VAV box reheat is active, damper is open to maximum ... - BetterBricks

VAV box reheat is active, damper is open to maximum ... - BetterBricks

VAV box reheat is active, damper is open to maximum ... - BetterBricks

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>VAV</strong> <strong>box</strong> <strong>reheat</strong> <strong>is</strong> <strong>active</strong>, <strong>damper</strong> <strong>is</strong> <strong>open</strong> <strong>to</strong><br />

<strong>maximum</strong> position<br />

Introduction<br />

Th<strong>is</strong> condition can ex<strong>is</strong>t in almost any variable-air-volume (<strong>VAV</strong>) system regardless of <strong>VAV</strong> <strong>box</strong> type or<br />

source of <strong>reheat</strong>. Please refer <strong>to</strong> your operation-and-maintenance (O&M) manuals <strong>to</strong> determine what type<br />

of <strong>VAV</strong> <strong>box</strong>es you have installed.<br />

An air handler delivers air <strong>to</strong> all of the zones it serves at the same temperature as determined by the<br />

control-program logic. Some zones may require cooling while others, usually on the building perimeter,<br />

may require heating. The air temperature <strong>is</strong> set <strong>to</strong> sat<strong>is</strong>fy the zones needing cooling, and the air delivered<br />

<strong>to</strong> the zones needing heating will be <strong>reheat</strong>ed by an electric or hydronic coil in the <strong>VAV</strong> <strong>box</strong> for that zone.<br />

Before the heating coils are energized, the <strong>damper</strong> in the <strong>VAV</strong> <strong>box</strong> should be set <strong>to</strong> the minimum position.<br />

As more heat <strong>is</strong> needed, the airflow should be as low as possible <strong>to</strong> minimize the volume of cooled air<br />

that has <strong>to</strong> be heated.<br />

There are conditions (noted below) where having a <strong>damper</strong> <strong>open</strong> at 100% does not necessarily mean that<br />

airflow <strong>is</strong> 100%. Also, there are special situations where <strong>reheat</strong> <strong>is</strong> used for humidity control and different<br />

control logic may apply.<br />

Reheat systems using heating water have no minimum requirement for coil air velocity, whereas electric<br />

<strong>reheat</strong> coils require a minimum air velocity <strong>to</strong> prevent the coil from overheating. Th<strong>is</strong> <strong>is</strong> typically around<br />

70 cfm/kW. Electric <strong>reheat</strong> coils can also be provided with stages of 1 kW through 5 kW. They can also be<br />

modulated using special controllers. These can greatly reduce electrical demand compared <strong>to</strong> staged<br />

<strong>reheat</strong>, which <strong>is</strong> often in 5 kW increments.<br />

How Th<strong>is</strong> Wastes Energy<br />

The <strong>VAV</strong>-<strong>box</strong> primary air <strong>damper</strong> (from the AHU) should be at its minimum position before the <strong>reheat</strong><br />

energizes. It <strong>is</strong> possible for the <strong>damper</strong> <strong>to</strong> be <strong>open</strong> more than minimum. Th<strong>is</strong> allows simultaneous heating<br />

and cooling which <strong>is</strong> prohibited by most, if not all, energy codes.<br />

Possible Causes for Th<strong>is</strong> Symp<strong>to</strong>m<br />

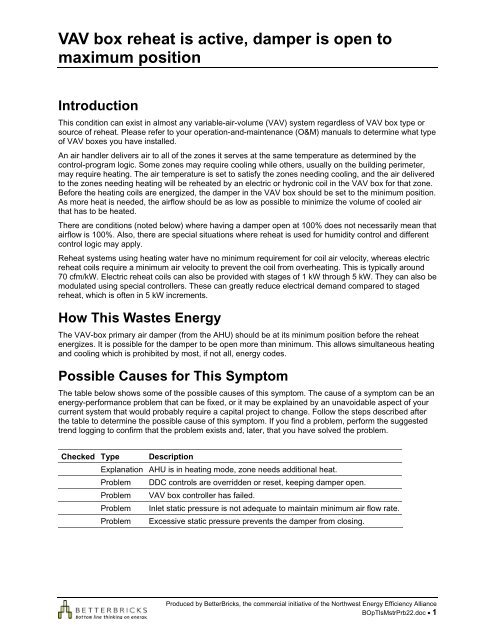

The table below shows some of the possible causes of th<strong>is</strong> symp<strong>to</strong>m. The cause of a symp<strong>to</strong>m can be an<br />

energy-performance problem that can be fixed, or it may be explained by an unavoidable aspect of your<br />

current system that would probably require a capital project <strong>to</strong> change. Follow the steps described after<br />

the table <strong>to</strong> determine the possible cause of th<strong>is</strong> symp<strong>to</strong>m. If you find a problem, perform the suggested<br />

trend logging <strong>to</strong> confirm that the problem ex<strong>is</strong>ts and, later, that you have solved the problem.<br />

Checked Type Description<br />

Explanation AHU <strong>is</strong> in heating mode, zone needs additional heat.<br />

Problem DDC controls are overridden or reset, keeping <strong>damper</strong> <strong>open</strong>.<br />

Problem <strong>VAV</strong> <strong>box</strong> controller has failed.<br />

Problem Inlet static pressure <strong>is</strong> not adequate <strong>to</strong> maintain minimum air flow rate.<br />

Problem Excessive static pressure prevents the <strong>damper</strong> from closing.<br />

Produced by <strong>BetterBricks</strong>, the commercial initiative of the Northwest Energy Efficiency Alliance<br />

BOpTlsMstrPrb22.doc • 1

How <strong>to</strong> Find the Problem(s) by Inspection<br />

Inspection Step 1<br />

Inspect the direct-digital-control (DDC) system <strong>to</strong> see if the AHU <strong>is</strong> in cooling or heating mode. If it <strong>is</strong> in<br />

heating mode, then the zone <strong>reheat</strong> <strong>is</strong> providing the additional heat that the AHU can’t provide. Th<strong>is</strong> can<br />

occur during morning warm-up.<br />

Inspection Step 2<br />

If the <strong>damper</strong> control has been overridden in the DDC programming, determine why before correcting the<br />

problem. Some reasons for override may be:<br />

• The space has a high minimum make-up-air requirement such as for a fume or exhaust hood.<br />

• The <strong>damper</strong> was overridden during the cooling season <strong>to</strong> meet a temporary need for space<br />

temperature and was not subsequently reset.<br />

• Tenant complaints about poor air circulation, or “dead-air” conditions.<br />

The first condition has no simple solution and may actually be part of the original design. The second and<br />

third conditions require a review of the space-cooling loads <strong>to</strong> ensure that proper primary air <strong>is</strong> available<br />

under all conditions. The diffuser d<strong>is</strong>tribution should also be checked <strong>to</strong> make sure the supply air <strong>is</strong> not<br />

short-circuiting <strong>to</strong> the return-air plenum.<br />

Inspection Step 3<br />

Inspect the <strong>damper</strong> opera<strong>to</strong>r <strong>to</strong> make sure it <strong>is</strong> operating properly. Cycle the <strong>damper</strong> using the DDC<br />

system while observing its response locally. If there <strong>is</strong> no change in position, the <strong>damper</strong> opera<strong>to</strong>r may<br />

have failed. A DDC technician can determine whether th<strong>is</strong> <strong>is</strong> the case. Make sure there are no obvious air<br />

leaks at the flex connection <strong>to</strong> the <strong>VAV</strong> <strong>box</strong>.<br />

Inspection Step 4<br />

The AHU may have a pressure-control problem that <strong>is</strong> starving the <strong>VAV</strong> <strong>box</strong> of primary air, forcing the<br />

<strong>damper</strong> <strong>to</strong> be wide <strong>open</strong> just <strong>to</strong> meet minimum airflow requirements. Inspect the AHU static pressure (SP)<br />

setpoint (in inches of water, typically denoted as "wg) and variable-speed-drive (VSD) speed <strong>to</strong> see if the<br />

static pressure design conditions are being met. Th<strong>is</strong> condition can also be caused by excessive duct<br />

leakage or a closed fire <strong>damper</strong> upstream of the <strong>VAV</strong> <strong>box</strong>.<br />

Inspection Step 5<br />

In conjunction with Inspection Step 4, the AHU static pressure may be <strong>to</strong>o high and the <strong>VAV</strong> <strong>box</strong> <strong>damper</strong><br />

actua<strong>to</strong>r does not have enough <strong>to</strong>rque <strong>to</strong> overcome it. Th<strong>is</strong> typically occurs in <strong>VAV</strong> <strong>box</strong>es close <strong>to</strong> the air<br />

handler where the duct static pressure <strong>is</strong> the highest.<br />

How <strong>to</strong> Confirm the Problem(s) by Trend Logging<br />

Trend log the following:<br />

• AHU supply-air temperature (SAT)<br />

• AHU static pressure (SP)<br />

• <strong>VAV</strong> <strong>box</strong> SAT, if available<br />

• Damper position<br />

• Heating coil percent capacity (feedback and not output from the DDC system)<br />

Graph the heating coil percent with respect <strong>to</strong> the other four points. Look for correlations in the trends.<br />

Produced by <strong>BetterBricks</strong>, the commercial initiative of the Northwest Energy Efficiency Alliance<br />

BOpTlsMstrPrb22.doc • 2

If the <strong>damper</strong> position <strong>is</strong> constant when you would expect variation, then the mo<strong>to</strong>r opera<strong>to</strong>r or DDC-<strong>box</strong><br />

controller (including the pressure transducer and its tubing) may be the problem.<br />

If the <strong>damper</strong> position <strong>is</strong> constant, the duct static pressure <strong>is</strong> not sat<strong>is</strong>fied, and the AHU VSD <strong>is</strong> at 100%,<br />

then the system capacity <strong>is</strong> inadequate, or there may be a large duct leak somewhere in the system.<br />

(Contrac<strong>to</strong>rs have been known <strong>to</strong> remove terminal units and leave the medium-pressure ducting wide<br />

<strong>open</strong> for added ventilation during renovation projects.)<br />

If the AHU SP <strong>is</strong> being maintained and the VSD <strong>is</strong> cycling as needed <strong>to</strong> maintain the setpoint, there may<br />

be a closed fire <strong>damper</strong> upstream of the <strong>VAV</strong> <strong>box</strong>. Inspect any other <strong>VAV</strong> <strong>box</strong>es being fed by the same<br />

branch duct (downstream of the last fire <strong>damper</strong>) <strong>to</strong> see if they exhibit similar problems.<br />

Example of Normal Operation<br />

If your graph looks similar <strong>to</strong> the one below then your system <strong>is</strong> operating as it should and the problem <strong>is</strong><br />

resolved. The <strong>damper</strong> <strong>is</strong> at minimum position while <strong>reheat</strong> <strong>is</strong> <strong>active</strong>. When the thermostat calls for cooling,<br />

the <strong>reheat</strong> goes <strong>to</strong> zero and the <strong>damper</strong> <strong>open</strong>s as needed <strong>to</strong> sat<strong>is</strong>fy the space requirements. Note that the<br />

fan static pressure <strong>is</strong> maintained throughout the day.<br />

Normal <strong>VAV</strong>-<strong>box</strong> operation<br />

Examples of Abnormal Operation<br />

<strong>VAV</strong> <strong>box</strong>es are no<strong>to</strong>rious for having many different modes of failure. Below are two examples of what a<br />

trend log of abnormal operation might look like, but your own trend-log graph will probably have its own<br />

unique features.<br />

If your graph looks similar <strong>to</strong> one below then your system <strong>is</strong> not operating as it should and the problem <strong>is</strong><br />

unresolved. The <strong>reheat</strong> <strong>is</strong> energized at 50% once the <strong>damper</strong> r<strong>is</strong>es above minimum setpoint. Airflow from<br />

the AHU <strong>to</strong> the pressure-sensor location <strong>is</strong> not a problem since it can maintain static pressure. Inspect the<br />

static pressure at the <strong>VAV</strong> <strong>box</strong> locally <strong>to</strong> make sure it has adequate pressure. There may be a partially<br />

Produced by <strong>BetterBricks</strong>, the commercial initiative of the Northwest Energy Efficiency Alliance<br />

BOpTlsMstrPrb22.doc • 3

closed <strong>damper</strong> upstream, so check other <strong>VAV</strong> <strong>box</strong>es fed by the same branch ducting <strong>to</strong> see if they have<br />

the same problems.<br />

Abnormal Operation: <strong>reheat</strong> not de-energized<br />

If your graph looks similar <strong>to</strong> the one below then your system <strong>is</strong> not operating as it should and the<br />

problem <strong>is</strong> unresolved. The <strong>reheat</strong> <strong>is</strong> energized at 50% once the <strong>damper</strong> r<strong>is</strong>es above minimum setpoint.<br />

Airflow from the AHU <strong>to</strong> the pressure-sensor location <strong>is</strong> a problem since it cannot maintain static<br />

pressure. The <strong>damper</strong> has <strong>open</strong>ed <strong>to</strong> 100% in an attempt <strong>to</strong> maintain the space setpoint. Th<strong>is</strong> chart<br />

depicts a <strong>reheat</strong> system that uses heating water. If the system has electric <strong>reheat</strong>, th<strong>is</strong> graph shows at<br />

least 70 cfm/kW of heating capacity, otherw<strong>is</strong>e the <strong>reheat</strong> would be at zero. Look for fan-speed<br />

restrictions, <strong>open</strong> duct-inspection ports, large leaks, or removed terminal units in a tenant renovation<br />

area. Checking above the ceiling for air no<strong>is</strong>e <strong>is</strong> a good way <strong>to</strong> locate a duct leak.<br />

Produced by <strong>BetterBricks</strong>, the commercial initiative of the Northwest Energy Efficiency Alliance<br />

BOpTlsMstrPrb22.doc • 4

Abnormal operation: AHU SP setpoint not met<br />

Labor Skills Required <strong>to</strong> Find and Resolve the Problem<br />

• DDC system opera<strong>to</strong>r/programmer<br />

• Service mechanic<br />

Produced by <strong>BetterBricks</strong>, the commercial initiative of the Northwest Energy Efficiency Alliance<br />

BOpTlsMstrPrb22.doc • 5