Maintenance Manual - Central States Industrial Equipment ...

Maintenance Manual - Central States Industrial Equipment ...

Maintenance Manual - Central States Industrial Equipment ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

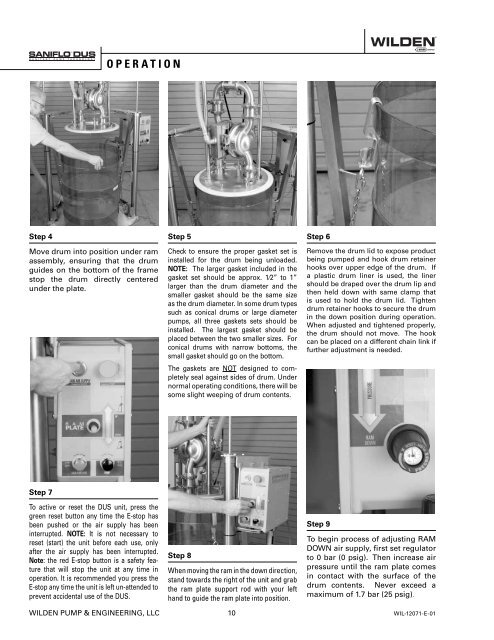

OPERATION<br />

Step 4<br />

Step 5<br />

Step 6<br />

Move drum into position under ram<br />

assembly, ensuring that the drum<br />

guides on the bottom of the frame<br />

stop the drum directly centered<br />

under the plate.<br />

Check to ensure the proper gasket set is<br />

installed for the drum being unloaded.<br />

NOTE: The larger gasket included in the<br />

gasket set should be approx. 1⁄2” to 1”<br />

larger than the drum diameter and the<br />

smaller gasket should be the same size<br />

as the drum diameter. In some drum types<br />

such as conical drums or large diameter<br />

pumps, all three gaskets sets should be<br />

installed. The largest gasket should be<br />

placed between the two smaller sizes. For<br />

conical drums with narrow bottoms, the<br />

small gasket should go on the bottom.<br />

The gaskets are NOT designed to completely<br />

seal against sides of drum. Under<br />

normal operating conditions, there will be<br />

some slight weeping of drum contents.<br />

Remove the drum lid to expose product<br />

being pumped and hook drum retainer<br />

hooks over upper edge of the drum. If<br />

a plastic drum liner is used, the liner<br />

should be draped over the drum lip and<br />

then held down with same clamp that<br />

is used to hold the drum lid. Tighten<br />

drum retainer hooks to secure the drum<br />

in the down position during operation.<br />

When adjusted and tightened properly,<br />

the drum should not move. The hook<br />

can be placed on a different chain link if<br />

further adjustment is needed.<br />

Step 7<br />

To active or reset the DUS unit, press the<br />

green reset button any time the E-stop has<br />

been pushed or the air supply has been<br />

interrupted. NOTE: It is not necessary to<br />

reset (start) the unit before each use, only<br />

after the air supply has been interrupted.<br />

Note: the red E-stop button is a safety feature<br />

that will stop the unit at any time in<br />

operation. It is recommended you press the<br />

E-stop any time the unit is left un-attended to<br />

prevent accidental use of the DUS.<br />

Step 8<br />

When moving the ram in the down direction,<br />

stand towards the right of the unit and grab<br />

the ram plate support rod with your left<br />

hand to guide the ram plate into position.<br />

Step 9<br />

To begin process of adjusting RAM<br />

DOWN air supply, first set regulator<br />

to 0 bar (0 psig). Then increase air<br />

pressure until the ram plate comes<br />

in contact with the surface of the<br />

drum contents. Never exceed a<br />

maximum of 1.7 bar (25 psig).<br />

WILDEN PUMP & ENGINEERING, LLC 10 WIL-12071-E-01