14. Appendix D: Risk-Based Soil Gas Cleanup Levels, Schlage OU

14. Appendix D: Risk-Based Soil Gas Cleanup Levels, Schlage OU

14. Appendix D: Risk-Based Soil Gas Cleanup Levels, Schlage OU

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

TABLE OF CONTENTS<br />

ACRONYMS AND ABBREVIATIONS ................................................................................................. Div<br />

D1.0 INTRODUCTION ..................................................................................................................... D1-1<br />

D2.0 BACKGR<strong>OU</strong>ND ....................................................................................................................... D2-1<br />

D2.1 Site Physical Setting ..................................................................................................... D2-1<br />

D2.2 Site Redevelopment Plans............................................................................................. D2-1<br />

D2.3 Previous Investigations ................................................................................................. D2-1<br />

D3.0 EXPOSURE ASSESSMENT .................................................................................................... D3-1<br />

D3.1 Potentially Exposed Populations ................................................................................... D3-1<br />

D3.2 Potential Exposure Pathways ........................................................................................ D3-1<br />

D3.2.1 <strong>Soil</strong> <strong>Gas</strong> Exposure Pathways ........................................................................ D3-1<br />

D3.3 Exposure Assumptions ................................................................................................. D3-2<br />

D4.0 TOXICITY ASSESSMENT ...................................................................................................... D4-1<br />

D4.1 Noncancer Toxicity Assessment ................................................................................... D4-1<br />

D4.1.1 Noncancer Reference Dose .......................................................................... D4-1<br />

D4.1.2 Target Hazard Index ..................................................................................... D4-1<br />

D4.2 Cancer Slope Factors and Target <strong>Risk</strong> Level ................................................................ D4-2<br />

D4.2.1 Cancer Slope Factors .................................................................................... D4-2<br />

D4.2.2 Target <strong>Risk</strong> Level ......................................................................................... D4-2<br />

D5.0 INDOOR AIR TARGET CONCENTRATIONS ...................................................................... D5-1<br />

D5.1 Indoor Air Target Concentrations ................................................................................. D5-1<br />

D5.2 Indoor Air Concentrations - Residential Living Space ................................................. D5-2<br />

D6.0 CLEANUP LEVELS ................................................................................................................. D6-1<br />

D6.1 <strong>Soil</strong> <strong>Gas</strong> <strong>Cleanup</strong> <strong>Levels</strong> ............................................................................................... D6-1<br />

D6.2 Redevelopment Zone <strong>Cleanup</strong> <strong>Levels</strong> .......................................................................... D6-1<br />

D6.2.1 Residential Over Commercial (Zone 2) and Residential Over Podium<br />

Garage (Zone 3) <strong>Cleanup</strong> <strong>Levels</strong> .................................................................. D6-2<br />

D7.0 APPLICATION OF CLEANUP LEVELS ................................................................................ D7-1<br />

D8.0 CONCLUSION .......................................................................................................................... D8-1<br />

D9.0 REFERENCES .......................................................................................................................... D9-1<br />

Dii

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

TABLES<br />

D3-1 Exposure Factors to Calculate <strong>Risk</strong> <strong>Based</strong> Human Health <strong>Cleanup</strong> <strong>Levels</strong> for Chlorinated<br />

Volatile Organic Compounds<br />

D4-1 Toxicity Values for Chlorinated Volatile Organic Compounds<br />

D5-1 Target Indoor Air Concentration<br />

D6-1 <strong>Soil</strong> <strong>Gas</strong> <strong>Cleanup</strong> <strong>Levels</strong> Protective of Indoor Air<br />

D6-2 Final <strong>Soil</strong> <strong>Gas</strong> <strong>Cleanup</strong> <strong>Levels</strong><br />

ATTACHMENT<br />

D-1 INTERSTATE TECHNOLOGY AND REGULATORY C<strong>OU</strong>NCIL SCENARIO FOR<br />

MULTI-FAMILY DWELLING<br />

Diii

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

ACRONYMS AND ABBREVIATIONS<br />

µg/L<br />

microgram per liter<br />

µg/m 3<br />

microgram per cubic meter<br />

1,1-DCE<br />

1,1-dichloroethene<br />

AF<br />

Attenuation factor (unitless)<br />

AMSL<br />

above mean sea level<br />

AT<br />

averaging time<br />

ATSDR<br />

Agency for Toxic Substances and Disease Registry<br />

B&M<br />

Burns and McDonnell Engineering Company, Inc.<br />

BAAQMD<br />

Bay Area Air Quality Management District<br />

BP<br />

BP PLT-1, LLC<br />

BW<br />

body weight<br />

Cµg/m 3 Ambient air background concentration (µg/m 3 )<br />

CalEPA<br />

California Environmental Protection Agency<br />

cfm/ft 2<br />

cubic feet per minute per square foot<br />

CHHSLs<br />

California Human Health Screening <strong>Levels</strong><br />

cis-1,2-DCE<br />

cis-1,2-dichloroethene<br />

COCs<br />

chemicals of concern<br />

C ppb<br />

Ambient air background concentration (ppb)<br />

CULs<br />

cleanup levels<br />

CVOCs<br />

chlorinated volatile organic compounds<br />

days/year<br />

days per year<br />

DTSC<br />

California Department of Toxic Substances Control<br />

ED<br />

exposure duration<br />

EF<br />

exposure frequency<br />

EIR<br />

environmental impact report<br />

EPA<br />

United States Environmental Protection Agency<br />

EPC<br />

exposure point concentration<br />

ET<br />

exposure time<br />

FS/RAP<br />

Feasibility Study/Remedial Action Plan<br />

IA Indoor air target concentration (µg/m 3 )<br />

IA c Carcinogen indoor air concentration (µg/m 3 )<br />

IA nc Noncarcinogen indoor air concentration (µg/m 3 )<br />

IRIS<br />

Integrated <strong>Risk</strong> Information System<br />

ITRC<br />

Interstate Technology and Regulatory Council<br />

IUR<br />

inhalation unit risk<br />

kg<br />

kilograms<br />

LOAEL<br />

lowest-observed-adverse-effect level<br />

MACTEC<br />

MACTEC Engineering and Consulting, Inc.<br />

mg/m 3<br />

milligrams per cubic meter<br />

MW<br />

Molecular weight of compound<br />

MW PCE Molecular weight of PCE = 165.8<br />

MW TCE Molecular weight of TCE – 131.4<br />

MW VC Molecular weight of VC = 62.5<br />

NOAEL<br />

no-observed-adverse-effect level<br />

OEHHA<br />

Office of Environmental Health Hazard Assessment<br />

PCE<br />

tetrachloroethene<br />

Div

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

PPRTV<br />

provisional peer review toxicity values<br />

RAP<br />

remedial action plan<br />

RfC<br />

reference concentration<br />

RSL<br />

Regional Screening <strong>Levels</strong><br />

<strong>Schlage</strong> <strong>OU</strong><br />

<strong>Schlage</strong> Lock Operable Unit<br />

SG <strong>Soil</strong> gas concentration (µg/m 3 )<br />

Site<br />

<strong>Schlage</strong> <strong>OU</strong> and San Francisco County portion of UPC <strong>OU</strong><br />

SP <strong>OU</strong>-1 Southern Pacific Rail Yard Operable Unit 1<br />

SP<br />

Southern Pacific<br />

T&R<br />

Treadwell and Rollo<br />

TCE<br />

trichloroethene<br />

THQ<br />

target hazard quotient<br />

TR<br />

Target risk (unitless)<br />

trans-1,2-DCE<br />

trans-1,2-dichloroethene<br />

TRL<br />

target risk level<br />

UCL<br />

upper confidence limit<br />

UPC <strong>OU</strong><br />

Universal Paragon Corporation Operable Unit<br />

UPC<br />

Universal Paragon Corporation<br />

VC<br />

Vinyl Chloride<br />

VOCs<br />

volatile organic compounds<br />

Dv

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

D1.0 INTRODUCTION<br />

On behalf of BP PLT-1, LLC (BP), MACTEC Engineering and Consulting, Inc. (MACTEC) is pleased to<br />

submit to the California Department of Toxic Substances Control (DTSC), this report that presents our<br />

risk analysis for the <strong>Schlage</strong> Lock Operable Unit (<strong>Schlage</strong> <strong>OU</strong>), San Francisco, California. The <strong>Schlage</strong><br />

<strong>OU</strong> is defined as the former <strong>Schlage</strong> Lock site, together with soil and groundwater on the northern portion<br />

of the former Southern Pacific Brisbane Rail Yard – Operable Unit 1 (SP <strong>OU</strong>-1) that is impacted with<br />

volatile organic compounds (VOCs). The Universal Paragon Corporation (UPC) <strong>OU</strong> is defined as soil<br />

and groundwater on SP <strong>OU</strong>-1 that is impacted with chemicals other than VOCs. Together, the <strong>Schlage</strong><br />

<strong>OU</strong> and the San Francisco portion of the UPC <strong>OU</strong> constitute the Site.<br />

For the <strong>Schlage</strong> <strong>OU</strong>, this risk analysis document presents the site physical setting, UPC’s planned<br />

redevelopment, a summary of previous investigations, and estimates of cleanup levels (CULs) for<br />

chemicals of concern (COCs) in soil gas at the Site.<br />

D1-1

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

D2.0 BACKGR<strong>OU</strong>ND<br />

D2.1 Site Physical Setting<br />

The <strong>Schlage</strong> <strong>OU</strong> consists of approximately 12.66 acres. The Site consists of approximately 20 acres in<br />

San Francisco, located north of Sunnyvale Avenue, between Bayshore Boulevard on the west, and the<br />

Union Pacific/Joint Powers Board railroad tracks on the east, and Blanken Avenue to the north. The<br />

surface elevation of the Site ranges from approximately 50 feet above mean sea level (AMSL) in the<br />

north to approximately 10 feet AMSL in the south.<br />

D2.2 Site Redevelopment Plans<br />

UPC plans to redevelop the Site in accordance with an Environmental Impact Report (EIR) certified by<br />

the San Francisco Redevelopment Agency on December 16, 2008 and the Planning Commission on<br />

December 18, 2008. The redevelopment plan consists of the following three redevelopment zones, which<br />

are consistent with the plans approved by the San Francisco Planning Department:<br />

• Zone 1 – Public open space on grade.<br />

• Zone 2 – Residential over commercial podium construction.<br />

• Zone 3 – Residential over podium parking construction.<br />

D2.3 Previous Investigations<br />

Investigations to assess the nature and extent of contaminants have been conducted on the Site, with<br />

regulatory oversight, beginning in 1982. Documentation of the field investigations are included in reports<br />

submitted to the DTSC (Treadwell and Rollo (T&R), 2001; Burns & McDonnell Engineering Company,<br />

Inc. [B&M], 2006a and 2006b). Historical soil analytical data is presented in <strong>Appendix</strong> A of the<br />

Feasibility Study/Remedial Action Plan (FS/RAP) for the Site. A compilation of cumulative water level<br />

and water quality data from groundwater monitoring wells at the Site is presented in the draft third quarter<br />

2008 groundwater monitoring report (MACTEC, 2008). A description of the nature and extent of soil and<br />

groundwater contamination and the COCs identified in soil at the <strong>Schlage</strong> <strong>OU</strong> and UPC <strong>OU</strong>s, and<br />

groundwater at the <strong>Schlage</strong> <strong>OU</strong> are presented in the Feasibility Study/Remedial Action Plan (FS/RAP) for<br />

the Site.<br />

D2-1

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

D3.0 EXPOSURE ASSESSMENT<br />

In the exposure assessment for the development of soil gas CULs, potential exposed populations and<br />

potential pathways of exposure are identified. The exposure assessment considers the current and future<br />

land use in order to identify pathways and potentially exposed populations. The exposure assessments<br />

from the Human Health <strong>Risk</strong> Assessment of Joint Groundwater Operable Unit (B&M, 2003), Human<br />

Health <strong>Risk</strong> Assessment for the San Francisco County Parcel of Operable Unit – 1 (B&M, 2006c), and<br />

Human Health <strong>Risk</strong> Assessment for the San Mateo County Parcel of Operable Unit – 1 (B&M, 2006d)<br />

were used in developing the populations and pathways in this CUL document.<br />

D3.1 Potentially Exposed Populations<br />

Potentially exposed populations include those persons whose locations and activities create an<br />

opportunity for contact with the COCs. As described in Section D2.2, the UPC <strong>OU</strong> redevelopment zones<br />

for the Site correspond to three human health exposure scenarios. Zone 1 corresponds to “Recreational”<br />

exposure scenario, and Zones 2 and 3 correspond to both “Mixed Use Multi-Family Residential” and<br />

“Commercial” exposure scenarios. A “Mixed Use Multi-Family Residential” (hereafter referred to as<br />

“residential”) exposure scenario was also evaluated for comparison purposes; however, although Zones 2<br />

and 3 both provide for residential development, the podium type of building construction precludes<br />

residential occupation of the ground level. The “Construction/Excavation Worker” exposure scenario<br />

was considered for the entire Site.<br />

The receptors selected are consistent with the receptors that were quantitatively evaluated in the risk<br />

assessments prepared by B&M (B&M, 2003 and 2006c, d), with the exception of recreational receptor.<br />

The previous risk assessments qualitatively evaluated Visitors/Trespassers, which are now quantitatively<br />

evaluated as recreational receptors. <strong>Soil</strong> gas CULs will be developed for commercial worker receptors,<br />

and residential receptors for comparison purposes only, as described below in Section D3.2.<br />

D3.2 Potential Exposure Pathways<br />

Health risks may occur when there is contact with a chemical by a receptor population. Exposed<br />

populations must then either ingest, inhale, or dermally absorb the chemical to complete an exposure<br />

pathway and experience a possible health risk. The following is a discussion of the pathways with which<br />

CULs were developed for the primary media of concern, which is soil gas. <strong>Soil</strong>, groundwater, and soil<br />

gas at <strong>Schlage</strong> <strong>OU</strong> have shown to contain chlorinated volatile organic compounds (CVOCs), which<br />

include 1,1-dichloroethene (1,1-DCE), cis-1,2-dichloroethene (cis-1,2-DCE), trans-1,2-dichloroethene<br />

(trans-1,2-DCE), tetrachloroethene (PCE), trichloroethene (TCE), and vinyl chloride (VC). CULs for the<br />

CVOCs will be developed for soil gas.<br />

D3.2.1<br />

<strong>Soil</strong> <strong>Gas</strong> Exposure Pathways<br />

Conceptually, CVOCs in groundwater can partition to soil gas. <strong>Soil</strong> gas can then passively migrate or be<br />

actively drawn into the enclosed space of structures that overlie the groundwater containing CVOCs. At<br />

the <strong>Schlage</strong> <strong>OU</strong>, soil gas could migrate to the air within the on-grade commercial buildings (podium<br />

construction) at redevelopment Zone 2, or to the air within the on-grade parking garages at redevelopment<br />

Zone 3. At each of these redevelopment zones, air within the on-grade buildings or parking garages could<br />

then migrate (or be drawn) into the residential spaces that are constructed on top of the buildings/garages,<br />

which is further discussed in Section D5.2. CULs will be developed that are protective of commercial<br />

workers expected to occupy the on-grade structures (full time workers in commercial buildings, or full<br />

D3-1

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

time parking attendant in garages) and be exposed via inhalation of indoor air. These CULs will also be<br />

protective of the residents living in the residential spaces constructed on top of the buildings/garages as<br />

described in Section D5.2. Under a residential exposure scenario, soil gas could migrate to the air within<br />

the multi-family residential on-grade building. CULs will be developed for comparison purposes only<br />

that are protective of residential receptors who maybe exposed via inhalation of indoor air. The<br />

commercial CULs can be compared with CVOC concentrations in soil gas collected prior to initiation of<br />

Site redevelopment activities. Construction/excavation workers and recreational receptors were<br />

considered to have incomplete pathways to soil gas because they were assumed to spend all of their time<br />

outdoors.<br />

D3.3 Exposure Assumptions<br />

The exposure assumptions used to evaluate the exposure pathways in B&M 2003 and 2006c, and d risk<br />

assessments are the same exposure assumptions used to develop soil gas CULs. Exposure assumptions<br />

are provided in Table D3-1.<br />

The adult receptors were assumed to weigh 70 kilograms (kg) (United States Environmental Protection<br />

Agency [EPA], 1991; DTSC, 1996) and child receptors were assumed to weigh 15 kg (EPA, 1991; DTSC,<br />

1996).<br />

The exposure frequency (EF) parameter of 350 days per year (days/year) is used for residential receptors<br />

(EPA, 1991; DTSC, 1996). The EF parameters for commercial worker receptors are based on a standard<br />

work schedule of 250 days/year. For the commercial worker, the exposure duration (ED) of 25 years is<br />

assumed (EPA, 1991; DTSC, 1996).<br />

The averaging time (AT) is the period over which exposure is averaged in days. The noncancer AT for<br />

all receptors is the ED multiplied by 365 days/year (EPA, 1989), which is provided on Table D3-1. The<br />

cancer AT is 70 year lifetime risk multiplied by 365 days/year for all receptors (EPA, 1989).<br />

The exposure time (ET) for the commercial worker receptor is 8 hours/day, which is based on the average<br />

work day (B&M, 2006c, d) in a garage and commercial building.<br />

D3-2

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

D4.0 TOXICITY ASSESSMENT<br />

Toxicity assessment is the process of using the existing toxicity information from human and/or animal<br />

studies to identify potential health risks at various dose levels in exposure populations (EPA, 1989). To<br />

estimate these potential health risks, the relationship between exposure to a chemical (in terms of chronic<br />

daily intake for individuals) and an adverse effect (in terms of bodily response to a specific intake dose<br />

level) must be quantified. The methodologies used to develop toxicity factors differ, depending on<br />

whether the CVOC is a potential carcinogen (i.e., has the potential to cause cancer) and/or has noncancer<br />

adverse effects.<br />

Both California and EPA-derived toxicity values were compiled for the CUL development. For<br />

California, the California Environmental Protection Agency’s (CalEPA) Office of Environmental Health<br />

Hazard Assessment (OEHHA) online toxicity database (OEHHA, 2008) was consulted. The EPA values<br />

were compiled from EPA’s Integrated <strong>Risk</strong> Information System (IRIS), an online database (EPA, 2008c),<br />

the Agency for Toxic Substances and Disease Registry (ATSDR), provided in EPA’s Regional Screening<br />

<strong>Levels</strong> (RSLs) tables (EPA, 2008a), and the provisional peer review toxicity values (PPRTVs), provided<br />

in EPA’s RSLs tables (EPA, 2008a). These sources are updated regularly based on toxicity and exposure<br />

studies. The toxicity values for the CVOCs are discussed below and presented in Table D4-1.<br />

D4.1 Noncancer Toxicity Assessment<br />

D4.1.1<br />

Noncancer Reference Dose<br />

In deriving dose-response criteria for assessing the potential for noncancer health effects from exposure to<br />

chemicals, it is assumed by regulatory agencies that noncancer health effects occur only after a threshold<br />

dose is reached. This threshold dose is usually estimated by regulatory agencies from the no-observed<br />

adverse effect level (NOAEL) or the lowest-observed adverse effect level (LOAEL) determined from<br />

chronic (i.e., long-term) animal studies or human epidemiological studies. The NOAEL is defined as the<br />

highest dose at which no adverse effects are observed, while the LOAEL is defined as the lowest dose at<br />

which adverse effects are observed.<br />

Uncertainty factors or safety factors are applied to the NOAEL or LOAEL observed in animal studies or<br />

human epidemiologic studies to establish inhalation “reference concentrations” (RfCs) in units of<br />

milligrams per cubic meter (mg/m 3 ). Chronic RfC are an estimate of a dose level that is not expected to<br />

result in adverse health effects in persons exposed for a lifetime, even among the most sensitive members<br />

of the population (e.g., children and the aged). Use of these uncertainty and modifying factors add<br />

conservatism into the derivation of the RfC. The chronic inhalation RfCs are presented in Table D4-1.<br />

D4.1.2<br />

Target Hazard Index<br />

Noncarcinogenic effects are health effects pertaining to the function of various organ systems due to<br />

chemically caused toxic endpoints other than cancer and gene mutations. Therefore, EPA (1991)<br />

established a target hazard quotient (THQ) to correspond to a hazard index of one or unity, which is<br />

equivalent to the degree of chemical exposure from all significant exposure pathways in a given medium<br />

below which it is unlikely for even sensitive populations to experience adverse health effects.<br />

D4-1

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

D4.2 Cancer Slope Factors and Target <strong>Risk</strong> Level<br />

D4.2.1<br />

Cancer Slope Factors<br />

Some chemicals have been shown, and many more are assumed to be, potential human carcinogens. To<br />

be health protective, the EPA (1989) assumes that a relatively small number of molecular events can elicit<br />

changes in a cell, ultimately resulting in uncontrolled cell proliferation and cancer. <strong>Based</strong> on this theory,<br />

the EPA uses a two-part process in evaluating the potential cancer risk of contaminants: (1) assigning a<br />

weight-of-evidence classification, and (2) calculating an inhalation unit risk (IUR) for inhalation<br />

exposures.<br />

The EPA (2005) weight-of-evidence classification system for carcinogenicity is as follows:<br />

• A Known human carcinogen;<br />

• B1 or B2 Probable human carcinogen;<br />

• C Possible human carcinogen;<br />

• D Not classifiable as to human carcinogenicity; and<br />

• E Evidence of noncarcinogenicity in humans.<br />

The weight-of-evidence classification is based on the source of the data (human epidemiology study or<br />

animal bioassay) and whether cancer has been observed in more than one animal species. These<br />

alphanumeric classifications are currently being phased out by EPA as toxicity data are reviewed and<br />

revised under the Guidelines for Carcinogenic <strong>Risk</strong> Assessment (EPA, 2005). Under the revised<br />

guidelines, a greater emphasis is placed on the conditions under which the observed effects may be<br />

expressed, such as whether the potential for carcinogenicity appears limited to a specific route of<br />

exposure, or whether carcinogenic activity may be secondary to another toxic effect. The current weightof-evidence<br />

system is a narrative classification, as follows (EPA, 2005):<br />

• Carcinogenic to humans;<br />

• Likely to be carcinogenic to humans;<br />

• Suggestive evidence of carcinogenicity, but not sufficient to assess human carcinogenic potential;<br />

• Data are inadequate for an assessment of human carcinogenic potential; and<br />

• Not likely to be carcinogenic to humans.<br />

In general, IURs have been calculated and are available for potential carcinogens in Groups A, B1, and<br />

B2, but are calculated only on a case-by-case basis for Group C (EPA, 1989). The IUR is used to develop<br />

inhalation CULs and is considered an upper-bound excess lifetime cancer risk estimated to result from<br />

continuous exposure to an agent at a concentration of 1 micrograms per cubic meter (µg/m 3 ) in air. IURs<br />

have been developed for known, likely, or suggestive evidence carcinogens for which inhalation<br />

assessments have been conducted and reviewed by EPA. The IURs for the development of CULs are<br />

presented in Table D4-1.<br />

D4.2.2<br />

Target <strong>Risk</strong> Level<br />

Since EPA (1989) assumes that a relatively small number of molecular events can elicit changes in a cell,<br />

EPA uses a two-part process in evaluating the potential cancer risk of contaminants. One part of the<br />

D4-2

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

process is calculating an IUR for inhalation exposures. The IUR directly relates to the incremental cancer<br />

risk over a lifetime, which is assumed to be 70 years. EPA (1991) considers a target risk range of one-inone<br />

million (1E -06 ) –to one in-ten thousand (1E -04 ) to be safe and protective of public health. Therefore, a<br />

target risk level (TRL) that corresponds to a 1E -06 was selected to evaluate the incremental risk of an<br />

individual developing cancer over a lifetime as a result of exposure to the potential carcinogen from all<br />

significant exposure pathways for a given medium. The TRL is presented on Table D3-1.<br />

D4-3

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

D5.0 INDOOR AIR TARGET CONCENTRATIONS<br />

This section describes the development and selection of residential and commercial indoor air target<br />

concentrations, and describes the approach that is used to evaluate potential exposures to residential<br />

receptors that live in residential units located over the garages or commercial space.<br />

D5.1 Indoor Air Target Concentrations<br />

CULs for soil gas and groundwater that are a vapor source to indoor air are developed by back-calculating<br />

a soil gas or groundwater CVOC concentration that would not result in unsafe levels of the CVOC in<br />

indoor air. Therefore, indoor air target concentrations were selected from published indoor air screening<br />

levels or calculated to represent the levels of CVOC in indoor air that would be safe (protective) for<br />

residents or commercial receptors. The residential and commercial indoor air screening levels from the<br />

California Human Health Screening <strong>Levels</strong> (CHHSLs) (CalEPA, 2005) were compared to the residential<br />

and industrial air RSLs (EPA, 2008a), respectively. The residential CHHSLs and RSLs for trans-1,2-<br />

DCE, PCE, and TCE were similar in value, but VC was not similar because RSL was derived using a less<br />

conservative IUR factor than the CHHSL value. A CHHSL value was not available for 1,1-DCE, and a<br />

RSL value was not available for cis-1,2-DCE. Therefore, the indoor air target concentrations for<br />

residential receptors were identified as the residential CHHSLs (CalEPA, 2005), with the exception of<br />

1,1-DCE, for which the residential air RSL (EPA, 2008a) was used. The commercial indoor air screening<br />

levels from the CHHSLs were not selected in that the CHHSL values are inconsistent with calculated<br />

indoor air commercial receptors. The calculated indoor air values are consistent with the RSLs, which are<br />

more current than the CHHSL values, with the exception of VC because a more conservative CalEPA<br />

IUR was selected than was used for the RSL. Therefore, the indoor air target concentrations for<br />

commercial receptors were calculated as risk-based values using the RSLs User Guide (EPA, 2008b). The<br />

noncancer and cancer indoor air concentrations were calculated to correspond to a hazard index of one or<br />

unity or a cancer risk of 1E -06 , respectively. The following equations were used to develop commercial<br />

target indoor air noncancer and cancer concentrations.<br />

Noncarcinogenic<br />

Where:<br />

µ g<br />

THQ × AT × 1000<br />

mg<br />

IA nc<br />

=<br />

1<br />

EF × ED × ET ×<br />

RfC<br />

IA nc = Noncarcinogen indoor air concentration (µg/m 3 );<br />

THQ = Target hazard quotient (unitless);<br />

AT = Averaging time (days);<br />

EF = Exposure frequency (days/year);<br />

ED = Exposure duration (years);<br />

ET = Exposure time (hours/hour); and<br />

RfC = Reference concentration (mg/m 3 ).<br />

Carcinogenic<br />

IA TR × AT<br />

= c EF × ED × ET × IUR<br />

D5-1

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

Where:<br />

IA c = Carcinogen indoor air concentration (µg/m 3 );<br />

TR = Target risk (unitless);<br />

AT = Averaging time (days);<br />

EF = Exposure frequency (days/year);<br />

ED = Exposure duration (years);<br />

ET = Exposure time (hours/hour); and<br />

IUR = Inhalation unit risk (µg/m 3 ) -1 .<br />

The exposure assumptions and toxicity values are provided on Tables D3-1 and D4-1, respectively.<br />

Calculated commercial indoor air concentrations and selected residential indoor air concentrations are<br />

provided on Table D5-1. For the CVOCs that have noncancer and cancer indoor air concentrations, the<br />

more conservative value was selected as the target indoor air concentration for the commercial worker<br />

receptors.<br />

D5.2 Indoor Air Concentrations - Residential Living Space<br />

For comparison purposes, the potential for airflow from on-grade commercial buildings or parking<br />

garages into residential living spaces that are located on top of the buildings/parking garages is evaluated<br />

by determining the amount of air leaking into the residential units from the garage or the commercial<br />

spaces below. The air leakage factor between the garage or commercial spaces and the residential units<br />

above was established based on published studies of airflow distribution in multifamily buildings (Feustel<br />

and Diamond, 1996; and Interstate Technology and Regulatory Council [ITRC], 2007). The ITRC<br />

scenario for multi-family dwelling that is located over a former gas station is provided in Attachment D-1.<br />

In these studies, the air leakage between the garage and the residential units above ranged from less than<br />

4%, to 5%. An air leakage value of 5% from ITRC was used to estimate the indoor air concentrations<br />

within the residential units. Specifically, the commercial indoor air target concentrations, which represent<br />

the maximum level of CVOCs that would exist in on-grade commercial buildings or parking garages,<br />

were multiplied by a 5% leakage factor to estimate the potential CVOC concentrations that could exist in<br />

overlying residential spaces.<br />

The estimated air concentrations within the residential units were compared to the residential CHHSLs<br />

(CalEPA, 2005) and ambient air background concentrations from the Bay Area Air Quality Management<br />

District (BAAQMD). A CHHSL value was not available for 1,1-DCE, so the residential air concentration<br />

from the RSLs (EPA, 2008a) was used. The ambient air background concentrations provided by<br />

BAAQMD are provided in parts per billion. The concentrations were converted to µg/m 3 using the<br />

following equation:<br />

Where:<br />

C 3 = 0. 0409 × C<br />

ppb<br />

× MW<br />

µ g / m<br />

C µg/m3 = Ambient air background concentration (µg/m 3 );<br />

C ppb = Ambient air background concentration (ppb);<br />

MW = Molecular weight of compound:<br />

MW PCE = Molecular weight of PCE = 165.8;<br />

MW TCE = Molecular weight of TCE = 131.4; and<br />

MW VC = Molecular weight of VC = 62.5.<br />

D5-2

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

The table below presents the calculated commercial indoor air target concentration, the estimated indoor<br />

air concentrations in overlying residential space (represented as 5% of the commercial indoor air<br />

concentration), residential CHHSLs, and ambient air background concentrations.<br />

Chemicals of Concern<br />

Commercial<br />

Indoor Air<br />

Target<br />

Concentration<br />

(µg/m 3 )<br />

Indoor Air Concentrations<br />

Estimated<br />

Residential<br />

Indoor Air<br />

Concentration b<br />

(µg/m 3 )<br />

Residential<br />

California<br />

Human Health<br />

Screening <strong>Levels</strong><br />

(CHHSLs)<br />

(µg/m 3 )<br />

Ambient Air<br />

Background<br />

Concentrations c<br />

(µg/m 3 )<br />

1,1-Dichloroethene a 876 44 210 --<br />

cis-1,2-Dichloroethene 153 7.7 36.5 --<br />

trans-1,2-Dichloroethene 263 13 73 --<br />

Tetrachloroethene 2.08 0.10 0.41 0.54<br />

Trichloroethene 6.13 0.31 1.22 0.16<br />

Vinyl chloride 0.16 0.008 0.03 0.38<br />

a The residential value is from EPA, 2008a because there is not a CHHSL value for 1,1-DCE.<br />

b Calculated as commercial indoor air target concentration x 5%.<br />

c Ambient air background concentrations from BAAQMD, 2007 and DTSC, 2009.<br />

-- = Not available.<br />

As indicated in this table, estimated indoor air concentrations in residential living space located above ongrade<br />

commercial buildings or parking garages would be below the residential CHHSLs. The estimated<br />

residential indoor air concentrations for PCE and VC are below the ambient air background<br />

concentrations. The estimated residential indoor air concentration of TCE is marginally higher than the<br />

ambient air background concentration. However, the soil gas or groundwater CULs are protective for<br />

vapor migration to on-grade commercial space occupied by full time workers (commercial buildings or<br />

parking garages) would also be protective for the indoor air in residential space located over (on top of)<br />

the commercial buildings/parking garages. An air leakage value of approximately 20% would be needed<br />

to meet the residential CHHSL values.<br />

D5-3

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

D6.0 CLEANUP LEVELS<br />

This section describes the development and selection of soil gas CULs by receptor. This section also<br />

provides the equations used to develop soil gas CULs.<br />

D6.1 <strong>Soil</strong> <strong>Gas</strong> <strong>Cleanup</strong> <strong>Levels</strong><br />

<strong>Soil</strong> gas CULs were developed to evaluate soil gas samples that will be collected when the soil and<br />

groundwater remediation is completed to ensure residual concentrations in soil and volatilization from<br />

groundwater is not a significant source to indoor air. The best method of evaluating potential vapor<br />

intrusion is via soil gas, and not soil or groundwater measurements. The soil gas CULs were developed<br />

using the Guidance for the Evaluation and Mitigation of Subsurface Vapor Intrusion to Indoor Air<br />

(DTSC, 2005) for commercial receptors for Zones 2 and 3, which assume there is a full-time commercial<br />

worker in the on-grade building for Zone 2 and a full-time parking attendant in the on-grade garage for<br />

Zone 3, and for residential receptors for comparison purposes, which assume that a resident lives in ongrade<br />

residential structures, using the following equation.<br />

Where:<br />

SG =<br />

IA<br />

AF<br />

SG = <strong>Soil</strong> gas concentration (µg/m 3 );<br />

IA = Indoor air target concentration (µg/m 3 ); and<br />

AF = Attenuation factor (unitless).<br />

The attenuation factors that were used to calculate the soil gas concentrations for residential and<br />

commercial receptors are default attenuation factors from the Guidance for the Evaluation and Mitigation<br />

of Subsurface Vapor Intrusion to Indoor Air (DTSC, 2005). The attenuation factor for future residential<br />

slab-on-grade was used to develop residential soil gas concentrations for comparison purposes only, and<br />

the future commercial slab-on-grade construction was used to develop commercial soil gas concentrations<br />

for the Site. The residential and commercial soil gas concentrations are provided on Table D6-1. The<br />

CHHSL values were not selected due to the inconsistencies with indoor air concentrations as stated in<br />

Section D5.1 for commercial workers, and the CHHSL soil gas concentrations for both residential and<br />

commercial workers were not developed for new construction. Also, the soil gas CULs are conservative<br />

as they do not take into consideration an air exchange rate that would further enhance dilution of CVOCs<br />

present in indoor air. In accordance with the 2007 California Mechanical Code Section 406.4.2 and<br />

Chapter 4 Table 4-4, a mechanical ventilation system shall be provided for an enclosed parking garage<br />

where the air exchange rate needs to meet a minimum exhaust rate of 0.75 cubic feet per minute per<br />

square foot (cfm/ft 2 ).<br />

D6.2 Redevelopment Zone <strong>Cleanup</strong> <strong>Levels</strong><br />

This section describes the selection of soil gas CULs for CVOCs at redevelopment zones 2 and 3 at the<br />

<strong>Schlage</strong> <strong>OU</strong>. The soil gas CULs for redevelopment zones 2 and 3 are provided below and on Table D6-2.<br />

D6-1

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

D6.2.1<br />

Residential Over Commercial (Zone 2) and Residential Over<br />

Podium Garage (Zone 3) <strong>Cleanup</strong> <strong>Levels</strong><br />

Redevelopment Zone 2 is designated as residential over commercial buildings, and Zone 3 as residential<br />

over podium parking construction. Both zones assume commercial receptors on the ground floor with<br />

residential receptors above. <strong>Soil</strong> gas CULs are protective of vapor intrusion to indoor air for commercial<br />

receptors, but are also protective for residential receptors that may be exposed to air that may leak from<br />

on-grade commercial buildings or parking garages to the overlying residential space.<br />

Chemicals of Concern<br />

<strong>Soil</strong> <strong>Gas</strong> <strong>Cleanup</strong> <strong>Levels</strong><br />

(g/m 3 )<br />

(g/L)<br />

1,1-Dichloroethene 2,190,000 2,190<br />

cis-1,2-Dichloroethene 383,250 383<br />

trans-1,2-Dichloroethene 657,000 657<br />

Tetrachloroethene 5,197 5.19<br />

Trichloroethene 15,330 15<br />

Vinyl chloride 393 0.39<br />

µg/L: micrograms per liter<br />

D6-2

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

D7.0 APPLICATION OF CLEANUP LEVELS<br />

The CULs will be compared to an exposure point concentration (EPC). The EPA defines EPCs as the<br />

representative chemical concentration a receptor may contact in an exposure area over the exposure<br />

period (EPA, 1989). The typical concept of human exposure at a Site or within a defined exposure area is<br />

an individual’s contact with the contaminated medium on a periodic and random basis. Because of the<br />

repeated nature of such contact, the human exposure does not really occur at a fixed point but rather at a<br />

variety of points with equal likelihood that any given point within the exposure area will be the contact<br />

location on any given day. Thus, the EPCs should be the arithmetic averages of chemical concentrations<br />

within the exposure area. To account for uncertainty in estimating the arithmetic mean concentration, the<br />

EPA recommends that an upper confidence limit (UCL) be used to represent the EPC. The EPCs for the<br />

CVOCs for each media of concern will be calculated using EPA’s ProUCL Version 4.0. The maximum<br />

concentration will be used for CVOCs that have insufficient number of samples to calculate a UCL.<br />

If the chemical specific ratio of the EPC to the CUL is less than 1, this indicates that a 1x10 -06 health risk<br />

for carcinogens and a hazard index of 1 for non-carcinogens has been met and that substantial health risks<br />

will not likely to be associated with that chemical. If the ratio of the EPC to the CUL is greater than 1,<br />

this indicates that the concentration of the chemical may exceed the value protective of public health. To<br />

evaluate possible exposure to multiple chemicals, the effects of multiple chemicals will be assumed to be<br />

additive and the ratios will be added together to calculate a ratio sum. A ratio sum of 1 or less indicates<br />

that substantial health risks are not likely to be associated with exposure to the multiple chemicals<br />

evaluated; whereas a ratio sum greater than 1 indicates further action may be necessary.<br />

D7-1

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

D8.0 CONCLUSION<br />

The soil gas CULs were developed using the previous risk assessments prepared by B&M as a guide for<br />

population selection, pathway selection, and exposure assumptions. Indoor air target concentrations were<br />

developed in order to calculate CULs for vapor intrusion from soil gas, soil, and groundwater. The soil<br />

gas CULs are presented on Table D6-1. The selected CULs for each redevelopment zone are provided on<br />

Table D6-2 and Section D6.2.<br />

D8-1

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

D9.0 REFERENCES<br />

Bay Area Air Quality Management District (BAAQMD), 2007. Annual Report 2003. Toxic Air<br />

Contaminant Control Program. August.<br />

Burns & McDonnell Engineering Company, Inc. (B&M), 2003. Human Health <strong>Risk</strong> Assessment of Joint<br />

Groundwater Operable Unit. March.<br />

_____, 2006a. Groundwater Monitoring & Sampling Results, <strong>Schlage</strong> Lock Company Site, San<br />

Francisco, California. January 11.<br />

_____, 2006b. <strong>Soil</strong> Sampling Summary Report, <strong>Schlage</strong> Lock Company Site, San Francisco, California.<br />

January 25.<br />

_____, 2006c. Human Health <strong>Risk</strong> Assessment for the San Francisco County Parcel of Operable Unit-1.<br />

April.<br />

_____, 2006d. Human Health <strong>Risk</strong> Assessment for the San Mateo County Parcel of Operable Unit-1.<br />

May.<br />

California Environmental Protection Agency (CalEPA), 2005. Use of California Human Health<br />

Screening <strong>Levels</strong> (CHHSLs) in Evaluation of Contaminated Properties. January.<br />

Department of Toxic Substances Control (DTSC), 1996. Supplemental Guidance for Human Health<br />

Multimedia <strong>Risk</strong> Assessments of Hazardous Waste Sites and Permitted Facilities. August.<br />

_____, 2005. Guidance for the Evaluation and Mitigation of Subsurface Vapor Intrusion to Indoor Air.<br />

California Environmental Protection Agency. Revised. February 7.<br />

_____, 2008. Consent Order, dated May 22, 2008, Docket Number HAS-CO 07/08-185.<br />

_____, 2009. Fwd: FW: Toxics Monitoring Data. Electronic mail correspondence between Calvin<br />

Willhite, DTSC, and Nyree Melancon, MACTEC. July 13.<br />

Feustel, H.E. and R.C. Diamond (Feustel and Diamond), 1996. Air Flow Distribution in a High-Rise<br />

Residential Building. Lawrence Berkeley National Laboratory, Berkeley, USA.<br />

Interstate Technology and Regulatory Council (ITRC), 2007. Technical and Regulatory Guidance<br />

Supplement; Vapor Intrusion Pathway: Investigative Approaches for Typical Scenarios. A Supplement to<br />

Vapor Intrusion Pathway: A Practical Guideline. Vapor Intrusion Team. January.<br />

MACTEC Engineering and Consulting, Inc. (MACTEC), 2008. Quarterly Groundwater Monitoring<br />

Report, Third Quarter 2008, <strong>Schlage</strong> <strong>OU</strong>, San Francisco and Brisbane, California. December 18.<br />

Office of Environmental Health Hazard Assessment (OEHHA), 2008. Toxicity Criteria Database.<br />

California Environmental Protection Agency (CalEPA).<br />

http://www.oehha.ca.gov/risk/ChemicalDB/index.asp. December.<br />

Treadwell and Rollo (T&R), 2001. <strong>Soil</strong> Operable Unit Remedial Investigation Report. <strong>Schlage</strong> Lock<br />

Company Site, 2401-2555 Bayshore Boulevard, San Francisco, California. June.<br />

United States Environmental Protection Agency (EPA), 1989. <strong>Risk</strong> Assessment Guidance for Superfund<br />

Volume I - Human Health Evaluation Manual, Part A (RAGS). EPA/540/1-89/002.<br />

_____, 1991. <strong>Risk</strong> Assessment Guidance for Superfund, Volume 1: Human Health Evaluation Manual,<br />

Supplemental Guidance, Standard Default Exposure Factors. Interim Final. OSWER Directive<br />

9285.6-03.<br />

D9-1

<strong>Appendix</strong> D, <strong>Schlage</strong> <strong>OU</strong>, San Francisco, California November 4, 2009<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>/UPC <strong>OU</strong><br />

MACTEC Project No. 4096088522<br />

KB63190 FS-RAP <strong>Appendix</strong> D Text-<strong>Schlage</strong><br />

_____, 2005. Guidelines for Carcinogen <strong>Risk</strong> Assessment. EPA/630/P-03/001F. March.<br />

_____, 2008a. Regional Screening <strong>Levels</strong>. Region 9. September.<br />

_____, 2008b. Regional Screening <strong>Levels</strong> User Guide. September 18.<br />

_____, 2008c. Integrated <strong>Risk</strong> Information System (IRIS). Http://www.epa.gov/iris. December.<br />

D9-2

TABLES

<strong>Appendix</strong> D<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>,<br />

San Francisco, California<br />

MACTEC Project 4096088522<br />

November 4, 2009<br />

KB63190 FS-RAP <strong>Appendix</strong> D Tables<br />

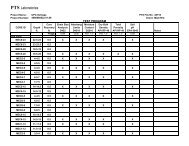

Table D3-1. Exposure Factors to Calculate <strong>Risk</strong> <strong>Based</strong> Human Health<br />

<strong>Cleanup</strong> <strong>Levels</strong> for Chlorinated Volatile Organic Compounds<br />

Exposure Parameters Units a Default or Assumed Value Reference b<br />

Target Noncancer Hazard Quotient (THQ) unitless 1 EPA, 1991<br />

Target Cancer <strong>Risk</strong> (TR) unitless 1.E-06 EPA, 1991<br />

Body Weight (BW)<br />

Child kg 15 EPA, 1991; DTSC, 1996; B&M, 2006c,d<br />

Adult kg 70 EPA, 1991; DTSC, 1996; B&M, 2006c,d<br />

Averaging Time (AT)<br />

Noncarcinogenic<br />

Residential<br />

Child days 2,190 EPA, 1991; DTSC, 1996; B&M, 2006c,d<br />

Adult days 8,760 EPA, 1991; DTSC, 1996; B&M, 2006c,d<br />

Commercial days 9,125 EPA, 1991; DTSC, 1996; B&M, 2006c,d<br />

Carcinogenic days 25,550 EPA, 1991; DTSC, 1996; B&M, 2006c,d<br />

Exposure Frequency (EF)<br />

Residential days/year 350 EPA, 1991; DTSC, 1996; B&M, 2006c,d<br />

Commercial days/year 250 EPA, 1991; DTSC, 1996; B&M, 2006c,d<br />

Exposure Duration (ED)<br />

Residential<br />

Child years 6 EPA, 1991; DTSC, 1996; B&M, 2006c,d<br />

Adult years 24 EPA, 1991; DTSC, 1996; B&M, 2006c,d<br />

Commercial years 25 EPA, 1991; DTSC, 1996; B&M, 2006c,d<br />

Conversion Factor (CF)<br />

µg/mg 1,000 --<br />

day/hour 0.042 --<br />

Exposure Time (ET)<br />

Residential hour/day 24 B&M, 2006c,d<br />

Commercial hour/day 8 B&M, 2006c,d<br />

Footnotes:<br />

a kg = kilogram; days/year = days per year; µg/mg = microgram per milligram; day/hour = day per hour; and hour/day = hours per day.<br />

b References:<br />

Burns & McDonnell (B&M), 2006c. Human Health <strong>Risk</strong> Assessment for the San Francisco County Parcel of Operable Unit - 1. Universal Paragon<br />

Corporation. April.<br />

Burns & McDonnell (B&M), 2006d. Human Health <strong>Risk</strong> Assessment for the San Mateo County Parcel of Operable Unit - 1. Universal Paragon<br />

Corporation. May.<br />

Department of Toxic Substances Control (DTSC), 1996. Supplemental Guidance for Human Health Multimedia <strong>Risk</strong> Assessments of Hazardous<br />

Waste Sites and Permitted Facilities. August<br />

United States Environmental Protection Agency (EPA), 1991. <strong>Risk</strong> Assessment Guidance for Superfund, Volume 1: Human Health Evaluation Manual,<br />

Supplemental Guidance, Standard Default Exposure Factors. Interim Final. OSWER Directive 9285.6-03.<br />

Checked: NAM<br />

Approved: MS<br />

Page 1 of 5

<strong>Appendix</strong> D<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>,<br />

San Francisco, California<br />

MACTEC Project 4096088522<br />

November 4, 2009<br />

KB63190 FS-RAP <strong>Appendix</strong> D Tables<br />

Analyte<br />

Table D4-1. Toxicity Values for Chlorinated Volatile Organic Compounds<br />

Noncancer Chronic Toxicity Values<br />

Reference Conc.<br />

(mg/m 3 )<br />

Source a<br />

RfC<br />

Cancer Toxicity Values<br />

Unit <strong>Risk</strong><br />

(µg/m 3 ) -1<br />

Source a<br />

IUR<br />

1,1-Dichloroethene 2.00E-01 (i) -- -- C<br />

cis-1,2-Dichloroethene 3.50E-02 (oral) -- -- D<br />

trans-1,2-Dichloroethene 6.00E-02 (p) -- -- --<br />

Tetrachloroethene 2.70E-01 (a) 5.90E-06 (o) B<br />

Trichloroethene 6.00E-01 (o) 2.00E-06 (o) B<br />

Vinyl chloride 1.00E-01 (i) 7.80E-05 (o) A<br />

Abbreviations:<br />

mg/m 3 = Milligrams per cubic meter.<br />

µg/m 3 = Micrograms per cubic meter.<br />

-- = Not available.<br />

EPA = United States Environmental Protection Agency.<br />

CalEPA = California Environmental Protection Agency.<br />

Footnotes:<br />

a Values compiled from the following sources:<br />

(a) - Agency for Toxic Substances and Disease Registry (ATSDR), provided in EPA, 2008a .<br />

(i) - Integrated <strong>Risk</strong> Information System (IRIS) online database (EPA, 2008c ).<br />

(p) - Provisional Peer Review Toxicity Values (PPRTVs), provided in EPA, 2008a .<br />

(o) - Office of Environmental Health Hazard Assessment (OEHHA) Toxicity Values, provided in CalEPA, 2008 .<br />

(oral) - Oral value used for inhalation by route-to-route extrapolation.<br />

b Weight of Evidence classification (EPA, 2005 ) as listed in OEHHA and IRIS:<br />

A - Known human carcinogen.<br />

B - Probable Human Carcinogen<br />

B1 - Limited evidence of carcinogenicity in humans<br />

B2 - Sufficient evidence of carcinogenicity in animals with inadequate or lack of evidence in humans.<br />

C - Possible human carcinogen.<br />

D - Not classifiable as to human carcinogenicity.<br />

E - Evidence of noncarcinogenicity for humans.<br />

Weight-of-<br />

Evidence b<br />

References:<br />

Office of Environmental Health Hazard Assessment (OEHHA), 2008. Toxicity Criteria Database . California Environmental Protection Agency<br />

(CalEPA). http://www.oehha.ca.gov/risk/ChemicalDB/index.asp. December.<br />

United States Environmental Protection Agency (EPA), 2005. Guidelines for Carcinogen <strong>Risk</strong> Assessment . EPA/630/P-03/001F. March.<br />

United States Environmental Protection Agency (EPA), 2008a. Regional Screening <strong>Levels</strong> . San Francisco, California. September.<br />

United States Environmental Protection Agency (EPA), 2008c. Integrated <strong>Risk</strong> Information System (IRIS) . Http://www.epa.gov/iris. December.<br />

Checked: NAM<br />

Approved: MS<br />

Page 2 of 5

<strong>Appendix</strong> D<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>,<br />

San Francisco, California<br />

MACTEC Project 4096088522<br />

November 4, 2009<br />

KB63190 FS-RAP <strong>Appendix</strong> D Tables<br />

Table D5-1. Target Indoor Air Concentration<br />

Calculated Indoor Air Concentrations<br />

Commercial<br />

Target Indoor Air Concentration<br />

Chemicals of Concern Noncancer a Cancer b Commercial c Residential d<br />

(µg/m 3 ) (µg/m 3 ) (µg/m 3 ) (µg/m 3 )<br />

C nc C c C c/i_ia C r_ia<br />

1,1-Dichloroethene 876 -- 876 210<br />

cis-1,2-Dichloroethene 153 -- 153 37<br />

trans-1,2-Dichloroethene 263 -- 263 73<br />

Tetrachloroethene 1,183 2.08 2.08 0.41<br />

Trichloroethene 2,628 6.13 6.13 1.22<br />

Vinyl chloride 438 0.16 0.16 0.03<br />

Abbreviations:<br />

µg/m 3 = Micrograms per cubic meter.<br />

-- = Not available / not applicable.<br />

Footnotes:<br />

a From Tables D3-1 and D4-1.<br />

C nc = (THQ x AT nc x CF µ/m ) / (EF x ED x ET x CF d/h x (1/RfC))<br />

b From Tables D3-1 and D4-1.<br />

C c = (TR x ATc) / (EF x ED x ET x CF d/h x IUR)<br />

c The lower value of the noncancer and cancer indoor air concentration selected as the target indoor air concentration.<br />

d The target residential indoor air concentration are indoor air California Human Health Screening <strong>Levels</strong> (CHHSLs)<br />

(CalEPA, 2005 ). A CHHSL value was not available for 1,1-DCE, so the residential air concentration from the RSLs<br />

(EPA, 2008a ) was used.<br />

References:<br />

California Environmental Protection Agency (CalEPA), 2005. Use of California Human Health Screening <strong>Levels</strong><br />

(CHHSLs) in Evaluation of Contaminated Properties . January.<br />

United States Environmental Protection Agency (EPA), 2008a. Regional Screening <strong>Levels</strong> . San Francisco, California.<br />

September.<br />

Checked: NAM<br />

Approved: MS<br />

Page 3 of 5

<strong>Appendix</strong> D<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>,<br />

San Francisco, California<br />

MACTEC Project 4096088522<br />

November 4, 2009<br />

KB63190 FS-RAP <strong>Appendix</strong> D Tables<br />

Table D6-1. <strong>Soil</strong> <strong>Gas</strong> <strong>Cleanup</strong> <strong>Levels</strong> Protective of Indoor Air<br />

Attenuation Factor a Target Indoor Air Concentration <strong>Soil</strong> <strong>Gas</strong> <strong>Cleanup</strong> <strong>Levels</strong> e<br />

Chemicals of Concern Residential a Commercial b Residential c Commercial d Residential Commercial<br />

(unitless) (unitless) (µg/m 3 ) (µg/m 3 ) (µg/m 3 ) (µg/L) (µg/m 3 ) (µg/L)<br />

1,1-Dichloroethene 0.0009 0.0004 210 876 233,333 233 2,190,000 2,190<br />

cis-1,2-Dichloroethene 0.0009 0.0004 37 153 40,556 41 383,250 383<br />

trans-1,2-Dichloroethene 0.0009 0.0004 73 263 81,111 81 657,000 657<br />

Tetrachloroethene 0.0009 0.0004 0.41 2.08 456 0.46 5,197 5.20<br />

Trichloroethene 0.0009 0.0004 1.22 6.13 1,356 1.36 15,330 15.33<br />

Vinyl chloride 0.0009 0.0004 0.03 0.16 33 0.033 393 0.393<br />

Abbreviations:<br />

µg/m 3 = Micrograms per cubic meter.<br />

µg/L = Micrograms per liter.<br />

Footnotes:<br />

a The attenuation factor is based on future residential slab-on-grade construction (DTSC, 2005 ).<br />

b The attenuation factor is based on future commercial slab-on-grade construction (DTSC, 2005 ).<br />

c The target residential indoor air concentration are indoor air California Human Health Screening <strong>Levels</strong> (CHHSLs)<br />

(CalEPA, 2005 ). A CHHSL value was not available for 1,1-DCE, so the residential air concentration from the RSLs<br />

(EPA, 2008a ) was used.<br />

d From Table D5-1.<br />

e <strong>Soil</strong> <strong>Gas</strong> Concentration = Indoor Air Concentration / Attenuation Factor<br />

References:<br />

California Environmental Protection Agency (CalEPA), 2005. Use of California Human Health Screening <strong>Levels</strong><br />

(CHHSLs) in Evaluation of Contaminated Properties . January.<br />

Department of Toxic Substances Control (DTSC), 2005. Guidance for the Evaluation and Mitigation of Subsurface<br />

Vapor Intrusion to Indoor Air . December 15, 2004. Revised February 7.<br />

United States Environmental Protection Agency (EPA), 2008a. Regional Screening <strong>Levels</strong> . San Francisco, California.<br />

September.<br />

Page 4 of 5<br />

Checked: NAM<br />

Approved: MS

<strong>Appendix</strong> D<br />

Feasibility Study/Remedial Action Plan, <strong>Schlage</strong> <strong>OU</strong>,<br />

San Francisco, California<br />

MACTEC Project 4096088522<br />

November 4, 2009<br />

KB63190 FS-RAP <strong>Appendix</strong> D Tables<br />

Table D6-2. Final <strong>Soil</strong> <strong>Gas</strong> <strong>Cleanup</strong> <strong>Levels</strong><br />

<strong>Soil</strong> <strong>Gas</strong> <strong>Cleanup</strong> Level<br />

Chemicals of Concern<br />

Commercial a<br />

(Zone 2 and 3)<br />

(µg/m 3 )<br />

(µg/L)<br />

1,1-Dichloroethene 2,190,000 2,190<br />

cis-1,2-Dichloroethene 383,250 383<br />

trans-1,2-Dichloroethene 657,000 657<br />

Tetrachloroethene 5,197 5.20<br />

Trichloroethene 15,330 15<br />

Vinyl chloride 393 0.39<br />

Abbreviations:<br />

µg/m 3 = Micrograms per cubic meter.<br />

µg/L = Micrograms per liter.<br />

Zone 2 = Residential over commercial construction.<br />

Zone 3 = Residential over podium parking construction.<br />

Checked: NAM<br />

Approved: MS<br />

Footnotes:<br />

a The soil gas cleanup level is protective of vapor intrusion to indoor air for<br />

commercial receptors.<br />

Page 5 of 5

ATTACHMENT D-1<br />

INTERSTATE TECHNOLOGY AND REGULATORY C<strong>OU</strong>NCIL SCENARIO<br />

FOR MULTI-FAMILY DWELLING

Technical and Regulatory Guidance<br />

Supplement<br />

Vapor Intrusion Pathway:<br />

Investigative Approaches for Typical Scenarios<br />

A Supplement to Vapor Intrusion Pathway: A Practical Guideline<br />

January 2007<br />

Prepared by<br />

The Interstate Technology & Regulatory Council<br />

Vapor Intrusion Team

AB<strong>OU</strong>T ITRC<br />

Established in 1995, the Interstate Technology & Regulatory Council (ITRC) is a state-led, national<br />

coalition of personnel from the environmental regulatory agencies of some 46 states and the District of<br />

Columbia, three federal agencies, tribes, and public and industry stakeholders. The organization is<br />

devoted to reducing barriers to, and speeding interstate deployment of better, more cost-effective,<br />

innovative environmental techniques. ITRC operates as a committee of the Environmental Research<br />

Institute of the States (ERIS), a Section 501(c)(3) public charity that supports the Environmental Council<br />

of the States (ECOS) through its educational and research activities aimed at improving the environment<br />

in the United States and providing a forum for state environmental policy makers. More information<br />

about ITRC and its available products and services can be found on the Internet at www.itrcweb.org.<br />

DISCLAIMER<br />

ITRC documents and training are products designed to help regulators and others develop a consistent<br />

approach to their evaluation, regulatory approval, and deployment of specific technologies at specific<br />

sites. Although the information in all ITRC products is believed to be reliable and accurate, the product<br />

and all material set forth within are provided without warranties of any kind, either express or implied,<br />

including but not limited to warranties of the accuracy or completeness of information contained in the<br />

product or the suitability of the information contained in the product for any particular purpose. The<br />

technical implications of any information or guidance contained in ITRC products may vary widely based<br />

on the specific facts involved and should not be used as a substitute for consultation with professional and<br />

competent advisors. Although ITRC products attempt to address what the authors believe to be all<br />

relevant points, they are not intended to be an exhaustive treatise on the subject. Interested parties should<br />

do their own research, and a list of references may be provided as a starting point. ITRC products do not<br />

necessarily address all applicable health and safety risks and precautions with respect to particular<br />

materials, conditions, or procedures in specific applications of any technology. Consequently, ITRC<br />

recommends also consulting applicable standards, laws, regulations, suppliers of materials, and material<br />

safety data sheets for information concerning safety and health risks and precautions and compliance with<br />

then-applicable laws and regulations. The use of ITRC products and the materials set forth herein is at the<br />

user’s own risk. ECOS, ERIS, and ITRC shall not be liable for any direct, indirect, incidental, special,<br />

consequential, or punitive damages arising out of the use of any information, apparatus, method, or<br />

process discussed in ITRC products. ITRC product content may be revised or withdrawn at any time<br />

without prior notice.<br />

ECOS, ERIS, and ITRC do not endorse or recommend the use of, nor do they attempt to determine the<br />

merits of, any specific technology or technology provider through ITRC training or publication of<br />

guidance documents or any other ITRC document. The type of work described in any ITRC training or<br />

document should be performed by trained professionals, and federal, state, and municipal laws should be<br />

consulted. ECOS, ERIS, and ITRC shall not be liable in the event of any conflict between ITRC training<br />

or guidance documents and such laws, regulations, and/or ordinances. Mention of trade names or<br />

commercial products does not constitute endorsement or recommendation of use by ECOS, ERIS, or<br />

ITRC. The names, trademarks, and logos of ECOS, ERIS, and ITRC appearing in ITRC products may not<br />

be used in any advertising or publicity, or otherwise indicate the sponsorship or affiliation of ECOS,<br />

ERIS, and ITRC with any product or service, without the express written permission of ECOS, ERIS, and<br />

ITRC.

Vapor Intrusion Pathway:<br />

Investigative Approaches for Typical Scenarios<br />

A Supplement to Vapor Intrusion Pathway: A Practical Guideline<br />

January 2007<br />

Prepared by<br />

The Interstate Technology & Regulatory Council<br />

Vapor Intrusion Team<br />

Copyright 2007 Interstate Technology & Regulatory Council<br />

444 North Capitol Street, NW, Suite 445, Washington, DC 20001

Permission is granted to refer to or quote from this publication with the customary<br />

acknowledgment of the source. The suggested citation for this document is as follows:<br />

ITRC (Interstate Technology & Regulatory Council). 2007. Vapor Intrusion Pathway:<br />

Investigative Approaches for Typical Scenarios. VI-1A. Washington, D.C.: Interstate<br />

Technology & Regulatory Council, Vapor Intrusion Team. www.itrcweb.org.

ACKNOWLEDGEMENTS<br />

The members of the Interstate Technology & Regulatory Council (ITRC) Vapor Intrusion Team<br />

wish to acknowledge the individuals, organizations, and agencies that contributed to this<br />

supplement to the technical and regulatory guidance document Vapor Intrusion Pathway: A<br />

Practical Guideline.<br />

As part of the broader ITRC effort, the Vapor Intrusion Team effort is funded primarily by the<br />

U.S. Department of Energy. Additional funding and support have been provided by the U.S.<br />

Department of Defense and the U.S. Environmental Protection Agency. ITRC operates as a<br />

committee of the Environmental Research Institute of the States (ERIS), a Section 501(c)(3)<br />

public charity that supports the Environmental Council of the States (ECOS) through its<br />

educational and research activities aimed at improving the environment in the United States and<br />

providing a forum for state environmental policy makers.<br />

The team co-leaders, Bill Morris (Kansas Department of Health and Environment) and John<br />

Boyer (New Jersey Department of Environmental Protection), also wish to recognize the<br />

individual efforts of the following state team members:<br />

• Delonda Alexander, North Carolina Department of Environment and Natural Resources<br />

• Tonia R. Burk, Georgia Environmental Protection Division<br />

• Mary Camarata, Oregon Department of Environmental Quality<br />

• Craig Dukes, South Carolina Department of Health and Environmental Control<br />

• Peter Eremita, Maine Department of Environmental Protection<br />

• Richard Galloway, Delaware Department of Natural Resources and Environmental Control<br />

• Jerry Grimes, Virginia Department of Environmental Quality<br />

• Marilyn Hajicek, Colorado Department of Labor and Employment<br />

• Jeanene Hanley, Arizona Department of Environmental Quality<br />

• Jim Harrington, New York Department of Environmental Conservation<br />

• Tom Higgins, Minnesota Pollution Control Agency<br />

• Greg Johnson, Colorado Department of Labor and Employment<br />

• Allan V. Jones, Utah Department of Environmental Quality<br />

• Bheem R. Kothur, Florida Department of Environmental Protection<br />

• Diedre Lloyd, Florida Department of Environmental Protection<br />

• William McKercher, Mississippi Department of Environmental Quality<br />

• John S. Mellow, Pennsylvania Department of Environmental Protection<br />

• Robin Mongeon, New Hampshire Department of Environmental Services<br />

• Evelina Morales, Oklahoma Department of Environmental Quality<br />

• Susan Newton, Colorado Department of Public Health and Environment<br />

• Richard Olm, Arizona Department of Environmental Quality<br />

• Nelly F. Smith, Alabama Department of Environmental Management<br />

• Neil Taylor, Utah Department of Environmental Quality<br />

• Rod Thompson, Indiana Department of Environmental Management<br />

i

The co-leaders also wish to thank the industry and federal agency team members, contributing in<br />

various forms, to the guidance: Leah Alejo, Naval Facilities Engineering Service Center; Harry<br />

Anderson, Andre Brown, Jay Hodny, and Jim Whetzel, W. L. Gore & Associates, Inc.; Vanessa<br />

J. Bauders, U.S. Army Corps of Engineers; Tom Biksey, Environmental Strategies Consulting,<br />

LLC; Anita Broughton, Haley & Aldrich, Inc; Richard Burns, Connestoga Associates; Douglas<br />

Cox, Mitretek Systems; Dianne Easly, U.S. Environmental Protection Agency Region 7; Diana<br />

Marquez, Burns and McDonnell Engineering Company, Inc; Amy L. Edwards, Holland &<br />

Knight, LLP; Bart Eklund, URS Corporation; Rachel Farnum, GE Global Research; Mark J.<br />

Fisher, U.S. Army Corps of Engineers; Douglas M. Fitton and Eric M. Nichols, LFR Inc.; David<br />

J. Folkes, EnviroGroup Limited; Kimberly Gates, Naval Facilities Engineering Service Center;<br />

Ken Gilland, Buck Engineering; Sandra Gaurin, BEM Systems, Inc.; Jonathan Gledhill, Policy<br />

Navigation Group; Annette Guiseppi-Elie and Jenny Liu, DuPont Engineering; Blayne Hartman,<br />

H&P Mobile Geochemistry; Stephen Hoffine, Burns & McDonnell Engineering Company, Inc.;<br />

Harley Hopkins, American Petroleum Institute; Alana Lee, U.S. Environmental Protection<br />

Agency Region 9; Ronald J. Marnicio, Tetra Tech, EC; Todd McAlary, GeoSyntec Consultants;<br />

Denise Miller, ARCADIS; Ian T. Osgerby, U.S. Army Corps of Engineers New England<br />

District; Gina M. Plantz, Newfields; Henry Schuver, U.S. Environmental Protection Agency<br />

Office of Solid Waste; Fred Tillman, U.S. Environmental Protection Agency Ecosystems<br />

Research Division; Matthew Traister, O’Brien & Gere; Robert S. Truesdale, RTI; and Yvonne<br />

Walker, Navy Environmental Health Center.<br />

Special thanks to the community stakeholders, Lenny Siegel (Center for Public Environmental<br />

Oversight) and Peter Strauss (PM Strauss and Associates) for their insightful contribution to the<br />