br />

0337 (All 2001), Okuma OSP-U10L Control, Max. Turning Diameter 24.41", Max. Turning Length<br />

11.02"; 12 Position Turret, Spindle Motor 60 HP Cont, Kitagawa Wheel Chuck<br />

8 – EDGE MASTER EM-ML-102 MOTORIZED WHEEL DEBURRING SYSTEMS, S/Ns ASU 26841<br />

through ASU 26848<br />

8 – WASH OFF TANKS<br />

2<br />

to schedule an auction, please call Hilco Industrial, LLC at 1-877-37-HILCO (44526)

(8) autOMateD aLuMInuM WHeeL MaCHInIng LInes • WHeeL MaCHInIng CnC’s<br />

Please contact Ken Planet at 248 238 7988 to discuss the<br />

opportunity to lease the building and operate the Torrid<br />

Paint/Wash Line and/or the Wheel Machining Lines in place.<br />

(8) AUTOMATED ALUMINUM WHEEL MACHINING LINES, CONT.<br />

LINES MAy BE OffErED IN BULk AND AS INDIvIDUAL MACHINES<br />

8 – SINTOKOGIO SNZ-1Y SHOT BLAST MACHINES, S/Ns 330282011 through 330282081,<br />

(All 2001), Workpiece Diameter 440 mm – 550 mm; Width 200 mm – 290 mm; Work<br />

Rotating Device 20-30 RPM; Two (2) x 20 HP Impellers, Auto Load & Unload, Work<br />

Detection, Pusher Slide, Rotation Roller, Mitsubishi Frequency Drives<br />

8 – OKUMA LAW-2S 4-AXIS CNC WHEEL LATHES, S/Ns 2446, 2449, 2451, 2453, 2455,<br />

2457, 2459, 2416 (All 2001), OSP-U100L Control, Max. Machining Diameter 24.8"; Swing<br />

Over Saddle 20.87"; Spindle Speeds 3,000 RPM Max; Spindle Motor 75 HP/60 HP (20<br />

Minute/Cont); 6 Position (Upper) & 4 Position (Lower) Turrets, Kitagawa Wheel Chuck<br />

8 – MICRO AIR OM6000 DUST COLLECTORS<br />

6 – KIWA KNH-400 4-AXIS CNC HORIZONTAL MACHINING CENTERS, S/Ns PB6146R,<br />

PB6147R, PB6155R, PB6156R, PB616212, PB6163R (All 2001), Fanuc Series 21i-M<br />

Control, Travels: X-23.62", Y-20.08", Z-19.68", Spindle Center To Table 1.97"-22.05"; Motor<br />

26 KW (35 HP)<br />

2 – KIWA KH-45 4-AXIS CNC HORIZONTAL MACHINING CENTERS, S/Ns JB469S (2003)<br />

& JB4697 (2008), Fanuc 21i-MB Control, 26 Position ATC, Dual Arm Tool Changer<br />

8 – OKUMA LAW-2S 4-AXIS CNC WHEEL LATHES, S/Ns 2447, 2450, 2452, 2454, 2456,<br />

2458, 2460, 2417 (All 2001), OSP-U100L Control, Max. Machining Diameter 24.8"; Swing<br />

Over Saddle 20.87"; Spindle Speeds 3,000 RPM Max; Spindle Motor 75 HP/60 HP (20<br />

Minute/Cont); 6 Position (Upper) & 4 Position (Lower) Turrets, Kitagawa Wheel Chuck<br />

8 – AUTOMATIC UNLOADER, CHAMFER SYSTEM & EXIT CONVEYORS<br />

2005<br />

2003<br />

2003<br />

INDIvIDUAL WHEEL MACHINING CNC MACHINES<br />

2 – OKUMA LAW-FL 2-AXIS CNC WHEEL LATHES, S/Ns 115116 & 116285<br />

(Both 2005), OSP-E100L Control, Max. Turning Diameter 24.41", Max.<br />

Turning Length 11.02"; 12 Position Turret, Spindle Motor 60 HP Cont,<br />

Kitagawa Wheel Chuck; Economoto 24" Chip Conveyor<br />

1 – EDGE MASTER EM-ML-102 MOTORIZED WHEEL DEBURRING<br />

SYSTEM, S/N ASU 32100-2 (2003)<br />

1 – OKUMA LAW-2S 4-AXIS CNC WHEEL LATHE, S/N 2382 (2001), OSP-<br />

U100L Control, Max. Machining Diameter 24.8" (Upper); Swing Over<br />

Saddle 20.87"; Spindle Speeds 3,000 RPM Max; Spindle Motor 75 HP/60<br />

HP (20 Minute/Cont); 6 Position (Upper) & 4 Position (Lower) Turrets<br />

1 – CHIRON WM08 4-AXIS HI-SPEED CNC VERTICAL MACHINING<br />

CENTER, S/N 164-56 (2003), Spindle Speeds 10,500 Max; Travels:<br />

X-29.5", Y-21.8", Z-25"; 12 Position ATC- Cat 40 Taper; GE Fanuc 18i-M<br />

Control; PEISELER Type AWUP 200 Rotary Trunnion Table, S/N 20982;<br />

RENISHAW Probing System<br />

1 – OKUMA LAW-FL 2-AXIS CNC WHEEL LATHE, S/N 0315 (2001), Okuma<br />

OSP-U10L Control, Max. Turning Diameter 24.41", Max. Turning Length<br />

11.02"; 12 Position Turret, Spindle Motor 60 HP Cont<br />

1 – OKUMA LNC-8 2-AXIS CADET CNC TURNING CENTER, S/N B303,<br />

OSP-5020L Control, Max. Turning Diameter 9.84", Max Turning Length<br />

19.68", Spindle Speeds 4,200 RPM; Programmable Tailstock, 12 Position<br />

Turret, Kitagawa Model B-08 3-Jaw Chuck<br />

For more information, please visit us on the web at www.hilcoind.com 3

autOMateD WHeeL WasH & PaInt LIne • PaInt aPPLICatIOn LIne<br />

AUTOMATED WHEEL WASH & PAINT LINES (2005)<br />

1 – POWDER LOAD CELL: Fanuc Model R-2000i-165F 6-Axis Servo Robot, F-49947<br />

(2001), Controller Model R-J3i, Teach Pendant; Conveyor Transfer System<br />

1 – LIQUID LOAD CELL: Fanuc Model R-2000iA-165F 6-Axis Servo Robot,<br />

F-71287 (2005), Model R-J3iB Controller, Conveyor Transfer System<br />

1 – TORRID 15-STAGE PRETREATMENT POWER SPRAY STAINLESS STEEL<br />

WASHER (2005), Job C370, Monorail Hanger Type, Approx Opening 30" W x<br />

64" H; Hanger holds 2 Wheels; Pre-Clean/Spray Alkaline Clean / Spray Rinse<br />

/ Halo / Caustic Etch / Spray Rinse / Deoxidizer / DI Water / Water Rinse / Halo<br />

/ Conversion Coating / Rinse / Halo; Total Length Approx 200'<br />

1 – TORRID 5-STAGE STAINLESS STEEL WASHER (2005), Job C370,<br />

Monorail Hanger Type, Monorial Hanger Type, Approx Opening 30" W x 64"<br />

H; Hanger holds 2 Wheels; Spray Alkaline / Rinse / Spray Rinse / Double<br />

Halo; Total Length Approx 60'<br />

1 – RO WATER SYSTEM, Culligan Brine Reclaim Kit, Product & Waste Flow<br />

Transmitters, Burkert Flow Read Out, Hours 8,766<br />

1 – DI HOLDING TANK / RO HOLDING TANK; Champion & Mettler Toledo<br />

200CR Control<br />

1 – TORRID TWO LANE ELEVATED DRY-OFF OVEN, Length Approx 100',<br />

20 HP Twin City Fan & Blower, 5 HP Twin City Fan & Blower<br />

Please contact Ken Planet at 248 238 7988 to discuss the<br />

opportunity to lease the building and operate the Torrid<br />

Paint/Wash Line and/or the Wheel Machining Lines in place.<br />

TOrrID LIQUID PAINT APPLICATION LINE<br />

CONSISTING Of:<br />

1 – FANUC R2000iA 165F 6-AXIS SERVO MATERIAL<br />

HANDLING ROBOT, F-68472 (2005), R-J3iB Controller,<br />

F-71288, Teach Pendant, Liquid Robot #3<br />

1 – FANUC M-6iB6s SERVO MASKING ROBOT, F-77774<br />

(2006), Mask Vision System Liquid Robot, Robot Controller,<br />

Teach Pendant<br />

1 – FANUC M-6iB6s SERVO DEMASKING ROBOT, F-78348<br />

(2006), R-J3iC Controller<br />

1 – MASK WASHER, S/N 048832, Wash Tank 160 Gallon,<br />

Rinse Tank 150 Gallon, Air Force 1 Blow Off System;<br />

Conveyor S/N NT 1473 9-06, Table 12", Work Height 12";<br />

Masking Return Conveyor<br />

1 – PAINT BAKE OVEN, S/N C370-080, Natural Gas, Burner<br />

Pressure 4-6" W.C., Max Heat Input 5,000,000 BTU/Hr; Max<br />

Operating Temp Zone 1 – 400° / Zone 2 – 350°;<br />

4 – LIQUID PAINT BOOTHS, ELECTROSTATIC COATING<br />

EQUIPMENT Model 9040 Cascade Low Voltage Modules; ITW<br />

Ransburg Color Select System, Each w/4 to 6 Gun Controls<br />

4<br />

to schedule an auction, please call Hilco Industrial, LLC at 1-877-37-HILCO (44526)

tOrrID CustOM buILt PaInt LInes • rObOts<br />

2005<br />

(1) TOrrID CUSTOM BUILT PAINT LINE<br />

CONSISTING Of:<br />

1 – FANUC R2000iA 6-AXIS SERVO ROBOT – POWDER LOADER,<br />

F-68472 (2004), RJ3iB Controller, Teach Pendant, Vision System<br />

1 – ITW GEMA TYPE ASO2 INDUSTRIAL POWDER PAINT BOOTH,<br />

S/N 14001.01255 (2005); Length 15', Opening 30" W x 48" H, Six (6)<br />

Optigun GA 20 Paint Guns & OptiTronic Controls; ITW Fluidization<br />

Control, S/N 5005636;<br />

1 – FANUC M-6iB SERVO MASKING ROBOT, F-80054 (2006), MASK<br />

VISION SYSTEM ACRYLIC ROBOT, R-J3iC Controller, Teach Pendant;<br />

Four (4) Camera Adaptor DC-700 Units; Enclosed Cabinet w/Air Lock;<br />

1 – FANUC M-6iB SERVO DEMASKING ROBOT, F-79087 (2006), R-J3iC<br />

Controller, Teach Pendant<br />

(1) TOrrID CUSTOM BUILT PAINT LINE<br />

CONSISTING Of:<br />

1 – ITW GEMA TYPE ASO2 INDUSTRIAL POLYESTER PAINT BOOTH,<br />

S/N 14001.01256 (2005); Length 15', Opening 30" W x 48" H; Nine (9)<br />

Optigun GA 20 Paint Guns & Opti Tronic Controls; ITW Fluidization<br />

Control, S/N 5005026;<br />

1 – FANUC M-6iB SERVO MASKING ROBOT, F-79334 (2006), MASK<br />

VISION SYSTEM POLYESTER ROBOT, R-J3iC Controller, Teach<br />

Pendant; Four (4) Camera Adaptor DC-700 Units ; Enclosed Cabinet<br />

w/Air Lock;<br />

1 – FANUC M-6iB SERVO DEMASKING ROBOT, F-78346 (2006), R-J3iC<br />

Controller<br />

MATErIAL HANDLING rOBOTS<br />

2 – FANUC R-2000iA 200F 6-AXIS SERVO ROBOT – SOUTH & NORTH<br />

ROBOT LOADING UNITS, F-71290 & F-71291 (2005); R-J3iB Controller,<br />

Teach Pendant; Canadian Takamatsu Control, S/N E0550, Conveyor<br />

4 – BINKS PAINT PUMPING STATIONS<br />

This Auction Will Be Conducted Onsite & Online at<br />

HILCAST TM<br />

www.hilcoind.com and<br />

2005<br />

For more information, please visit us on the web at www.hilcoind.com 5

ItW PaInt FInIsHIng systeM • WHeeL x-ray InsPeCtIOn & testIng<br />

ITW PAINT fINISHING SySTEM<br />

1 – ITW BGK ACRYLIC WHEEL INFRARED OVEN, Allen Bradley Panelview Plus<br />

600 Terminal, Opening 28" W x 15" H, Approx Length 40'<br />

1 – TORRID POWDER CURE OVEN, S/N C370-030 (2005), Natural Gas, Burner<br />

Press 4-6" W.C.; Max Heat Input 2,500,000 BTU/Hr; Max Operating Temp 475° F;<br />

Oven Exhaust 4,334 CFM; Max Powder Load 200 Lbs/Hour<br />

1 – TORRID DRY-OFF OVEN, S/N C370-081 (2005), Natural Gas, Burner Press 4-6"<br />

W.C.; Max Heat Input 2,500,000 BTU/Hr; Max Operating Temp 400° F; Oven<br />

Exhaust 5,358 CFM; Max Powder Load 200 Lbs/Hour<br />

CHAIN BRUSH CLEANING SYSTEM<br />

QUANTITY OF INVERTED CONVEYOR SYSTEM W/CARRIERS<br />

2005<br />

2005<br />

2006<br />

2005<br />

WHEEL X-rAy INSPECTION & TESTING SySTEMS<br />

1 – YXLON X-RAY INSPECTION MACHINE, S/N MU-231-A1, 2-Axis Wheel<br />

Manipulator (Y), 2-Axis C-Manipulator, Travels: X (Carriage) – 300 mm; Y (Length)<br />

– 650 mm, Rotation/Wheel 360 Degree, Z (Cross Axis) – 300 mm; Camera Head<br />

Part #TH9438QK, S/N 91105661 (2006)<br />

2 – VJ TECHNOLOGIES VJ-AWM-160 KV X-RAY INSPECTION MACHINES, S/N<br />

100402, Gulmay Model MP1/6 Controller, S/N 976-1002, Table Diameter 26.5"<br />

1 – KOKUSAI FARC 6142W WHEEL UNIFORMITY MEASURING MACHINE, S/N<br />

36C0950 (2005), Low Point Wheel Balancer, Reject Conveyor, Mark Module<br />

1 – KOKUSAI FDBR 6142W-H WHEEL BALANCE UNIFORMITY TEST SYSTEM,<br />

S/N 39C-1600, High Speed Automatic Wheel Balancer, Low Point Marker & Etcher,<br />

In-Feed Conveyor<br />

1 – GOAL MACHINE CORP RFT-V1 RADIAL FATIGUE TEST MACHINE, S/N 204,<br />

Load Capacity 7,500 Lbs; Wheel Size 12"-22" Dia; Speed Range 40-90 MPH; 40<br />

HP Drive<br />

1 – GOAL MACHINE CORP IMT-V3 IMPACT TEST MACHINE, S/N 202, Wheel<br />

Diameter Capacity 12"-22", Between Posts 40", Milwaukee 2 Ton Electric Hoist,<br />

Control Optical Velocity Sensor<br />

2 – GOAL MACHINE CORP ROTARY FATIGUE TEST MACHINES, 10 HP<br />

1 – HUNTER ENGINEERING CO TC3500 TIRE CHANGER, S/N 03568 (2001),<br />

Clamp System Rotating Speed 15 CW & CCW<br />

1 – ITW AKRON 100 FX-SPC WHEEL GAUGING MACHINE, S/N 5516, Control<br />

ML-100FX<br />

1 – SCHENCK ROTEC 700 WHEEL BALANCING MACHINE<br />

1 – DUAL DRAW 10 STATION DOWN DRAFT WHEEL FINISHING LINE, 10 x 2 HP<br />

Motor & Blower, Conveyor Line<br />

6<br />

to schedule an auction, please call Hilco Industrial, LLC at 1-877-37-HILCO (44526)

HIgH Pressure DIe Cast MaCHInes • Heat treat eQuIPMent<br />

HIGH PrESSUrE DIE CAST MACHINES<br />

2 – UBE RVSC2500 2500 TON HIGH PRESSURE ALUMINUM DIE CAST<br />

MACHINES, S/Ns 73300 & 73299; 3-Stage Rotating Table, Shuttle System;<br />

Cutler Hammer Freedom Series 2100 Motor Control Center (2001)<br />

4 – 4-POST HYDRAULIC TRIM PRESSES, Between Posts 28” x 40”, Stroke 38”<br />

Approx.<br />

HEAT TrEAT EQUIPMENT<br />

2 – CONSOLIDATED ENGINEERING CO RH6-T6 HEAT TREAT OVENS &<br />

AGING OVENS, S/Ns 2750 & 2751 (Both 2001); Furnace Length Approx<br />

104’; Age Oven Length Approx 95’ Cool Unit Length Approx 13’; Furnace<br />

Interior 91.5” W; Job 02-2750, T6 Solution Heat Treat System – Workload<br />

3,500 Lbs. Max Fully Loaded, Natural Gas Heat Capacity 950 Btu/SCF;<br />

Operating Temperature 530° C (986° F); Age Oven Operating Temperature<br />

160° C (320° F); Water Quench System – Capacity 7800 Gallons, Operating<br />

Temperature 70° C (158° F); Allen Bradley Panelview 1000 Terminal,<br />

Honeywell Recorder<br />

2 – MURATA R-200 ALUMINUM WHEEL TRANSPORT SYSTEM LOADING<br />

SYSTEMS<br />

15 – MURATA AGV CARS, Conveyor Size 54" x 84"<br />

2 – MURATA STORAGE & RETRIEVAL SYSTEMS (Both 2001), Crane Type<br />

UH09, Rated Load 1635 Kg, Hoisting Load 3550 Kg, Storage Rack – O/A<br />

Height 8.39 M, Lift Height 5.32 M; Storage Compartment – 1224 mm W x<br />

2095 mm D x 2203 mm H; Each System 1 Row x 16 Bays x 3 Levels<br />

APPROX 250 – HEAT TREAT FURNACE TRAYS – Spec Dimensions 82.5" W<br />

x 49" L x 86.75" H<br />

QUANTITY OF MURATA<br />

CHARGERS, S/Ns 007087-1Q, 007088-1Q, 018008-2Q, 007089-2Q<br />

MISC SPARE PARTS – Rollers, Exhaust Fans, Smog Hogs<br />

– YUASA MFG RAPID CHARGERS & FINE<br />

For more information, please visit us on the web at www.hilcoind.com 7

aLuMInuM MeLtIng FurnaCes • aIr HanDLIng eQuIPMent<br />

ALUMINUM MELTING fUrNACES<br />

1 – SCHAEFER 36 TON ALUMINUM MELTING FURNACE, S/N 008-2000-0152,<br />

Natural Gas, Max Input 20 Mbtuh, Opening 12' W x 84' H, SDW Hearth Door,<br />

Charge Well, Opening Height 4' 6", Furnace Length 25' Approx<br />

1 – GASMAC 27 TON ALUMINUM MELTING FURNACE, S/N JW040676 (2004),<br />

Natural Gas, Max Temperature 1400° F, Max Input 18,000,000 BTUH;<br />

Honeywell Hold Bath & Well Controllers, Opening 46" x 132"<br />

1 – SCHAEFER 10,000 LB CAPACITY ALUMINUM HOLDING FURNACE, S/N<br />

20000159 (2001)<br />

2 – SCHAEFER 3,400 LB CAPACITY ALUMINUM HOLDING FURNACES, S/Ns<br />

08-2000-0156 & 08-2000-0157<br />

1 – SCHAEFER HEATED LAUNDER DELIVERY SYSTEM & SHAKERS<br />

1 – PREMELT SYSTEMS METAL SCRAP CLEANING SYSTEM, Screw Conveyor,<br />

Magnetic Separator, Hot Screw Conveyor; DEVANSCO JET V-13 CHIP<br />

WASHER, S/N 240DVC30, 100 HP, Northern Blower<br />

1 – CATALYTIC PRODUCTS QUADRANT IR-8000 THERMAL OXIDIZER; Natural<br />

Gas Max Input 7,500,000 BTUH; Gas Inlet Pressure 20 PSI, Burner Manifold<br />

Pressure – Max 30" WIC / Min 15" WIC, Min Purge Time 2 Minutes; Honeywell<br />

Fluid Power Gas Valves & Pressure Switches; Approx Dimensions 33' x 84" Dia;<br />

30 HP Twin City Blower<br />

2004<br />

AIr COMPrESSOrS / DryErS / BOILErS / AIr SCrUBBErS<br />

3 – KOBELCO KNW2 350 HP WATER COOLED RECIPROCATING AIR COMPRESSORS, S/Ns<br />

00G0560, 00G0561 & 00G0562, Kobelco KNW Series Programmable Control<br />

1 – INGERSOLL RAND C35024M3 CENTAC 500 HP AIR COMPRESSOR, S/N C12332<br />

1 – KOBELCO DS-6AB COMPRESSOR SEQUENCE CONTROL, S/N 6107030<br />

2 – PNEUMATECH ADW-3200 NON-CYCLING REFRIGERATED AIR DRYERS, S/N ICP-0480,<br />

Capacity 3200 SCFM, Operating Pressure 100 PSIG, Max Pressure 150 PSIG, Compressor<br />

15 HP<br />

2 – AIR RECEIVER TANKS<br />

2 – MIURA LX-100 STEAM BOILERS, S/Ns 46S411238 & 46S411239 (Both 2001), Natural Gas,<br />

Max Allowable Pressure 170 PSI, Heating Surface Area 248 Sq Ft, Design Temp 400° F, Rated<br />

Steam Capacity 3,520 Lb/Hour; Intelligent Steam Manager Display; MIURA MP100<br />

TERMINAL PRESSURE CONTROLLER<br />

1 – DEVANSCO JET V-18 WET AIR SCRUBBER, S/N 221DVC10 (2006), Capacity 10,000 CFM;<br />

Discharge Conveyor Width Approx 40"; Sludge Conveyor #220DVC10<br />

8<br />

to schedule an auction, please call Hilco Industrial, LLC at 1-877-37-HILCO (44526)

InsPeCtIOn eQuIPMent • tOOL rOOM eQuIPMent<br />

INSPECTION EQUIPMENT<br />

2 – MITUTOYO BRIGHT-A1212 BRIDGE TYPE COORDINATE<br />

MEASURING MACHINES, S/Ns M027106 & 1024811, #4010M-<br />

3112, Measuring Range: X-47.44, Y-47.44", Z-39.57"; Granite Plate<br />

55.12" x 85.83", UC220 Apex Controller V2.41 & V2.32; Joystick<br />

Control; Renishaw Model PH10M Motorized Index Head; Renishaw<br />

SCR200 6-Position Probe Holder; PHC10-2 Probe Head Controller<br />

1 – LLOYD LR30K PLUS MATERIAL TESTING MACHINE, S/N<br />

106000, Capacity 30 Kn, Max Crosshead Travel 34.3", Model Level<br />

2 DRO<br />

1 – STARRETT SIGMA HE400 BENCH TOP OPTICAL COMPARATOR,<br />

S/N 24-94, Capacity 400 mm (15.75"); QC-2200-HH DRO, S/N<br />

24076; Heidenhain Scale<br />

2 – NEW AGE 7000 HARDNESS TESTERS, S/Ns 110 & 118<br />

1 – MAGNA FLUX INSPECTION BOOTH w/ZB100 Light; Powder<br />

Application & Dryer<br />

1 – SPECTROLAB TYPE LAVFA05B SPARK ANALYZER, S/N 4L0171<br />

QUANTITY OF MITUTOYO DIGIMATIC MICROMETERS TO 475 mm;<br />

ABSOLUTE DIGIMATIC VERNIER CALIPERS; ABSOLUTE<br />

ID MICROMETERS<br />

QUANTITY OF MITUTOYO GRADE A GRANITE SURFACE PLATES,<br />

Size 24" x 36" x 5", Code 517-808<br />

TOOL rOOM EQUIPMENT<br />

1 – JHS CYTURN CY-S2060G ENGINE LATHE, S/N<br />

201, Swing 20" x Centers 60", Hole Through<br />

Spindle 2 1/4", Spindle Speeds 20-2000 RPM; 3-<br />

Jaw Chuck 9.75" Dia; Tailstock, Cross Slide,<br />

Steady Rest<br />

1 – ACRA TURN 1640G ENGINE LATHE, S/N N/A,<br />

Swing 16" x Centers 40", Hole Through Spindle 2<br />

1/4", Spindle Speeds 70-1800 RPM; 3-Jaw Chuck<br />

7.875" Dia; Tailstock, Cross Slide, Inch/Metric<br />

1 – KBC GRIP-1340G ENGINE LATHE, S/N 441883<br />

(2004), Swing 13" x Centers 40", Hole Through<br />

Spindle 1.5", Spindle Speeds 70-2000 RPM;<br />

3-Jaw Chuck 6 1/4" Dia; Tailstock, Cross Slide<br />

1 – MAXIMART 4VS-S VERTICAL MILL, S/N<br />

982001 (1998), 5 HP, Power Feed Table 10" x 54",<br />

Spindle Speeds 60-3400 RPM<br />

1 – LILIAN VERTICAL MILL, S/N 30519 (2001),<br />

3 HP, Table 10" x 50", Spindle Speeds 60-4200<br />

RPM<br />

1 – DO ALL 2013-V 20" VERTICAL BAND SAW, S/N<br />

500-012662, Tilt Table 26" x 26", Welder/Grinder<br />

Model DBW-15<br />

1 – ROYAL DCM-5 20" VERTICAL BAND SAW, S/N<br />

N/A, Tilt Table 20" x 23.5", Blade Welder & Grinder<br />

1 – GROB 4V-18 18" VERTICAL BAND SAW, S/N<br />

5723 (1998), Tilt Table 28" x 24"<br />

For more information, please visit us on the web at www.hilcoind.com 9

Lab eQuIPMent • rObOts • brIDge Cranes • rOLLIng stOCK<br />

LAB EQUIPMENT<br />

1 – FISHER SCIENTIFIC ISOTEMP 228 WATER BATH<br />

1 – GRIEVE HT-1000 3,000 WATT ELECTRIC OVEN<br />

1 – Q PANEL OGR COATING CHIPPING RESISTANCE TESTER, S/N 8810-590<br />

1 – ATLAS SALT FOG & HUMIDITY CORROSION EVAPORATIVE SYSTEM<br />

1 – ATOTECH SALT SPRAY CABINET, Partlow Arc 4100 Recorder<br />

1 – BUEHLER ABRASIMET 2 ABRASIVE CUTTER, S/N 574-MSC-3065<br />

1 – BUEHLER 20-1415 SIMPLIMET 1000 AUTOMATIC MOUNTING PRESS, S/N 573-N1K-00388<br />

1 – BUEHLER 45-2809 METASERV 2000 GRINDER/POLISHER, S/N 573-MGV-B20<br />

1 – BUEHLER 39-1572 HANDIMET TWO ROLL GRINDER, S/N 574-HRG-1394, Four (4) Grinding<br />

Surfaces<br />

1 – BUEHLER FIBRFLEX LIGHT SOURCE<br />

1 – PROCEQ EQUO TIP HARDNESS TESTER, S/N 9198235<br />

1 – ELECTROPHYSICS EZ THERM XP THERMAL VIDEO SYSTEM (2006), Camera Model TVS-<br />

500E, S/N 2406F0188 / 35597<br />

1 – NEW AGE OS-300-4 BRINELL OPTICAL SCANNING SYSTEM, S/N 213<br />

1 – NIKON ECLIPSE TS100 MICROSCOPE, Sony Exwave HAD Digital Color Video Camera<br />

1 – NIKON SMZ800 MICROSCOPE<br />

1 – MINOLTA CR400 COLORIMETER<br />

QUANTITY OF OMEGA MICROPROCESSOR THERMOMETER; FLUKE THERMOCOUPLE<br />

CALIBRATOR; FARNSWORTH-MUNSELL 100 HUE TEST KIT; FISCHER DUAL SCOPE MP20<br />

THICKNESS GAUGE<br />

SErvO rOBOTS<br />

1 – FANUC R-2000iA 165F 6-AXIS SERVO MATERIAL HANDLING ROBOT (2003),<br />

R-J3iB Controller, F-56643 (7222 Hours), Teach Pendant, Cables<br />

8 – FANUC S-420i 6-AXIS SERVO MATERIAL HANDLING ROBOTS, F-31288 /<br />

F-30392 / F-30389 / F-30383 / F-30286 / F-30136 / F-27785 / F-26887 (All 1996),<br />

R-J2 Controllers, F-56643, Teach Pendant, Cables, Some w/Buffing Attachments<br />

2 – FANUC S-420 6-AXIS SERVO MATERIAL HANDLING ROBOTS (Both 1995)<br />

BrIDGE CrANES<br />

1 – CANADIAN OVERHEAD HANDLING INC 50 / 30 METRIC TON (55 / 33 TON)<br />

DOUBLE GIRDER TOP RUNNING BRIDGE CRANE, S/N 2656, Span 60'<br />

Approx, Auxiliary Hoist 30 Metric Ton; Radio Remote Control; Runway Length 400'<br />

1 – CANADIAN OVERHEAD HANDLING INC 5,000 KG. CAPACITY SINGLE<br />

GIRDER TOP RUNNING BRIDGE CRANE, S/N 2662, Span 45' Approx, Rail<br />

Length 80' Approx, 6-Way Pendant<br />

2 – CANADIAN OVERHEAD HANDLING INC 8,000 KG. CAPACITY DOUBLE<br />

GIRDER TOP RUNNING SEMI-GANTRY CRANES, S/Ns 2663 & 2664, Span 21'<br />

Approx, Height Floor to Rail 22' Approx, 6-Way Pendant, Runway Length 120’<br />

1 – CANADIAN OVERHEAD INC 5,000 KG. CAPACITY SINGLE GIRDER UNDER-<br />

HUNG BRIDGE CRANE, S/N 2661, Span 30' Approx, 6-Way Pendant<br />

1 – DALMEC PRC INDUSTRIAL MANIPULATOR, Code 85 03 0508; Hoist Rotation<br />

360 Degrees, Load Balancer Attachment Capacity 75 Kg<br />

rOLLING STOCk<br />

1 – FREIGHTLINER TRUCK TRACTOR, VIN 2FUYDCYB8NA477973, Miles<br />

135,171; Dual 120 Gallon Diesel Fuel Tanks, Eaton Fuller 10-Speed<br />

Transmission, Airshield Roof High Cab – 13' 6" Tall<br />

9 – FREUHAUF, TRAILMOBILE, STOUGHTON & STRICK CORP 53’ & 48’ TWO<br />

AXLE BOX TRAILERS – Some With Wheel Dunnage Trays<br />

1 – BOBCAT 863 COMPACT SKID STEER LOADER, S/N 51444 7071, Diesel Fuel,<br />

Bucket Width 68"<br />

1 – TOYOTA 7FGCU35 7,000 LB. CAPACITY FORKLIFT, S/N 60971, CNG Fuel,<br />

Side Shift, Lift 187", 3-Stage Mast, Forks 48", Hours 5,121<br />

2 – NISSAN 60 6,000 LB. CAPACITY FORKLIFTS, S/Ns MCUG1F2F30LV &<br />

MCU1F2A30LV, CNG Fuel, Lift 4750 mm (187"), 3-Stage Mast, Forks 60"<br />

3 – TOYOTA 7FGCU25 5,000 LB. CAPACITY FORKLIFTS, S/N 63637, 62409 &<br />

63610, CNG Fuel, Side Shift, Lift 4500 mm (189"), 3-Stage Mast, Forks 60"<br />

1 – MOTIVATION LCH5 12' FORKLIFT BOOM EXTENSION, S/N 14709-01<br />

1 – TENNANT HF2-V4-TN 24-20 WALK BEHIND FLOOR SCRUBBER, S/N 392145<br />

(2008), Hours 340<br />

1– TENNANT M5400 WALK BEHIND FLOOR SCRUBBER, S/N 5400-10287139<br />

10<br />

to schedule an auction, please call Hilco Industrial, LLC at 1-877-37-HILCO (44526)

WeLDers • FaCILItIes systeMs • sHOP eQuIPMent • InventOry<br />

WELDErS<br />

3 – LINCOLN DC-400 WELDING POWER SOURCES, S/Ns<br />

C1990100233, C1990100230 & C1990300198; LN-7 Wire Feeds<br />

1 – PANASONIC WIG STAR WX 300 WELDER<br />

1 – POWERMAX 1250 G3 SERIES PLASMA CUTTER, S/N 1250-022280<br />

1 – POWERMAX 1000 G3 SERIES PLASMA CUTTER, S/N 1000-001245<br />

1 – LINCOLN MOBIFLEX 200-M PORTABLE FUME COLLECTOR, S/N<br />

M0570160035<br />

2 – UNITED AIR SPECIALISTS SH-20-PE-H AIR CLEANERS, S/Ns<br />

60021937 (2001) & 60046806 (2000), Blower Type 9-7-M<br />

fACILITIES SySTEMS<br />

LARGE QTY OF STAINLESS STEEL PIPING - UP TO 6" DIA.<br />

LARGE QTY SWITCH GEAR & Copper/Aluminum TEC Cable;<br />

CUTLER HAMMER; ELSPEC Capacitors<br />

1 – FUEL MAKER COMPRESSED NATURAL GAS #FMQ-10 REFUELING<br />

SYSTEM, S/N E001780 & #FF350D-CN STORAGE SYSTEM, S/N<br />

0286B, Flow Rate 200 SCFM Max, PSIG 3,000<br />

1 – US FILTER WATER FILTRATION SYSTEM Including: NETZSCH<br />

Model 1000 SP/LP Plate Filter Press, Max Operating Pressure 100<br />

PSIG; SRS Model 1020 Centrifuge; (2) Pressure Tanks; Soft Water<br />

Storage Tank; Waste Water Holding Tanks; Mixing Tanks; Sludge<br />

Tanks; Sand Filter System; Clarifiers; Cutler Hammer Switches<br />

1 – ELMIRA COOLING TOWER CONTROL, S/N 2001-07-02 with<br />

MARLEY NC8305C2CS NC CLASS TWO-SECTION COOLING<br />

TOWER, S/N NC-209079-A1 & NC-209079-A2 (2001); Three x 100<br />

HP Motor & Pumps; and MARLEY NC8303FL2SS NC CLASS<br />

TWO-SECTION COOLING TOWER, S/N 209073-A1 & 209073-A2<br />

(2001); Three x 25 HP Motor & Pumps<br />

1 – ALECTRONIC SCALE SYSTEMS STEEL KING TRUCK SCALE, S/N<br />

5276, Class III HD, Steel Plate Approx 80' L x 10' W; CHAMBERLAIN<br />

Model BG770-50-11 Lift Master Gate Arm, S/N 042903N; GSE Weight<br />

Indicator, S/N 06611 & ESP Printer<br />

1 – NATIONAL CONVEYOR SYSTEMS ALUMINUM CHIP RECYCLING<br />

SYSTEM (2001) Including: METAL CRUSHER / WET CHIP HOPPER<br />

/ CHIP WRINGER<br />

1 – HENRY 4360 SID 2-3-14 FILTRATION SYSTEM (2001), Filter<br />

w/Primary Conveyor<br />

MISCELLANEOUS SHOP EQUIPMENT<br />

1 – MOTORIZED WELDING POSITIONER, Plate 27.5" Diameter<br />

1 – MORSE 400A-60S 800 LB. CAPACITY BARREL MANIPULATOR,<br />

S/N 220908A<br />

1 – WULFTEC WHP-150 PALLET WRAPPING MACHINE, S/N 4163-1-0702,<br />

Platform 48" x 48"<br />

1 – CARDINAL FLOOR SCALE, 32" x 32", Model 204 Weight Indicator,<br />

Capacity 500 Lb x .2 Lb<br />

1 – INTERNATIONAL SURFACE TECHNOLOGIES 4248-S-DCM-160<br />

BLAST CABINET, S/N MS 36B1-0023, Side Door Power Lift, 2 HP,<br />

Dust Collector<br />

2 – MARATHON EQUIPMENT COMPACTORS<br />

1 – RIDGID 1822-1 PIPE THREADER, S/N EA02861<br />

1 – RIDGID 535 PIPE THREADER, S/N EAM23798 L01<br />

1 – POWER FIST 50 TON H-FRAME PRESS, Between Columns 34",<br />

2 HP Motor & Hyd Pump<br />

1 – 20 TON PNEUMATIC SHOP PRESS, Between Columns 20"<br />

1 – WILTON-STRANDT TYPE 24514 25" SINGLE SPINDLE DRILL<br />

PRESS, S/N 86050, Floor Mount, Table 15" x 21", Spindle Speeds<br />

85-1460 RPM<br />

1 – TOOLEX 7" x 12" METAL CUTTING BAND SAW (2002)<br />

1 – 10,000 LB. CAPACITY FLOOR SCALE, Size 60" x 60", Read Out<br />

1 – SETRA 50 KG SCALE; OHAUS MB45 SCALE<br />

1 – 20' CAPACITY BAR STORAGE RACK & MATERIAL<br />

1 – AIR ROVER XL14-AGG PORTABLE AIR CONDITIONER, S/N<br />

24901201; BTU/H 13,500<br />

8 – FIBERGLASS STORAGE TANKS – 8,400 L – Approx Size 13' T x<br />

100" Dia. / 4,200 L – Approx Size 13' T x 72" Dia.<br />

ELECTRICAL SWITCHGEAR – CUTLER HAMMER 2000 Amp to 4000<br />

Amp; ELSPEC 300-600 KVA Capacitors<br />

Self Dumping Hoppers, Steel Tables, Wood Top Desks, Pedestal & Belt<br />

Grinders, Vises, Kalamazoo Chop Saw; Husky Floor Buffer; Shop Fans;<br />

Goodway Shop Vac; Quantity of TIMKEN Bearings; WILDEN &<br />

VERSAMATIC Pumps; 40 Taper Tool Holders; BIND Tool Presetter; JUST<br />

RITE Flammable Storage Cabinets & Acid Storage Cabinets; RUBBERMAID<br />

Rolling Utility Containers; Hand Tools; PALLET RACKING; Rolling Staircases;<br />

DELL Power Vault Servers; NORSTAR / NORTEK Telephone System<br />

ALUMINUM WHEEL & TIrE INvENTOry<br />

OVER 1,000 – WIP ALUMINUM WHEELS FOR AMG, MERCEDES RAM<br />

SRT, PORSCHE<br />

QTY – UNUSED TIRES – BF GOODRICH / MICHELIN / GOOD YEAR /<br />

YOKOHAMA / CONTITRAC / PIRELLI<br />

OvEr $2,500,000 SPArE PArTS –<br />

For Die Cast Machines, Heat Treat, CNC Machines,<br />

Motors & Drives, Bearings, Blowers, etc.<br />

For more information, please visit us on the web at www.hilcoind.com 11

Atlanta • Birmingham • Birmingham (UK) • Boston • Charlotte • Chicago • Connecticut • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong<br />

Irapuato (MX) • Leeds (UK) • London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • San Francisco • Toronto • Villahermosa (MX)<br />

Hilco Industrial, LLC<br />

A u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s<br />

Headquarters<br />

31555 W. Fourteen Mile Road, Suite 207<br />

Farmington Hills, MI 48334<br />

Ph: 877-37-HILCO (44526)<br />

Fx: 248.254.9995<br />

www.hilcoind.com<br />

Presorted<br />

First Class Mail<br />

U.S. Postage<br />

PAID<br />

Detroit, Mich.<br />

Permit No. 2655<br />

Forwarding Service Requested<br />

HILCO WebCast/OnsIte auCtIOn<br />

Former assets of<br />

UBE Automotive North America Sarnia Plant, Inc.<br />

HILCO Industrial, LLC is a division of Hilco trading, LLC • Headquarters 5 revere Drive, ste. 206 • northbrook, IL 60062 • all rights reserved<br />

Hilco asset sales, Canada; City of sarnia auctioneer & License: bruce Lyle: License #269 • Hilco Industrial, LLC: IL License #444.000215<br />

Printed in usa • ube0115 • IL License #444.000215 • Please visit our website at www.hilcoind.com to review our complete terms and conditions.<br />

Terms of Sale<br />

An 18% buyer's premium will be charged for all Bidspotter<br />

sales. A 15% buyer's premium will be charged for all Hilco<br />

Webcast sales and on-site sales. Everything will be sold to<br />

the highest bidder for cash, in accordance with the<br />

Auctioneer’s customary “Terms of Sale”, copies of which will<br />

be posted on the premises of the sale and subject to additional<br />

terms announced the day of sale. All items will be sold<br />

“as is, where-is” without any warranties, express or implied.<br />

Although obtained from sources deemed reliable, the<br />

Auctioneer makes no warranty or guarantee to the accuracy<br />

of the information herein contained. Bidders are encouraged<br />

to thoroughly inspect the items on which they intend<br />

to bid prior to sale. Absolutely no items will be removed until<br />

the day after the conclusion of the sale and payment is<br />

made in full. Subject to additions, deletions and prior sale.<br />

Payment: ALL PURcHASES MUST BE PAID IN FULL ON<br />

THE DAy OF THE AUcTION. If you intend to pay by wire<br />

transfer, we will accept payment the day after the sale<br />

ONLy IF a deposit of 25% of total purchases is made on<br />

the day of the sale. contact our office for wire transfer<br />

instructions. All payments must be made in canadian<br />

Funds by cash, cashier’s check, wire transfer or company<br />

check. Personal checks will not be accepted. company<br />

check payable to Hilco Industrial canada ULc will be<br />

accepted only if accompanied by a bank letter of guarantee.,<br />

(see sample letter below). All sales are subject to sales<br />

tax. Purchasers claiming exemptions from taxes must provide<br />

proof satisfactory to the Auctioneer of their entitlement<br />

to claim such exemptions.<br />

Sample Bank Letter<br />

(Bank Name) unconditionally guarantees payment to<br />

Hilco Industrial canada ULc from (company Name).<br />

This guarantee will be valid for purchases made at<br />

the Auction of UBE Automotive North America Sarnia<br />

Plant, Inc. on May 3, 2012.<br />

Follow<br />

Us on: