Founded In 1995

Founded In 1995

Founded In 1995

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

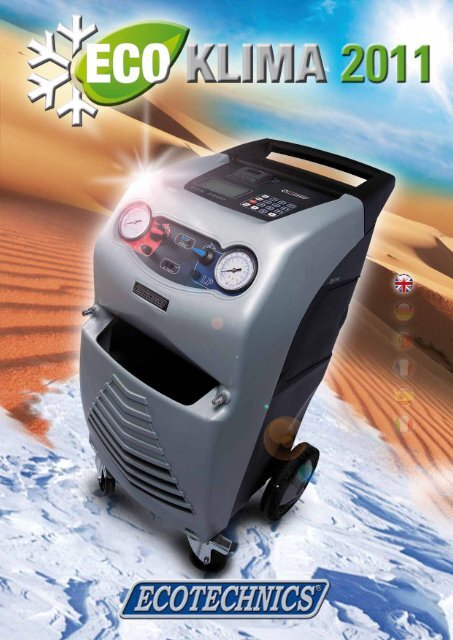

Ecotechnics was founded in <strong>1995</strong> with the aim<br />

of producing technologically advanced systems<br />

for today’s auto repair shop.<br />

Ecotechnics product range is strictly aligned<br />

with new repair shop working philosophy:<br />

less direct intervention on the engine and<br />

better service exploiting with new environment-friendly<br />

processes.<br />

<strong>In</strong> just a few years, Ecotechnics has become a world leader in the airconditioning<br />

sector, boasting technical expertise on developing new<br />

products, new design content, and new-model patents and prototypes<br />

in-house, with spacious showroom and training facilities with practical<br />

test and demonstrations on vehicles.<br />

All this is supported by close ties with various vehicle manufacturers,<br />

whose precious collaboration has helped Ecotechnics to generate ideas<br />

and solutions designed and tailored for the new-generation automobiles<br />

and coordinated with the new working parameters applied in modern<br />

repair shops.<br />

Continuing investment in Research and Development, an efficient production<br />

cycle, a never-ending search for perfection in assembly of its<br />

products, and use of only premier-quality approved components has<br />

made Ecotechnics brand name a byword at the world level.<br />

Another Ecotechnics accent is on Quality Control. All our machines are<br />

rigorously checked by automatic testing programs and specialized test<br />

technicians, who with the aid of sophisticated computerized diagnostic<br />

systems check each single function to verify that each machine is in perfect<br />

operating condition when it leaves the factory.<br />

These are the simple but fundamental parametres on which company<br />

philosophy is based. And it is this philosophy that has made Ecotechnics<br />

a world leader in its sector in such a short time with Ecotechnics products<br />

now distributed in over 50 countries throughout the world.<br />

2

Functions Table<br />

news<br />

HFO1234yf<br />

R134a<br />

ECK2900-HFO<br />

ECK2500-HFO<br />

ECK 3900<br />

ECK 3000-N8<br />

ECK 2900-UP<br />

ECK 2500-UP<br />

ECK 1900<br />

ECK 1500-N8<br />

ECK 1000-UP<br />

ECK 760<br />

ECK BUS-PRO<br />

ECK BUS<br />

Recovery<br />

A A A A A A A A A<br />

Oil discharge<br />

A A A A A A A A A<br />

Vacuum<br />

A A A A A A A A A<br />

Tracer<br />

Oil reintegration<br />

Gas charging<br />

High precision<br />

A* A* A A* – A* – A* A*<br />

A A A A M A M A A<br />

A A A A A A A A A<br />

X X X X – – – – –<br />

Big-screen graphic<br />

display with intuitive<br />

and easy to use icon<br />

interface.<br />

SANI<br />

PATENT PENDING<br />

The first integrated purification<br />

system in an air-conditioning<br />

recharging station. With Saniflux,<br />

the user may set the air treatment<br />

time on the basis of vehicle size.<br />

USB port<br />

Refrigerant<br />

management<br />

Graphic display<br />

Data Base<br />

X X – X X X X X X<br />

X X X X X X X X X<br />

X X X X – – – – –<br />

X X X X X X X X X<br />

Patented hybrid<br />

vehicle function:<br />

the integrated<br />

HYBRID system for<br />

decontamination of<br />

oil residues from other<br />

standard A/C systems permits using<br />

a single station with standard and<br />

hybrid vehicles.<br />

Refrigerant identifier<br />

Dynamic A/C<br />

diagnosis<br />

Static A/C diagnosis<br />

Air purge<br />

Self-diagnosis<br />

Leak check<br />

Filling on-board bottle<br />

Bottle alarm<br />

– – * – – – – – –<br />

– – * * – – – – –<br />

– – – * * * * – –<br />

A A A A M M M A A<br />

– – X – – – – – –<br />

A A A A A/M A/M A/M A A<br />

A A A A A A A A A<br />

X X X X X X X X X<br />

* with transformation kit<br />

“UPgradable” models:<br />

designed to work with<br />

R134a but prepared for<br />

upgrading for use with<br />

the new HFO1234YF<br />

refrigerant.*<br />

NEW<br />

HERMETICALLY-<br />

SEALED<br />

CARTRIDGES<br />

for new oil:<br />

➜ Protection against<br />

ambient humidity<br />

➜ Option of<br />

charging oils<br />

with specific<br />

viscosities<br />

➜ Cartridge change<br />

with no risk of<br />

contamination<br />

from previouslyused<br />

oil<br />

Printer<br />

X X X X * X * X X<br />

Update via serial port<br />

X X X X X X X X X<br />

Service alarm<br />

A A A A A A A A A<br />

Nitrogen bottle<br />

connector<br />

Flushing software<br />

* * X * – – – – –<br />

– – X X X X X X X<br />

90 Kg<br />

Saniflux<br />

* * * * * – – – –<br />

Hybrid<br />

Upgradable<br />

R134a ➜ HFO1234yf<br />

– – * * – – – – –<br />

– – – X – X – – –<br />

A AUTOMATIC M MANUAL X SERIES – NOT AVAILABLE * OPTIONAL<br />

105 cm<br />

122 cm<br />

INFORMATION REGARDING DIMENSIONS, DATA, MODELS, AND COLORS IS NOT BINDING. ECOTECHNICS RESERVES THE RIGHT TO MAKE<br />

ANY MODIFICATIONS DEEMED NECESSARY. THE PRODUCTS ARE NOT COVERED BY ANY OTHER EXPRESS OR IMPLICIT WARRANTIES.<br />

3<br />

55 cm<br />

60 cm<br />

69 cm<br />

70 cm

A/C SERVICE<br />

Ecotechnics<br />

and high-precision<br />

technology<br />

1<br />

Years of investment and research in the climatecontrol<br />

sector have permitted Ecotechnics to<br />

develop a unique technology and design of a new<br />

range of machines with special characteristics that<br />

meet even strict U.S. standards (SAE J-2788).<br />

Technology Specifications<br />

THE ONLY COMPANY WORLDWIDE<br />

SANI<br />

DAMP + COLD + DARK<br />

FORMATION OF:<br />

BACTERIA + MOLD + ODORS<br />

PERSISTENT, ANNOYING ODORS<br />

PATENT PENDING<br />

The first integrated purification<br />

system in an air-conditioning<br />

recharging station. With Saniflux, the<br />

user may set the air treatment time<br />

on the basis of vehicle size<br />

THE PROBLEM<br />

2<br />

(under SAE J-2788):<br />

ALLERGENS AND IRRITANTS<br />

THE SOLUTION<br />

1Stations must recover at least 95% of the<br />

gas contained in the A/C system in particularly<br />

challenging conditions (low temperature and<br />

flooded systems).<br />

Recovering 95% ca.<br />

of the gas means:<br />

A. <strong>In</strong>creasing profitability and productivity at every<br />

vehicle service interval.<br />

B. Faster return on investment.<br />

2<br />

Stations must charge with a tolerance of<br />

14 g (1/2 oz).<br />

Better tolerance<br />

means:<br />

A. The newer A/C systems are increasingly<br />

compact and use smaller quantities of<br />

refrigerant; for this reason, it is essential<br />

to respect manufacturer’s tolerances since<br />

system efficiency is strictly correlated with<br />

precision charging of the correct quantity of<br />

refrigerant gas.<br />

B. Avoiding customer complaints that may<br />

arise from charging erroneous quantities of<br />

refrigerant.<br />

REFRIGERANT<br />

RECHARGING SYSTEM<br />

COMBINED SYSTEM<br />

HOW DOES IT WORK<br />

• Operation is fully controlled<br />

by the A/C charging station<br />

• Fully integrated, automatic operation<br />

• No operator intervention required<br />

• Ultrasound nebulization of the product<br />

• Certified purification liquid<br />

PASSENGER COMPARTMENT<br />

AIR PURIFICATION SYSTEM<br />

ECK SANI+<br />

ECK SANI+<br />

• Treatment time setting according to<br />

vehicle type *<br />

• Large-capacity tank with practical top<br />

access *<br />

• Powerful nebulized flow<br />

• 1-liter bottle of Saniflux Liquid<br />

*available only on ECK1900/ECK1500 - ECK2900-UP/ECK2500-UP<br />

4

OFFERING 4 SERVICE OPTIONS IN A SINGLE A/C STATION<br />

Patented Ecotechnics<br />

Flushing Kit<br />

2<br />

1<br />

Patented<br />

3 4<br />

diagnosis system<br />

incorporated in<br />

the recycling<br />

stations<br />

PATENT NO.: EP 1177924 US 6,629,420<br />

Diagnosis is an increasingly critical tool for anyone -<br />

climate-control specialists and not -wanting to expand<br />

their business to include A/C system repair.<br />

2<br />

1<br />

PATENT PENDING<br />

ALL THE ADVANTAGES<br />

• Easy to use<br />

• Fast, accurate diagnosis of problems<br />

• Printout of diagnosis and possible remedial actions<br />

• Reliability<br />

• Cost savings, thanks to perfect station integration.<br />

1<br />

Why flush an A/C system<br />

• The compressor is a moving mechanical organ, and as such is subject to wear<br />

and - in time - to failure.<br />

• For correct repair in the case of compressor failure, it is essential to remove any<br />

metal shavings that may have accumulated inside the system - and which could<br />

jeopardize good operation - before the new compressor is installed.<br />

• Many compressor manufacturers void their warranties on the new component<br />

if the A/C system is not cleaned, using a suitable flushing system,<br />

before the component is installed.<br />

Novelties<br />

• The kit does not use solvents, only refrigerant for flushing.<br />

• Thanks to the vacuum bottle, the kit guarantees complete, safe removal of all<br />

metal shavings.<br />

• The vacuum in the bottle produces a “ramrod” effect, forcing the refrigerant<br />

through any obstructions in the system.<br />

All the Advantages<br />

• Speeds up the flushing procedure, for considerable time-saving.<br />

• The operator is free to do other work while the machine flushes the system.<br />

• Environmentally friendly.<br />

• Full automation if used with Ecotechnics stations equipped with dedicated<br />

software.<br />

• May be used with other charging stations (in the manual mode).<br />

• Since only refrigerant is used, flushing introduces no humidity into the A/C system.<br />

• Since no solvents are used, the kit complies with OEM manufacturers’ standards.<br />

• Safe and easy to use.<br />

Standard equipment<br />

Adapters carry-case<br />

5-liter bottle.<br />

Optional features<br />

Metal support: AEK102-N7-R2.<br />

VW adapter: AEK102-N7-R1.<br />

Set of bypass adapters: AEK102-N7-R5<br />

AEK102-N7-R5<br />

2<br />

Static Diagnosis<br />

This type of diagnosis utilizes the pressure and<br />

temperature values entered by the operator from<br />

the station pressure gauges and the thermometer,<br />

supplied as standard equipment.<br />

<br />

Dynamic Diagnosis<br />

With the pressure and temperature sensors<br />

connected to the system, analysis is fully automatic<br />

and conducted in real time for the entire duration of<br />

measurement.<br />

Sherlock 2000 CLIMA TESTER<br />

AEK102-N7<br />

AEK102-N7-R1<br />

AEK102-N7-R2<br />

5

ECK 3900<br />

ECK 3000-N8<br />

Fully automatic single-gas station for<br />

recovering, recycling, and recharging R134<br />

refrigerant.<br />

AUTOMATIC FUNCTIONS:<br />

RECOVERY<br />

OIL<br />

DISCHARGE<br />

VACUUM<br />

TRACER<br />

OIL REINTE-<br />

GRATION<br />

GAS<br />

CHARGING<br />

STANDARD FEATURES<br />

• SELF-DIAGNOSIS: automatic for each onboard solenoid valve.<br />

• LEAK TEST: automatic during the vacuum phase.<br />

• NITROGEN BOTTLE CONNECTOR (bottle not included): the station<br />

automatically charges the A/C system with nitrogen and checks for leaks,<br />

monitoring pressure drops and giving a leak alarm.<br />

• AUTOMATIC DISCHARGE of non-condensable gases from the bottle.<br />

• ONBOARD BOTTLE FILLING: automatic.<br />

• SERVICE ALARM: acoustic and visual, for maintenance and filter<br />

replacement request.<br />

• REFRIGERANT MANAGEMENT: for creating a customized archive of all<br />

refrigerant transactions.<br />

• OPERATOR CODE: for assigning an operator password to protect against<br />

unauthorized use of the station.<br />

• DISTRIBUTOR GROUP: built-in, patented unit optimized for top<br />

performance and dependability.<br />

• DATABASE ADVANCED: integrated database vehicle + truck allowing the<br />

user to enter new vehicle models.<br />

• AUTOMATIC TRACER with collapsible cartridges.<br />

• FLUSHING SOFTWARE for automatic flushing of series A/C systems. For<br />

use with AEK102-N7.<br />

• SOFTWARE UPDATE: via <strong>In</strong>ternet and RS-232 serial port.<br />

OPTIONS<br />

SANIFLUX (SANI+): the first sanitizing<br />

system integrated in an A/C charging<br />

station.<br />

SANI<br />

PATENT PENDING<br />

ECK3000-N8: XK602A000002 STANDARD VERSION<br />

ECK3900: XK702A000002 STANDARD VERSION<br />

Type of refrigerant R134a<br />

Service procedure Fully automatic or manual<br />

Voltage<br />

220-240 V - 50/60 Hz<br />

Scale resolution 10 g<br />

Oil scale resolution 5 g<br />

Working temperature range 11/49°C<br />

Filter system 2 filters for humidity<br />

Vacuum pump 115 liter/min capacity, 0.1 mbar vacuum level<br />

Sealed compressor 12 cc, high-pressure<br />

Recovery speed 300 g/min in liquid phase<br />

Refrigerant bottle 22 litres, refillable<br />

Hoses<br />

3 metres<br />

Overall size<br />

55 x 60 x 105 cm<br />

Weight<br />

90 kg<br />

Thermal printer Standard equipment<br />

Pressure sensors Class 1<br />

Pressure gauges Class 1<br />

Display<br />

Graphic<br />

Bottle temperature sensor <strong>In</strong>tegrated<br />

Bottle heater Automatic<br />

6<br />

FLUSHING KIT (AEK102-N7): for flushing<br />

the A/C system with refrigerant. External<br />

bottle and metal adapters included.<br />

A/C DIAGNOSIS MODULE (DIAKIT):<br />

integrated, for all types of A/C systems,<br />

featuring printout of diagnosis and<br />

problem solution.<br />

GAS IDENTIFIER MODULE<br />

(XS160.000000) featuring printout of<br />

analysis results.<br />

HYBRID:<br />

hybrid-vehicle service<br />

tube flushing function<br />

HYBRID

Fully automatic single-gas station for<br />

recovering, recycling, and recharging R134<br />

refrigerant.<br />

AUTOMATIC FUNCTIONS:<br />

ECK 2900-UP<br />

ECK 2500-UP<br />

RECOVERY<br />

OIL<br />

DISCHARGE<br />

VACUUM<br />

TRACER<br />

optional<br />

OIL REINTE-<br />

GRATION<br />

GAS<br />

CHARGING<br />

STANDARD FEATURES<br />

• LEAK TEST: automatic during the vacuum phase.<br />

• ONBOARD BOTTLE FILLING: automatic.<br />

• AUTOMATIC DISCHARGE of non-condensable gases from the bottle.<br />

• SERVICE ALARM: acoustic and visual, for maintenance and filter<br />

replacement request.<br />

• USB PORT for software updates.<br />

• REFRIGERANT MANAGEMENT: for creating a customized archive of all<br />

refrigerant transactions.<br />

• OPERATOR CODE: for assigning an operator password to protect against<br />

unauthorized use of the station.<br />

• DISTRIBUTOR GROUP: built-in, patented unit optimized for top<br />

performance and dependability.<br />

• DATABASE ADVANCED: integrated database vehicle + truck allowing the<br />

user to enter new vehicle models.<br />

• FLUSHING SOFTWARE for automatic flushing of series A/C systems. For<br />

use with AEK102-N7.<br />

• HFO UPgradable: Ecotechnics charging machines can now be upgraded for use<br />

with the new HFO1234YF refrigerant, using a specific transformation kit<br />

• HERMETICALLY-SEALED NEW-OIL CARTRIDGE<br />

OPTIONS<br />

SANIFLUX (SANI+): the first sanitizing<br />

system integrated in an A/C charging<br />

station.<br />

SANI<br />

PATENT PENDING<br />

FLUSHING KIT (AEK102-N7): for flushing<br />

the A/C system with refrigerant. External<br />

bottle and metal adapters included.<br />

A/C DIAGNOSIS MODULE (DIAKIT):<br />

integrated, for all types of A/C systems,<br />

featuring printout of diagnosis and<br />

problem solution.<br />

AUTOMATIC TRACER KIT (UVKIT-7)<br />

featuring collapsible cartridges for<br />

injecting a predetermined quantity of<br />

tracer.<br />

NITROGEN BOTTLE CONNECTOR (N2)<br />

(bottle not included): the station<br />

automatically charges the A/C system with<br />

nitrogen and checks for leaks, monitoring<br />

pressure drops and giving a leak alarm.<br />

STATIC DIAGNOSIS KIT (KITSTA001.00)<br />

for diagnosing A/C systems.<br />

HYBRID:<br />

hybrid-vehicle service<br />

tube flushing function<br />

<br />

HYBRID<br />

ECK2900-UP: K1P0A000000R STANDARD VERSION<br />

ECK2500-UP: K1Q0A000000R STANDARD VERSION<br />

Type of refrigerant R134a<br />

Service procedure Fully automatic or manual<br />

Voltage<br />

220-240 V - 50/60 Hz<br />

Scale resolution 10 g<br />

Oil scale resolution 5 g<br />

Working temperature range 11/49°C<br />

Filter system 2 filters for humidity<br />

Vacuum pump 100 liter/min capacity, 0.1 mbar vacuum level<br />

Sealed compressor 12 cc, high-pressure<br />

Recovery speed 300 g/min in liquid phase<br />

Refrigerant bottle 22 litres, refillable<br />

Hoses<br />

3 metres<br />

Overall size<br />

55 x 60 x 105 cm<br />

Weight<br />

90 kg<br />

Thermal printer Standard equipment<br />

Pressure gauges Class 1<br />

Display<br />

Graphic<br />

Bottle temperature sensor <strong>In</strong>tegrated<br />

Bottle heater Automatic<br />

7

ECK 1900<br />

ECK 1500-N8<br />

Automatic single-gas station for<br />

recovering, recycling, and recharging<br />

R134 refrigerant.<br />

AUTOMATIC FUNCTIONS:<br />

RECOVERY<br />

OIL<br />

DISCHARGE<br />

VACUUM<br />

GAS<br />

CHARGING<br />

STANDARD FEATURES<br />

• SERVICE ALARM: acoustic and visual, for maintenance and filter<br />

replacement request.<br />

• ONBOARD BOTTLE FILLING: automatic.<br />

• REFRIGERANT MANAGEMENT: for creating a customized archive<br />

of all refrigerant transactions.<br />

• OPERATOR CODE: for assigning an operator password to protect against<br />

unauthorized use of the station.<br />

• FLUSHING SOFTWARE for automatic flushing of series A/C systems. For<br />

use with AEK102-N7.<br />

• GUIDED LEAK TEST: permits programming a delay time after the vacuum<br />

phase to conduct visual inspection for leaks by checking the pressure<br />

gauges.<br />

• DISTRIBUTOR GROUP: built-in, patented unit optimized for top<br />

performance and dependability.<br />

• DATABASE ADVANCED: integrated database vehicle + truck allowing the<br />

user to enter new vehicle models.<br />

• USB PORT for software updates.<br />

OPTIONS<br />

SANIFLUX (SANI+): the first sanitizing<br />

system integrated in an A/C charging<br />

station. For use with printer.<br />

SANI<br />

PATENT PENDING<br />

ECK1500-N8: XK630A000000 STANDARD VERSION<br />

ECK1900: XK730A000000 STANDARD VERSION<br />

Type of refrigerant R134a<br />

Service procedure Automatic or manual<br />

Voltage<br />

220-240 V - 50/60 Hz<br />

Scale resolution 10 g<br />

Working temperature range 11/49°C<br />

Filter system 2 filters for humidity<br />

Vacuum pump 115 liter/min capacity, 0.1 mbar vacuum level<br />

Sealed compressor 12 cc, high-pressure<br />

Recovery speed 300 g/min in liquid phase<br />

Refrigerant bottle 22 litres, refillable<br />

Hoses<br />

3 metres<br />

Overall size<br />

55 x 60 x 105 cm<br />

Weight<br />

90 kg<br />

Thermal printer Optional<br />

Pressure gauges Class 1<br />

Bottle pressure gauge Class 2.5<br />

Display<br />

LCD<br />

Bottle temperature sensor <strong>In</strong>tegrated<br />

Bottle heater Automatic<br />

8<br />

FLUSHING KIT (AEK102-N7): for flushing<br />

the A/C system with refrigerant. External<br />

bottle and metal adapters included.<br />

STATIC DIAGNOSIS KIT (KITSTA001.00)<br />

(for use with printer) for diagnosing A/C<br />

systems.<br />

THERMAL PRINTER (STM0006):<br />

provides a complete report of station<br />

operations.

Fully automatic single-gas station for<br />

recovering, recycling, and recharging R134<br />

refrigerant.<br />

ECK 1000-UP<br />

AUTOMATIC FUNCTIONS:<br />

RECOVERY<br />

OIL<br />

DISCHARGE<br />

VACUUM<br />

TRACER<br />

optional<br />

OIL REINTE-<br />

GRATION<br />

GAS<br />

CHARGING<br />

STANDARD FEATURES<br />

• SERVICE ALARM: automatically informs the user when the filters require<br />

replacement.<br />

• ONBOARD BOTTLE FILLING: automatic.<br />

• REFRIGERANT MANAGEMENT: for creating a customized archive<br />

of all refrigerant transactions.<br />

• OPERATOR CODE: for assigning an operator password to protect against<br />

unauthorized use of the station.<br />

• FLUSHING SOFTWARE for automatic flushing of series A/C systems. For use<br />

with AEK102-N7.<br />

• GUIDED LEAK TEST: permits programming a delay time after the vacuum phase<br />

to conduct visual inspection for leaks by checking the pressure gauges.<br />

• DISTRIBUTOR GROUP: built-in, patented unit optimized for top performance and<br />

dependability.<br />

• DATABASE ADVANCED: integrated database vehicle + truck allowing the<br />

user to enter new vehicle models.<br />

• USB PORT for software updates.<br />

• HFO UPgradable: Ecotechnics charging machines can now be upgraded for use<br />

with the new HFO1234YF refrigerant, using a specific transformation kit<br />

• HERMETICALLY-SEALED NEW-OIL CARTRIDGE<br />

OPTIONS<br />

FLUSHING KIT (AEK102-N7): for flushing<br />

the A/C system with refrigerant. External<br />

bottle and metal adapters included.<br />

STATIC DIAGNOSIS KIT (KITSTA001.00)<br />

for diagnosing A/C systems.<br />

AUTOMATIC TRACER KIT (UVKIT-7)<br />

featuring collapsible cartridges for<br />

injecting a predetermined quantity of<br />

tracer.<br />

<br />

ECK1000-UP: K1C0A000000R STANDARD VERSION<br />

Type of refrigerant R134a<br />

Service procedure Fully automatic or manual<br />

Voltage<br />

220-240 V - 50/60 Hz<br />

Scale resolution 10 g<br />

Oil scale resolution 5 g<br />

Working temperature range 11/49°C<br />

Filter system 2 filters for humidity<br />

Vacuum pump 100 liter/min capacity, 0.1 mbar vacuum level<br />

Sealed compressor 12 cc, high-pressure<br />

Recovery speed 300 g/min in liquid phase<br />

Refrigerant bottle 12 litres, refillable<br />

Hoses<br />

3 metres<br />

Overall size<br />

55 x 60 x 105 cm<br />

Weight<br />

90 kg<br />

Thermal printer Standard equipment<br />

Pressure gauges Class 1<br />

Bottle pressure gauge Class 2.5<br />

Display<br />

LCD<br />

Bottle temperature sensor <strong>In</strong>tegrated<br />

Bottle heater Automatic<br />

9

ECK 760<br />

Automatic single-gas station for<br />

recovering, recycling, and recharging<br />

R134 refrigerant.<br />

AUTOMATIC FUNCTIONS:<br />

RECOVERY<br />

OIL<br />

DISCHARGE<br />

VACUUM<br />

GAS<br />

CHARGING<br />

STANDARD FEATURES<br />

• ALARMS: high pressure, full bottle, empty bottle.<br />

• SERVICE ALARM: acoustic and visual, for maintenance and filter<br />

replacement request.<br />

• ONBOARD BOTTLE FILLING: automatic.<br />

• REFRIGERANT MANAGEMENT: for creating a customized archive of all<br />

refrigerant transactions.<br />

• OPERATOR CODE: for assigning an operator password to protect against<br />

unauthorized use of the station.<br />

• DISTRIBUTOR GROUP: built-in, patented unit optimized for top<br />

performance and dependability.<br />

• SOFTWARE UPDATE: via <strong>In</strong>ternet and RS-232 serial port.<br />

• DATABASE ADVANCED: integrated database vehicle + truck allowing the<br />

user to enter new vehicle models.<br />

• FLUSHING SOFTWARE for automatic flushing of series A/C systems. For<br />

use with AEK102-N7.<br />

• USB PORT for software updates<br />

• GUIDED LEAK TEST: permits programming a delay time after the vacuum<br />

phase to conduct visual inspection for leaks by checking the pressure<br />

gauges.<br />

OPTIONS<br />

ECK760: XK8L0A000000 STANDARD VERSION<br />

Type of refrigerant R134a<br />

Service procedure Automatic or manual<br />

Voltage<br />

220-240 V - 50/60 Hz<br />

Scale resolution 10 g<br />

Working temperature range 11/49°C<br />

Filter system 1 filter for humidity<br />

Vacuum pump 72 liter/min capacity, 0.1 mbar vacuum level<br />

Sealed compressor 12 cc, high-pressure<br />

Recovery speed 300 g/min in liquid phase<br />

Refrigerant bottle 12 litres, refillable<br />

Hoses<br />

3 metres<br />

Overall size<br />

55 x 60 x 105 cm<br />

Weight<br />

90 kg<br />

Thermal printer Optional<br />

Pressure gauges Class 1<br />

Bottle pressure gauge Class 2.5<br />

Display<br />

LCD<br />

Bottle temperature sensor <strong>In</strong>tegrated<br />

Bottle heater Automatic<br />

10<br />

STATIC DIAGNOSIS KIT (KITSTA001.00)<br />

(for use with printer) for diagnosing A/C<br />

systems.<br />

FLUSHING KIT (AEK102-N7): for flushing<br />

the A/C system with refrigerant. External<br />

bottle and metal adapters included.<br />

THERMAL PRINTER (STM0006):<br />

provides a complete report of station<br />

operations.

Fully automatic single-gas station for recovering,<br />

recycling, and recharging R134 refrigerant,<br />

for use with buses and industrial vehicles.<br />

AUTOMATIC FUNCTIONS:<br />

ECK BUS-PRO<br />

ECK BUS<br />

RECOVERY<br />

OIL<br />

DISCHARGE<br />

VACUUM<br />

TRACER<br />

optional<br />

OIL REINTE-<br />

GRATION<br />

GAS<br />

CHARGING<br />

STANDARD FEATURES<br />

• ALARMS: high pressure, full bottle, empty bottle.<br />

• SERVICE ALARM: acoustic and visual, for maintenance and filter<br />

replacement request.<br />

• ONBOARD BOTTLE FILLING: automatic.<br />

• AUTOMATIC LEAK check during vacuum phase<br />

• DISTRIBUTOR GROUP: built-in, patented unit optimized for top<br />

performance and dependability.<br />

• AUTOMATIC DISCHARGE of non-condensable gases from the bottle.<br />

• GEAR PUMP for refrigerant charging.<br />

• SOFTWARE UPDATE: via <strong>In</strong>ternet and RS-232 serial port.<br />

• DATABASE ADVANCED: integrated database vehicle + truck allowing the<br />

user to enter new vehicle models.<br />

• REFRIGERANT MANAGEMENT: for creating a customized archive of all<br />

refrigerant transactions.<br />

• FLUSHING SOFTWARE for automatic flushing of series A/C systems. For<br />

use with AEK102-N7.<br />

• USB PORT for software updates.<br />

OPTIONS<br />

FLUSHING KIT (AEK102-N7): for flushing<br />

the A/C system with refrigerant. External<br />

bottle and metal adapters included.<br />

AUTOMATIC TRACER KIT (UVKIT-7)<br />

featuring collapsible cartridges.<br />

ECK-BUS<br />

Same features of<br />

ECK BUS-PRO but:<br />

• without gear pump<br />

• with bottle heather<br />

ECKBUS: XK250A000000 STANDARD VERSION<br />

ECKBUS-PRO: XK255A000000 STANDARD VERSION<br />

Type of refrigerant R134a<br />

Service procedure Fully automatic or manual<br />

Voltage<br />

220-240 V - 50/60 Hz<br />

Scale resolution 20 g<br />

Oil scale resolution 5 g<br />

Working temperature range 11/49°C<br />

Filter system 2 filters for humidity<br />

Vacuum pump 170 liter/min capacity, 0.1 mbar vacuum level<br />

Sealed compressor 21 cc, high-pressure<br />

Gear pump<br />

1 kg/min capacity<br />

Refrigerant bottle 27 litres, refillable<br />

Hoses<br />

3 metres<br />

Overall size<br />

50 x 50 x 115 cm<br />

Weight<br />

100 kg<br />

Thermal printer Standard equipment<br />

Display<br />

LCD<br />

Bottle temperature sensor <strong>In</strong>tegrated<br />

Pressure sensors Class 1<br />

Bottle heater Automatic<br />

11

OPTIONS<br />

SANI<br />

PATENT PENDING<br />

ECK 2900-HFO<br />

AUTOMATIC FUNCTIONS:<br />

RECOVERY<br />

OIL<br />

DISCHARGE<br />

VACUUM<br />

TRACER<br />

optional<br />

OIL REINTE-<br />

GRATION<br />

GAS<br />

CHARGING<br />

STANDARD FEATURES<br />

• LEAK TEST: automatic during the vacuum phase.<br />

• ONBOARD BOTTLE FILLING: automatic.<br />

AUTOMATIC TRACER KIT<br />

(UVKIT-7)<br />

NITROGEN BOTTLE<br />

CONNECTOR (N2)<br />

ECK2900-HFO: K1P0A000000H STANDARD VERSION<br />

Type of refrigerant<br />

HFO1234YF<br />

Service procedure<br />

Fully automatic or manual<br />

Voltage<br />

220-240 V - 50/60 Hz<br />

Scale resolution<br />

10 g<br />

Oil scale resolution 5 g<br />

Working temperature range<br />

11/49°C<br />

Filter system<br />

2 filters for humidity<br />

Vacuum pump<br />

100 liter/min capacity, 0.1 mbar vacuum level<br />

Sealed compressor<br />

12 cc, high-pressure<br />

Recovery speed<br />

300 g/min in liquid phase<br />

Refrigerant bottle<br />

12 litres, refillable<br />

Hoses<br />

3 metres<br />

Overall size<br />

55 x 60 x 105 cm<br />

Weight<br />

90 kg<br />

Thermal printer<br />

Standard equipment<br />

Pressure gauges Class 1<br />

Display<br />

Graphic<br />

Bottle temperature sensor<br />

<strong>In</strong>tegrated<br />

Bottle heater<br />

Automatic<br />

OPTIONS<br />

SANI<br />

PATENT PENDING<br />

• AUTOMATIC DISCHARGE of non-condensable gases from the bottle.<br />

• SERVICE ALARM: acoustic and visual, for maintenance and filter<br />

replacement request.<br />

• USB PORT for software updates.<br />

• REFRIGERANT MANAGEMENT: for creating a customized archive of all<br />

refrigerant transactions.<br />

• OPERATOR CODE: for assigning an operator password to protect against<br />

unauthorized use of the station.<br />

• DISTRIBUTOR GROUP: built-in, patented unit optimized for top<br />

performance and dependability.<br />

• HERMETICALLY-SEALED NEW OIL CARTRIDGE<br />

HFO1234YF<br />

Fully automatic single-gas station for<br />

recovering, recycling, and recharging<br />

HFO1234YF refrigerant.<br />

ECK 2500-HFO<br />

AUTOMATIC FUNCTIONS:<br />

AUTOMATIC TRACER KIT<br />

(UVKIT-7)<br />

RECOVERY<br />

OIL<br />

DISCHARGE<br />

VACUUM<br />

TRACER<br />

optional<br />

OIL REINTE-<br />

GRATION<br />

GAS<br />

CHARGING<br />

STANDARD FEATURES<br />

• LEAK TEST: automatic during the vacuum phase.<br />

• ONBOARD BOTTLE FILLING: automatic.<br />

ECK2500-HFO: K1Q0A000000H STANDARD VERSION<br />

Type of refrigerant<br />

HFO1234YF<br />

Service procedure<br />

Fully automatic or manual<br />

Voltage<br />

220-240 V - 50/60 Hz<br />

Scale resolution<br />

10 g<br />

Oil scale resolution 5 g<br />

Working temperature range<br />

11/49°C<br />

Filter system<br />

2 filters for humidity<br />

Vacuum pump<br />

100 liter/min capacity, 0.1 mbar vacuum level<br />

Sealed compressor<br />

12 cc, high-pressure<br />

Recovery speed<br />

300 g/min in liquid phase<br />

Refrigerant bottle<br />

12 litres, refillable<br />

Hoses<br />

3 metres<br />

Overall size<br />

55 x 60 x 105 cm<br />

Weight<br />

90 kg<br />

Thermal printer<br />

Standard equipment<br />

Pressure gauges Class 1<br />

Display<br />

Graphic<br />

Bottle temperature sensor<br />

<strong>In</strong>tegrated<br />

Bottle heater<br />

Automatic<br />

NITROGEN BOTTLE<br />

CONNECTOR (N2)<br />

12<br />

• AUTOMATIC DISCHARGE of non-condensable gases from the bottle.<br />

• SERVICE ALARM: acoustic and visual, for maintenance and filter<br />

replacement request.<br />

• USB PORT for software updates.<br />

• REFRIGERANT MANAGEMENT: for creating a customized archive of all<br />

refrigerant transactions.<br />

• OPERATOR CODE: for assigning an operator password to protect against<br />

unauthorized use of the station.<br />

• DISTRIBUTOR GROUP: built-in, patented unit optimized for top<br />

performance and dependability.<br />

• HERMETICALLY-SEALED NEW OIL CARTRIDGE

Sherlock 2000<br />

XS100.000000<br />

Data Base Online<br />

COD. DBK001<br />

A patented<br />

diagnostics system<br />

for determining<br />

the causes of<br />

malfunctions in<br />

any A/C system<br />

through analysis<br />

of pressures and<br />

temperatures.<br />

PATENTED<br />

TYPES OF REFRIGERANT R134a and R12<br />

TYPES OF SYSTEMS Traditional, flooded, and continual cutin<br />

flooded systems.<br />

2 MINUTES for results.<br />

DIAGNOSIS PRINTOUT complete with data, graphs, and<br />

solution for the problem.<br />

EXAMPLES OF DIAGNOSIS<br />

- No refrigerant in system<br />

- Defroster pressure switch<br />

- Clogged intake line<br />

- Refrigerant low<br />

- Capillary valve<br />

- Clogged condenser or hose<br />

- Air flow to evaporator<br />

- System OK<br />

- Excess refrigerant<br />

- <strong>In</strong>correct condenser airflow<br />

- Air in system<br />

- Check mixing door<br />

- High and low pressures inverted<br />

- Pulley does not engage<br />

- Replace compressor<br />

SOFTWARE UPDATES via <strong>In</strong>ternet, RS232 serial port.<br />

All the advantages of the new Data Base<br />

Online service:<br />

• Up-to-the-minute data on refrigerant quantities, wiring<br />

diagrams, and the positions of service connections.<br />

• For any data not available, just send an update request:<br />

the requested datum will be made rapidly available on<br />

the website.<br />

• The data requested may be printed.<br />

• Easy to use.<br />

Refrigerant types<br />

Voltage<br />

Hoses<br />

<strong>In</strong>strument dimensions<br />

<strong>In</strong>strument weight<br />

Case dimensions<br />

Full case weight<br />

DATA<br />

REPORT<br />

COLOR<br />

GRAPHICS<br />

DIAGNOSIS<br />

REPORT<br />

COLOR PRINT<br />

OPTION<br />

R12 and R 134a<br />

12V (automobile battery)<br />

1,5 metres<br />

350 x 160 x 120 mm<br />

1,5 kg<br />

480 x 370 x 180 mm<br />

3 kg<br />

Sherlock PC – PC INTERFACE<br />

with the “Sherlock PC” program<br />

Data Base Advanced<br />

COD. KITDB002.11<br />

USB-RS232<br />

For downloading<br />

Refrigerant Management<br />

contents directly to a USB<br />

memory key<br />

COD.SCH8182<br />

13

Leak Detection Products & Consumables<br />

‹<br />

AEK203<br />

COBRA KIT HD<br />

Leak detector kit<br />

for A/C circuits<br />

including: goggles,<br />

UV lamp, hermetic<br />

dye cartridge<br />

(55ml), injector.<br />

‹<br />

AEK204<br />

OIL KIT FOR<br />

HYBRID VEHICLES<br />

including cartridge<br />

oil for hybrid<br />

vehicles (55 ml),<br />

injector<br />

‹<br />

AEK203-H<br />

COBRA KIT HD<br />

HYBRID<br />

Like AEK203 but<br />

with dye cartridge<br />

for hybrid vehicle<br />

‹<br />

AEK204-H-5<br />

Box of 5 sealed<br />

bottles of oil for<br />

hybrid vehicles<br />

(55 ml)<br />

Box of 5 sealed<br />

‹ bottles of tracer<br />

AEK203-C-5 (55 ml)<br />

Box of 6 bottles of<br />

‹<br />

AC POE oil (237 ml)<br />

AEK125-1-6<br />

Box of 5 sealed<br />

bottles of tracer<br />

‹ (55 ml) for hybrid<br />

AEK203-H-C-5 vehicles<br />

‹<br />

AEK145-4<br />

COBRA BOTTLE<br />

KIT - Leak detection<br />

kit for A/C<br />

circuits, including:<br />

UV lamp, goggles,<br />

6 bottles (7.4 ml<br />

each) of tracer,<br />

injector, 1 bottle<br />

(120 ml) tracer dye<br />

cleaner liquid<br />

PAG46<br />

AEK250<br />

PAG100<br />

AEK255<br />

PAG150<br />

AEK260<br />

‹<br />

AEK250<br />

AEK255<br />

AEK260<br />

‹<br />

AEK222-1<br />

carton of 6<br />

hermetically-sealed<br />

bottles<br />

of oil (250 ml)<br />

SANIFLUX LIQUID<br />

bottle 1000 ml<br />

‹<br />

AEK145<br />

‹<br />

AEK146<br />

Cobra lamp +<br />

safety goggles<br />

Tracer injection<br />

gun, including 1<br />

bottle of universal<br />

tracer (64 applications),<br />

hose and<br />

connection for<br />

R134a, high-pressure<br />

adapter, air<br />

purge connector<br />

‹<br />

AEK107-3<br />

‹<br />

AEK107-6<br />

ELECTRONIC<br />

LEAK<br />

DETECTION:<br />

a single instrument<br />

for identifying all<br />

halogen gases,<br />

including CFC,<br />

HCFC, HFC<br />

ELECTRONIC<br />

LEAK<br />

DETECTOR<br />

for combustible gases<br />

(50-1000 ppm)<br />

ideal for Nitrogen +<br />

Hydrogen mix<br />

‹<br />

AEK126-4<br />

350-ml bottle of<br />

universal tracer<br />

‹<br />

AEK147-1<br />

Rechargeable UV<br />

lamp 12V, 50W<br />

‹<br />

AEK126-3-6<br />

Box of 6 sealed<br />

bottles of tracer<br />

(125 ml)<br />

‹<br />

AEK160<br />

AIR FRESH<br />

Deodorant spray<br />

‹<br />

AEK133-1<br />

Package of 12 vials<br />

(7.4 ml each)<br />

‹<br />

AEK161<br />

DYE CLEANER<br />

Liquid detergent<br />

for tracer (474 ml)

A/C Accessories<br />

‹<br />

XK184.000000<br />

EASYREC<br />

Refrigerant recovery unit<br />

- It works with all refrigerants<br />

- Compressor type: oil less<br />

- Air cooled<br />

- It works with gas and liquid refrigerant<br />

- Recovery rate (vapour): 17 kg/h<br />

- Recovery rate (liquid): 50 kg/h<br />

- Recovery rate (push-pull): 240 kg/h<br />

EASYREC PLUS<br />

Identical to Easyrec, with<br />

‹ carrycase<br />

XK184.000039 for hoses and couplings<br />

R12/R134a<br />

‹<br />

AEK515<br />

AEK525<br />

AEK535<br />

Set of flexible hoses<br />

90 cm<br />

150 cm<br />

180 cm<br />

‹<br />

CNT4010<br />

40-liter bottle for R134a,<br />

R22, R404a, R507, R407C<br />

‹<br />

TUB1158<br />

6-m service hose,<br />

low pressure<br />

‹<br />

AEK120-E<br />

Digital thermometer<br />

‹<br />

AEK221<br />

Laser thermometer<br />

‹<br />

TUB1168<br />

6-m service hose,<br />

high pressure<br />

‹<br />

AEK220<br />

Digital thermometer with<br />

probe<br />

‹<br />

AEK114<br />

Pair of retrofit adapters<br />

‹<br />

AEK303<br />

DIGITAL VACUUM METER<br />

- Range 0-12000 microns<br />

‹<br />

AEK116<br />

Reducer fitting for bottle<br />

‹<br />

AEK302<br />

‹<br />

AEK214<br />

ELECTRONIC SCALE<br />

- LCD Display<br />

- Max capacity: 100 kg<br />

- Resolution: 10 g<br />

- Accurate charging of +/-<br />

10 g% of readings<br />

- Operating temperature:<br />

-10°C / +50°C<br />

Cutter for rubber hoses<br />

+<br />

‹<br />

AEK116-1<br />

ACME hose reducer fitting<br />

for bottle<br />

‹<br />

AEK215<br />

‹<br />

AEK211<br />

Valve-extractor screwdriver<br />

Special quick-connect<br />

coupling<br />

‹<br />

AEK118<br />

Compressor vane comb<br />

‹<br />

AEK109A<br />

‹<br />

AEK109B<br />

Terminal valve, high<br />

pressure<br />

Terminal valve, low<br />

pressure

Ecotechnics S.p.A - Via L. Longo, 21/23 - 50019 Sesto F.no (FI)<br />

Tel. +39 055 4207372 - Fax +39 055 4217972<br />

www.ecotechnics.com email: ecotechnics@ecotechnics.com