Boilers and Pressure Vessels Repairs and Alteration Report

Boilers and Pressure Vessels Repairs and Alteration Report

Boilers and Pressure Vessels Repairs and Alteration Report

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

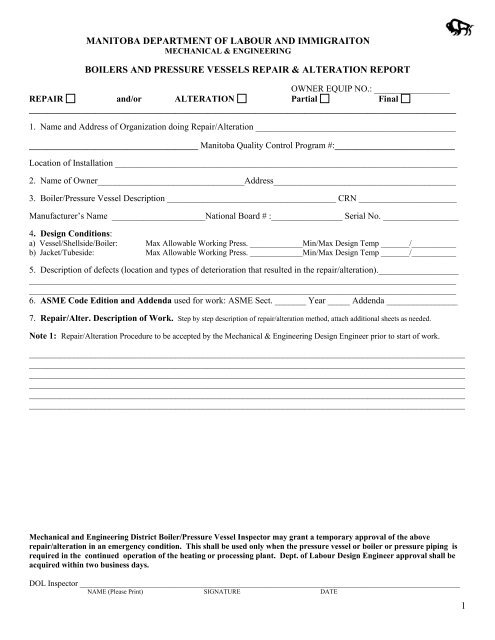

MANITOBA DEPARTMENT OF LABOUR AND IMMIGRAITONMECHANICAL & ENGINEERINGBOILERS AND PRESSURE VESSELS REPAIR & ALTERATION REPORTOWNER EQUIP NO.: _________________REPAIR <strong>and</strong>/or ALTERATION Partial Final________________________________________________________________________________________________1. Name <strong>and</strong> Address of Organization doing Repair/<strong>Alteration</strong> ___________________________________________________________________________________ Manitoba Quality Control Program #:___________________________Location of Installation _____________________________________________________________________________2. Name of Owner_________________________________Address_________________________________________3. Boiler/<strong>Pressure</strong> Vessel Description ______________________________________ CRN ______________________Manufacturer’s Name _____________________National Board # :________________ Serial No. _________________4. Design Conditions:a) Vessel/Shellside/Boiler: Max Allowable Working Press. _____________Min/Max Design Temp _______/___________b) Jacket/Tubeside: Max Allowable Working Press. _____________Min/Max Design Temp _______/___________5. Description of defects (location <strong>and</strong> types of deterioration that resulted in the repair/alteration).__________________________________________________________________________________________________________________________________________________________________________________________________________________6. ASME Code Edition <strong>and</strong> Addenda used for work: ASME Sect. _______ Year _____ Addenda ________________7. Repair/Alter. Description of Work. Step by step description of repair/alteration method, attach additional sheets as needed.Note 1: Repair/<strong>Alteration</strong> Procedure to be accepted by the Mechanical & Engineering Design Engineer prior to start of work.____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________Mechanical <strong>and</strong> Engineering District Boiler/<strong>Pressure</strong> Vessel Inspector may grant a temporary approval of the aboverepair/alteration in an emergency condition. This shall be used only when the pressure vessel or boiler or pressure piping isrequired in the continued operation of the heating or processing plant. Dept. of Labour Design Engineer approval shall beacquired within two business days.DOL Inspector ______________________________________________________________________________________________NAME (Please Print) SIGNATURE DATE1

8. Material – List any material used in repair/alteration <strong>and</strong> any base material welded on:ItemMaterial Spec.Thick/Sch Diam Item Material Spec.Thick/SchShell/DrumHeads/EndsTubesheetTubesNozzles Flanges/Fittings ClassDiam9. Welding Procedure __________ Registration Number WP-_________ WPS Numbers used: ___________________10. Heat Treatment: Bake Out (Temp. /Time) ______________________________________/___________ Preheat Temp ______________Post Weld HT (Temp. /Time) _______/_________11. Non Destructive Examination (Specify type <strong>and</strong> extent).______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________DEPT. OF LABOUR REPAIR/ALTERATION APPROVAL #___________________OWNER EQUIP NO.__________12. <strong>Pressure</strong> Test Vessel/Boiler/Shellside Tubeside/Jacketa) Hydrostatic______________________________ ______________________________________________b) Other Test_______________________________ ______________________________________________13. Welded Replacement Parts: Attached are Manufacturer’s Partial Data <strong>Report</strong>s or Repair/<strong>Alteration</strong> <strong>Report</strong>sproperly identified <strong>and</strong> signed by Authorized Inspectors for the following items of this report: (Welded parts suppliedby others)._____________________________________________________________________________________14. Responsibility Owner/Client: Identify below items that the owner/client has assumed responsibility for. Note (2)a) Design Submission: _______ b) Repair/<strong>Alteration</strong> Procedure: ___________ c) Material Control ___________d) Welding Control: _________ NDE __________ f) Heat Treatment: _________g) <strong>Pressure</strong> Test ____________Note 2: Owner/client must have a valid M.B.Quality Program for the scope of work performed, to assume responsibilityfor function c, d, e, f, or g.15. REMARKS: _________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________2

16. CERTIFICATE OF COMPLIANCEWe certify that the statements made in this <strong>Report</strong> are correct <strong>and</strong> that all design, material, construction <strong>and</strong> workmanshipon this repair/alteration conform to the requirements of the Manitoba Steam <strong>and</strong> <strong>Pressure</strong> Plants Act <strong>and</strong> Regulations.a) For all items except for items identified in 14: b) For items identified in 14 only:_____________________________________________________________________________(Repair/<strong>Alteration</strong> Organization Name)(Owner/Client Organization Name)____________________________________________________(Q.C.P. Number & Expiry Date)____________________________________________________(Signature & Date)____________________________________________________(Print Name)______________________________________________________(Q.C.P. Number & Expiry Date)______________________________________________________(Signature & Date)______________________________________________________(Print Name)17. DATE WORK WAS COMPLETED: ____________________________18. CERTIFICATE OF INSPECTIONI have inspected the repairs <strong>and</strong>/or alterations described in this report. To the best of my knowledge this work has beendone in accordance with the Manitoba Steam <strong>and</strong> <strong>Pressure</strong> Plants Act <strong>and</strong> Regulations.a) Repair/<strong>Alteration</strong> Organization b)_____________________________________________Company Name, Q.C.P. # & Expiry Date_______________________________________________________________ _______________________________________________________________Q. C. M. Signature & Date Mechanical & Engineering Inspector, Signature & Date_______________________________________________________________Name (Please Print)_______________________________________________________________Print Name_______________________________________________________________________________________________________________________________________<strong>Report</strong> Received by Department of Labour <strong>and</strong> ImmigrationMechanical & Engineering:__________________________________________________________________________________________DateNOTES:Dept. of Labour Approval Stamp.Dept. of Labour Design Engineer3