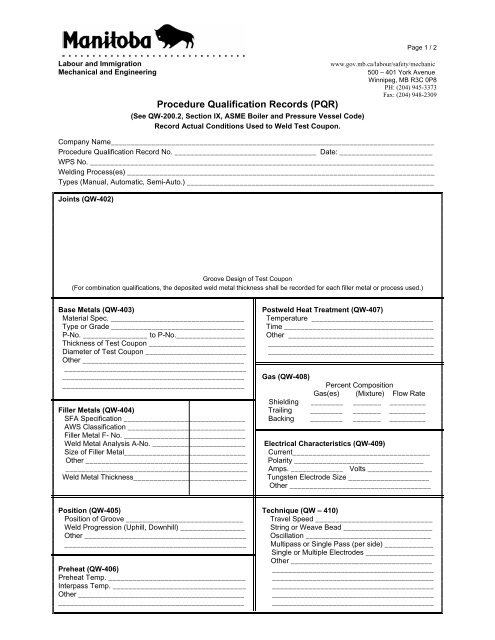

Procedure Qualification Records (PQR) Form

Procedure Qualification Records (PQR) Form

Procedure Qualification Records (PQR) Form

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Labour and Immigration<br />

Mechanical and Engineering<br />

<strong>Procedure</strong> <strong>Qualification</strong> <strong>Records</strong> (<strong>PQR</strong>)<br />

(See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)<br />

Record Actual Conditions Used to Weld Test Coupon.<br />

Page 1 / 2<br />

www.gov.mb.ca/labour/safety/mechanic<br />

500 – 401 York Avenue<br />

Winnipeg, MB R3C 0P8<br />

PH: (204) 945-3373<br />

Fax: (204) 948-2309<br />

Company Name________________________________________________________________________________<br />

<strong>Procedure</strong> <strong>Qualification</strong> Record No. ___________________________________ Date: _______________________<br />

WPS No. _____________________________________________________________________________________<br />

Welding Process(es) ____________________________________________________________________________<br />

Types (Manual, Automatic, Semi-Auto.) _____________________________________________________________<br />

Joints (QW-402)<br />

Groove Design of Test Coupon<br />

(For combination qualifications, the deposited weld metal thickness shall be recorded for each filler metal or process used.)<br />

Base Metals (QW-403)<br />

Material Spec. _________________________________<br />

Type or Grade _________________________________<br />

P-No. ________________ to P-No._________________<br />

Thickness of Test Coupon ________________________<br />

Diameter of Test Coupon _________________________<br />

Other ________________________________________<br />

_____________________________________________<br />

_____________________________________________<br />

_____________________________________________<br />

Postweld Heat Treatment (QW-407)<br />

Temperature ______________________________<br />

Time _____________________________________<br />

Other ____________________________________<br />

_________________________________________<br />

_________________________________________<br />

Gas (QW-408)<br />

Percent Composition<br />

Gas(es) (Mixture) Flow Rate<br />

Shielding ________ _______ _________<br />

Filler Metals (QW-404) Trailing ________ _______ _________<br />

SFA Specification ______________________________ Backing ________ _______ _________<br />

AWS Classification _____________________________<br />

Filler Metal F- No. ______________________________<br />

Weld Metal Analysis A-No. _______________________<br />

Size of Filler Metal______________________________<br />

Other ________________________________________<br />

_____________________________________________<br />

Weld Metal Thickness____________________________<br />

Electrical Characteristics (QW-409)<br />

Current__________________________________<br />

Polarity ________________________________<br />

Amps. _____________ Volts ________________<br />

Tungsten Electrode Size ____________________<br />

Other ___________________________________<br />

Position (QW-405) Technique (QW – 410)<br />

Position of Groove _____________________________ Travel Speed _____________________________<br />

Weld Progression (Uphill, Downhill) ________________ String or Weave Bead ______________________<br />

Other ________________________________________ Oscillation _______________________________<br />

_____________________________________________ Multipass or Single Pass (per side) ____________<br />

Single or Multiple Electrodes _________________<br />

Other ___________________________________<br />

Preheat (QW-406)<br />

________________________________________<br />

Preheat Temp. __________________________________ ________________________________________<br />

Interpass Temp. _________________________________ ________________________________________<br />

Other _________________________________________ ________________________________________<br />

______________________________________________ ________________________________________

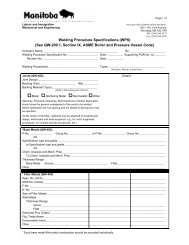

<strong>Procedure</strong> <strong>Qualification</strong> <strong>Records</strong> (<strong>PQR</strong>) Page 2 / 2<br />

Tensile Test (QW-150)<br />

Specimen<br />

No.<br />

Width Thickness Area<br />

Ultimate Total<br />

Load, lb<br />

Ultimate Unit<br />

Stress, psi<br />

<strong>PQR</strong> No.________<br />

Type of<br />

Failure &<br />

Location<br />

Guided-Bend Tests (QW-160)<br />

Type and Figure No.<br />

Result<br />

Toughness Tests (QW-170)<br />

Specimen<br />

No.<br />

Notch<br />

Location<br />

Specimen<br />

Size<br />

Test Temp.<br />

Impact<br />

Values<br />

ft-lb % Shear Mils<br />

Drop<br />

Weight<br />

Break (Y/N)<br />

Comments ____________________________________________________________________________________<br />

_____________________________________________________________________________________________<br />

Fillet-Weld Test (QW-180)<br />

Result – Satisfactory: Yes ________ No _________ Penetration into Parent Metal: Yes ________ No __________<br />

Macro – Results ________________________________________________________________________________<br />

Other Tests<br />

Type of Test ___________________________________________________________________________________<br />

Deposit Analysis _______________________________________________________________________________<br />

Other ________________________________________________________________________________________<br />

Welder’s Name ____________________________________ Clock No. ___________ Stamp No. ___________<br />

Tests conducted by :________________________________________ Laboratory Test No. __________________<br />

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in<br />

accordance with the requirements of Section IX of the ASME Code.<br />

Manufacturer: _______________________________<br />

Date __________________________________________<br />

By ________________________________________<br />

(Detail of record of tests are illustrative only and may be modified to conform to the type and number of tests required by the Code.)