Integrating Structural and Hydrologic Design - Belgard

Integrating Structural and Hydrologic Design - Belgard

Integrating Structural and Hydrologic Design - Belgard

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INTEGRATING STRUCTURAL AND HYDROLOGIC DESIGN<br />

CONSIDERATIONS IN PERMEABLE PAVEMENT<br />

David R. Smith, Technical Director<br />

Interlocking Concrete Pavement Institute<br />

13921 Park Center Road, Suite 270<br />

Herndon, Virginia 20171 USA<br />

Tel: 703-657-6900 Fax: 703-657-6901<br />

dsmith@icpi.org<br />

ABSTRACT<br />

Pervious concrete, porous asphalt <strong>and</strong> permeable interlocking concrete pavements combine<br />

stormwater infiltration, detention <strong>and</strong> a riding surface for vehicles into one location. These three<br />

sustainable pavements rely on an open-graded crushed stone base for water storage, infiltration <strong>and</strong><br />

vehicular support. Much research has been conducted on the hydrologic <strong>and</strong> water quality aspects<br />

provided by these bases. State <strong>and</strong> municipal best management practice (BMP) <strong>and</strong> low impact<br />

development (LID) manuals have incorporated design guidelines developed from university<br />

research, industry guidelines <strong>and</strong> experience by various agencies. However, stormwater agencies<br />

generally possess a paucity of information on the structural aspects of pavements for sustainable<br />

urban drainage. This information is essential to providing durable designs that can withst<strong>and</strong><br />

repeated vehicular traffic.<br />

This paper reviews hydrological <strong>and</strong> structural solutions for permeable interlocking concrete<br />

pavement for use by design professionals <strong>and</strong> stormwater agencies. Using a software program, the<br />

hydrological analysis within it determines if the volume of water from user-selected rainfall events<br />

can be stored <strong>and</strong> released by the pavement base. User defined parameters determine how much<br />

water infiltrates the soil subgrade <strong>and</strong>/or is carried away by subdrains or flows off the pavement<br />

surface. <strong>Structural</strong> capacity for repeated vehicular loads is determined using the American<br />

Association of State Highway <strong>and</strong> Transportation Officials (AASHTO) 1993 structural design<br />

equations. This paper explains commonly used structural <strong>and</strong> hydrological design methodologies<br />

with examples. The non-proprietary software program illustrates the range of input design<br />

considerations as well as outputs for integrated stormwater drainage <strong>and</strong> pavement design. These<br />

considerations apply to all types of sustainable pavements.<br />

Keywords: sustainable paving, permeable pavements, permeable pavement structural design,<br />

permeable interlocking concrete pavement, stormwater infiltration<br />

INTRODUCTION<br />

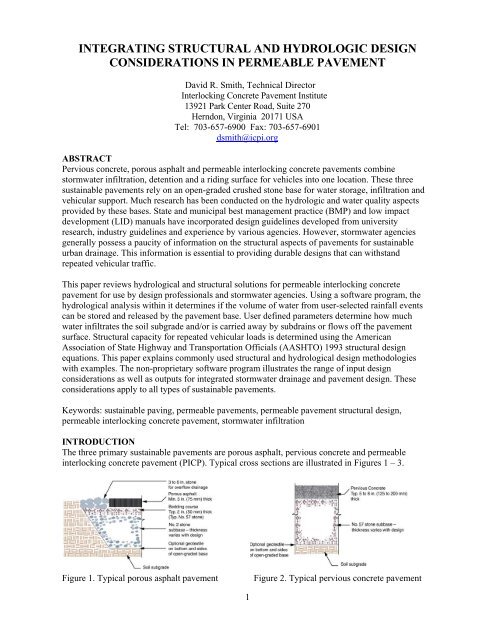

The three primary sustainable pavements are porous asphalt, pervious concrete <strong>and</strong> permeable<br />

interlocking concrete pavement (PICP). Typical cross sections are illustrated in Figures 1 – 3.<br />

Figure 1. Typical porous asphalt pavement<br />

Figure 2. Typical pervious concrete pavement<br />

1

Their hydrological design generally relies on the<br />

following variables:<br />

• design storm or storms, typically issued by the<br />

local stormwater agency<br />

• long-term soil infiltration rate, estimated from soil<br />

samples or field measured<br />

• base/subbase reservoir thickness <strong>and</strong> storage<br />

capacity<br />

Figure 3. Typical permeable interlocking concrete pavement (PICP)<br />

<strong>Hydrologic</strong>al design is patterned after infiltration trench design that accounts for rainfall entering<br />

directly into the pavement surface plus runoff from adjacent contributing pervious <strong>and</strong> impervious<br />

surfaces. Permeable/porous/pervious pavements may be designed to contain water for a few days for<br />

the purposes of nutrient reduction. In such cases, detention pond design principles can be applied to<br />

inflow, storage <strong>and</strong> outflow calculations. Excess water that cannot be contained by the base is<br />

allowed to exit via swales or bioretention areas adjacent to the pavement, through pipes in the base,<br />

<strong>and</strong>/or into catch basins. Figures 4, 5 <strong>and</strong> 6 illustrate some overflow options.<br />

Figure 4. Overflow to bioswale at Elmhurst<br />

College parking lot, Elmhurst, Illinois<br />

Figure 5. Catch basin overflow at Wal-mart<br />

parking lot Rehobeth Beach, Delaware<br />

For all permeable/porous/pervious pavements, the<br />

base/subbase thickness is determined for hydrological<br />

<strong>and</strong> structural (traffic loading) needs, <strong>and</strong> the<br />

thicker section is selected. <strong>Hydrologic</strong>al design for<br />

permeable/porous/pervious pavement is described in<br />

books <strong>and</strong> BMP manuals, but structural (base<br />

thickness) design is not due to a lack of information<br />

on the structural performance of open-graded bases<br />

used in them. This paper reviews structural design<br />

approaches for these pavements published by their<br />

representative industries <strong>and</strong> it presents some tools<br />

to integrate hydrological design.<br />

Figure 6. Outflow via perforated drain pipe is set to drain into a utility structure. The pipe is elevated<br />

above a low infiltration soil subgrade to detain water in the open-graded stone base, promote nutrient<br />

reduction <strong>and</strong> eventual infiltration.<br />

2

Inflow-Outflow Analysis<br />

Performed at 5 min. time intervals<br />

Pavement<br />

•Slope<br />

• Infiltration<br />

Amount of Rainfall<br />

•Storm pattern<br />

•Storm year<br />

Adjacent Areas<br />

•Size<br />

• Drainage properties<br />

Inflow Analyses<br />

Drainage Characteristics<br />

• Results of <strong>Structural</strong> Analysis<br />

• Porosity of pavement layers<br />

• Permeability of pavement layers<br />

• Subgrade infiltration<br />

• Drainage pipes<br />

• Layer thickness<br />

•Slopes, etc.<br />

Outflow Analysis<br />

• Amount of surface runoff<br />

• Depth of water on the pavement surface<br />

• Volume of water entering the pavement surface<br />

• Depth of water in pavement granular layers<br />

• Volume of water entering subgrade<br />

• Outflow through drains, etc.<br />

Consider changing<br />

• Drainage characteristics<br />

Yes<br />

Is the<br />

drainage<br />

adequate<br />

No<br />

Consider changing<br />

• Thickness of pavement granular layers<br />

To structural analysis<br />

Figure 8. <strong>Hydrologic</strong>al analysis flow chart for permeable pavement<br />

PICP <strong>Structural</strong> Analysis<br />

To assess the structural capacity of PICP, the program uses the AASHTO 1993 structural design<br />

equation to develop base thicknesses for supporting vehicular traffic. This design method relies on<br />

inputs such as traffic information, soils <strong>and</strong> pavement material information, reliability <strong>and</strong><br />

serviceability levels. As previously noted, the AASHTO empirical design method calculates a<br />

structural number (SN) which is the sum of layer coefficients, a dimensionless characterization of the<br />

stiffness of each pavement layer. <strong>Design</strong>ed for use in the United States <strong>and</strong> Canada, the user can<br />

instantly move from SI or U.S. customary units even while inputting data.<br />

To determine the thickness of the required pavement layers, layer coefficients (default values or<br />

those assigned by the user) determine if the open-graded base types <strong>and</strong> thicknesses meet the design<br />

structural number or design SN. While the user can change default values, the program assumes that<br />

layer coefficients for open-graded bases are lower than those associated with dense-graded bases<br />

used under conventional impervious pavements.<br />

The PICP paving layer thickness is consistently specified at 3 1/8 in. (80 mm) for the pavers plus 2 in.<br />

(50 mm) for the bedding layer. While a conservative default value of 0.3 per inch layer coefficient is<br />

assumed for the pavers <strong>and</strong> bedding layer, the user can nominate a paver-specific layer coefficient<br />

should it be available. Since the paving layer thickness is constant <strong>and</strong> its stiffness is characterized<br />

by this layer coefficient, only the open-graded base (usually the ASTM No. 57 stone held constant at<br />

4 in. or 100 mm thickness) <strong>and</strong> the subbase thickness (ASTM No. 2 stone layer) requires designing.<br />

The subbase thickness is rounded up to the nearest inch (25 mm) to ensure a reasonable <strong>and</strong><br />

conservative value for constructability. The software program applies to PICP subject to axle loads<br />

up to 24,250 lbs (11,000 kg) or a maximum vehicle load of 50,000 lb (22,680 kg) trafficked up to 1<br />

million 80 kN (18-kip) equivalent single axle loads (ESALs). Users are cautioned when the design<br />

load exceeds 600,000 ESALs. Figure 9 illustrates similar truck loads on a PICP project.<br />

7

INTEGRATING STRUCTURAL AND HYDROLOGICAL DESIGN IN PICP<br />

The designer can conduct sophisticated sensitivity analysis on structural <strong>and</strong> hydrological input<br />

variables using a software program recently released by the Interlocking Concrete Pavement Institute<br />

(ICPI 2008). The flow chart shown in Figure 7 illustrates the integration of hydrological <strong>and</strong><br />

structural design using this software. Like many software programs, this one enables the user to test<br />

the sensitivity of input variables with limited data <strong>and</strong> therefore design conservatively. Besides<br />

traffic loads <strong>and</strong> soil infiltration rates, other difficult-to-predict variables that can be modeled can<br />

include the long term surface infiltration rate, possible lower soil subgrade strengths when near<br />

saturation, antecedent water conditions in the base reservoir, as well as the long-term soil subgrade<br />

infiltration rate.<br />

<strong>Structural</strong> Analysis<br />

<strong>Hydrologic</strong>al<br />

Analysis<br />

Pavement Structure:<br />

Type <strong>and</strong> thickness of<br />

pavement layers<br />

Drainage <strong>Design</strong>:<br />

Drainage features<br />

<strong>and</strong> characteristics<br />

Yes<br />

Is the<br />

drainage<br />

adequate<br />

No<br />

Consider changing<br />

• Drainage characteristics<br />

Consider changing<br />

• Thickness of pavement<br />

granular layers<br />

Figure 7. An overview of structural <strong>and</strong> hydrological analysis for permeable pavement<br />

PICP <strong>Hydrologic</strong>al Analysis<br />

Figure 8 summarizes the hydrological modelling process. The hydrological analysis determines if the<br />

volume of water from user-selected rainfall events can be stored, infiltrated <strong>and</strong> released by the<br />

pavement structure. All water is modelled as a water balance using small time steps to characterize<br />

water inflow from precipitation into the PICP surface <strong>and</strong> runoff contributed from adjacent areas.<br />

The program holds a significant rainfall library for many cities in the U.S. <strong>and</strong> Canada consisting of<br />

5, 10, 25, 50 <strong>and</strong> 100 year return periods for 24 hour events.<br />

Besides characterizing contributing runoff from adjacent areas, the user can elect to include<br />

perforated drain pipes in the base to accommodate outflow in low infiltration soils. These can be<br />

modeled at the bottom of the subbase or raised within it to create some detention. The program also<br />

calculates the curve number <strong>and</strong> runoff coefficient for user selected rainfall events for the site.<br />

Outflow is also estimated by calculating infiltrated water flowing directly into the PICP <strong>and</strong> from<br />

contributing areas, as well as drainage from the base into the soil or to drainage pipes during each<br />

time step. The combined process continually estimates the water level in the base <strong>and</strong> the amount<br />

draining from the PICP, during <strong>and</strong> after the storm. Output includes hydrographs for the rainfall,<br />

inflow from contributing areas, infiltration <strong>and</strong> outflow through drain pipes if required. Output<br />

variables can be set for water storage <strong>and</strong> harvesting if needed.<br />

6

Traffic<br />

Load<br />

<strong>Design</strong><br />

Axle<br />

Load, lbs<br />

(kN)<br />

Repetitions<br />

Pervious Concrete<br />

Thickness, in.<br />

(mm)<br />

Low 4,000 (18) Unlimited 4 (100) Unlimited<br />

Moderate 12,000 (53)

The number of ESALs is determined by the weight of each of the axles <strong>and</strong> dividing them by a<br />

‘st<strong>and</strong>ard’ ESAL of 18,000 lbs (80 kN). A five axle tractor-trailer truck provides an example: two<br />

rear axles on the trailer each exert 18,000 lbs or 80 kN; two on the back of the truck at 15,800 lbs or<br />

70 kN; <strong>and</strong> one in the front (steering) at 11,000 lbs or 50 kN. AASHTO uses the following<br />

relationships called load equivalency factors or LEFs for each axle to estimate ESALs. LEF <strong>and</strong><br />

ESALs for this truck are as follows:<br />

Trailer: (80/80) 4 = 1 (x 2 axles) = 2 ESALs<br />

Truck rear: (70/80) 4 = 0.6 (x 2 axles) = 1.2 ESALs<br />

Truck front: (50/80) 4 = 0.15 ESALs<br />

When added together, all LEFs = 3.35 ESALs. For every pass across a pavement, this truck exerts<br />

3.35 18,000 lb (80 kN) ESALs. To put automobile axle loads into perspective, the weight of one<br />

passenger car placed into the formula yields about 0.0002 ESALs. Therefore, pavement design is<br />

primarily considers trucks because they exert the highest loads <strong>and</strong> most damage. In contrast,<br />

thous<strong>and</strong>s of cars are required to apply the same loading <strong>and</strong> damage as one passage of a truck.<br />

POROUS ASPHALT STRUCTURAL DESIGN<br />

Porous pavement thickness design is addressed in industry literature. Table 1 indicates thicknesses<br />

for porous asphalt design (NAPA 2008). This is excerpted from the National Asphalt Pavement<br />

Association porous asphalt manual which does not quantify maximum traffic loading.<br />

Minimum Compacted<br />

Thickness, in. (mm)<br />

Traffic Loading<br />

Parking – Little or no trucks 2.5 (65)<br />

Residential street – Some trucks 4.0 (100)<br />

Heavy Trucks 6 (150)<br />

Table 1. Minimum compacted porous asphalt thicknesses<br />

Regarding AASHTO layer coefficients per inch (25 mm) of pavement layer thickness for porous<br />

asphalt, NAPA (2008) recommends the following in Table 2.<br />

Material<br />

Layer Coefficient (per in.)<br />

Porous Asphalt 0.40 – 0.42<br />

Asphalt-treated permeable base 0.30 – 0.35<br />

Porous aggregate (open-graded) base 0.10 – 0.14<br />

Table 2. AASHTO layer coefficients for porous asphalt, treated base <strong>and</strong> open-graded base<br />

PERVIOUS CONCRETE STRUCTURAL DESIGN<br />

The National Concrete Ready Mix Association manual, <strong>Hydrologic</strong> <strong>Design</strong> of Pervious Concrete<br />

(2007 Leming) provides a methodology that utilizes the Natural Resource Conservation Service<br />

(NRCS) Curve Number method. The manual reviews software for hydrological calculations. While<br />

the software program does not include structural design, some recommendations are provided as<br />

charts in the appendix. Depending on axle loads, pavement thickness charts recommend 4, 6 <strong>and</strong> 8 in.<br />

(100, 150 <strong>and</strong> 200 mm) thick pervious concrete on soils with infiltration rates no lower than 0.1<br />

in./hr. (0.3 cm/hr).<br />

There is no design guidance on the thickness of open-graded base required for traffic load support.<br />

The user is directed to consulting a design professional (e.g. civil engineer) for determining pervious<br />

concrete <strong>and</strong> base thicknesses on soils less than 0.1 in./hr (0.3 cm/hr) infiltration rate. Table 3 below<br />

replicates the pavement thickness information by Leming. The right h<strong>and</strong> column is added by the<br />

author to demonstrate the ESAL ranges supported by the various pervious concrete pavement<br />

thicknesses. The design charts note that a design professional should be consulted for lifetime<br />

designs greater than 720,000 ESALs.<br />

4

BASIS FOR STRUCTURAL DESIGN<br />

For structural design of impervious (conventional) roads <strong>and</strong> base, many local, state <strong>and</strong> provincial<br />

agencies design methods published by the American Association of State Highway <strong>and</strong><br />

Transportation Officials (AASHTO). While the AASHTO methodology is familiar to some civil<br />

engineers, stormwater agency personnel who do not deal with pavement design are encouraged to<br />

become more familiar with them <strong>and</strong> reference them in permeable pavement design<br />

recommendations for local, state or provincial BMP <strong>and</strong> LID manuals, <strong>and</strong> regulatory documents.<br />

Highway engineers are increasingly using AASHTO 2002 Mechanistic-Empirical Pavement <strong>Design</strong><br />

Guide which relies on mechanistic design <strong>and</strong> modeling, i.e. analysis of loads <strong>and</strong> resultant stresses<br />

<strong>and</strong> strains on materials <strong>and</strong> the soil subgrade. The AASHTO 2002 mechanistic design model was<br />

developed <strong>and</strong> calibrated by state, provincial <strong>and</strong> federal highway agencies across a wide range of<br />

highway loads, load testing, soil types <strong>and</strong> climatic conditions. This model has not been calibrated<br />

for permeable pavements (subject to significantly less traffic loads) constructed with open-graded,<br />

crushed stone bases.<br />

Many local agencies use the empirically-based AASHTO 1993 Guide for <strong>Design</strong> of Pavement<br />

Structures whose underlying concepts emerged from test pavements in the 1950s repeatedly<br />

trafficked by trucks that established relationships among materials types, loads <strong>and</strong> serviceability.<br />

The AASHTO equation in the 1993 Guide calculates a <strong>Structural</strong> Number or SN given traffic loads,<br />

soil type, climate <strong>and</strong> moisture conditions. The designer then finds the appropriate combination of<br />

pavement surfacing <strong>and</strong> base materials to meet or exceed the <strong>Structural</strong> Number. This empirical<br />

design approach appears to be applicable to permeable pavements with consideration given to input<br />

variables.<br />

Due to their load distribution means, porous asphalt <strong>and</strong> PICP are considered flexible pavement<br />

systems <strong>and</strong> the flexible pavement design concepts in AASHTO can be applied to them. A key input<br />

for flexible pavement design is the layer coefficient which characterizes each pavement layer with a<br />

number. The higher the coefficient, the stiffer the material <strong>and</strong> the coefficient is expressed per inch<br />

or per millimeter of pavement layer thickness. The thickness of each material is multiplied by the<br />

layer coefficients <strong>and</strong> all coefficients are added to equal or exceed the <strong>Structural</strong> Number.<br />

For example, given site specific inputs on subgrade soil strength, climate, moisture <strong>and</strong> traffic loads<br />

into the AASHTO equation yields a required structural number of 2.5. The designer then identifies<br />

the combination of pavement layer materials whose layer coefficients total at least 2.5. In this<br />

illustration, a compacted, dense-graded crushed stone base typically has a layer coefficient of 0.14.<br />

Asphalt typically has a layer coefficient of 0.44. If 3 in. (75 mm) of asphalt are selected, then the SN<br />

for this layer is 0.44 x 3 = 1.32. The base layer thickness required would then be 2.5 – 1.32 =<br />

1.18/0.14 = 8.4 or about 9 in. (225 mm) which satisfies the required <strong>Structural</strong> Number.<br />

CHARACTERIZING TRAFFIC LOADS<br />

When a vehicle passes over a pavement, it damages it. The cumulative effects of many passes<br />

eventually causes ruts or cracks making the pavement unserviceable <strong>and</strong> needing rehabilitation.<br />

Vehicles passing over a pavement exert a wide range of loads. Compared to cars, trucks <strong>and</strong> busses<br />

do the most damage to pavements because their wheel loads <strong>and</strong> tire pressures are much heavier <strong>and</strong><br />

higher than cars. One pass of a fully loaded truck will do more damage to pavement than several<br />

thous<strong>and</strong> cars passing over it. The AASHTO Guide characterizes traffic loads as the number of<br />

18,000 lbs or 80 kN equivalent single axle loads or ESALs. The 18,000 lb load emerged from the<br />

AASHTO road tests conducted in the 1950s <strong>and</strong> has remained as a convenient means to quantify<br />

loads.<br />

3

CONCLUSION<br />

Stormwater agencies provide permeable<br />

pavement design guidelines through BMP<br />

<strong>and</strong> LID manuals <strong>and</strong> other publications.<br />

Most of the guidelines focus on design for<br />

managing stormwater <strong>and</strong> its pollutants.<br />

There is little information provided on<br />

structural design or it is imprecisely<br />

quantified. Better structural design<br />

information is needed to raise designer<br />

confidence. Compared to impervious<br />

pavement structural design, permeable<br />

pavement structural design is in its<br />

formative stages. Industry guidelines for<br />

each permeable pavement system should<br />

be followed with advice from a qualified<br />

design professional.<br />

Figure 9. PICP demonstrates an ability to support<br />

loaded trucks at Elmhurst College, Elmhurst, Illinois.<br />

The structural behavior of open-graded bases requires more research <strong>and</strong> testing to determine<br />

relationships between load <strong>and</strong> deformation (e.g., surface rutting <strong>and</strong>/or cracking). There is limited<br />

laboratory <strong>and</strong> field (accelerated traffic load) testing information on open-graded bases as reliable<br />

inputs for structural design. The AASHTO 1993 methodology appears to be a suitable empiricallybased<br />

design approach until more design data is developed from the structural response <strong>and</strong><br />

serviceability of permeable/porous/pervious pavements under a range of climates, soils <strong>and</strong> traffic.<br />

The author wishes to thank D. J. Swan with Applied Research Associates, Inc. for the flow charts in<br />

this paper.<br />

REFERENCES<br />

AASHTO 1993. Guide for <strong>Design</strong> of Pavement Structures, American Association of State Highway<br />

<strong>and</strong> Transportation Officials, Washington, DC.<br />

AASHTO 2002. Mechanistic-Empirical Pavement <strong>Design</strong> Guide, American Association of State<br />

Highway <strong>and</strong> Transportation Officials, Washington, DC.<br />

ICPI 2008. Applied Research Associates, Inc., Permeable <strong>Design</strong> Pro Software, Interlocking<br />

Concrete Pavement Institute, Herndon, Virginia.<br />

Leming 2007. Leming, M. L., Malcom, H. R., <strong>and</strong> Tennis, P. D., <strong>Hydrologic</strong> <strong>Design</strong> of Pervious<br />

Concrete, EB303, Portl<strong>and</strong> Cement Association, Skokie, Illinois, <strong>and</strong> National Ready Mixed<br />

Concrete Association, Silver Spring, Maryl<strong>and</strong>, 72 pages.<br />

NAPA 2008. Porous Asphalt Pavements for Stormwater Management, Information Series 131,<br />

National Asphalt Pavement Association, Lanham, Maryl<strong>and</strong>, 24 pages.<br />

Smith 2006. Smith, D. R., Permeable Interlocking Concrete Pavements – <strong>Design</strong> Specification<br />

Construction Maintenance, Interlocking Concrete Pavement Institute, Herndon, Virginia, 48 pages.<br />

8