You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

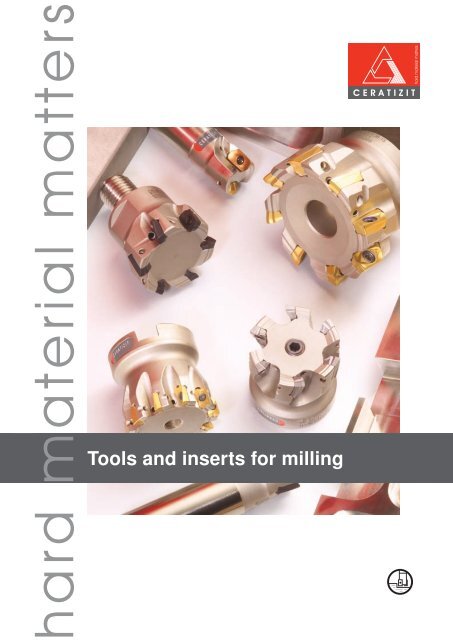

<strong>Tools</strong> <strong>and</strong> <strong>inserts</strong> <strong>for</strong> <strong>milling</strong>

CERATIZIT - secrets of success<br />

Secrets of success<br />

• CERATIZIT is your partner <strong>for</strong> exceptional hard<br />

material solutions. Hard materials <strong>and</strong> tools<br />

from CERATIZIT - our solutions to complex<br />

problems are an integral part of our customers'<br />

success. Our products guarantee: economy -<br />

long life - speed! And it is precisely this<br />

combination which gives our business partners<br />

a direct competitive advantage.<br />

• Premier per<strong>for</strong>mance is only possible through a<br />

total appreciation of the requirements of our<br />

business partners. A per<strong>for</strong>mance achieved<br />

through flexible thinking <strong>and</strong> continuous<br />

dialogue with our customers. A pioneering spirit<br />

<strong>and</strong> a deep underst<strong>and</strong>ing of powder<br />

metallurgy characterize the history of<br />

CERATIZIT. One of the attributes of our<br />

company philosophy is the search <strong>for</strong><br />

perfection: target oriented - sustainably -<br />

passionately!<br />

• Intensive research <strong>and</strong> development activities,<br />

taking into account the precise requirements<br />

<strong>and</strong> working processes of the customer, are<br />

today's investment <strong>for</strong> the solutions of tomorrow<br />

- <strong>and</strong> beyond.<br />

Corporate values<br />

The views <strong>and</strong> focus of our business<br />

partners matter<br />

Innovative <strong>and</strong> flexible<br />

thinking matters<br />

Communication matters<br />

Employee development<br />

matters<br />

Professionalism matters<br />

Our environment<br />

matters<br />

Tailored cutting tool solutions<br />

• Cutting materials, coatings, <strong>inserts</strong>, tooling<br />

systems <strong>and</strong> machining solutions - all this is<br />

included in the cutting tool division at<br />

CERATIZIT.<br />

• Worldwide well-known companies process<br />

advanced materials applying cutting tool<br />

products from CERATIZIT: from the automotive<br />

industry to the aerospace industry, mechanical<br />

engineering <strong>and</strong> tool construction to the oil<br />

industry.<br />

• The basis of these long-term business relations<br />

is the faith of the customers in the extensive<br />

know-how of the carbide specialists.<br />

A2

H<br />

A<br />

C<br />

H<br />

L<br />

R<br />

S<br />

T<br />

V<br />

W<br />

X<br />

Z<br />

A3<br />

A8-A9<br />

A10-A13<br />

A14-A15<br />

A16-A31<br />

A32-A33<br />

A34-A40<br />

A41-A44<br />

B2-B3<br />

B4-B5<br />

B6-B7<br />

B8-B9<br />

B10-B11<br />

D4-D29<br />

D30-D36<br />

D38-D47<br />

D48-D52<br />

D53-D81<br />

D82-D99<br />

E3-E11<br />

E12-E23<br />

E24-E45<br />

E46-E55<br />

E56-E66<br />

E65-E70<br />

E70-E71<br />

E72-E76<br />

E77-E83<br />

E84-E85<br />

C4-C5<br />

C6-C7<br />

C8<br />

C9-C14<br />

C16-C18<br />

C19-C27<br />

C28-C29<br />

C30<br />

C31<br />

C32-C40<br />

C41<br />

C42-C44<br />

C45-C48<br />

Application<br />

<strong>Tools</strong><br />

Introduction<br />

Technical in<strong>for</strong>mation<br />

Inserts<br />

Other systems<br />

Contents

Our facilities <strong>and</strong> production<br />

methods represent state-of-the-art<br />

technology<br />

We have more than 80 years of<br />

experience in the field of powder<br />

metallurgy<br />

Engineering know-how <strong>and</strong> on site<br />

application advice<br />

We promote intensive dialogue<br />

with our business partners<br />

Our quality management systems meet<br />

the highest st<strong>and</strong>ards<br />

A4

www.ceratizit.com<br />

Applications<br />

Contact<br />

One mouse-click will provide you with:<br />

News<br />

> News from the world of powder metallurgy<br />

> Extensive in<strong>for</strong>mation about the CERATIZIT product<br />

range<br />

> St<strong>and</strong>ard <strong>and</strong> special solutions in the field of metal<br />

working<br />

> Clear explanations concerning application <strong>and</strong><br />

materials<br />

> Retrievable product <strong>and</strong> tooling catalogues<br />

> Possibility of direct contact via e-mail worldwide<br />

> Tips <strong>for</strong> application <strong>and</strong> in<strong>for</strong>mation about training<br />

courses<br />

Products<br />

Service<br />

A5

www.ceratizit.com<br />

SPEED<br />

> Configurate over 11,000 products online <strong>and</strong> order immediately<br />

> Immediate order confirmation<br />

> Online check regarding delivery status of product<br />

> Rapid product search via material numbers <strong>and</strong> ISO designations<br />

> Orders placed by 6 p.m. (CET) will be dispatched on the same day<br />

INFORMATION<br />

> Up-to-date CERATIZIT product catalogue including all technical<br />

details <strong>and</strong> graphic illustrations<br />

> Create more than 100,000 tool combinations online<br />

> Accessories <strong>and</strong> tool alternatives<br />

> Well-structured navigation, easy user guidance<br />

SERVICES<br />

> 98 % delivery availability <strong>for</strong> online orders<br />

> Available around the clock<br />

> Direct link to your personal contact person<br />

> 1:1 dxf true-to-scale drawings <strong>for</strong> download<br />

> Service support through the E-SOLUTIONS Centre<br />

> Optimum safety by means of SSL-encoding <strong>and</strong> personal access<br />

authorisation<br />

BUSINESS<br />

> Order online at individual net prices <strong>and</strong> conditions<br />

> Check invoices, consignments <strong>and</strong> payments<br />

> 'Last-minute' changes of open orders possible<br />

> Usage of personal order templates possible<br />

> Check dispatch (Track & Trace)<br />

A6

CERATIZIT WinTool<br />

The electronic tooling catalogue CERATIZIT WinTool is a modern tooling in<strong>for</strong>mation system which<br />

provides additional support <strong>for</strong> you when choosing <strong>and</strong> applying cutting tools.<br />

arguments in favour of WinTool:<br />

Electronic tooling catalogue<br />

> Up-to-date <strong>and</strong> complete data<br />

> Possibility to add personal comments<br />

> Structured data usable in various<br />

applications<br />

Easy to use PC software<br />

> Easy installation<br />

> Minimal training requirements<br />

> Structured user-friendly search <strong>for</strong> tool<br />

data<br />

Extendable<br />

> Integration of customer-specific data<br />

<strong>and</strong> other manufacturer’s data is<br />

possible without problems<br />

Continuous 1:1 graphic<br />

support<br />

> Simple recognition of tool components<br />

> True-to-scale representation of complete<br />

tools<br />

> Attractive design<br />

‘Compact’ - ‘Professional’<br />

versions<br />

'Compact' version:<br />

> Very low acquisition price<br />

Additional features of ‘Professional’<br />

version over 'Compact' version:<br />

> Import of individual component data<br />

> Assembly of more than 20 complete<br />

tools<br />

> Creation of individual tool lists<br />

> Data export<br />

A7

Easy Choice<br />

Selection has never been so easy!<br />

Easy Choice<br />

The <strong>milling</strong> catalogue has been divided into 5 chapters.<br />

A8-A9<br />

The different colours of the navigation bars on the<br />

right-h<strong>and</strong> side of the catalogue make an initial quick<br />

selection to the various chapters.<br />

(See illustration on right-h<strong>and</strong> side)<br />

Tool selection via the chapter ‘Application’<br />

Look <strong>for</strong> the machining method of your choice using the right navigation bar.<br />

Here you can choose the appropriate tooling system.<br />

In horizontal direction you will find the available tools listed according to the application <strong>and</strong> the<br />

associated tooling system.<br />

The tool's basic dimensions <strong>and</strong> a cross-reference to the page containing detailed data<br />

complete the in<strong>for</strong>mation.<br />

A8

Easy Choice<br />

Selection has never been so easy!<br />

Chapter ‘Inserts’<br />

A8-A9<br />

In<strong>for</strong>mation about the application of the tools<br />

<strong>and</strong> <strong>inserts</strong>.<br />

H<br />

Reference to the appropriate <strong>inserts</strong> <strong>and</strong><br />

tools.<br />

A10-A13<br />

Cutting materials, colour codes:<br />

Uncoated carbide<br />

Coated carbide<br />

A14-A15<br />

Cermet<br />

CBN, PCD<br />

A16-A31<br />

A32-A33<br />

Chapter ‘<strong>Tools</strong>’<br />

Chapter ‘Technical in<strong>for</strong>mation’<br />

A34-A40<br />

A41-A44<br />

A9

CERATIZIT designation system<br />

Milling tools<br />

C<br />

270 = face <strong>milling</strong> cutters<br />

272 = chamfering cutters<br />

251 = button insert cutters<br />

Shoulder/slot cutters<br />

A10-A11<br />

260 = cassette cutters<br />

211 = shoulder/slot cutters<br />

H<br />

A12-A13<br />

Metric measuring<br />

system<br />

G<br />

M<br />

A<br />

210 = shoulder/slot cutters<br />

141 = shoulder/slot cutters<br />

241 = shoulder/slot cutters<br />

490 = shoulder/slot cutters<br />

BF = drill <strong>and</strong> slot cutters<br />

212 = drill <strong>and</strong> slot cutters<br />

244 = long edge cutters<br />

HSC= high-speed cutters<br />

HPC= high-per<strong>for</strong>mance<br />

cutters<br />

HFC = high-feed cutters<br />

Face <strong>milling</strong> cutters<br />

Button insert cutters<br />

Cassette cutters<br />

KF<br />

NF<br />

ZF<br />

= ball nose cutters<br />

= T-slot cutters<br />

= circlip groove cutters<br />

Connection/<br />

interface<br />

HEC= high-efficiency cutters<br />

System<br />

Diameter<br />

Cutting<br />

direction<br />

Diameter<br />

US / Imperial<br />

measuring system<br />

d 1<br />

=<br />

.<br />

063 = 5 / 8 "<br />

.<br />

100 = 1"<br />

.<br />

125 = 1 1 / 4 "<br />

.<br />

250 = 2 1 / 2 "<br />

350 = 3 1 / 2 "<br />

500 = 5"<br />

.<br />

inch<br />

1000 = 10"<br />

A10

CERATIZIT designation system<br />

Milling tools<br />

01<br />

02<br />

A T/V C/S H L R W O<br />

A<br />

d A<br />

= d 1<br />

l 2<br />

[mm]<br />

l 1<br />

[mm]<br />

03<br />

04<br />

05<br />

06<br />

07<br />

08<br />

10<br />

11<br />

12<br />

14<br />

17<br />

18<br />

22<br />

(05)<br />

(08)<br />

Effective<br />

number of<br />

edges<br />

d[mm] A T/VC/S H L R W O<br />

5,00 - - - - - 05 - -<br />

5,56 - 09 05 - 08 - 03 -<br />

6,00 - - - - - 06 - -<br />

6,35 - 11 06 03 10 - 04 02<br />

6,65 10 - - - - - - -<br />

7,94 - - 07 - - - - -<br />

8,00 - - - - - 08 - -<br />

9,00 - - - - 12 - - -<br />

9,52 - 16 09 05 15 - 06 04<br />

9,57 15 - - - - - - -<br />

10,00 - - - - - 10 - -<br />

12,00 - - - - - 12 - -<br />

12,70 22 12 07 20 08 05<br />

15,87 27 15 09 10 06<br />

16,00 16<br />

16,74 16<br />

19,05 33 19 11 13 07<br />

20,00 20<br />

Cutting edge<br />

length<br />

Insert shape<br />

A20<br />

d A<br />

= 20 mm<br />

B<br />

d A<br />

= d 1<br />

20 mm<br />

B25<br />

d A<br />

= 25 mm<br />

25<br />

mm<br />

H63A<br />

Details<br />

connection<br />

/ interface Working length<br />

Overall length<br />

A8-A9<br />

A10-A13<br />

A14-A15<br />

A16-A31<br />

H<br />

A32-A33<br />

Cutting edge length connection /<br />

interface<br />

Working<br />

length<br />

Combination<br />

metric-inch<br />

A34-A40<br />

A T/V C/S H L R W O<br />

A100<br />

Insert shape<br />

d A<br />

= 1"<br />

mm<br />

Inches<br />

d [inch] A T/V C/S H L R W O<br />

.197 - - - - - 05 - -<br />

7/32 - 09 05 - 08 - 03 -<br />

.236 - - - - - 06 - -<br />

1/4 - 11 06 03 10 - 04 02<br />

.262 10 - - - - - - -<br />

5/16 - - 07 - - - - -<br />

.315 - - - - - 08 - -<br />

.354 - - - - 12 - - -<br />

3/8 - 16 09 05 15 - 06 04<br />

.377 15 - - - - - - -<br />

.394 - - - - - 10 - -<br />

.472 - - - - - 12 - -<br />

1/2 22 12 07 20 08 05<br />

5/8 27 15 09 10 06<br />

.630 16<br />

.659 16<br />

3/4 33 19 11 13 07<br />

.787 20<br />

A125<br />

d A<br />

= 1 1 / 4 "<br />

B125<br />

d A<br />

= 1 1 / 4 "<br />

H63A<br />

l 2<br />

= inch<br />

100 = 1"<br />

125 = 1 1 / 4 "<br />

150 = 1 1 / 2 "<br />

200 = 2"<br />

250 = 2 1 / 2 "<br />

350 = 3 1 / 2 "<br />

400 = 4"<br />

Inches<br />

Inches<br />

mm<br />

mm<br />

A41-A44<br />

A11

ISO designation system<br />

Inserts<br />

A10-A11<br />

H<br />

A12-A13<br />

Metric measuring<br />

system<br />

A 85°<br />

B 82°<br />

K 55°<br />

H 120°<br />

L 90°<br />

O 135°<br />

P 108°<br />

C 80°<br />

D 55°<br />

E 75°<br />

M 86°<br />

V 35°<br />

R -<br />

S 90°<br />

T 60°<br />

W 80°<br />

X Special shapes<br />

Insert<br />

shape<br />

α<br />

A 3°<br />

B 5°<br />

C 7°<br />

D 15°<br />

E 20°<br />

F 25°<br />

G 30°<br />

N 0°<br />

P 11°<br />

O<br />

Special<br />

version<br />

d<br />

m<br />

d<br />

m<br />

d m s<br />

[±mm] [±mm] [±mm]<br />

A 0,025 0,005 0,025<br />

C 0,025 0,013 0,025<br />

E 0,025 0,025 0,025<br />

F 0,013 0,005 0,025<br />

G 0,025 0,025 0,13<br />

H 0,013 0,013 0,025<br />

0,05 0,005 0,025<br />

J 0,08 0,005 0,025<br />

0,10 0,005 0,025<br />

0,05 0,013 0,025<br />

K 0,08 0,013 0,025<br />

0,10 0,013 0,025<br />

d<br />

m<br />

s<br />

d m s<br />

[±mm] [±mm] [±mm]<br />

0,05 0,08 0,13<br />

M 0,08 0,13 0,13<br />

0,10 0,15 0,13<br />

0,05 0,08 0,025<br />

N 0,08 0,13 0,025<br />

0,10 0,15 0,025<br />

0,08 0,13 0,13<br />

U 0,13 0,20 0,13<br />

0,18 0,27 0,13<br />

d=6,35/9,52<br />

d=12,7<br />

d=15,8/19,05<br />

d=6,35/9,52<br />

d=12,7<br />

d=15,8/19,05<br />

A<br />

F<br />

G<br />

M<br />

N<br />

Q<br />

R<br />

T<br />

U<br />

W<br />

X Special shapes<br />

A T/V C/S H L R W O<br />

Insert shape<br />

d[mm] A T/ C/<br />

V S H L R W O<br />

5,00 - - - - - 05 - -<br />

5,56 - 09 05 - 08 - 03 -<br />

6,00 - - - - - 06 - -<br />

6,35 - 11 06 03 10 - 04 02<br />

6,65 10 - - - - - - -<br />

7,94 - - 07 - - - - -<br />

8,00 - - - - - 08 - -<br />

9,00 - - - - 12 - - -<br />

9,52 - 16 09 05 15 - 06 04<br />

9,57 15 - - - - - - -<br />

10,00 - - - - - 10 - -<br />

12,00 - - - - - 12 - -<br />

12,70 22 12 07 20 08 05<br />

15,87 27 15 09 10 06<br />

16,00 16<br />

16,74 16<br />

19,05 33 19 11 13 07<br />

20,00 20<br />

Clearance<br />

angle Tolerances<br />

Form of top<br />

surface Cutting edge length<br />

Tolerances<br />

Cutting edge length<br />

US / Imperial<br />

measuring system<br />

d<br />

m<br />

d<br />

m<br />

d<br />

±inch<br />

m<br />

±inch<br />

s<br />

±inch<br />

A 0,0010 0,0002 0,001<br />

C 0,0010 0,0005 0,001<br />

E 0,0010 0,0010 0,001<br />

F 0,0005 0,0002 0,001<br />

G 0,0010 0,0010 0,005<br />

H 0,0005 0,0005 0,001<br />

J* 0,002 - 0,006 0,0002 0,001<br />

K* 0,002 - 0,006 0,0005 0,001<br />

L* 0,002 - 0,006 0,0010 0,001<br />

d<br />

m<br />

d= 1 /4, 3 /8<br />

d= 1 /2<br />

d= 5 /8, 3 /4<br />

s<br />

d<br />

±inch<br />

m<br />

±inch<br />

s<br />

±inch<br />

M* 0,002 - 0,006 0,003 - 0,008 0,005<br />

N* 0,002 - 0,006 0,003 - 0,008 0,001<br />

U* 0,003 - 0,010 0,005 - 0,015 0,005<br />

* According to size<br />

d= 1 /4, 3 /8<br />

d= 1 /2<br />

d= 5 /8, 3 /4<br />

A T/V C/S H L R W O<br />

Insert shape<br />

d<br />

[inch] A T/V C/S H L R W O<br />

.197 - - - - - 05 - -<br />

7/32 - 09 05 - 08 - 03 -<br />

.236 - - - - - 06 - -<br />

1<br />

/4 - 11 06 03 10 - 04 02<br />

.262 10 - - - - - - -<br />

.313 - - 07 - - - - -<br />

.315 - - - - - 08 - -<br />

.354 - - - - 12 - - -<br />

3<br />

/8 - 16 09 05 15 - 06 04<br />

.377 15 - - - - - - -<br />

.394 - - - - - 10 - -<br />

.472 - - - - - 12 - -<br />

1<br />

/2 22 12 07 20 08 05<br />

5/8 27 15 09 10 06<br />

.630 16<br />

.659 16<br />

3<br />

/4 33 19 11 13 07<br />

.787 20<br />

A12

ISO designation system<br />

Inserts<br />

r<br />

’ n<br />

Manufacturer<br />

specific detail<br />

s [mm]<br />

01 1,59<br />

T1 1,98<br />

02 2,38<br />

03 3,18<br />

T3 3,97<br />

04 4,76<br />

05 5,56<br />

06 6,35<br />

07 7,94<br />

09 9,52<br />

κ r<br />

A 45°<br />

D 60°<br />

E 75°<br />

F 85°<br />

P 90°<br />

Z Others<br />

M0*<br />

1st sign<br />

Radius<br />

02 0,2<br />

04 0,4<br />

08 0,8<br />

r (mm)<br />

12 1,2<br />

etc.<br />

* Shape R only<br />

α‘ n<br />

A 3°<br />

B 5°<br />

C 7°<br />

D 15°<br />

E 20°<br />

F 25°<br />

G 30°<br />

N 0°<br />

P 11°<br />

Z Others<br />

r<br />

2nd sign<br />

F<br />

Sharp<br />

E<br />

Honed<br />

S<br />

Chamfered <strong>and</strong><br />

honed<br />

T<br />

Chamfered<br />

particularly <strong>for</strong>:<br />

Non ferrous<br />

-27<br />

metals<br />

-29 Steel<br />

-31 Cast iron<br />

-33 Stainless<br />

steels<br />

F50 Fine<br />

M50 Medium<br />

R50 Rough<br />

additional<br />

characteristic:<br />

Polished<br />

P<br />

(Microfinish)<br />

R Rough<br />

M Medium<br />

A8-A9<br />

A10-A13<br />

A14-A15<br />

H<br />

Insert thickness<br />

Facet<br />

corner radius<br />

Cutting edge<br />

Cutting<br />

direction<br />

F<br />

Fine<br />

Chip groove<br />

A16-A31<br />

A32-A33<br />

Insert thickness<br />

A34-A40<br />

A41-A44<br />

s [inch]<br />

01 1<br />

/16<br />

T1 5<br />

/64<br />

02 3<br />

/32<br />

03 1<br />

/8<br />

T3 5<br />

/32<br />

04 3<br />

/16<br />

05 7/32<br />

06 1<br />

/4<br />

07 5<br />

/16<br />

09 3<br />

/2 Pt<br />

A13

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0 2 4 6 8 10<br />

MasterGuide<br />

Material<br />

A14-A15<br />

A16-A19<br />

Based on VDI 3323 CERATIZIT's MasterGuide divides<br />

materials into six main groups.<br />

Each is given a colour, according to the system partly<br />

adopted in ISO 513.<br />

A20-A22<br />

Blue: steel<br />

Machining, cementation,<br />

tempered <strong>and</strong> constructional<br />

steels<br />

Yellow: stainless steel<br />

Ferritic Cr-steels, austenitic<br />

CrNi-steels, martensitic<br />

Cr-steels, duplex steels<br />

Red: cast iron<br />

Cast iron, grey cast iron,<br />

tempered iron, spheroidal<br />

cast iron, CGI, sintered iron<br />

A23-A24<br />

Green: non ferrous metals<br />

<strong>and</strong> non metals<br />

Al wrought <strong>and</strong> Al cast alloys,<br />

copper, copper alloys, non<br />

metal materials<br />

Orange: heat resistant<br />

alloys / titanium<br />

Ni/Co-base alloys, Ti alloys<br />

White: hard materials<br />

Hardened steels (≥ 45 HRC),<br />

chilled castings, hard cast<br />

irons<br />

A25-A26<br />

Machining application type<br />

A27-A28<br />

A29-A30<br />

Each coloured segment is divided into three sections, <strong>and</strong><br />

each section indicates the relevant machining application<br />

type:<br />

A31<br />

R = rough machining<br />

M = medium machining<br />

F = fine machining<br />

A14

MasterGuide<br />

Application<br />

A8-A9<br />

The ideal application area <strong>for</strong> each insert is indicated by a black<br />

square. Extended applications are indicated by an open square.<br />

The CERATIZIT MasterGuide provides you with an easily<br />

underst<strong>and</strong>able structure <strong>for</strong> choosing a product <strong>and</strong> enables<br />

youto reduce grade <strong>and</strong> geometry inventory.<br />

A10-A13<br />

H<br />

Main application<br />

A14-A15<br />

Extended application<br />

A16-A31<br />

The right indexable insert at a glance<br />

A32-A33<br />

A34-A40<br />

A41-A44<br />

Main application:<br />

Medium, finish <strong>and</strong> rough machining of steel.<br />

Extended application:<br />

Medium machining of heat resistant alloys.<br />

Medium, fine <strong>and</strong> rough machining of stainless steels.<br />

A15

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0 2 4 6 8 10<br />

SR226+<br />

SR226+<br />

Grade overview<br />

Wear resistance<br />

10<br />

A14-A15<br />

8<br />

TCM10<br />

CTP1625<br />

6<br />

GM43+<br />

CTP1235<br />

A16-A19<br />

4<br />

S26T<br />

2<br />

SM80<br />

A20-A22<br />

0<br />

0 2 4 6 8 10<br />

Toughness<br />

Wear resistance<br />

10<br />

A23-A24<br />

A25-A26<br />

8<br />

6<br />

TCM10<br />

CTP1625<br />

GM43+<br />

CTC5240<br />

CTC5235<br />

GM246<br />

CTP2235<br />

4<br />

A27-A28<br />

2<br />

0<br />

SM80<br />

0 2 4 6 8 10<br />

Toughness<br />

A29-A30<br />

Wear resistance<br />

10<br />

CTD4205<br />

8<br />

CTN3105<br />

TA201<br />

A31<br />

6<br />

SR216<br />

CTC3215<br />

CTP6215<br />

4<br />

AMZ<br />

2<br />

H216T<br />

CTW4615<br />

0<br />

0 2 4 6 8 10<br />

Toughness<br />

A16

Grade overview<br />

Grade<br />

designation<br />

St<strong>and</strong>ard<br />

designation<br />

Cutting material<br />

Application range<br />

05 15 25 35 45<br />

01 10 20 30 40 50<br />

A R F N S H<br />

AMZ HC-K10 P<br />

○○○●○<br />

CTC3215 HC-K15 C<br />

●<br />

CTC5235 HC-M35 C<br />

○ ●<br />

CTC5240 HC-M40 C<br />

●<br />

CTP1235<br />

CTP1625<br />

HC-P35 P<br />

●<br />

HC-M30 P<br />

○ ○<br />

HC-P25 P<br />

●<br />

HC-M25 P<br />

● ○<br />

HC-K20 P<br />

○<br />

HC-P40 P<br />

○<br />

CTP2235<br />

HC-M40 P<br />

● ○<br />

CTP6215 HC-K15 P<br />

● ●<br />

CTW4615 HW-K15 W<br />

●●<br />

GM246<br />

HC-P40 C<br />

○<br />

HC-M40 C<br />

● ●<br />

HC-P35 C<br />

●<br />

GM43+<br />

HC-M35 C<br />

○ ○<br />

H216T HW-K15 W<br />

●●<br />

S26T HW-P20 W<br />

●○<br />

SM80 PM-HSS H<br />

●● ○○<br />

SR216 HC-K10 C<br />

●<br />

SR226+<br />

HC-P25 C<br />

●<br />

HC-M25 C<br />

○<br />

HC-K20 C<br />

●<br />

Steel<br />

Stainless<br />

Cast iron<br />

Non ferrous metals<br />

Heat resistant<br />

Hard materials<br />

A8-A9<br />

A10-A13<br />

A14-A15<br />

A16-A31<br />

A32-A33<br />

A34-A40<br />

A41-A44<br />

H<br />

01 10 20 30 40 50<br />

05 15 25 35 45<br />

Main application<br />

Extended application<br />

A17

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0 2 4 6 8 10<br />

Grade overview<br />

A14-A15<br />

A16-A19<br />

A20-A22<br />

Grade<br />

designation<br />

TCM10<br />

TSC30<br />

St<strong>and</strong>ard<br />

designation<br />

Cutting material<br />

Application range<br />

05 15 25 35 45<br />

01 10 20 30 40 50<br />

HT-P15 T<br />

●<br />

HT-M10 T<br />

●<br />

HT-K10 T<br />

○<br />

A R F N S H<br />

HC-P35 P<br />

●<br />

HC-M35 P<br />

● ●<br />

HC-K30 P<br />

○○<br />

TSM30 HW-K30 W<br />

○●○<br />

Steel<br />

Stainless<br />

Cast iron<br />

Non ferrous metals<br />

Heat resistant<br />

Hard materials<br />

01 10 20 30 40 50<br />

05 15 25 35 45<br />

Main application<br />

Extended application<br />

A23-A24<br />

A25-A26<br />

A27-A28<br />

A29-A30<br />

A31<br />

A18

Grade overview<br />

Grade<br />

designation<br />

St<strong>and</strong>ard<br />

designation<br />

Cutting material<br />

Application range<br />

0 05 10 15 20 25<br />

0 05 10 15 20 25<br />

A R F N S H<br />

CTD4205 DP-K01 D<br />

●<br />

TA201 BN-K10 B<br />

○ ○ ●<br />

CTN3105 K05 N<br />

●<br />

Steel<br />

Stainless<br />

Cast iron<br />

Non ferrous metals<br />

Main application<br />

Extended application<br />

Heat resistant<br />

Hard materials<br />

A8-A9<br />

A10-A13<br />

H<br />

A14-A15<br />

A16-A31<br />

A32-A33<br />

A34-A40<br />

A41-A44<br />

A19

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0 2 4 6 8 10<br />

A14-A15<br />

CTP1235<br />

HC-P35<br />

HC-M30<br />

Grade description<br />

Steel<br />

Composition:<br />

Co 9.0%; composite carbides 4.0%; WC rest<br />

Grain size:<br />

1-1.5 µm<br />

Hardness:<br />

HV 1510<br />

A16-A19<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

PVD<br />

(Ti,Al)N + TiN; 4 µm<br />

A20-A22<br />

.<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A23-A24<br />

A25-A26<br />

CTP1625<br />

HC-P25<br />

HC-M25<br />

HC-K20<br />

Composition:<br />

Co 9.5%; composite carbides 20.6%; WC<br />

rest<br />

Grain size:<br />

1.5 µm<br />

Hardness:<br />

HV 1550<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

PVD<br />

TiN + TiAlN + TiN; 3-4 µm<br />

A27-A28<br />

Carbide grade <strong>for</strong> <strong>milling</strong><br />

with side <strong>and</strong> face <strong>milling</strong><br />

cutters<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A29-A30<br />

GM43+<br />

HC-P35<br />

HC-M35<br />

Composition:<br />

Co 9.0%; composite carbides 4.0%; WC rest<br />

Grain size:<br />

1 - 1.5 µm<br />

A31<br />

Hardness:<br />

HV 1510<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

CVD<br />

TiN + Ti(C,N) + TiC; 3 µm<br />

.<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A20

SR226+<br />

HC-P25<br />

HC-M25<br />

HC-K20<br />

Grade description<br />

Steel<br />

Composition:<br />

Co 9.0%; composite carbides 4.0%; WC rest<br />

Grain size:<br />

1 - 1.5 µm<br />

A8-A9<br />

Hardness:<br />

HV 1510<br />

H<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

CVD<br />

AI 2<br />

O 3<br />

+ TiN + Ti (C,N); 5,5 µm<br />

A10-A13<br />

.<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A14-A15<br />

S26T<br />

HW-P20<br />

Composition:<br />

Co 9.5%; composite carbides 20.6%; WC<br />

rest<br />

Grain size:<br />

1.5 µm<br />

Hardness:<br />

HV 1550<br />

A16-A31<br />

A32-A33<br />

Toughness<br />

0 2 4 6 8 10<br />

.<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A34-A40<br />

SM80<br />

PM-HSS<br />

Composition:<br />

Sintered HSS<br />

Grain size:<br />

5 µm<br />

Hardness:<br />

HV 800<br />

A41-A44<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

PVD<br />

(Ti, Al)N-TiN; 3-4 µm<br />

HSS, coated<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A21

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0 2 4 6 8 10<br />

A14-A15<br />

TCM10<br />

HT-P15<br />

HT-M10<br />

HT-K10<br />

Grade description<br />

Steel<br />

Composition: cermet<br />

Co/Ni 8.0%; WC 16.0%; TaNbC 10.0%; TiCN<br />

rest<br />

Hardness:<br />

HV 1780<br />

A16-A19<br />

Toughness<br />

0 2 4 6 8 10<br />

A20-A22<br />

.<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A23-A24<br />

TSC30<br />

HC-P35<br />

HC-M35<br />

HC-K30<br />

Composition:<br />

Co 10.0%; WC rest<br />

Grain size:<br />

0.7 µm<br />

A25-A26<br />

Toughness<br />

0 2 4 6 8 10<br />

Hardness:<br />

HV 1550<br />

Coating specification:<br />

PVD<br />

TiAlN + Ti (C,N); 4-8 μm<br />

A27-A28<br />

Special grade <strong>for</strong> solid<br />

carbide <strong>milling</strong> cutters<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A29-A30<br />

A31<br />

A22

Grade description<br />

Stainless steel<br />

CTP2235<br />

HC-P40<br />

HC-M40<br />

Composition:<br />

Co 12.5%; composite carbides 2.0%; WC<br />

rest<br />

Grain size:<br />

1 µm<br />

A8-A9<br />

Hardness:<br />

HV 1380<br />

H<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

PVD<br />

(TiAl)N; 4 µm<br />

A10-A13<br />

.<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A14-A15<br />

GM246<br />

HC-P40<br />

HC-M40<br />

Composition:<br />

Co 8.0%; WC rest<br />

Grain size:<br />

2 µm<br />

A16-A31<br />

Toughness<br />

0 2 4 6 8 10<br />

Hardness:<br />

HV 1280<br />

Coating specification:<br />

CVD<br />

TiN + Ti(C,N) + TiC; 3 µm<br />

A32-A33<br />

.<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A34-A40<br />

SM80<br />

PM-HSS<br />

Composition:<br />

Sintered HSS<br />

Grain size:<br />

5 µm<br />

Hardness:<br />

HV 800<br />

A41-A44<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

PVD<br />

(Ti, Al)N-TiN; 3-4 µm<br />

HSS, coated<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A23

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0 2 4 6 8 10<br />

A14-A15<br />

TCM10<br />

HT-P15<br />

HT-M10<br />

HT-K10<br />

Grade description<br />

Stainless steel<br />

Composition: cermet<br />

Co/Ni 8.0%; WC 16.0%; TaNbC 10.0%; TiCN<br />

rest<br />

Hardness:<br />

HV 1780<br />

A16-A19<br />

Toughness<br />

0 2 4 6 8 10<br />

A20-A22<br />

.<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A23-A24<br />

TSC30<br />

HC-P35<br />

HC-M35<br />

HC-K30<br />

Composition:<br />

Co 10.0%; WC rest<br />

Grain size:<br />

0.7 µm<br />

A25-A26<br />

Toughness<br />

0 2 4 6 8 10<br />

Hardness:<br />

HV 1550<br />

Coating specification:<br />

PVD<br />

TiAlN + Ti (C,N); 4-8 μm<br />

A27-A28<br />

Special grade <strong>for</strong> solid<br />

carbide <strong>milling</strong> cutters<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A29-A30<br />

A31<br />

CTP1625<br />

HC-P25<br />

HC-M25<br />

HC-K20<br />

Composition:<br />

Co 9.5%; composite carbides 20.6%; WC<br />

rest<br />

Grain size:<br />

1.5 µm<br />

Hardness:<br />

HV 1550<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

PVD<br />

TiN + TiAlN + TiN; 3-4 µm<br />

Carbide grade <strong>for</strong> <strong>milling</strong><br />

with side <strong>and</strong> face <strong>milling</strong><br />

cutters<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A24

Grade description<br />

Cast iron<br />

CTC3215<br />

HC-K15<br />

Composition:<br />

Co 6.0%; composite carbides 2.0%; WC rest<br />

Grain size:<br />

1 µm<br />

A8-A9<br />

Hardness:<br />

HV 1630<br />

H<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

CVD<br />

Ti(C,N) + AI 2<br />

O 3<br />

; 5 µm<br />

A10-A13<br />

Special grade <strong>for</strong> the<br />

machining of cast iron<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A14-A15<br />

CTW4615<br />

HW-K15<br />

Composition:<br />

Co 6%; WC rest<br />

Grain size:<br />

1 µm<br />

A16-A31<br />

Hardness:<br />

HV 1630<br />

A32-A33<br />

Toughness<br />

0 2 4 6 8 10<br />

Precision manufactured<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A34-A40<br />

H216T<br />

HW-K15<br />

Composition:<br />

Co 6.0%; WC rest<br />

A41-A44<br />

Grain size:<br />

1 µm<br />

Hardness:<br />

HV 1630<br />

Toughness<br />

0 2 4 6 8 10<br />

Microfinish<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A25

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0 2 4 6 8 10<br />

Grade description<br />

Cast iron<br />

SR216<br />

HC-K10<br />

Composition:<br />

Co 6.0%; WC rest<br />

A14-A15<br />

Grain size:<br />

1 µm<br />

Hardness:<br />

HV 1630<br />

A16-A19<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

CVD<br />

AI 2<br />

O 3<br />

+ Ti(C,N) + Ti(C,N); 5,5 µm<br />

A20-A22<br />

.<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A23-A24<br />

SR226+<br />

HC-P25<br />

HC-M25<br />

HC-K20<br />

Composition:<br />

Co 9.0%; composite carbides 4.0%; WC rest<br />

Grain size:<br />

1 - 1.5 µm<br />

A25-A26<br />

Toughness<br />

0 2 4 6 8 10<br />

Hardness:<br />

HV 1510<br />

Coating specification:<br />

CVD<br />

AI 2<br />

O 3<br />

+ TiN + Ti (C,N); 5,5 µm<br />

A27-A28<br />

.<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A29-A30<br />

A31<br />

CTP6215<br />

HC-K15<br />

Composition:<br />

Co 12%; WC rest<br />

Grain size:<br />

0.4 µm<br />

Hardness:<br />

HV 1730<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

PVD<br />

(TiAl)N; 4 µm<br />

Carbide grade <strong>for</strong> hard<br />

machining<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A26

Grade description<br />

Non ferrous metals <strong>and</strong> non metals<br />

AMZ<br />

HC-K10<br />

Composition:<br />

Co 6.0%; WC rest<br />

Grain size:<br />

1 µm<br />

A8-A9<br />

Hardness:<br />

HV 1630<br />

H<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

PVD<br />

TiAIN; 2 - 4 µm<br />

A10-A13<br />

.<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A14-A15<br />

CTD4205<br />

DP-K01<br />

Composition:<br />

Polycrystalline diamond (PCD)<br />

Grain size:<br />

~ 25 µm<br />

A16-A31<br />

A32-A33<br />

Toughness<br />

0 2 4 6 8 10<br />

PCD <strong>for</strong> <strong>milling</strong> non<br />

ferrous metals, plastics<br />

<strong>and</strong> graphite<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A34-A40<br />

CTW4615<br />

HW-K15<br />

Composition:<br />

Co 6%; WC rest<br />

A41-A44<br />

Grain size:<br />

1 µm<br />

Hardness:<br />

HV 1630<br />

Toughness<br />

0 2 4 6 8 10<br />

Precision manufactured<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A27

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0 2 4 6 8 10<br />

Grade description<br />

Non ferrous metals <strong>and</strong> non metals<br />

H216T<br />

HW-K15<br />

Composition:<br />

Co 6.0%; WC rest<br />

A14-A15<br />

Grain size:<br />

1 µm<br />

Hardness:<br />

HV 1630<br />

A16-A19<br />

Toughness<br />

0 2 4 6 8 10<br />

A20-A22<br />

Microfinish<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A23-A24<br />

TSM30<br />

HW-K30<br />

Composition:<br />

Co 10.0%; WC rest<br />

Grain size:<br />

0.7 µm<br />

A25-A26<br />

Hardness:<br />

HV 1550<br />

Toughness<br />

0 2 4 6 8 10<br />

A27-A28<br />

Special grade <strong>for</strong> solid<br />

carbide <strong>milling</strong> cutters<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A29-A30<br />

A31<br />

A28

Grade description<br />

Heat resistant alloys / titanium<br />

CTC5235<br />

HC-M35<br />

Composition:<br />

10.0% binder; WC rest<br />

Grain size:<br />

2 µm<br />

A8-A9<br />

Hardness:<br />

HV 1330<br />

H<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

CVD<br />

TiN-Ti (C,N); AI 2<br />

O 3<br />

; Ti (N,B); 6 µm<br />

A10-A13<br />

Carbide grade <strong>for</strong> <strong>milling</strong><br />

heat-resistant alloys (e.g.<br />

turbine blades etc.)<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A14-A15<br />

CTC5240<br />

HC-M40<br />

Composition:<br />

10.0% binder; WC rest<br />

Grain size:<br />

2 µm<br />

A16-A31<br />

Toughness<br />

0 2 4 6 8 10<br />

Hardness:<br />

HV 1330<br />

Coating specification:<br />

CVD<br />

TiN + TiB 2<br />

; 4 µm<br />

A32-A33<br />

Carbide grade <strong>for</strong> <strong>milling</strong><br />

titanium alloys<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A34-A40<br />

GM246<br />

HC-P40<br />

HC-M40<br />

Composition:<br />

Co 8.0%; WC rest<br />

Grain size:<br />

2 µm<br />

A41-A44<br />

Hardness:<br />

HV 1280<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

CVD<br />

TiN + Ti(C,N) + TiC; 3 µm<br />

.<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A29

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0 2 4 6 8 10<br />

A14-A15<br />

TSC30<br />

HC-P35<br />

HC-M35<br />

HC-K30<br />

Grade description<br />

Heat resistant alloys / titanium<br />

Composition:<br />

Co 10.0%; WC rest<br />

Grain size:<br />

0.7 µm<br />

Hardness:<br />

HV 1550<br />

A16-A19<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

PVD<br />

TiAlN + Ti (C,N); 4-8 μm<br />

A20-A22<br />

Special grade <strong>for</strong> solid<br />

carbide <strong>milling</strong> cutters<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A23-A24<br />

A25-A26<br />

A27-A28<br />

A29-A30<br />

A31<br />

A30

Grade description<br />

Hard materials<br />

CTP6215<br />

HC-K15<br />

Composition:<br />

Co 12%; WC rest<br />

Grain size:<br />

0.4 µm<br />

A8-A9<br />

Hardness:<br />

HV 1730<br />

H<br />

Toughness<br />

0 2 4 6 8 10<br />

Coating specification:<br />

PVD<br />

(TiAl)N; 4 µm<br />

A10-A13<br />

Carbide grade <strong>for</strong> hard<br />

machining<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A14-A15<br />

TA201<br />

BN-K10<br />

Composition:<br />

Cubic boron nitride (CBN), 65 vol.% + binder<br />

(TiN)<br />

A16-A31<br />

Grain size:<br />

~ 2 µm<br />

Insert type:<br />

Brazed segment<br />

A32-A33<br />

Toughness<br />

0 2 4 6 8 10<br />

Particularly suitable <strong>for</strong><br />

hard materials.<br />

Wear resistance<br />

0 2 4 6 8 10<br />

Wet / dry:<br />

A34-A40<br />

A41-A44<br />

A31

Chip grooves<br />

Chip grooves<br />

A32-A33<br />

F..<br />

Application<br />

27P/F20 Non ferrous metals, aluminium alloys<br />

F40 Titanium alloys<br />

F50<br />

- Stainless steels<br />

- Nickel based super alloys<br />

- Long chipping, tough materials<br />

- Finishing of steel<br />

γ = 12-30°<br />

33<br />

- Stainless steels,<br />

- Resistant to notching<br />

M..<br />

M31 Turbine blade machining<br />

M50<br />

- Mainly steel<br />

- Machining of stainless steels where higher stability is<br />

required<br />

- Cast iron in general<br />

γ = 10-18°<br />

29/29M<br />

- Steel<br />

- Stable cutting edges<br />

R..<br />

R50<br />

- Steel, stainless steel, cast iron machining where very<br />

high stability is required<br />

- Burnished edge, cast skins<br />

- Chromium based super alloys<br />

- Short chipping materials<br />

R60 Hardened materials up to .... ~60 HRC<br />

γ = 0-12°<br />

31<br />

- Grey cast iron, spheroidal cast iron, tempered iron<br />

- Very good chip evacuation<br />

Additional insert geometries<br />

- FN steel (e.g. SM80)<br />

- TR finishing (e.g. TA201)<br />

- EN, FN, SN withoug chip groove ...(all grades)<br />

A32

Chip grooves<br />

fine<br />

Geometry<br />

medium<br />

rough<br />

0 10 20 30 40 50 60 70 80 90 100<br />

A8-A9<br />

sharp<br />

27P<br />

increasing chamfer width<br />

(stable cutting edges)<br />

H<br />

F20<br />

F40<br />

A10-A13<br />

F50<br />

33<br />

A14-A15<br />

29M<br />

M31<br />

A16-A31<br />

29<br />

M50<br />

A32-A33<br />

31<br />

A34-A40<br />

R50<br />

R60<br />

A41-A44<br />

decreasing rake angle (soft cutting action)<br />

robust<br />

New chip grooves<br />

A33

MaxiMill system<br />

Tooling<br />

systems<br />

A34-A40<br />

MaxiMill 270<br />

● Maximal chip volume<br />

● 45° approach angle<br />

● Soft cutting action<br />

1 Face <strong>milling</strong><br />

2 Angled ramping<br />

3 Helical plunge <strong>milling</strong><br />

4 Slot <strong>milling</strong><br />

5 Chamfering<br />

wide<br />

normal<br />

09 12 15<br />

close<br />

Milling cutters Ø 6-160 mm<br />

MaxiMill 260<br />

● Universal application<br />

● Adjustable wiper edges<br />

● Long tool life<br />

1 Peripheral <strong>milling</strong><br />

2 Face <strong>milling</strong><br />

3 Slot <strong>milling</strong><br />

4 Shoulder <strong>milling</strong><br />

Milling cutters Ø 80-400 mm<br />

> 100 combinations<br />

A34

MaxiMill system<br />

MaxiMill 251<br />

● Very high feed rates<br />

● Maximum stability<br />

● 8 indexes<br />

A8-A9<br />

1 Slot <strong>milling</strong><br />

2 Profile <strong>milling</strong><br />

3 Plunging<br />

4 Angled ramping<br />

5 Turn <strong>milling</strong><br />

6 Face <strong>milling</strong><br />

7 Reverse copy <strong>milling</strong><br />

A10-A13<br />

A14-A15<br />

H<br />

normal<br />

A16-A31<br />

close<br />

Milling cutters Ø 10-125 mm<br />

A32-A33<br />

MaxiMill 490<br />

● 4 cutting edges<br />

● Optimum price-per<strong>for</strong>mance ratio<br />

● 90° approach angle<br />

A34-A40<br />

1 Face <strong>milling</strong><br />

2 Slot <strong>milling</strong><br />

3 Shoulder <strong>milling</strong><br />

A41-A44<br />

normal<br />

09 12<br />

close<br />

Milling cutters Ø 25-125 mm<br />

A35

MaxiMill system<br />

Tooling<br />

systems<br />

A34-A40<br />

MaxiMill HFC<br />

● Extreme feed rates<br />

● Soft cutting with chip groove<br />

M50<br />

● HyperCoat <strong>inserts</strong><br />

1 Face <strong>milling</strong><br />

2 Angled ramping<br />

3 Plunging<br />

normal<br />

09 12<br />

close<br />

Milling cutters Ø 25-100 mm<br />

MaxiMill HEC-11<br />

● 8 usable cutting edges<br />

● Low cutting <strong>for</strong>ces<br />

● High process security<br />

1 Face <strong>milling</strong><br />

One insert with three cutting materials:<br />

ceramic, CBN, hard materials<br />

Milling cutters Ø 50-125 mm<br />

A36

MaxiMill system<br />

MaxiMill HSV-22<br />

● Stable <strong>and</strong> secure<br />

● Robust insert<br />

A8-A9<br />

1 Face <strong>milling</strong><br />

2 Slot <strong>milling</strong><br />

A10-A13<br />

H<br />

A14-A15<br />

A16-A31<br />

Monobloc shell <strong>milling</strong> cutters<br />

HSK63A<br />

Milling cutters Ø 50-125 mm<br />

A32-A33<br />

MaxiMill HPC-12<br />

● High productivity matters<br />

● Low cutting <strong>for</strong>ces<br />

● Easy radial precision adjustment<br />

A34-A40<br />

1 Face <strong>milling</strong><br />

2 Slot <strong>milling</strong><br />

3 Shoulder <strong>milling</strong><br />

A41-A44<br />

Semi-finishing <strong>and</strong> finishing of aluminium<br />

components,<br />

finishing of cast iron components<br />

Milling cutters Ø 40-315 mm<br />

A37

MaxiMill system<br />

Tooling<br />

systems<br />

A34-A40<br />

MaxiMill 211<br />

● Milling with radial <strong>for</strong>ce compensation<br />

● Minimum vibration<br />

● Maximum chip removal rates<br />

1 Peripheral <strong>milling</strong><br />

2 Shoulder <strong>milling</strong><br />

3 Angled ramping & pocket <strong>milling</strong><br />

4 Axial plunging & helical plunging<br />

5 Trochoidal slot <strong>milling</strong><br />

6 Slot <strong>milling</strong><br />

7 Shoulder & face <strong>milling</strong><br />

wide<br />

normal<br />

07 11 15<br />

close<br />

Milling cutters Ø 10-160 mm<br />

MaxiMill HSC/HPC<br />

● Aluminium <strong>milling</strong> at high speed<br />

● Maximum chip removal rates<br />

1 Peripheral <strong>milling</strong><br />

2 Shoulder <strong>milling</strong><br />

3 Angled ramping<br />

4 Axial plunging & helical plunge<br />

<strong>milling</strong><br />

5 Pocket <strong>milling</strong><br />

6 Slot <strong>milling</strong><br />

7 Shoulder & face <strong>milling</strong><br />

XDHT-11<br />

XDKT-11<br />

XDHT-19<br />

XDHX-19<br />

normal<br />

close<br />

Milling cutters<br />

Ø 16-100 mm<br />

A38

HeliMax system & side <strong>and</strong> face <strong>milling</strong> cutters<br />

HeliMax<br />

● The ideal extension <strong>for</strong> the MaxiMill systems<br />

● Also <strong>for</strong> HSC applications on aluminium<br />

A8-A9<br />

1 Shoulder <strong>milling</strong><br />

2 Drilling<br />

3 Helical plunge <strong>milling</strong><br />

4 Pofile <strong>milling</strong><br />

5 Slot <strong>milling</strong><br />

6 Peripheral <strong>milling</strong><br />

A10-A13<br />

H<br />

A14-A15<br />

A16-A31<br />

Milling cutters Ø 2-40 mm<br />

Number of teeth 2-8<br />

A32-A33<br />

Side <strong>and</strong> face <strong>milling</strong> cutter 90LN/90CN<br />

● With HyperCoat insert CTP1625<br />

● High stability thanks to tangential<br />

<strong>inserts</strong><br />

● Variable cutting width adaptation<br />

1 Slot <strong>milling</strong>, gang cutting<br />

2 Shoulder <strong>milling</strong><br />

3 Deep slotting<br />

4 Counterboring<br />

5 Backface <strong>milling</strong><br />

A34-A40<br />

A41-A44<br />

Milling cutters Ø 80-200 mm<br />

Cutting width 6-9 mm <strong>and</strong> 14-22 mm<br />

A39

MaxiMill profile <strong>milling</strong> cutter system<br />

Tooling<br />

systems<br />

A34-A40<br />

Profile <strong>milling</strong> cutters<br />

● Always a solution <strong>for</strong> specific machining<br />

tasks<br />

A41<br />

1 Groove <strong>milling</strong> (circlip)<br />

2 T-slot <strong>milling</strong><br />

3 Chamfering<br />

4 Profile <strong>milling</strong><br />

A42<br />

A43<br />

A44<br />

A40

CERATIZIT specialist solutions<br />

Automotive<br />

OvalFlex<br />

A8-A9<br />

H<br />

Programme see special<br />

catalogue<br />

'OvalFlex - the oval allrounder<br />

<strong>for</strong> aluminium wheel<br />

machining', no. 391<br />

A10-A13<br />

A14-A15<br />

A16-A31<br />

MaxiMill HPC-12<br />

Programme see special catalogue<br />

'HPC machining with PCD - MaxiMill HPC12 <strong>and</strong><br />

HSV22', no. 283<br />

A32-A33<br />

MaxiMill HEC-11<br />

See CERATIZIT News<br />

'MaxiMill HEC 11', no. 435<br />

A34-A40<br />

A41-A44<br />

Ceramic<br />

Programme see special catalogue<br />

'SiniCut CTN3105', no. 271<br />

A41

CERATIZIT specialist solutions<br />

Mechanical engineering<br />

A41<br />

Bearing industry<br />

A42<br />

A43<br />

Programme see special<br />

catalogue<br />

'CombiEdge', no. 406<br />

A44<br />

Bar pealing & roll machining<br />

Programme see special catalogue<br />

'<strong>Tools</strong> <strong>and</strong> indexable <strong>inserts</strong><br />

<strong>for</strong> bar peeling', no. 174<br />

'Roll machining made easy with<br />

one source <strong>for</strong> all your tooling<br />

needs', no. 274<br />

Heavy machining<br />

Programme see special catalogue<br />

’<strong>Tools</strong> <strong>and</strong> <strong>inserts</strong> <strong>for</strong><br />

roll machining’, no. 442<br />

New:<br />

MaxiMill HDM<br />

A42

CERATIZIT specialist solutions<br />

Energy <strong>and</strong> transport<br />

MaxiMill<br />

HSC/HPC<br />

MaxiMill<br />

AirFoil Cutter<br />

A8-A9<br />

H<br />

Programme see special catalogue<br />

'HSC-11 <strong>milling</strong> tools <strong>for</strong> aluminium<br />

machining', no. 229<br />

A10-A13<br />

Titanium machining<br />

A14-A15<br />

Turbine machining<br />

A16-A31<br />

A32-A33<br />

A34-A40<br />

Programme see special catalogue<br />

'Wheel set machining' no. 152<br />

A41-A44<br />

Wheel set machining<br />

A43

CERATIZIT specialist solutions<br />

Oil industry<br />

A41<br />

A42<br />

Programme see special catalogue<br />

'<strong>Tools</strong> <strong>and</strong> <strong>inserts</strong> <strong>for</strong> tube manufacturing',<br />

no. 130<br />

A43<br />

A44<br />

A44

A8-A9<br />

H<br />

A10-A13<br />

A14-A15<br />

A16-A31<br />

A32-A33<br />

A34-A40<br />

A41-A44<br />

A45

Application<br />

Face <strong>milling</strong><br />

45°<br />

C270-09<br />

C251-05<br />

C251-08<br />

C251-10<br />

a p<br />

≤ 4 ma<br />

a p<br />

≤ 2,5 mm<br />

a p<br />

≤ 4 mm<br />

a p<br />

≤ 5 mm<br />

Ø = 6 - 32 mm D4 Ø = 10 - 20 mm D6 Ø = 16 - 32 mm D7 Ø = 20 - 32 mm D9<br />

G251-08<br />

G251-10<br />

90° G490-09<br />

90° GHFC-09/-12<br />

a p<br />

≤ 4 ma<br />

a p<br />

≤ 5 mm<br />

a p<br />

≤ 8 mm<br />

a p<br />

≤ 1-2 mm<br />

Ø = 16 mm D38 Ø = 20 - 42 mm D39 Ø = 25 - 32 mm D41 Ø = 25 - 35 mm D10<br />

90° MHPC-12<br />

a p<br />

≤ 3-11 mm<br />

Ø = 40 - 160 mm D51<br />

45°<br />

A270-09/<br />

-12/-15<br />

90° AHPC-12<br />

90° AHEC-11<br />

90° A490-09/-12<br />

a p<br />

≤ 4-9 mi<br />

a p<br />

≤ 3-11 mm<br />

a p<br />

≤ 3 - 5 mm<br />

a p<br />

≤ 8-10 mm<br />

Ø = 32 - 160 mm D53 Ø = 40 - 315 mm D76 Ø = 50 - 160 mm D62 Ø = 40 - 125 mm D64<br />

45°<br />

A260/041<br />

A260/031<br />

45°<br />

A260/029<br />

45°<br />

A260/032<br />

75° A260/018<br />

a p<br />

≤ 4-6 mi<br />

a p<br />

≤ 6 mm<br />

a p<br />

≤ 9 mm<br />

a p<br />

≤ 9 mm<br />

Ø = 80 - 398 mm D82 Ø = 80 - 398 mm D84 Ø = 75 - 393 mm D85 Ø = 82 - 400 mm D87<br />

B2

Application<br />

Face <strong>milling</strong><br />

90° C490-09<br />

90° CHFC-09/-12<br />

a p<br />

≤ 8 mm<br />

a p<br />

≤ 1-2 mm<br />

B2-B3<br />

Ø = 25 - 32 mm D12 Ø = 25 - 35 mm D10<br />

B4-B5<br />

B6-B7<br />

B8-B9<br />

B10-B11<br />

A251-10/-12/<br />

-16/-20<br />

90° AHFC-09/-12<br />

a p<br />

≤ 5-10 mm<br />

a p<br />

≤ 1-2 mm<br />

Ø = 40 - 125 mm D56-D59 Ø = 32 - 100 mm D10<br />

90° A260/039<br />

A260/055<br />

A260/052<br />

A260/053<br />

60°<br />

A260/023<br />

a p<br />

≤ 8-10 mm<br />

a p<br />

≤ 6 mm<br />

a p<br />

≤ 8 mm<br />

a p<br />

≤ 7 mm<br />

Ø = 89 - 407 mm D92 Ø = 80 - 398 mm D88 Ø = 76 - 394 mm D89 Ø = 82 - 400 mm D86<br />

B3

Application<br />

Shoulder <strong>and</strong> slot <strong>milling</strong><br />

90° C211-07/<br />

-11/-15<br />

90° C210-10<br />

90° C141-15<br />

90° C BF<br />

a p<br />

≤ 7-14 mm<br />

a p<br />

≤ 8 mm<br />

a p<br />

≤ 14 mm<br />

a p<br />

≤ 13 mm<br />

Ø = 10 - 40 mm D14 Ø = 15,7 - 32 mm D17 Ø = 16 - 40 mm D21 Ø = 10 - 20 mm D19<br />

90° E06<br />

90° E110<br />

90° E120<br />

90° E130<br />

a p<br />

≤ 38 mm<br />

a p<br />

≤ 63 mm<br />

a p<br />

≤ 63 mm<br />

a p<br />

≤ 32 mm<br />

Ø = 6 - 20 mm D30 Ø = 2 - 40 mm D31 Ø = 2 - 40 mm D32 Ø = 3 - 20 mm D33<br />

90° G211-07/<br />

-11/-15<br />

90° G210-10<br />

90° GHSC-11<br />

90° GHSC-19<br />

a p<br />

≤ 7-14 mm<br />

a p<br />

≤ 8 mm<br />

a p<br />

≤ 10 mm<br />

a p<br />

≤ 18 mm<br />

Ø = 16 - 40 mm D43 Ø = 16 - 32 mm D17 Ø = 16 - 40 mm D46 Ø = 25 - 40 mm D47<br />

90° MHSC-11<br />

90° MHSC-19<br />

90° MHSV-22<br />

MHPC-19<br />

a p<br />

≤ 10 mm<br />

a p<br />

≤ 18 mm<br />

a p<br />

≤ 5-15 mm<br />

Ø = 25 - 50 mm D48 Ø = 25 - 50 mm D49-D50 Ø = 50 - 125 mm D52<br />

90° A211-07/<br />

90° A210-10<br />

90° A241-15<br />

-11/-15<br />

90° A244<br />

a p<br />

≤ 7-14 mm<br />

a p<br />

≤ 8 mm<br />

a p<br />

≤ 14 mm<br />

a p<br />

≤ 45 mm<br />

Ø = 40 - 160 mm D67 Ø = 40 - 63 mm D70 Ø = 40 - 125 mm D72 Ø = 40 - 63 mm D71<br />

90° A260/054<br />

90° A260/042<br />

90° A260/039<br />

90° A260/051<br />

A260/055<br />

a p<br />

≤ 10 mm<br />

a p<br />

≤ 8 mm<br />

a p<br />

≤ 8-10 mm<br />

a p<br />

≤ 14 mm<br />

Ø = 89 - 407 mm D90 Ø = 89 - 407 mm D91 Ø = 89 - 407 mm D92 Ø = 89 - 407 mm D94<br />

B4

Application<br />

Shoulder <strong>and</strong> slot <strong>milling</strong><br />

90° C212<br />

90° C244<br />

90° CHSC-11/19<br />

CHPC-19<br />

90° C490-09<br />

a p<br />

≤ 19 mm<br />

a p<br />

≤ 55 mm<br />

a p<br />

≤ 10-18 mm<br />

a p<br />

≤ 8 mm<br />

B2-B3<br />

Ø = 20 - 25 mm D18 Ø = 20 - 40 mm D20 Ø = 16 - 32 mm D22-D26 Ø = 25 - 32 mm D12<br />

90° E140<br />

B4-B5<br />

a p<br />

≤ 38 mm<br />

B6-B7<br />

Ø = 6 - 40 mm D34<br />

90° G490-09<br />

a p<br />

≤ 8 mm<br />

B8-B9<br />

Ø = 25 - 32 mm D41<br />

B10-B11<br />

90° A490-09/-12<br />

90° AHSC-11<br />

90° AHSC-19<br />

AHPC-19<br />

90° AHSV-22<br />

a p<br />

≤ 8-10 mm<br />

a p<br />

≤ 10 mm<br />

a p<br />

≤ 18 mm<br />

a p<br />

≤ 5-15 mm<br />

Ø = 40 - 125 mm D64 Ø = 40 - 100 mm D73 Ø = 40 - 100 mm D74-D75 Ø = 50 - 125 mm D78<br />

90° A260/040<br />

90° A260/025<br />

90° A260/026<br />

a p<br />

≤ 14 mm<br />

a p<br />

≤ 18 mm<br />

a p<br />

≤ 18 mm<br />

Ø = 89 - 407 mm D95 Ø = 89 - 407 mm D96 Ø = 89 - 407 mm D97<br />

B5

Application<br />

Slot <strong>milling</strong><br />

90° 90LN<br />

90° 90CN<br />

b = 6-9 mm<br />

b = 14-22 mm<br />

Ø = 80 - 125 mm D80 Ø = 125 - 200 mm D81<br />

B6

Application<br />

Slot <strong>milling</strong><br />

B2-B3<br />

B4-B5<br />

B6-B7<br />

B8-B9<br />

B10-B11<br />

B7

Application<br />

Form <strong>milling</strong><br />

90° CHSC-11/19<br />

CHPC-19<br />

C251-05<br />

C251-08<br />

C251-10<br />

a p<br />

≤ 10-18 mm<br />

a p<br />

≤ 2,5 mm<br />

a p<br />

≤ 4 mm<br />

a p<br />

≤ 5 mm<br />

Ø = 16 - 32 mm D24-D26 Ø = 10 - 20 mm D6 Ø = 16 - 32 mm D7 Ø = 20 - 32 mm D9<br />

90° R112<br />

90° R114<br />

a p<br />

≤ 32 mm<br />

a p<br />

≤ 38 mm<br />

Ø = 2 - 20 mm D35 Ø = 3 - 20 mm D36<br />

90° GHSC-11<br />

90° GHSC-19<br />

G251-08<br />

G251-10<br />

a p<br />

≤ 10 mm<br />

a p<br />

≤ 18 mm<br />

a p<br />

≤ 4 ma<br />

a p<br />

≤ 5 mm<br />

Ø = 16 - 40 mm D46 Ø = 25 - 40 mm D47 Ø = 16 mm D38 Ø = 20 - 42 mm D39<br />

90° MHSC-11<br />

90° MHSC-19<br />

MHPC-19<br />

a p<br />

≤ 10 mm<br />

a p<br />

≤ 18 mm<br />

Ø = 25 - 50 mm D48 Ø = 25 - 50 mm D49-D50<br />

A251-10/-12/<br />

90° AHSC-11<br />

-16/-20<br />

90° AHSC-19<br />

AHPC-19<br />

a p<br />

≤ 5-10 mm<br />

a p<br />

≤ 10 mm<br />

a p<br />

≤ 18 mm<br />

Ø = 40 - 125 mm D57 Ø = 40 - 100 mm D73 Ø = 40 - 100 mm D74-D75<br />

A260/052<br />

A260/053<br />

a p<br />

≤ 6 mm<br />

a p<br />

≤ 8 mm<br />

Ø = 80 - 398 mm D88 Ø = 76 - 394 mm D89<br />

B8

Application<br />

Form <strong>milling</strong><br />

C KF<br />

a p<br />

≤ 16 mm<br />

B2-B3<br />

Ø = 12 - 32 mm D27<br />

B4-B5<br />

B6-B7<br />

B8-B9<br />

B10-B11<br />

B9

Application<br />

Profile <strong>milling</strong><br />

90° C NF<br />

90° C ZF<br />

45°<br />

C272-09<br />

a p<br />

≤ 20 mm<br />

a p<br />

≤ 4,15 mm<br />

a p<br />

≤ 4 mm<br />

Ø = 17,5 - 48 mm D28 Ø = 16 - 25 mm D29 Ø = 6 - 25 mm D5<br />

B10

Application<br />

Profile <strong>milling</strong><br />

B2-B3<br />

B4-B5<br />

B6-B7<br />

B8-B9<br />

B10-B11<br />

B11

Inserts<br />

Overview<br />

A<br />

C<br />

H<br />

L<br />

O<br />

AD..<br />

CN..<br />

HP..<br />

LD..<br />

C4<br />

C6<br />

C8<br />

C9-C11<br />

AP..<br />

CP..<br />

LE..<br />

CERATIZIT<br />

systems<br />

C5<br />

C7<br />

C9<br />

LN..<br />

C12-C13<br />

LP..<br />

C14<br />

AP..<br />

HN..<br />

LD..<br />

OF..<br />

C45<br />

C45<br />

C45<br />

C46<br />

Other<br />

systems<br />

OD..<br />

C42<br />

Finishing<br />

C2

Inserts<br />

Overview<br />

R<br />

S<br />

T<br />

V/W<br />

X<br />

Z<br />

RD..<br />

SC..<br />

TC..<br />

VC..<br />

XD..<br />

ZN..<br />

C16<br />

C19-C24<br />

C28<br />

C30<br />

C32-C38<br />

C41<br />

RP..<br />

SD..<br />

TP..<br />

WP..<br />

XD../XO..<br />

C16-C17<br />

C25<br />

C29<br />

C31<br />

C40<br />

R..<br />

SE..<br />

C18<br />

C26-C27<br />

S..<br />

TN..<br />

C46-C47<br />

C48<br />

SP..<br />

TP..<br />

C47<br />

C48<br />

SP..<br />

XD..<br />

C43<br />

C44<br />

C3

Inserts<br />

Shape A<br />

AD..<br />

C4<br />

AP..<br />

C5<br />

-29<br />

SR226+<br />

CTP1235<br />

GM43+<br />

CTP2235<br />

(l) Type,<br />

d l s l 1<br />

r d 1<br />

α<br />

[mm] description<br />

[mm] [mm] [mm] [mm] [mm] [mm] [°]<br />

15 ADKT 1505PDSR-29 R R R R 9.57 15.20 5.65 1.2 0.80 4.40 15<br />

Steel<br />

Stainless<br />

Cast iron<br />

Non ferrous metals<br />

Heat resistant<br />

Hard materials<br />

Main application<br />

Extended application<br />

RRRr<br />

rrRR<br />

rrrr<br />

International CERATIZIT range, <strong>for</strong> present availability see price list<br />

Ordering example: 10 pieces ADKT 1505PDSR-29 GM43+<br />

E34-E45 A32-A33 A20-A31<br />

A260/040<br />

D95<br />

C4

Inserts<br />

Shape A<br />

A<br />

C4-C5<br />

C<br />

-27P -29 -29M -31 -33 APHW<br />

C6-C7<br />

H<br />

H216T<br />

S26T<br />

AMZ<br />

CTC3215<br />

SR216<br />

SR226+<br />

CTP1235<br />

GM43+<br />

GM246<br />

TCM10<br />

TA201<br />

r Type,<br />

d l s l 1<br />

l 2<br />

d 1<br />

α<br />

[mm] description<br />

[mm] [mm] [mm] [mm] [mm] [mm] [°]<br />

0.20 APHT 100302FR-27P R R 6.65 9.80 3.50 1.7 2.80 11<br />

0.40 APHT 100304FR-27P R R 6.65 9.80 3.50 1.7 2.80 11<br />

0.80 APHT 100308FR-27P R R 6.65 9.80 3.50 1.7 2.80 11<br />

0.80 APHT 100308SR-33 R 6.65 9.80 3.50 1.7 2.80 11<br />

0.80 APHT 100308SR-33P R 6.65 9.80 3.50 1.7 2.80 11<br />

1.20 APHT 100312SR-33 R 6.65 9.80 3.50 2.0 2.80 11<br />

2.00 APHT 100320SR-33 R 6.65 9.80 3.50 1.0 2.80 11<br />

3.20 APHT 100332SR-33 R 6.65 9.80 3.50 2.80 11<br />

0.20 APHW 100302TR R 6.65 10.10 3.50 5.0 2.80 11<br />

0.80 APHW 100308SR R 6.65 10.10 3.50 1.4 2.80 11<br />

0.50 APKT 1003PDSR-29 R R R R 6.65 9.80 3.50 1.0 2.80 11<br />

0.50 APKT 1003PDSR-29M R R R 6.65 9.94 3.80 1.6 2.80 11<br />

0.50 APKT 1003PDSR-31 R R 6.65 9.80 3.50 1.0 2.80 11<br />

Steel R RRR R<br />

Stainless<br />

rrrRR<br />

Cast iron R rRRR rr<br />

Non ferrous metals R R<br />

Heat resistant rr r<br />

Hard materials<br />

Main application<br />

Extended application<br />

International CERATIZIT range, <strong>for</strong> present availability see price list<br />

Ordering example: 10 pieces APHT 100302FR-27P AMZ<br />

R<br />

d<br />

l<br />

l 2<br />

r<br />

CBN<br />

<br />

d 1<br />

s<br />

C8<br />

L<br />

C9-C14<br />

R<br />

C16-C18<br />

S<br />

C19-C27<br />

T<br />

C28-C29<br />

C30<br />

V<br />

W<br />

C31<br />

X<br />

C32-C40<br />

Z<br />

C41<br />

E34-E45 A32-A33 A20-A31 E66<br />

C/G210 C212 C/A244 A210 A260-042<br />

D17+D45 D18 D20+D71 D70 D91<br />

C42-C44<br />

Other<br />

systems<br />

C45-C48<br />

C5

Inserts<br />

Shape C<br />

CN..<br />

C6<br />

CP..<br />

C7<br />

CNHT<br />

CNHW<br />

H216T<br />

CTP1625<br />

(l) Type,<br />

d l s d 1<br />

[mm] description<br />

[mm] [mm] [mm] [mm]<br />

10 CNHT 1005 R R 10.00 10.15 5.40 4.70<br />

10 CNHW 1005 R R 10.00 10.15 5.40 4.70<br />

12 CNHT 1205 R R 10.00 12.90 5.40 4.70<br />

12 CNHW 1205 R R 10.00 12.90 5.40 4.70<br />

R<br />

r<br />

R<br />

R<br />

r<br />

Steel<br />

Stainless<br />

Cast iron<br />

Non ferrous metals<br />

Heat resistant<br />

Hard materials<br />

Main application<br />

Extended application<br />

International CERATIZIT range, <strong>for</strong> present availability see price list<br />

Ordering example: 10 pieces CNHT 1005 CTP1625<br />

E34-E45 A32-A33 A20-A31<br />

CN.. S90CN<br />

D81<br />

C6

Inserts<br />

Shape C<br />

A<br />

C4-C5<br />

C<br />

CPMT<br />

CPMW<br />

C6-C7<br />

H<br />

H216T<br />

S26T<br />

SR216<br />

GM43+<br />

(l) Type,<br />

d l s r d 1<br />

α<br />

[mm] description<br />

[mm] [mm] [mm] [mm] [mm] [°]<br />

06 CPMT 060304EN R 6.35 6.40 3.18 0.40 2.80 11<br />

06 CPMW 060304EN R 6.35 6.40 3.18 0.40 2.80 11<br />

09 CPMT 09T308SN R R 9.52 9.70 3.97 0.80 4.40 11<br />

09 CPMW 09T308EN R R 9.52 9.70 3.97 0.80 4.40 11<br />

Steel R R<br />

Stainless R<br />

Cast iron R R<br />

R<br />

r<br />

Non ferrous metals<br />

Heat resistant<br />

Hard materials<br />

Main application<br />

Extended application<br />

International CERATIZIT range, <strong>for</strong> present availability see price list<br />

d<br />

l<br />

r<br />

<br />

d 1<br />

s<br />

C8<br />

L<br />

C9-C14<br />

R<br />

C16-C18<br />

S<br />

C19-C27<br />

T<br />

Ordering example: 10 pieces CPMT 060304EN GM43+<br />

C28-C29<br />

V<br />

C30<br />

W<br />

C31<br />

X<br />

C32-C40<br />

Z<br />

C41<br />

E34-E45 A32-A33 A20-A31<br />

CP.. C NF<br />

D28<br />

C42-C44<br />

Other<br />

systems<br />

C45-C48<br />

C7

Inserts<br />

Shape H<br />

HP..<br />

C8<br />

LD..<br />

C9-C11<br />

HPEW<br />

LE..<br />

C9<br />

LN..<br />

C12-C13<br />

LP..<br />

H216T<br />

SR216<br />

(l) Type,<br />

d l s r d 1<br />

α<br />

[mm] description<br />

[mm] [mm] [mm] [mm] [mm] [°]<br />

09 HPEW 090408EN R R 15.88 9.17 4.76 0.80 5.50 11<br />

Steel<br />

Stainless<br />

Cast iron<br />

Non ferrous metals<br />

Heat resistant<br />

Hard materials<br />

Main application<br />

Extended application<br />

RR<br />

R<br />

International CERATIZIT range, <strong>for</strong> present availability see price list<br />

Ordering example: 10 pieces HPEW 090408EN H216T<br />

r<br />

d<br />

d 1<br />

<br />

l<br />

s<br />

C14<br />

E34-E45 A32-A33 A20-A31<br />

A260/023<br />

D86<br />

C8

Inserts<br />

Shape L<br />

A<br />

C4-C5<br />

C<br />

-29 LE..-29 LEHW<br />

C6-C7<br />

H<br />

GM43+<br />

(l) Type,<br />

d l s r d 1<br />

α<br />

[mm] description<br />

[mm] [mm] [mm] [mm] [mm] [°]<br />

10 LDHT 100204ER-29 R 6.35 10.00 2.38 0.40 2.80 15<br />

C8<br />

L<br />

08 LEHT 08T104ER-29 R 5.56 8.00 1.98 0.40 2.50 20<br />

08 LEHW 08T104ER R 5.56 8.00 1.98 0.40 2.50 20<br />

Main application<br />

Steel<br />

Stainless<br />

Cast iron<br />

Non ferrous metals<br />

Heat resistant<br />

Hard materials<br />

R<br />

R<br />

Extended application<br />

International CERATIZIT range, <strong>for</strong> present availability see price list<br />

Ordering example: 10 pieces LDHT 100204ER-29 GM43+<br />

r<br />

d<br />

l<br />

r<br />

<br />

d 1<br />

s<br />

C9-C14<br />

R<br />

C16-C18<br />

S<br />

C19-C27<br />

T<br />

C28-C29<br />

V<br />

C30<br />

W<br />

C31<br />

X<br />

C32-C40<br />

Z<br />

C41<br />

E34-E45 A32-A33 A20-A31<br />

C BF<br />

D19<br />

C42-C44<br />

Other<br />

systems<br />

C45-C48<br />

C9

Inserts<br />

Shape L<br />

LD..<br />

C9-C11<br />

LE..<br />

C9<br />

-27P<br />

LN..<br />

C12-C13<br />

LP..<br />

C14<br />

H216T<br />

r Type,<br />

d l s l 1<br />

d 1<br />

α<br />

[mm] description<br />

[mm] [mm] [mm] [mm] [mm] [°]<br />

0.40 LDHT 120404FR-27P R 9.00 12.00 4.00 1.0 3.40 15<br />

0.80 LDHT 120408FR-27P R 9.00 12.00 4.00 1.5 3.40 15<br />

2.50 LDHT 120425FR-27P R 9.00 12.00 4.00 3.40 15<br />

4.00 LDHT 120440FR-27P R 9.00 12.00 4.00 3.40 15<br />

Main application<br />

Steel<br />

Stainless<br />

Cast iron<br />

Non ferrous metals<br />

Heat resistant<br />

Hard materials<br />

R<br />

R<br />

Extended application<br />

International CERATIZIT range, <strong>for</strong> present availability see price list<br />

d<br />

l<br />

r<br />

l 1<br />

<br />

d 1<br />

s<br />

Ordering example: 10 pieces LDHT 120404FR-27P H216T<br />