GustoMSC Hydraulic Jacking System High Performance Elevation

GustoMSC Hydraulic Jacking System High Performance Elevation

GustoMSC Hydraulic Jacking System High Performance Elevation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

equipment<br />

Product sheet / Rev.1<br />

<strong>GustoMSC</strong> © 08.107<br />

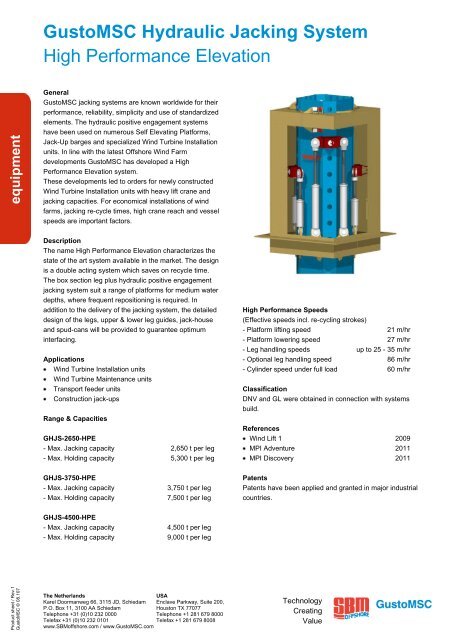

<strong>GustoMSC</strong> <strong>Hydraulic</strong> <strong>Jacking</strong> <strong>System</strong><br />

<strong>High</strong> <strong>Performance</strong> <strong>Elevation</strong><br />

General<br />

<strong>GustoMSC</strong> jacking systems are known worldwide for their<br />

performance, reliability, simplicity and use of standardized<br />

elements. The hydraulic positive engagement systems<br />

have been used on numerous Self Elevating Platforms,<br />

Jack-Up barges and specialized Wind Turbine Installation<br />

units. In line with the latest Offshore Wind Farm<br />

developments <strong>GustoMSC</strong> has developed a <strong>High</strong><br />

<strong>Performance</strong> <strong>Elevation</strong> system.<br />

These developments led to orders for newly constructed<br />

Wind Turbine Installation units with heavy lift crane and<br />

jacking capacities. For economical installations of wind<br />

farms, jacking re-cycle times, high crane reach and vessel<br />

speeds are important factors.<br />

Description<br />

The name <strong>High</strong> <strong>Performance</strong> <strong>Elevation</strong> characterizes the<br />

state of the art system available in the market. The design<br />

is a double acting system which saves on recycle time.<br />

The box section leg plus hydraulic positive engagement<br />

jacking system suit a range of platforms for medium water<br />

depths, where frequent repositioning is required. In<br />

addition to the delivery of the jacking system, the detailed<br />

design of the legs, upper & lower leg guides, jack-house<br />

and spud-cans will be provided to guarantee optimum<br />

interfacing.<br />

Applications<br />

Wind Turbine Installation units<br />

Wind Turbine Maintenance units<br />

Transport feeder units<br />

Construction jack-ups<br />

Range & Capacities<br />

GHJS-2650-HPE<br />

- Max. <strong>Jacking</strong> capacity 2,650 t per leg<br />

- Max. Holding capacity 5,300 t per leg<br />

GHJS-3750-HPE<br />

- Max. <strong>Jacking</strong> capacity 3,750 t per leg<br />

- Max. Holding capacity 7,500 t per leg<br />

GHJS-4500-HPE<br />

- Max. <strong>Jacking</strong> capacity 4,500 t per leg<br />

- Max. Holding capacity 9,000 t per leg<br />

The Netherlands USA<br />

Karel Doormanweg 66, 3115 JD, Schiedam Enclave Parkway, Suite 200,<br />

P.O. Box 11, 3100 AA Schiedam Houston TX 77077<br />

Telephone +31 (0)10 232 0000 Telephone +1 281 679 8000<br />

Telefax +31 (0)10 232 0101 Telefax +1 281 679 8008<br />

www.SBMoffshore.com / www.<strong>GustoMSC</strong>.com<br />

<strong>High</strong> <strong>Performance</strong> Speeds<br />

(Effective speeds incl. re-cycling strokes)<br />

- Platform lifting speed 21 m/hr<br />

- Platform lowering speed 27 m/hr<br />

- Leg handling speeds up to 25 - 35 m/hr<br />

- Optional leg handling speed 86 m/hr<br />

- Cylinder speed under full load 60 m/hr<br />

Classification<br />

DNV and GL were obtained in connection with systems<br />

build.<br />

References<br />

Wind Lift 1 2009<br />

MPI Adventure 2011<br />

MPI Discovery 2011<br />

Patents<br />

Patents have been applied and granted in major industrial<br />

countries.<br />

Technology<br />

Creating<br />

Value

equipment<br />

Product sheet / Rev.1<br />

<strong>GustoMSC</strong> © 08.107<br />

Features:<br />

<strong>High</strong> leg handling speeds<br />

Platform leveling during lifting & lowering<br />

Long cylinder stroke at Touchdown<br />

Equal distribution of the leg load over all pin<br />

engagements per leg<br />

Protection against damage due to overload<br />

Continuous positive engagement between jacking<br />

systems and legs<br />

The jacking system is designed for the maximum preload,<br />

thus ensuring additional safety during normal<br />

jacked up operations<br />

Fail-safe dual hydraulic power packs enabling<br />

redundant operation if a pump failure should occur<br />

Continuous leg load control reading<br />

Central control panel with joy-stick operation<br />

Vertical Leg position indication<br />

Possibility of fully automatic jacking<br />

Minimum maintenance requirements<br />

Leg sea-fastening remote system included<br />

Optimized jacking speed for units over four legs<br />

Optional faster leg handling possibilities<br />

Optional possibility to use the hydraulic power unit for<br />

<strong>GustoMSC</strong> Column Crane, Mooring system and/or<br />

<strong>Hydraulic</strong> Piling hammer<br />

<strong>GustoMSC</strong> NG-9000-HPE with four GHJS-4500-HPE systems<br />

BARD “Wind Lift 1” with four GHJS-2650-HPE systems<br />

Technology<br />

Creating<br />

Value<br />

Typical side and top view of the GHJS<br />

jacking system showing the jackhouse<br />

inside, jacking system and leg<br />

<strong>GustoMSC</strong> Main Control Cabinet of GHJS-2650-HPE systems<br />

“MPI Adventurer” and “MPI Discovery” with six GHJS-3750-HPE systems