Packaged Metering Manhole Specifications.pdf - Plasti-Fab, Inc.

Packaged Metering Manhole Specifications.pdf - Plasti-Fab, Inc.

Packaged Metering Manhole Specifications.pdf - Plasti-Fab, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PART 3<br />

EXECUTION<br />

3.01 INSTALLATION<br />

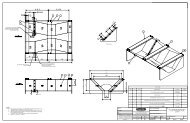

A. PMMS TOO LARGE TO SHIP FLATBED WILL BE SHIPPED IN FLANGED<br />

AND MATCH-DRILLED SECTIONS ALONG WITH STAINLESS STEEL<br />

FASTENERS FOR ONSITE ASSEMBLY.<br />

B. Verify that dimensions are correct and project conditions are suitable for<br />

installation. Do not proceed with installation until unsatisfactory<br />

conditions have been corrected.<br />

C. Thoroughly clean and remove all shipping materials prior to setting.<br />

D. Install products in accordance with engineer’s specifications, local codes,<br />

general comments below and the Manufacturer’s recommendations.<br />

E. Care shall be taken in the handling, storage and placement of the PMM in<br />

preparation for installation. The contractor shall become familiar with the<br />

recommended handling and installation procedures used with fiberglass<br />

<strong>Metering</strong> <strong>Manhole</strong>s to insure that the manhole is not damaged, and that<br />

the flume is installed in a manner that is consistent with obtaining good<br />

Open Channel flow results.<br />

F. Slinging will be accomplished using nylon or other fabric material. Under no<br />

circumstances shall cable or chain slings be used in direct contact with<br />

fiberglass surfaces<br />

G. The PMM shall be installed level end-to-end and side-to-side, and must<br />

remain level throughout installation. The flume is factory installed in the<br />

<strong>Metering</strong> <strong>Manhole</strong> so that it is absolutely level from front to back and<br />

from side to side, and must remain level after installation.<br />

H. The site shall be excavated wide enough to accommodate the manhole and<br />

to provide a safe working environment for workers.<br />

I. The contractor shall provide a level concrete slab with a smooth troweled<br />

surface. Pad elevation shall be as shown on the drawings, and<br />

positioned so that the invert of manhole piping matches that of the<br />

pipeline. Prior to manhole placement the slab shall be cleaned of all<br />

sharp objects and debris.<br />

J. The foam pad supplied with the manhole shall be placed in the proper<br />

position.<br />

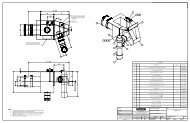

K. If the pipe is already in place the neoprene boots and s/s bands shall be<br />

slipped onto the pipe ends before lowering manhole onto concrete slab.<br />

The neoprene boots can be slipped over pipe ends and the stainless<br />

steel clamps tightened securely. Under no circumstances shall<br />

petroleum lubricants of any type be used to install neoprene boots.<br />

L. <strong>Packaged</strong> <strong>Metering</strong> <strong>Manhole</strong> shall be lowered onto pad in accordance with<br />

the manufacturer's written recommendations.<br />

M. Flume level shall be checked and PMM adjusted if necessary.<br />

N. After the level is confirmed all anchor bolts shall be securely tightened.<br />

O. On larger flumes all open spaces under the flume shall be filled with grout to<br />

provide adequate structural support.<br />

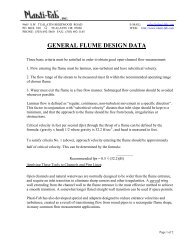

P. Backfill<br />

1. Care shall be taken to avoid uneven backfill loads on the FRP<br />

manhole and flume.<br />

2. Groundwater or surface water runoff shall not be allowed to<br />

accumulate in the open excavation around a manhole that has not<br />

been completely backfilled.<br />

3. Backfill materials shall be placed evenly around the packaged<br />

manhole in approximately 12” (305mm) lifts.<br />

6